Displaying items by tag: valmet

Valmet carried out the first maintenance shutdown of CMPC Guaíba's new pulp line in Brazil

Valmet was given an important role in the first maintenance shutdown of CMPC Guaíba's new pulp line in Brazil. The executed shutdown is one of the biggest shutdowns managed by Valmet. The facility's pulp line 2, also called G2, invested in planned maintenance in order to reach its annual capacity of 1.5 million tons/year of bleached eucalyptus pulp. The maintenance shutdown was carried out by Valmet and it took place between July 31 and August 10, 2016.

"We made careful planning with the customer for several months, and thanks to this work we were able to start the line again faster than planned. The geographical location of CMPC Guaíba's pulp mill demands special attention on safety and environmental issues as well as good cooperation with local community. In this respect, our role is not only to ensure that the equipment is running well, we also need to take care of the overall aspects which are part of the mill's operation", says Rogério Duarte, Valmet's Mill Sales Manager.

"Valmet contributed to the successful shutdown of G2 with its personnel's technical skills and organization, and its planning, safety and environmental state-of-the-art criteria. There is no doubt, Valmet and CMPC reinforced their partnership and I believe the company will be a strong candidate for future planned shutdowns," says Fernando Pereira, Maintenance Manager at CMPC.

Working towards a common goal

Valmet's expertise was the key for a well-planned shutdown. "We avoided rework during G2 maintenance as both Valmet and CMPC teams worked together focusing on the same goal," says Paulo Ormeneze, Valmet's Services Manager in South America.

Valmet was in charge of the overall maintenance of the core equipment delivered to this Southern Brazilian pulp mill including cooking, the fiber line, drying machines, causticizing, the evaporation plant and the recovery boiler. All maintenance activities were performed in line with Valmet's and CMPC's safety, quality and environmental criteria.

The first shutdown at CMPC Guaíba G2 was executed by Valmet's Service and Project Execution teams. Taking into account third-party companies and suppliers, Valmet managed altogether over 600 people at the site during 10 days.

Information about the customer CMPC and Guaíba mill

CMPC Celulose Riograndense Ltda is part of the Chilean group, CMPC Celulosa, one of the largest forestry-based companies in Latin America. Its mills in Chile and Brazil produce around 4 million tonnes of pulp per year.

Guaíba pulp mill in Rio Grande do Sul state in southern Brazil has two pulp production lines. The new line G2 was delivered by Valmet and was started up in May 2015.

Calle Loikkanen appointed Director, Investor Relations at Valmet

Calle Loikkanen (M.Sc.Econ) has been appointed Director, Investor Relations (IR) at Valmet. He starts in his new position on September 20, 2016 and reports to Kari Saarinen, CFO at Valmet.

Calle Loikkanen (M.Sc.Econ) has been appointed Director, Investor Relations (IR) at Valmet. He starts in his new position on September 20, 2016 and reports to Kari Saarinen, CFO at Valmet.

Calle has previously worked as Investor Relations manager at Valmet and as Portfolio manager and Investment advisor at Aktia.

"Calle has worked in our Investor Relations team for several years ever since Valmet became an independent, stock listed company. This background and his previous experience provide a good basis to continue Valmet's strong investor relations work," says Kari Saarinen.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to rebuild Metsä Tissue's tissue machines in Raubach in Germany and Pauliström in Sweden

Metsä Tissue has selected Valmet as supplier for the upgrades of tissue machine TM3 in Raubach, Germany and the tissue machine in Pauliström, Sweden.

The orders were included in Valmet's second quarter 2016, orders received. The value of the orders will not be disclosed.

The orders were included in Valmet's second quarter 2016, orders received. The value of the orders will not be disclosed.

Earlier this year Metsä Tissue started up its tissue machine TM1 in Raubach, Germany after Valmet's extensive rebuild of the wet section, where a new OptiFlo II TIS headbox and an Advantage ViscoNip press were installed. The target of this rebuild was to enhance the product qualities as well as energy efficiency and process performance in a sustainable way.

TM3 in Raubach will be equipped with the same headbox as TM1 while Pauliström will replace its existing shoe press and Yankee dryer with Valmet's Advantage ViscoNip press and cast iron Yankee cylinder.

