Displaying items by tag: valmet

Valmet to deliver second tissue production line to Faderco in Algeria

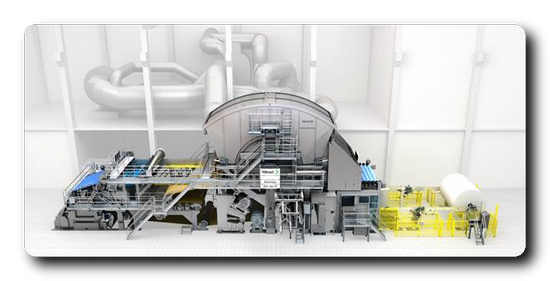

Valmet will supply a complete Advantage DCT 100HS tissue production line to Faderco in Algeria. The order also includes a rewinder and an extensive automation package including process and quality control solutions.

The order was included in Valmet's first quarter 2019 orders received. The value of the order will not be disclosed.

The new line will be installed at the company's mill, Warak, in Setif, Algeria. The start-up is planned for June 2020. Valmet has previously supplied an Advantage DCT100+ tissue line to the mill, started up in 2015.

The new tissue line will fulfill Faderco's need of new capacity for tissue products. The Warak mill currently produces baby diapers, sanitary napkins, adult diapers and tissue paper for the domestic market and surrounding countries. The new line will support Faderco's ambition to consolidate its position as the Algerian leader in the sector by reaching 35 percent of market share in 2019. With an addition of 30,000 annual tons, Algeria will move from importer to exporter of tissue products.

Valmet Advantage DCT 100HS tissue machine

Valmet Advantage DCT 100HS tissue machine

"The investment in Valmet's Advantage DCT technology, the new complex, will boost our production and support our ambition to reach the position as the 5th exporter in the Mediterranean region. We are already present in Morocco, Tunisia, Libya, Mauritania, Senegal, Togo, Mali, Guinea Conakry and Qatar, among others," says Amor Habes, CEO, Faderco.

"With this new, high-quality tissue making installation, we are very pleased to continue the journey together with Faderco; a journey which started in 2013. Valmet's leading Advantage DCT technology as well as it's Reelite ENS Winder will support Faderco's ambition for first class tissue paper production," says Bernhard Glifberg, Sales Manager, Tissue Mills Business Unit, Valmet.

Technical information about the delivery

The new tissue machine line will have a width of 2.8 m and a design speed of 2,000 m/min. It will add 30,000 tons tissue paper per year to Faderco's current production of tissue products.

Valmet's scope of delivery will comprise a complete tissue production line featuring bale handling, stock preparation system, the Advantage DCT 100HS tissue machine, a rewinder and auxiliaries. The tissue machine will be equipped with an OptiFlo II TIS headbox, a cast alloy Yankee cylinder, the Advantage technologies ViscoNip press, the AirCap hood and WetDust dusthandling systems as well as a F(O)CUS Rewinder with its unique ENS technology. The stock preparation line includes OptiSlush pulper, OptiFiner conical refiners and deflaker and OptiScreen technology.

The delivery also includes an automation package with the Valmet DNA process controls and Valmet IQ quality controls. Complete installation supervision, training, start-up and commissioning are also part of the delivery. The supply is based on total mill engineering by Valmet.

About the customer Faderco Warak

Faderco is an Algerian company active in the industrial hygiene field, through cotton derived products and hygiene items with absorbent pads. The company was founded in 1986 and became a joint stock company in 2009. Today, with more than 1,800 employees, 11 brands in 7 strategic business areas and 2 subsidiaries, Faderco continues to strive for a well-established international ambition.

The company produces baby diapers, adult diapers and paper products in the industrial Complex at Setif, opened in July 2012. In addition, the company has another production facility in Algiers. With both wholesale and direct sales, Faderco's commercial coverage is 80% of the Algerian national territory. The company exports products to other countries in Northwest Africa and sub-Sahara.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply key board machine technologies to Kraft of Asia Paperboard & Packaging in Vietnam

Valmet will supply key board making technologies to Kraft of Asia Paperboard & Packaging for its new containerboard making line, which will be located in Phu My, Vietnam.

The order was included in Valmet's orders received of the first quarter 2019. The value of the order will not be disclosed.

