Displaying items by tag: valmet

Valmet included in the Ethibel Sustainability Index Excellence Europe

Valmet has been included in the Ethibel Sustainability Index (ESI) Excellence Europe for 2017. The index contains 200 of the European stock listed companies that display the best performance in terms of corporate social responsibility (CSR).

Ethibel is constantly looking out for companies which may be eligible for ethical investments and to be included in its ethical investment register. From the investment register 200 of the best companies are selected to the Ethibel Sustainability Index. Main areas of assessment are human capital, environmental management, market ethics, governance, social impact and human rights. The assessment is based on external information sources such as sustainability reporting and company web sites.

Ethibel is constantly looking out for companies which may be eligible for ethical investments and to be included in its ethical investment register. From the investment register 200 of the best companies are selected to the Ethibel Sustainability Index. Main areas of assessment are human capital, environmental management, market ethics, governance, social impact and human rights. The assessment is based on external information sources such as sustainability reporting and company web sites.

"The inclusion in the Ethibel Sustainability Index further strengthens Valmet's position as one of the global sustainability leaders. For investors Valmet's inclusion in this index provides further assurance of the company as an ethical investment target. In its assessment, Ethibel is using only external information sources, and thus the inclusion in the index is also a recognition for Valmet's transparent and comprehensive reporting and communications around sustainability," says Anu Salonsaari-Posti, SVP, Marketing, Communications and Sustainability at Valmet.

In 2016, Valmet was included in the Dow Jones Sustainability World and Europe indices for the third consecutive year with a record high result, and in the CDP Climate A-list for its actions and strategy to mitigate climate change.

About the Ethibel Sustainability Index Excellence Europe

The Ethibel Sustainability Index Excellence Europe includes the 200 best performing European companies in the field of corporate social responsibility. The analysis is based on research carried out by the rating agency Vigeo Eiris. Ethibel actively promotes socially responsible investing and corporate social responsibility on the financial markets. Read more

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply a fine paper line for Ittihad International Investment in United Arab Emirates

Valmet will supply a fine paper line for Ittihad International Investment L.L.C. in Abu Dhabi, United Arab Emirates. The new greenfield production line (PM 1) with a wide automation package will be producing high-quality printing and writing paper grades for the growing domestic markets and the Middle East and North Africa region. The start-up of the machine is scheduled for the end of year 2018.

The order is included in Valmet's first quarter of 2017 orders received. The value of the order will not be disclosed. The value of an order of this type is typically around EUR 45-70 million.

The order was placed by China Light Industry International Engineering Co., Ltd, an EPC (engineering, procurement and construction work) company, which will be responsible for the complete turnkey delivery of the mill site.

OptiConcept M fine paper machine

OptiConcept M fine paper machine

"Ittihad enters the papermaking business for the first time with this new OptiConcept M machine. By guiding and supporting from the very beginning of the sales process, Valmet wanted to ease Ittihad in the complex investment puzzle. We were also able to display well our papermaking concept with good references. The OptiConcept M line enables high productivity and resource efficiency, excellent quality and low operating cost," says Antero Kunnari, Sales Director, Valmet.

Technical details about the delivery

Valmet's delivery includes a complete fine papermaking line from a stock preparation line and headbox to a reel followed by a parent roll cart and two winders. The delivery includes also a wide scope of automation. The selected technology and automation improve runnability, quality, and the cost, material and energy efficiency. It is possible to lower basis weight still maintaining stiffness and opacity, which results in raw material savings.

The 7,100 mm wide (wire) paper machine will produce uncoated woodfree paper (WFU) grades. The design speed of the machine will be 1,700 m/min with daily capacity of 1,200 tonnes.

About the customer Ittihad International Investment and EPC contractor CLIEC

Established in 2008, Ittihad International Investment group governs several companies in the Middle East. Ittihad Paper Mill (IPM) is the first printing and writing paper production facility in the area of the Gulf Cooperation Council. IPM is located on a 230,000 square meter plot in the Industrial City of Abu Dhabi (ICAD) and is the largest producer of printing & writing paper in the MENA (Middle East and North Africa) region covering around 10% of the MENA market.

China Light Industry International Engineering Co., Ltd. (CLIEC) was founded in January 1953. CLIEC has provided engineering design, consulting and project general contracting services for more than 5,000 medium and large scale projects in China and more than 60 medium, and large scaled projects abroad in more than 20 countries.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply a winder for Shandong Chenming Paper in China

Valmet will supply a new winder for Shandong Chenming Paper Ltd. at its Zhanjiang site in Guangdong province, China. The board machine BM 4 producing folding box board (FBB) will be equipped with a new winder to increase winding capacity. The new winder will be started-up in 2018.