"We are impressed by the results of the new OptiFlo headbox and the Advantage ViscoNip press, but also by the great team work we had in the TM1 project at our Raubach mill. Altogether it has convinced us to extend our cooperation with Valmet also for the new projects in Germany and Sweden," says Guido Bröcker, Senior Vice President Technology from Metsä Tissue.

"With this kind of upgrades the performance and product quality of existing tissue machines can be increased significantly without major investments. We are proud to continue the excellent teamwork we have developed with Metsä Tissue also in the coming projects. We are looking forward to working together to improve their production assets as well as energy efficiency and product quality with Valmet's state-of-the-art technology," says Björn Magnus, Sales Director, Tissue Mills Business Unit from Valmet

Technical information

The machine rebuild to be delivered by Valmet for TM3 in Raubach includes a new OptiFlo II TIS headbox, upgrade of the approach flow system and new screens. The Pauliström tissue machine rebuild consists of an Advantage ViscoNip press and a cast iron Yankee cylinder as well as installation services.

Information about the customer Metsä Tissue

Metsä Tissue is one of the leading tissue paper products suppliers to households and professionals in Europe and the world's leading supplier of baking and cooking papers. Metsä Tissue is part of Metsä Group, which is a forest industry group focusing on wood supply and forest services, wood products, pulp, fresh forest fibre paperboards and tissue and cooking papers. Metsä Group's sales totalled EUR 5.0 billion in 2015, and it employs approximately 9,600 people. The Group operates in some 30 countries.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet Celulose, Papel é Energia Ltda has been notified of arbitration proceedings initiated against it by Suzano Papel e Celulose S.A.

Suzano Papel e Celulose S.A. has filed a request for arbitration against Valmet Celulose, Papel é Energia Ltda, Valmet AB and Valmet Technologies Oy, subsidiaries of Valmet Oyj, claiming approximately Euro 80 million.

The arbitration relates to separate Equipment Sales Agreements for the Suzano Imperatriz pulp mill project in Brazil. Valmet disputes the claims brought by Suzano and will also actively pursue claims of its own against Suzano for breach by Suzano of its obligations under the Agreements.

The arbitration relates to separate Equipment Sales Agreements for the Suzano Imperatriz pulp mill project in Brazil. Valmet disputes the claims brought by Suzano and will also actively pursue claims of its own against Suzano for breach by Suzano of its obligations under the Agreements.

Further information, please contact:

Rasmus Oksala, General Counsel, Valmet, tel. +358 10 672 0026

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +358 10 672 0007

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com, www.twitter.com/valmetglobal

Valmet to deliver a quality control system to Tembec Tartas SAS in France

Tembec's specialty dissolving pulp mill in Tartas, France, has ordered a Valmet IQ quality control system (QCS) and an expansion of its existing Valmet DNA distributed control system (DCS) for its pulp dryer. By complementing its current control system with this investment, the mill is targeting to improve process stability and reduce lost time during transition phases such as start-ups, breaks and speed changes. Start-up of the new QCS is scheduled for October 2016.

The order was included in Valmet's second quarter 2016 orders received. Typically the order value of this kind of automation system deliveries is below EUR one million.

The order was included in Valmet's second quarter 2016 orders received. Typically the order value of this kind of automation system deliveries is below EUR one million.

"We decided to change our DCS and QCS according to our obsolescence management plan. The choice was done between our existing supplier and Valmet. We chose Valmet because of better reactivity and potential quality benefits," says Ludovic Berdinel, Project Department Director at Tembec Tartas SAS.

"The mill was convinced about our capability to improve their pulp dryer performance through our automation solution and process skills," says Boris Hosteins, Sales Manager, France & North Africa, Automation, Valmet.

Technical details about the delivery

Replacing an obsolete third-party QCS, Valmet's delivery includes a Valmet IQ scanner with basis weight and moisture sensors, machine-direction controls and reporting. Valmet IQ is a comprehensive quality monitoring and control system. The solution combines all of the key elements of a QCS system from measurements, controls and profilers to condition monitoring and machine vision into one scalable system. Guaranteed compatibility between different generation Valmet products helps to future-proof investments and maximizes the effectiveness of existing equipment.