Kraft of Asia Paperboard & Packaging is a new company established by Marubeni Corporation (Marubeni). By establishing the new company with a new board production line (PM 1), Marubeni aims to proactively expand its containerboard business in the growing Vietnamese market. Kraft of Asia Paperboard & Packaging has received the permits for one million ton annual capacity and the company plans to invest in three board machines in the following 10 years. The start-up of the first machine (PM 1) is scheduled for the second half of 2020.

Technical details about the delivery

Valmet's delivery will include three OptiFlo Foudrinier headboxes for excellent profiles and good formation, and an OptiPress Linear press section to achieve excellent end product properties, high dewatering capacity and good runnability. The delivery will also include a start-up package of spare parts and consumables.

About the customer Kraft of Asia Paperboard & Packaging

Kraft of Asia Paperboard & Packaging Co., Ltd. (KOA), is a new company established by Marubeni to start a containerboard manufacturing and packaging material sales business in Vietnam. Marubeni is engaged in importing, exporting and trading of domestic and overseas products and commodities, and also in production activity in various business fields. In pulp and paper business, Marubeni also operates afforestation and produces woodchip, pulp, printing & writing paper and containerboard all over the world.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply a quality management solution to Cartones Ponderosa in Mexico

Valmet will supply a Valmet IQ Quality Management Solution to Cartones Ponderosa's cartonboard machine BM1 in Mexico. The comprehensive solution will improve machine efficiency and the overall end-product quality.

The order was included in Valmet's fourth quarter 2018 orders received. Typically, the value of these kinds of automation system deliveries is below EUR two million.

"This project gives our customer the most complete and innovative single quality management solution of all Mexican mills. It provides measurements for fiber analysis online, coating characteristics, such as surface topography, and PPS (Parker Print Surf) direct photographic readings for printability predictions. With our solution, the mill can achieve its desired end-product properties with improved efficiency," says Miguel Sagahon, Sales Manager, Automation, Valmet.

Valmet will supply a Valmet IQ Quality Management Solution to Cartones Ponderosa's cartonboard machine BM1 in Mexico.

Valmet will supply a Valmet IQ Quality Management Solution to Cartones Ponderosa's cartonboard machine BM1 in Mexico.

Information about Valmet's delivery

Valmet's delivery consists of a Valmet IQ Quality Control System (QCS) with three scanners and related measurements and controls. The scope of basis weight, coating and moisture measurements and controls is complemented with surface topography, fiber orientation, optical caliper as well as gloss measurements and controls. This will open up an opportunity for a deep, unrivaled analysis of the paper structure and quality properties.

Valmet IQ Steam Profiler and Valmet IQ Induction Profiler provide effective moisture and caliper profile management to improve production efficiency and board quality. The Valmet IQ profilers feature advanced self-diagnostics and a compact design for easy maintenance and installation.

Information about the customer Cartones Ponderosa

Cartones Ponderosa, based in Mexico, produces and supplies recycled coated board for the manufacture of folding cartons. The company produces more than 50% of the total Mexican recycled coated board grades and is the only exporter in its field. Located in San Juan del Río, Querétaro, the mill started production in 1979 with a total capacity of 66,000 tons per year. At present, it produces 240,000 tons per year and is continuously investing in its boxboard machine, making it one of the most productive and efficient machines on the continent.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to launch a new-generation web inspection system at PaperCon 2019

Valmet will launch a new-generation Valmet IQ Web Inspection System (IQ WIS), which enables board and paper producers to inspect and improve product quality in greater detail. IQ WIS works in real time, enabling immediate root-cause analysis and corrective action. IQ WIS is one of the integral elements of the Valmet IQ Process and Quality Vision system; another element is the Valmet IQ Web Monitoring System.

Improved quality through excellent synergy

Valmet IQ Web Inspection System has been developed in collaboration with Dr. Schenk, a global supplier of inspection and measurement solutions.

"The collaboration between Dr. Schenk and Valmet is a showcase of excellent synergy by smartly combining the know-how and experience from the world's best inspection system provider with a world-class paper process specialist. After having delivered a total of 450 Valmet IQ Process and Quality Vision systems globally, this new product launch is an important step toward even higher precision in quality control. Valmet continues to support the existing installed base and offers a seamless upgrade path. The advantages offered by the new features can be integrated into existing systems through upgrades," comments Marko Toskala, Director, Quality Management Systems, Automation, Valmet.

The new-generation Valmet IQ Web Inspection System utilizes an intelligent 8K camera technology for high measurement precision.