The order is included in Valmet's first quarter of 2017 orders received. The value of the order will not be disclosed. The value of orders of this type and scope is typically around EUR 5-10 million.

Technical details about the delivery

Valmet's delivery for BM 4 includes a high-capacity OptiWin Drum two-drum winder. The winder is easy to operate, has excellent web separation and its set changes are reliable and fast.

"The high-capacity winder with the latest two-drum technologies is designed for the widest and fastest paper and board machines. This is the third winder with same modern sub-floor concept for Shandong Chenming. The customer has been very happy with the previous two. In this winder model, the winding drums are located below floor level and special attention has been paid to the dynamical behavior of the winder ensuring excellent runnability," comments Senior Technology Manager Jaakko Haapanen from Valmet.

9,620 mm wide (trimmed web width) BM 4 produces folding box board grades with a basis weight range of 175-450 g/m2. The design speed for the winder is 3,000 m/min. The daily production is about 1,670 tonnes.

Information about the customer Shandong Chenming Paper Ltd.

Founded in 1958, Chenming Group is one of the leading enterprises in papermaking industry. The group's annual pulp and paper capacity is 8.5 million tonnes with a wide variety of pulp, paper and board grades. Its production sites are located in the provinces of Shandong, Guangdong, Hubei, Jiangxi and Jilin.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply two containerboard machines for Nine Dragons in China

Valmet will supply two containerboard production lines and related automation systems for Nine Dragons Industries Co., Ltd. in China. The new production lines (PM 39 in Quanzhou and PM 40 in Chongqing) are planned to produce high-quality testliner and fluting grades out of 100 percent recycled raw materials. The start-ups of the machines are scheduled for 2018.

The order was included in Valmet's fourth quarter of 2016 orders received. The value of the order will not be disclosed. The value of an order of this type and scale is typically valued around EUR 110-130 million.

"The order is a continuation of the long and good cooperation between Nine Dragons and Valmet. We have done business together for many years. In a project of this magnitude, the customer needs to have a reliable partner to ensure fast start-up and good capabilities for continuous services and production support", says Jari Vähäpesola, President of Paper Business Line, Valmet.

"The modern industrial design of the board machines proved to be important decision making criteria as well. The delivery will include led lighting and video screens located at the both ends of the machine. In addition to increasing safety and usability, they have a positive effect on the customer's brand. The board machines are also very energy and resource efficient and suitable for high-speed production", comments Senior Sales Manager Pekka Turtinen from Valmet.

Technical details about the delivery

Valmet's delivery for the both board machines will include pulpers for stock preparation, two OptiFlo Fourdrinier headboxes to ensure higher productivity, OptiFormer Multi forming section, a center-roll based OptiPress press section, a dryer section with OptiAir high humidity hood combining systems for ventilation, runnability and heat recovery, OptiSizer Combi, a sizer with film and pond application, coating air dryers, OptiCalender Hard nip calender, OptiReel Center driven linear reel and OptiWin Drum two-drum base winder. The delivery includes also process ventilation equipment for the board machine and Valmet DNA machine control system.

With OptiReel center driven linear reel, the parent reel is moved and built up on solid rails. This new technology increases productivity and improves safety and usability. OptiWin Drum two-drum base winder has a high capacity to meet the production needs and it is also easy to operate. The winder is equipped with Dual Unwind enabling the parent roll change in only one minute. PM 39 and PM 40 will produce testliner and fluting grades with a basis weight range of 75 - 140 g/m2.

About the customer Nine Dragons

Founded in 1995, Nine Dragons Paper Group is the world's largest in recovered paper based paper manufacturing in terms of production capacity. The company and its subsidiaries produce linerboard, high performance corrugating medium and coated duplex board. The group's paper machines in China are located in a number of locations. The group produces printing and writing paper in Dongguan and Taicang and packaging paperboard and specialty paper in Leshan, Sichuan Province. The group has also acquired 100% control equity interest in Hebei Yongxin Paper Co., Ltd.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet-supplied fine paper making line for Asia Symbol (GD) Paper started-up ahead of schedule in China

Valmet-supplied fine paper production line for Asia Symbol (Guangdong) Paper Co., Ltd. was successfully started up one month ahead of schedule on January 29, 2017. The new production line PM 12 produces top quality fine papers and it increases the company's capability to produce value-added products. All the produced paper has been saleable from the very start.