Valmet will also expand the mill's Valmet DNA distributed control system that has controlled the pulp dryer processes for the past four years. The delivery includes additional 650 I/Os to replace outdated programmable logic controllers.

Information about the customer Tembec Tartas SAS

Tembec Tartas SAS is the leader in production of specialty cellulose used in consumer-oriented industries such as cosmetics, pharmaceuticals, packaged foods and construction. Its parent company Tembec is a large, diversified and integrated forest products company which stands as the global leader in sustainable forest management practices. The company's principal operations are located in Canada and France.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet's automated paper testing laboratory convinces paper and board makers - nine new orders received

Valmet has recently received all together nine orders for its automated paper testing laboratory from various paper mills around the world. Three of the Valmet Paper Lab units will be delivered to North America, four to Europe and two to Asia. The deliveries will take place later this year.

"Valmet Paper Lab provides papermakers with tools to manage quality and optimize the papermaking process. In addition to laboratories, today paper testing is increasingly carried out by operators, right next to the production line. By receiving rapid, reliable test results, operators are able to quickly make necessary adjustments and get back to running paper production on-spec. This is directly linked to optimal raw material and energy utilization as well as minimized environmental impact," tells Jukka Nokelainen, Business Manager of Valmet Paper Analyzers.

Bringing laboratory next to the paper machine

"An increasing number of papermakers have been convinced of the ability of the Valmet Paper Lab to match their needs and requirements in today's paper making. Our solution gives papermakers freedom to move - from the lab right out next to the line - to give them the instant interactivity and real-time communications they need for faster results," Nokelainen adds.

One of the reasons why papermakers choose Valmet Paper Lab is its user friendliness. Valmet's unit is easy to use all the way from sample cutting, measurements through to getting the analyses.

To present the system in action and enable paper and board makers test its performance in their own mills, Valmet has a trial lab unit available for test use.

Technical information about the Valmet Paper Lab

Valmet Paper Lab is a modular and scalable automated paper testing system with the widest selection of industry standard tests on the market to test over 400 properties in all kinds of grades from 15 up to 650 g/m2and even up to 800 g/m2.

The testing system is based on over 30 years of world's leading experience in automated paper testing. The latest Valmet Paper Lab represents the third generation in the product range. Up to this point, approximately 300 units have been delivered to paper mills around the world, many of which have replaced their older Valmet Paper Lab units with new ones.

For further information, please contact:

Jukka Nokelainen, Business Manager, Paper Analyzers, Automation, Valmet,

Tel. +358 400 284 150

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to introduce a new quality management system for the self-adhesive laminating process

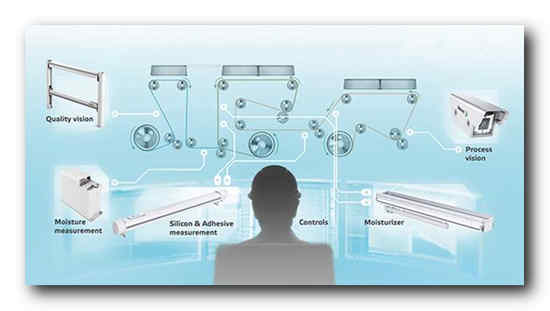

Valmet launched a new quality management system application at the Label Expo Americas exhibition which was held on September 13 - 15 in Rosemount, Illinois. New sheet quality measurements, innovative moisture profiling as well as web monitoring and inspection systems for self-adhesive laminating processes are now combined in the Valmet IQ quality control system.

Patented sensor technology

While adhesive coat weight control has been available for several years, successful control of the silicone release layer has lacked a suitable online sensor until now. The Valmet IQ Silicone and Adhesive Measurement is designed especially for demanding paper and self-adhesive laminating applications to measure silicone coated release liners. Mounted on a single sided scanning frame to provide continuous cross direction measurement profiles of the silicone coat weight, a second sensor after the adhesive application measures the adhesive coat weight. The accurate scan averages and high-resolution CD profiles measured by the new sensor provide a solid foundation for Valmet IQ's machine- and cross-direction silicone and adhesive controls.

Curl control with moisturizer sprayboom

The Moisturizer sprayboom is used to control final laminate curl and the moisture profile of the release liner to improve laminate uniformity and runnability. IQ Moisturizer sprays a fine mist to the paper in a controlled way, providing a very high degree of control and very fast response to quality destroying conditions.