The new-generation Valmet IQ Web Inspection System utilizes an intelligent 8K camera technology for high measurement precision.

"We are pleased with the development of the new Valmet IQ WIS. Valmet is the frontrunner in the pulp and paper business. Through their strong sales and service organization, we can offer our leading inspection technology to these processes globally," says Dr. Peter-M. Heinze, Sales Manager, Dr. Schenk.

Efficient tools for analysis and paper quality rating

Valmet IQ Web Inspection System utilizes intelligent 8K camera technology, which combines the best features of an area scan (matrix) camera and line scan camera technologies. It enables immediate identification of production that does not meet quality criteria through a wide range of technical features.

High measurement precision can be reached even with higher maximum paper web speeds. More sensitive and reliable defect analysis can be achieved with multigeometry. It is also possible to replace several camera beams with one unit, resulting in cost-efficient, compact installation and lower service needs.

Technical information about Valmet IQ Web Inspection System

The latest IQ WIS technologies provide paper processors with the means to achieve profound quality monitoring and control. Unique lighting technology enables the detection of print-critical defects that have not been visible before. This illumination provides excellent opportunities for 3D defect contrasting. Particularly longitudinal structures and oil stains, for example, which are often hard to detect with standard lights, are also highlighted. Precise detailed defect classifications can be made by means of the MIDA (Multiple Image Defect Analysis) and the latest software algorithms based on artificial intelligence principles.

Multigeometry inspection gives more sensitive and reliable defect information. Unique lighting technology enables the detection of print-critical defects that have not been visible before.

Multigeometry inspection gives more sensitive and reliable defect information. Unique lighting technology enables the detection of print-critical defects that have not been visible before.

Valmet Industrial Internet solutions can utilize the data from the web inspection system to further benefit customers. A comprehensive process picture is created by combining the data from the quality control system and the machine vision system. By adding other key process data, it is possible to find optimal solutions to ensure desired process performance and end-product quality.

Information about Dr. Schenk

Dr. Schenk GmbH, established in 1985, is an innovative high-tech company based near Munich, Germany. It develops, produces and markets optical inspection and measurement solutions for automated quality assurance and production process monitoring. The systems are a key success factor in the making and converting of many materials for a multitude of markets. Throughout the world, Dr. Schenk's 300+ employees continue to set new standards for inspection.

Information about PaperCon

PaperCon is a technical conference for the paper and packaging industry, taking place on May 5-8, 2019 in Indianapolis, Indiana, USA. Developed by experts and business leaders in the paper, packaging and nonwovens industries, PaperCon 2019 offers networking events and informative sessions that provide tangible takeaways to solve many of today's technical challenges.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply automation and quality management systems to Suzhou Taison Paper in China

Valmet will supply a Valmet DNA automation system and a Valmet IQ quality management solution to Suzhou Taison Paper Co., Ltd. in China. The systems will be installed on two tissue machines, enabling the mill to increase production efficiency and improve product quality.

The order was included in Valmet's first quarter 2019 orders received. The delivery will take place in the third quarter of 2019.

"We have very good cooperation with Valmet. We already have Valmet's automation systems installed on four tissue machines in the Taison Group's Jiangxi mill, and their performance has exceeded our expectations. Valmet's advanced technology fits perfectly with our company's strategy to implement innovative solutions," says Shengyou Zhu, Deputy General Manager, Taison Paper.

"We have very good cooperation with Valmet. We already have Valmet's automation systems installed on four tissue machines in the Taison Group's Jiangxi mill, and their performance has exceeded our expectations. Valmet's advanced technology fits perfectly with our company's strategy to implement innovative solutions," says Shengyou Zhu, Deputy General Manager, Taison Paper.

"Valmet ensures maximum and sustainable performance of production lines with its accurate and reliable process and product measurements. We are happy that the customer relies on us and are delighted to provide solutions to move their performance forward," states Andy Zhang, Area Sales Manager, China, Automation, Valmet.

Information about Valmet's delivery

Valmet's delivery consists of a Valmet DNA automation system and a Valmet IQ quality management solution. Valmet's comprehensive and scalable automation solution is geared toward optimum productivity, energy efficiency and product quality.

Information about the customer Taison Group

Suzhou Taison Paper Co., Ltd. is one of the subsidiaries of the Taison Group, a large and comprehensive international enterprise, which integrates forestry, pulp making, plastic packaging, timber processing, real estate and trading.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet continues to strengthen its stable business by acquiring J&L Fiber Services Inc. in the U.S.