"The cooperation with the customer has been excellent. It has been a pleasure to work with the highly motivated and professional teams of both the customer and Valmet. These teams and the outsourced installation company worked well together to meet the revised start-up schedule. The start-up itself was smooth: the machine is operating well and the number of web breaks has remained very low. The start-up curve has proven to be excellent with high daily tonnages," comments Senior Project Manager Jari Laine from Valmet.

Valmet-supplied fine paper making line PM 12 for Asia Symbol (GD) Paper started-up on January 29, 2017

Producing high quality fine paper

The project is representing the long-lasting and good cooperation between Asia Symbol and Valmet. Paper making line 11 (start up in 2012) has been producing fine paper at top speeds and maximum efficiency, and has also become a leading fine paper producing machine in China.

For the PM 12, Valmet's delivery includes a complete fine paper making line from stock preparation to reel with an approach flow system, white water systems, air systems, and clothing for the whole machine line as well as a winder. A comprehensive automation package comprises Valmet DNA process, machine and drive controls and conditioning monitoring as well as Valmet IQ quality control system and profilers. The delivery will also include wet end analyzers. With these automation solutions, the entire production process and the end product quality can be optimized for maximized business results.

The new 9.35 m-wide (wire) machine produces wood free uncoated paper grades in the basis weight of 80 g/m2. The production capacity of the machine is approximately 1,700 tons per day and the design speed 1,800 m/min.

Information about the customer Asia Symbol (Guangdong) Paper

Asia Symbol, is part of RGE (Royal Golden Eagle) Group, is a world-leading producer of pulp and paper. It has an annual production capacity of 1.8 million tons of pulp, 1.0 million tons of fine paper and 470,000 tons of paper board. Its products are sold in more than 20 countries. Asia Symbol's paper mill plant in Xin Hui, Guangdong province, has become a leading fine paper producer in China since its opening in July 2012. It produces stable fine paper quality grades, which set a reference grade quality for the global and Asian markets.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply an evaporation line to Sappi's pulp mill in Ngodwana, South Africa

Valmet will supply an evaporation line to Sappi Southern Africa Limited to be built at the company's pulp mill in Ngodwana, South Africa. The new evaporation line 3 will replace the existing line 1, and will meet the future needs of the mill's ongoing pulp production capacity expansion, together with existing evaporation line 2 that was upgraded by Valmet in 2013. The overall steam economy of the mill will also improve with this investment.

The order was included in Valmet's fourth quarter 2016 orders received. The value of an order of this type is typically valued below EUR 10 million. The new evaporation line is planned to be started up during latter part of 2018.

"The number 1 evaporator plant at Sappi's Ngodwana Mill was commissioned when the mill was built in 1966. Recent upgrades to the mill's product line and production expansions provided an opportunity to replace the original evaporator plant with a modern state of the art plant. Various companies submitted proposals for the expansion project and Valmet was successful in their submission for various reasons, including offering the best technical solution," says SW Engelbrecht, General Manager, Sappi Ngodwana Mill.

"Valmet's global teams, including South African organization, have worked together with Sappi teams to create a new high efficiency evaporation line for dissolving pulp liquor, an application where we have many good modern references globally," says B Syamsundar, Sales Director, Pulp and Energy, Valmet.

Details about Valmet's delivery

Valmet will supply a 6-effect evaporation line tailor-made for dissolving pulp liquor application. The delivery covers main evaporator effects, a surface condenser, flash tanks, platforms and main supporting structures, a vacuum system, as well as vapor ducting and liquor circulation piping.

The new evaporation line 3, will feature same REVAP Concentrator technology as that used for recent evaporation line 2 upgrade, as well as five Tube Evaporators. The new evaporator line includes Valmet's patented ICT (Internal Condensate Treatment) for producing more clean condensate for recycling in the mill. Line 3 will have a design capacity of 310 tons of water per hour, producing heavy liquor at 70% dry solids.

Information about the customer Sappi

Sappi is a global company focused on providing dissolving wood pulp, paper pulp, paper based and biorefinery solutions to its direct and indirect customer base. Sappi has almost 12,000 employees in over 20 countries and manufacturing operations on three continents which produce approximately 5.4 million tons per year of paper, 2.3 million tons per year of paper pulp, and 1.3 million tons per year of dissolving wood pulp.