Online quality control

Valmet IQ Process and Quality Vision (PQV) provides web inspection and monitoring tools for online defect inspection, detecting coating streaks and voids and video monitoring of key process operations. Defect inspection at unwinding, for instance, helps identify raw material problems like holes or other serious defects that can cause streaks and quality issues not originating in the laminating machine itself. Printing surface inspection at the reeler provides the final quality assurance step. Production and quality parameters can be easily monitored with the system providing a clear view into process and product quality at all times.

Comprehensive quality management with Valmet IQ

Valmet IQ is a quality management solution designed and built with the experience of thousands of system deliveries by Valmet over more than half a century. Designed for pulp, paper, board and tissue production, it is a customizable quality control, information and management solution that is now further developed for the converting industries such as corrugated board and self-adhesive laminates.

Labelexpo Americas

Labelexpo Americas 2016, the largest event for the label and package printing industry in the Americas, is held at the Donald E. Stephens Convention Center in Rosemont, a suburb of Chicago. Valmet will be exhibiting on stand 1559 in Hall B.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply key technologies for Cheng Loong's new board machine in Vietnam

Valmet will supply Cheng Loong Binh Duong Paper Company with key process technology for its new BM 1 containerboard machine to be located in the company's Ben Cat mill in Binh Duong Province in Vietnam. Valmet's delivery includes a headbox, forming and press sections, a winder and quality measurement system.

The order is included in Valmet's third quarter 2016 orders received. The value of the order will not be disclosed. The value of an order of this type is typically EUR 15 - 20 millions.

Cheng Loong decided to invest in this new recycled containerboard mill and box plant aiming to tap into Vietnam's growing packaging demands. The start-up of the greenfield machine is scheduled for the beginning of 2018.

Cheng Loong decided to invest in this new recycled containerboard mill and box plant aiming to tap into Vietnam's growing packaging demands. The start-up of the greenfield machine is scheduled for the beginning of 2018.

"The containerboard market is growing globally driven by increasing e-commerce and new packaging applications. Valmet has developed a number of excellent solutions to meet the market needs. Energy efficiency, high board quality and very good productivity are among the most important highlights of Cheng Loong's board machine," says Jari Vähäpesola, President of Paper Business Line, Valmet.

Technical details of the delivery

Valmet's delivery for the new containerboard machine will include equipment for approach flow system, a new OptiFlo Fourdrinier headbox to ensure higher productivity, OptiFormer Hybrid forming section with blade technology and a center-roll based OptiPress press section with modern shoe press technology for high dryness to improve energy efficiency. Forming section is equipped with a VacuMaster high-vacuum suction box to significantly improve dryness, thus, energy efficiency. OptiWin Drum two-drum base winder has a high capacity to meet the production needs of BM 1 and it is also easy to operate. The delivery will also include Valmet IQ quality measurement system (QCS) to optimize production process and to maximize production.

"Cheng Loong wanted to have a reliable supplier with high-level technology for its greenfield machine. Technology-wise, a headbox, forming and press sections are key solutions in order to secure high energy and production efficiency in containerboard manufacturing. A reliable winder with high capacity is essential for such a containerboard machine. With earlier successful deliveries to Cheng Loong (the latest in Taiwan), Valmet has proven to be able to respond to Cheng Loong's needs," comments Petteri Soini, Senior Sales Manager of Valmet.

The 6,250 mm wide (wire) BM 1 will produce recycled fluting with a basis weight range of 90 - 180 g/m2 at maximum speed of 1,000 m/min. The annual production of BM 1 is 260,000 tonnes.

Information about the customer Cheng Loong Binh Duong Paper Company

Cheng Loong Binh Duong Paper Company is part of Cheng Loong Corporation, which was established in 1959. The company has four paper mills, seven box plants and a business form plant. It has also established manufacturing and sales sites in China, Vietnam, Japan, and the United States. Its annual production capacity is 2.12 million metric tonnes in paper and paperboard and nearly 2 billion square meters in converting products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet included in the Dow Jones Sustainability Index

Valmet has been included in the Dow Jones Sustainability Index (DJSI) for the third consecutive year and thus maintains its position among the world's sustainability leaders. Valmet was listed both in the Dow Jones Sustainability World and Europe indices.

