Displaying items by tag: synthron

Synthron launches a new innovative release aid for the paper industry

The Paper Making Industry has faced a lot of restructuring over recent years. But despite all of the changes SYNTHRON has continued to develop new and exciting products for this Industrial Sector.

The Paper Making Industry has faced a lot of restructuring over recent years. But despite all of the changes SYNTHRON has continued to develop new and exciting products for this Industrial Sector.

SYNTHRON is a subsidiary of the PROTEX INTERNATIONAL Group and has been active for more than 40 years in the paper making industry. The Group invests 5% of sales turnover in R&D to develop innovative products for paper-makers and paper pulp producers.

SYNTHRON has a strong range of products for tissue making, packaging and specialty papers, SYNTHRON anticipates the needs of customers by developing expertise for products and applications which can be applied to a wide variety of substrates, in the this strongly growing segment.

SYNTHRON manufactures Paper Making chemical auxiliary products at the industrial site of Saint-Avold in Moselle and Auzouer-en-Touraine in Indre-et-Loire in France and also in United States and in China.

SYNTHRON recently launched SYNTHRO®-PEL SCR 38, which has been developed, produced and marketed in Europe. The interesting feature of SYNTHRO®-PEL SCR 38 is that the product based on different chemistry to replace the silicone which is usually contained in most Release Aids, which also usually require the use of a separate catalyst which can then add to production costs...

SYNTHRO®PEL SR 38 is based on non-silicone materials and the application process does not require the need for a separate catalyst this can offer some interesting potential cost-savings.

Many paper based products have a requirement for a “Release Aid”, such as product labels, glassine paper, transfer papers which are use print a motif on textiles and clothing.

According to Robert MOOR, President of SYNTHRON: “our Company is involved in various industrial sectors, and we have worked in the Paper Making manufacturing sector for many years. Here our main focus has been on specialties and niches, such as Release Aids. We have a Research Centre in France and product application centres round the world SYNTHRON continues to enjoy an excellent reputation for new product development and innovation”

SYNTHRON continues to build strong partnerships with both private and public, French and overseas R + D organizations, within a framework of a research programme for paper making auxiliary chemicals. And in particular, Robert MOOR stays on the lookout for opportunities for external growth to strengthen the Groups overall position.

About PROTEX INTERNATIONAL: PROTEX INTERNATIONAL is one of the last independent family owned French chemical groups. The company, was founded in 1932, and initially sold auxiliary products for textile processing and then diversified into niche markets, such as ink and paints, adhesives, water treatment, perfume compositions and more recently speciality products for electronics.

The Group has a turnover of 170 million Euro turnover in 2014 and forecasts 200 million Euro sales in 2015, 80% of sales are outside France. There are 700 employees in more than twenty industrial and commercial subsidiaries in Europe, United-States, and South-East Asia (China, South Korea, Thailand, Indonesia, and Taiwan) and more recently in Brazil.

Today with a healthy internal organic growth, the Group also pursues a policy of external growth via acquisition of targeted companies, in France or abroad.

New Innovation from Synthron for Tissue Paper Manufacturing

The “traditional” European Paper Making Industry has been declining and restructuring in Europe over recent years. Nonetheless there are opportunities which do appear in this industrial sector, thanks mainly to the development of new applications and product innovations. This is particularly apparent in the fields of tissue making, packaging and with specialty papers. SYNTHRON, a subsidiary of PROTEX INTERNATIONAL has a 40 year history in the paper making industry: SYNTHRON – considers that innovation is a priority – and allocates 5% of its turnover for R&D in order to develop new applications and novel chemistries for paper making and to anticipate the future requirements of this particular market.

The “traditional” European Paper Making Industry has been declining and restructuring in Europe over recent years. Nonetheless there are opportunities which do appear in this industrial sector, thanks mainly to the development of new applications and product innovations. This is particularly apparent in the fields of tissue making, packaging and with specialty papers. SYNTHRON, a subsidiary of PROTEX INTERNATIONAL has a 40 year history in the paper making industry: SYNTHRON – considers that innovation is a priority – and allocates 5% of its turnover for R&D in order to develop new applications and novel chemistries for paper making and to anticipate the future requirements of this particular market.

For Robert MOOR, CEO of SYNTHRON: “we have to anticipate the future requirements of paper making which is presently in transformation. To remain focused in the chemistry of this sector, our Center of Studies and Discoveries develops products and searches to innovate constantly”.

SYNTHRON has refined and specializes its product range by launching a new auxiliary: SYNTHRO®STAB HE which is used in tissue making manufacturing process to remove bad odours. The tissue making sector produces paper for public and domestic sanitary use also products like disposable handkerchiefs, baby’s diapers, temporary medical sheeting used for examinations, domestic kitchen roll, tablecloths and towels…), this market segment is growing.

The tissue making process can involve either virgin pulp fibres of cellulose or contain some recycled cellulose fibres. One of the main problems encountered by the producers of this type of paper is the presence of bad odours, often caused by residues of hexanal (or hexanaldehyde C6H120). SYNTHRO®-STAB HE, functions by interfering with the chemical reaction which releases the smell by blocking and the deactivating the catalysts of the reaction. SYNTHRO®-STAB HE meets the requirements of the Food and Drug Administration (FDA).

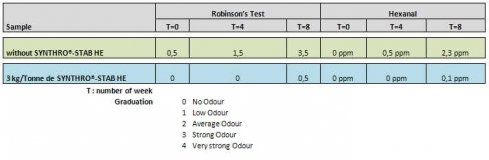

Robinson’s test proves the efficacy of SYNTHRO ®-STAB HE:

After 8 weeks, the background concentration of the treated product is 0,1 ppm versus 2,3 ppm this clearly demonstrates the effectiveness of SYNTHRO®-STAB HE as the bad odour has been eliminated from the tissue.

Generally paper tissue usage increases with rise of living standards, and for the Consumer it’s important to improve the quality of the tissue and to offer an effective solution to eradicate bad odours from the product.

The SYNTHRO®-STAB HE manufactured at industrial site of Auzouer-en-Touraine in Indre et Loire and in Saint-Avold in Moselle (France).