Valmet has on May 1, 2019 completed the acquisition of J&L Fiber Services Inc., a manufacturer and provider of refiner segments to the pulp, paper and fiberboard industry. The company is located in Wisconsin, U.S. The enterprise value of the acquisition is approximately EUR 51 million on a cash and debt free basis subject to ordinary post-closing adjustments.

J&L Fiber Services manufactures and supplies low-consistency refiner segments that are important wear parts used in pulp and paper production, complementing Valmet's offering in refiner segments. It also supplies high-consistency refiner segments that are used in thermomechanical pulping and medium density fiberboard (MDF) refining.

J&L Fiber Services manufactures and supplies low-consistency refiner segments that are important wear parts used in pulp and paper production, complementing Valmet's offering in refiner segments. It also supplies high-consistency refiner segments that are used in thermomechanical pulping and medium density fiberboard (MDF) refining.

In the last twelve months, the company had net sales of approximately EUR 30 million with an EBITA margin of around 15 percent. The acquired operations employ about 100 people, most of whom are located in Wisconsin, U.S. J&L Fiber Services operates globally through a sales representative and distribution network. Over 75 percent of its sales goes to North America. The acquired business becomes a part of Valmet's Services business line, as Waukesha Service Center.

"We are continuously strengthening our stable business, meaning Services and Automation. The recent acquisition of North America -based GL&V is now followed by adding J&L Fiber Services' complementary refiner segment products to our services offering. This acquisition also further strengthens our local presence especially in North America. I warmly welcome the 100 new employees to become part of the Valmet team and into our strong, global Services organization," says Pasi Laine, President and CEO of Valmet.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply a containerboard making line with an extensive scope for Papierfabrik Palm in Germany

Valmet will supply a containerboard making line (PM 5) with extensive packages of mill-wide automation and services for Papierfabrik Palm's (Palm) Aalen-Neukochen mill in Germany. The new high-capacity board machine will replace three existing smaller machines and will be designed to produce lightweight and high-quality recycled fluting and testliner grades. The start-up is scheduled for 2021.

Major part of the order is included in Valmet's orders received of the second quarter 2019. The value of the order will not be disclosed. The total value of an order of this type and scope is typically around EUR 150-200 million.

"We wanted to make a competitive investment for the next 50 years and aimed for a very wide and high-capacity containerboard machine to be ready for the future changes. Valmet was selected because of their high-level and differentiating technology for lightweight grades. The concept was verified at the pilot trials," says Dr. Wolfgang Palm, Chief Executive Officer of Palm.

"Palm PM 5 will be the largest containerboard machine in the world. We offered Palm an outstanding combination of high-end technology, comprehensive selection of service, automation and industrial internet. I'm pleased to say that Palm and Valmet have been cooperating for decades and hopefully this good relationship will continue over the coming decades," says Jari Vähäpesola, Paper Business Line President of Valmet.

From left: Jürgen Kosse (Palm), Manfred Eberhardt (Valmet), Dr. Andreas Haas (Palm), Stephan Gruber (Palm), Tobias Hain (Valmet), Dr. Wolfgang Palm (Palm), Pasi Laine, Jari Vähäpesola, Harri Heikkilä and Juha Kivimaa (all from Valmet)

From left: Jürgen Kosse (Palm), Manfred Eberhardt (Valmet), Dr. Andreas Haas (Palm), Stephan Gruber (Palm), Tobias Hain (Valmet), Dr. Wolfgang Palm (Palm), Pasi Laine, Jari Vähäpesola, Harri Heikkilä and Juha Kivimaa (all from Valmet)

Technical details about the delivery

Valmet's delivery for PM 5 will include a high-speed containerboard making line from broke collection to reel and winder. OptiPress Center with transfer belt technology enables closed sheet transfer from press to dryer for high runnability and production efficiency at high speeds.

OptiSizer Hard is a unique size application method where hard covered nip rolls press the size deep into the paper web improving surface and internal strengths. OptiReel Linear reel combined with OptiWin Pro winder with Dual Unwind deliver substantially high capacity level without any compromises on safety. The delivery will also include complete process air system for board machine and machine hall ventilation.

The mill-wide automation package includes Valmet DNA Automation System for process and drive controls as well as runnability and condition monitoring. The Valmet IQ Quality Management Solution features scanning measurements, related machine and cross direction controls and profilers.