The annual evaluation conducted by a Swiss investment specialist RobecoSAM comprehensively reviews the company's performance with regard to social, environmental and financial factors. In total 316 companies were included in the DJSI World for 2016-2017.

The annual evaluation conducted by a Swiss investment specialist RobecoSAM comprehensively reviews the company's performance with regard to social, environmental and financial factors. In total 316 companies were included in the DJSI World for 2016-2017.

"Maintaining our position in the Dow Jones Sustainability Index is an excellent achievement for Valmet. It proofs that we have been able to improve our sustainability performance year by year, which is a key criteria for inclusion. We have systematically proceeded with our sustainability agenda, and by doing so achieved many concrete results. We will now continue this work by implementing our updated sustainability action plans for the next three years," says Pasi Laine, President and CEO of Valmet Corporation.

Valmet defined its sustainability agenda named Sustainability360º initially in early 2014. The agenda focuses on five core areas: sustainable supply chain; health, safety and environment; people and performance; sustainable solutions, and corporate citizenship. In the action plans for 2016-2018, special focus continues on ensuring a globally sustainable supply chain and continuous improvement of safety culture.

About the Dow Jones Sustainability Indices

The DJSI is a sustainability index family which includes the global sustainability leaders across industries. The company inclusion is based on a best-in-class approach, which means that the indices only include the top ranked companies within each industry. The index serves as a benchmark for investors who are committed to ethical investing and review companies' sustainability performance as part of their analyses.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet supplied tissue machine started up ahead of schedule at Hengan, Wuhu, China

Hengan's 19th tissue machine, an Advantage DCT 200HS tissue line supplied by Valmet, successfully started up in August at the company's mill in Wuhu, Anhui province in China. The installation and commissioning were performed in record time and the start-up went very smoothly. The new tissue machine adds another 60,000 annual tons of tissue products to Hengan's current production of more than one million tons per year.

PM 19 is Valmet's fifth tissue machine delivery to Hengan. The previous four Valmet Advantage DCT machines are located at Jinjiang, Changde and Weifang mills and were installed in 2006, 2007, 2009 and 2010. Currently the installation of a sixth Valmet delivered tissue machine PM 20 is ongoing, and it will start up later in 2016.

PM 19 is Valmet's fifth tissue machine delivery to Hengan. The previous four Valmet Advantage DCT machines are located at Jinjiang, Changde and Weifang mills and were installed in 2006, 2007, 2009 and 2010. Currently the installation of a sixth Valmet delivered tissue machine PM 20 is ongoing, and it will start up later in 2016.

"Joint effort and great work from the joint Valmet and Hengan team ensured a successful start-up of our new PM19 at exactly 10:48, August 8. The new machine will raise Hengan Group's total production capacity to 1,080,000 annual tons of tissue and reduce the current production shortage," saysCui Jiantong, Project Manager, HenganGroup

"This start-up is a good example of what can be achieved by the efficient combination of the well proven Valmet Advantage DCT technology and excellent team work. Thanks to very good and transparent cooperation and joint efforts from the teams involved, we finalized the installation and commissioning in record time. It has been a pleasure to work with Hengan's project and production team and we are looking forward to next start-up," says Svenerik Olsson, Director, China Tissue Business from Valmet.

Technical information about the delivery

Valmet's scope of delivery comprised a complete tissue production line featuring stock preparation systems, Advantage DCT 200HS tissue machine and an automation package from Valmet with Valmet DCS and QCS process control system. The tissue machine has a width of 5.6 m and a design speed of 2,000 m/min and is equipped with OptiFlo headbox and cast alloy Yankee cylinder. The machine is also featured with the well proven Advantage tissue technology including gas heated AirCap hood, WetDust dust system and a SoftReel P reel. Basic engineering, installation supervision, training, start-up and commissioning were also included in the delivery.

Information about the customer Hengan

Hengan International Group Company Limited is an investment holding company mainly engaged in the trading of personal hygienic products. The Company and its subsidiaries are principally engaged in the manufacturing, distribution and sale of personal hygiene products, including sanitary napkins products, disposable diapers products and tissue papers products, food and snacks products and others in the People's Republic of China, Hong Kong and certain overseas markets.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.