Sappi Ngodwana mill produces 330,000 tons of paper pulp for own consumption, 210,000 tons of dissolving wood pulp and 380,000 tons of paper (newsprint and linerboard used for packaging) per annum. 70% of the mill's product is exported and the balance is used locally.

The mill generates its own energy in the form of steam and electricity from renewable and other sources. On average, the mill exports power to the national grid, helping to fuel the growing local economy.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet has published the Annual Report and the Corporate Governance Statement for 2016

Valmet has, on March 1, 2017, published its Annual Report for 2016 on the company's website www.valmet.com/annualreports. The Annual Report consists of three separate parts: the Annual Review, the Financial Statements and the GRI Supplement. The GRI Supplement is available in English only.

The printed copies of the Annual Review and the Financial Statements will be available in Finnish and English during the week of March 20, 2017 at the latest. They can be ordered at www.valmet.com/subscribe.

The printed copies of the Annual Review and the Financial Statements will be available in Finnish and English during the week of March 20, 2017 at the latest. They can be ordered at www.valmet.com/subscribe.

The GRI Supplement is available as PDF only. The report defines Valmet's sustainability reporting scope and principles, and alignment with the Global Reporting Initiative (GRI).

Valmet has also published its Corporate Governance Statement including the Remuneration Statement for 2016. It has been prepared in accordance with the recommendations of the Finnish Corporate Governance Code and is available at www.valmet.com/governance.

The Annual Review, the Financial Statements, the GRI Supplement and the Corporate Governance Statement are attached to this stock exchange release.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet Annual Review 2016

Valmet Financial Statements 2016

Valmet GRI Supplement 2016

Valmet Corporate Governance Statement 2016

Valmet to supply a paper machine rebuild for Sappi Maastricht in the Netherlands

Valmet will supply a paper machine rebuild for Sappi Maastricht in the Netherlands. With the rebuilt paper machine 6 (PM 6), Sappi will be able to improve the existing graphical board products and move into producing high quality solid bleached board (SBB) and folding box board (FBB) grades. Today PM 6 is producing coated woodfree (CWF) paper grades. The start-up of the rebuilt machine is scheduled for early 2018.

The order is included in Valmet's first quarter 2017 orders received. The value of the order will not be disclosed.

"All the technical ideas were tested in pilot conditions at our Paper Technology Centers. With the results from the pilot trials and in close partnership, Sappi and Valmet were able to develop a new concept for Sappi Maastricht - a concept with some unique solutions", says Sales Manager Kari Sorsa from Valmet.

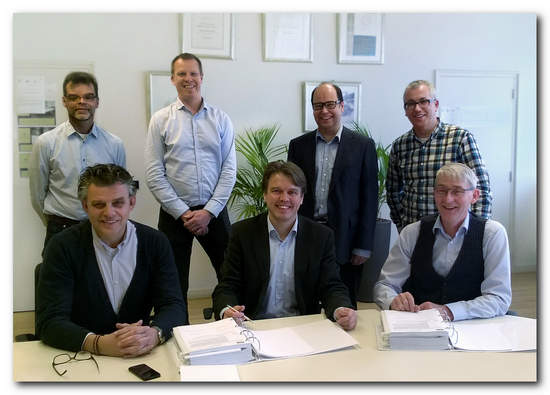

Signing the contract. Back row from the left Marco Duschak (Valmet), Iiro Luostarinen (Sappi), Kari Sorsa (Valmet), Peter Pijpers (Sappi), front row from the left Rob de Koning (Sappi), Marko Oinonen (Valmet) and Peter Loubele (Sappi)

Technical information about the delivery

Valmet's delivery for the PM 6 will include a new type of OptiFlo headbox and OptiCalender Metal Belt calender. With the headbox, an optimal sheet structure with improved paper properties can be achieved.

The calender ordered by Sappi Maastricht will be the ninth OptiCalender Metal Belt to be supplied by Valmet. With this unique technology, bulk of the produced board can be increased significantly. The surface smoothness, topography and printability of the calendered end products are excellent.

PM 6 will be producing graphical board, SBB and FBB in the basis weight range of 220-450 g/m². The mill has a total capacity of 280,000 tonnes/year.