Valmet's delivery will also include a vast services package. Steep start-up curve and optimal production conditions of PM 5 will be ensured with a long-term Valmet Performance Agreement and a comprehensive spare parts and consumables package. Long-term Valmet Performance Agreement was also signed for another Palm machine. Valmet's maintenance expert located on-site will support the maintenance establishment of Palm PM 5. The establishment support, in addition to the provided master data, will set a strong foundation for the maintenance operations. Five-year agreements of Valmet Paper Machine Clothing and Valmet Roll Service are also included.

The start-up and the further optimization of the new board machine will be supported remotely from Valmet Performance Center and with Valmet Industrial Internet solutions. Online strength information and the quality predictions gained with Valmet Pulp to Paper Optimizer help the optimizing of raw material and chemical consumption. Valmet Paper Machine Diagnostics tool provides in-depth information about the machine performance and condition of the equipment, which can be used to predict and avoid production losses and increase the process reliability. Also, automation system control loop and actuator performance are continuously monitored and analyzed by automated tools.

The 11,700-mm-wide (wire) board machine will produce recycled fluting and testliner grades with the basis weight range of 60-110 g/m2. The design speed of the machine will be 2,000 m/min and the annual capacity 750,000 tonnes.

Information about the customer Papierfabrik Palm

Palm is one of the leading companies in the European paper industry and Germany's largest family owned business in the paper industry. The Palm Group is divided into the paper division with its 5 paper mills for the manufacture of paper and the packaging division with 26 plants for the manufacture of corrugated board. The third pillar of Palm's operations, which encompasses the purchasing of raw materials for all its papers, and corrugated boards made from 100% recycled paper are joined under the umbrella of Palm Recycling consisting of two recycling companies. The plant in Aalen-Neukochen is the origin and the head office of both the Palm Group and Papierfabrik Palm.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet has completed the acquisition of GL&V, a global provider of technologies and services to the pulp and paper industry

Valmet has just completed the acquisition of GL&V, which was announced on February 26, 2019. GL&V is a global provider of technologies and services to the pulp and paper industry. The enterprise value of the acquisition is approximately EUR 113 million on a cash and debt free basis subject to ordinary post-closing adjustments.

GL&V will be a part of the Services business line

The acquired business becomes a part of Valmet's Services business line. GL&V supplies technologies, upgrades and optimization services, rebuilds, and spare parts for the pulp and paper industry globally. The acquired operations had net sales of approximately EUR 160 million in calendar year 2018 and employ about 630 people.

The acquired business becomes a part of Valmet's Services business line. GL&V supplies technologies, upgrades and optimization services, rebuilds, and spare parts for the pulp and paper industry globally. The acquired operations had net sales of approximately EUR 160 million in calendar year 2018 and employ about 630 people.

GL&V will be included in Valmet's financial reporting for the first time in Valmet's Half Year Financial Review January 1-June 30, 2019.

As announced on February 26, 2019, GL&V's washing, oxygen delignification and bleaching operations with Compact Press®, pumps and mixers technology for chemical pulping as well as the related Product Center in Karlstad Sweden are not included in the transaction scope.

Pasi Laine, President and CEO of Valmet: Valmet's stable business and services capabilities are now further strengthened

"The acquisition was completed as planned, and we welcome our 630 new colleagues to Valmet. This strengthens Valmet's global services business further and complements our technology offering for the pulp and paper industry customers. The acquisition also consolidates our local presence and capabilities globally. The combination of Valmet's global reach and GL&V's product and services offering for chemical pulping, stock preparation, papermaking and finishing create a good basis for new business opportunities and for serving our customers even better," says Pasi Laine, President and CEO of Valmet.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland, and its shares are listed on the Nasdaq Helsinki.

Valmet to convert a recovery boiler into a biomass boiler at DA Alizay in France

Valmet has received an order from Biomasse Energie d'Alizay to convert a recovery boiler into a biomass boiler utilizing bubbling fluidized bed combustion technology (BFB) at DA Alizay mill in France. Biomasse Energie d'Alizay will start producing steam and electricity from biomass at the existing power plant.

The order is included in Valmet's first quarter of 2019 orders received. Typically, the value of this kind of order is EUR 20 million. Valmet's delivery is scheduled for 2020.