Information about the customer Sappi Europe

Headquartered in Brussels, Belgium, Sappi Europe is the leading European producer and supplier of coated fine paper, packaging and specialty papers. In Europe the company has seven mills, 14 sales offices and 5,100 employees.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Fifth Valmet supplied tissue machine started up at Hayat Kimya in Egypt

Hayat Kimya's Tissue Machine (TM6) started up at the company's new mill in Egypt in mid-January. It marked sixth successful start-up based on the same team from Valmet and Hayat Kimya working together in cooperation. Valmet has previously installed five new machines and provided an extensive rebuild of Hayat's TM1 in Izmit, in Turkey. The new line in Egypt will add 70.000 tons of high quality tissue to the company's current production of facial, toilet and towel tissue.

The new line is part of Hayat Kimya's expansion plan in the Middle East where Valmet have supplied five Advantage DCT 200TS tissue lines to Turkey, Iran, Russia and now also Egypt.

"I would like to express my gratitude to all members in the Valmet and Hayat teams. Once again excellent team work ensured a successful start-up of a new machine. To start-up five new machines and one rebuild with the same team has been a great and positive experience for us all. As our people are familiar with Valmet's Advantage tissue technology we can manage very fast start-ups and high production efficiency" says Lütfi Aydin, Director Paper Group, Hayat Kimya.

"I would like to express my gratitude to all members in the Valmet and Hayat teams. Once again excellent team work ensured a successful start-up of a new machine. To start-up five new machines and one rebuild with the same team has been a great and positive experience for us all. As our people are familiar with Valmet's Advantage tissue technology we can manage very fast start-ups and high production efficiency" says Lütfi Aydin, Director Paper Group, Hayat Kimya.

"During the years, we have developed a very open relationship where we work closely together towards a common goal: to support Hayat Kimya's expansion plan and future success. I am proud to be part of that work," says Rolf Tellack, Project manager, Valmet.

Technical information

The new tissue machine has a width of 5.6 m and a design speed of 2,200 m/min.

The raw material for the new line is virgin fiber and the production line is optimized to save energy and to enhance the quality of the final product.

Valmet's scope of delivery comprises a complete tissue production line featuring stock preparation systems, an Advantage DCT 200 TS tissue machine and two Valmet Focus Rewinder systems. The tissue machine is equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It is also featured with the Advantage tissue technology including a ViscoNip press, an AirCap hood prepared for co-generation, a WetDust dust system, sheet transfer system and a SoftReel L reel. The stock preparation line consists of OptiSlush pulpers, OptiFiner conical refiners and OptiScreen machine screens. To enhance the production efficiency, the tissue machine is complemented with two Focus Rewinders with a width of 2,8 meter and 5,6 meter.

Furthermore, the delivery includes an extensive automation package with Valmet DNA machine and process controls and Valmet IQ quality controls. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

Information about Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 210,000 tonnes and a converting capacity of 135,000 tonnes per year. Through the new start-up the total production capacity of Hayat Kimya will reach 420,000 tonnes.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet's roll service center extension strengthens service capabilities close to customers in Europe

Valmet has expanded its roll maintenance operations with the latest technology equipment for rubber and composite roll covers in Karlstad, Sweden. This investment particularly strengthens Valmet's service capabilities close to its customers in Scandinavia, while also supporting Valmet's roll service offering to customers throughout Europe. The extended roll service center started operating at the end of 2016.

In addition to Sweden, Valmet has three other European roll service centers, providing both roll maintenance and roll covers. The other centers are located in Finland, France and the UK.

Valmet's Karlstad location, the roll service center on the left in the middle

"Now we also have the capacity in Scandinavia to handle even the biggest rolls. We invest in supporting our customers at the mills by bringing roll cover production closer to them. Our customers can get all the covers they need for all the positions they want from us," says Anders Nilsson, Senior Workshop Manager at Valmet.

The increased roll cover capacity is also visible in shortened delivery times for Valmet's European customers.

Roll service agreements aligned to customer needs

"Valmet has a strong position in Scandinavia in roll maintenance service agreements, and we believe that now the additional possibility to offer roll covers close to our customers further strengthens our position. A Valmet service agreement gives customers tailor-made and cost-effective solutions for rolls. Customers' roll maintenance costs can be reduced significantly and higher machine reliability and improved process performance achieved with on-time maintenance and the right choice of roll covers. Our agreements are always aligned to the customer's needs," says Mikael Nyman, Director, Service Operations Scandinavia at Valmet.

By bringing services closer to customers and finding the right solutions together with the customer, Valmet realizes its new services approach, Shared Journey Forward.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.