"Valmet is the leader in BFB conversion with more than 60 references over the past 30 years, including boilers initially manufactured by third parties. It is very efficient and cost-saving way to modernize and prolong the lifetime of high-capex plants to serve the customers' future needs," says Jouko Kylänpää, Director, Rebuilds and Conversions, Pulp and Energy business line, Valmet.

"Valmet is the leader in BFB conversion with more than 60 references over the past 30 years, including boilers initially manufactured by third parties. It is very efficient and cost-saving way to modernize and prolong the lifetime of high-capex plants to serve the customers' future needs," says Jouko Kylänpää, Director, Rebuilds and Conversions, Pulp and Energy business line, Valmet.

Information about Valmet's delivery

Valmet's delivery scope includes converting the existing recovery boiler into a biomass boiler utilizing bubbling fluidized bed combustion technology (BFB). Electricity production of the plant will be 50 MWe, and it will also produce process steam for the paper mill. Additionally, Valmet will deliver a complete Valmet DNA automation system for the power plant, including steam network optimization with the paper mill. The plant is expected to start in 2020.

Information about Biomasse Energie d'Alizay and DA Alizay mill

Biomasse Energie d'Alizay is a subsidiary of DA Alizay SAS. DA Alizay mill employs about 180 people and has an annual production capacity of 300,000 tons of paper. The mill is specialized in high quality paper.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland, and its shares are listed on the Nasdaq Helsinki.

Valmet to deliver fifth tissue production line to Papel San Francisco in Mexico

Valmet will supply an Advantage DCT 100TS tissue production machine to Papel San Francisco in Mexico. The new machine will be installed at the company's mill in Mexicali and the start-up is planned for the third quarter of 2020.

The order is included in Valmet's first quarter 2019 orders received. The value of the order is not disclosed.

Valmet Advantage DCT 100TS tissue machine

Valmet Advantage DCT 100TS tissue machine

The new tissue line will fulfill Papel San Francisco's need of new capacity for standard tissue products. Valmet has previously delivered four tissue machines to the company. Three Advantage DCT machines started up in 2006, 2009 and 2018. In addition, Papel San Francisco was the first to start up an Advantage NTT line in 2013, which fulfills the company's demand of textured tissue.

"The choice to select the Advantage DCT machine was quite easy. Equipped with the Advantage ViscoNip press, it is the most efficient and best choice for the grades we need to produce. It is also in our philosophy to go for low energy consumption and lowest possible emissions to air and water. With this new tissue line, we expect to achieve the best tissue quality combined with lowest energy consumption," says Dario Palma y Meza Espinoza, Operational Director, Papel San Francisco.

"We are very proud to be the chosen supplier and partner for yet another expansion by Papel San Francisco. After many years of several projects together, we know that Papel San Francisco is a very demanding customer expecting continuous improvements. The company is continuously running their assets at or near world record speed and still achieving very high efficiency numbers. This is yet another opportunity for us to take another step forward in performance in a very strong and trustful relationship," says Jan Larsson, Director of Sales, North America, Tissue Mills Business Unit, Valmet.

From left: Jan Erikson (Valmet), Dario Palma y Meza (PSF), Julio Rodriguez (PSF), Jan Larsson (Valmet), Fernando De La Torre (PSF), Enrique Zarate (PSF), Anders Lorentzon (Valmet) and Jose Luis Emanuel Garcia (PSF).

From left: Jan Erikson (Valmet), Dario Palma y Meza (PSF), Julio Rodriguez (PSF), Jan Larsson (Valmet), Fernando De La Torre (PSF), Enrique Zarate (PSF), Anders Lorentzon (Valmet) and Jose Luis Emanuel Garcia (PSF).

Technical information about the delivery

The new tissue machine will have a width of 2.8 m and a design speed of 2,200 m/min. It will add 30,000 tons tissue paper per year to Papel San Francisco's current production of toilet tissue, kitchen towels and napkins.

Valmet's scope of delivery will comprise an Advantage DCT 100TS tissue machine. The machine will be equipped with OptiFlo headbox and cast alloy Yankee cylinder. The machine will also be featured with the well proven Advantage tissue technology including ViscoNip press, AirCap hood and WetDust dust system. Start-up and commissioning are also included in the delivery.

About the customer Papel San Francisco

Papel San Francisco started up their first tissue machine in 1980. In the past 35 years the company has grown steadily and is today operating six tissue machines with a yearly capacity of 180 000 tons of tissue products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.