Displaying items by tag: valmet

Ari Saario appointed Director, Research & Development at Valmet

To strengthen Valmet's R&D operations Mr. Ari Saario (D.Sc. Tech.) has been appointed Director, R&D at Valmet as of January 18, 2016. He will report to Juha Lappalainen, Senior Vice President of Valmet's Strategy and Operational Development corporate function.

To strengthen Valmet's R&D operations Mr. Ari Saario (D.Sc. Tech.) has been appointed Director, R&D at Valmet as of January 18, 2016. He will report to Juha Lappalainen, Senior Vice President of Valmet's Strategy and Operational Development corporate function.

The aim of Valmet's research and technology development work is to ensure an advanced and competitive offering of technologies and services, enhance raw material and energy efficiency, and to promote the use of renewable raw materials. The R&D director position is new in the company, and Ari Saario will concentrate on ensuring an effective R&D process and commercialization of new innovations, right R&D project portfolio and a clear R&D road-map to secure Valmet's technological leadership also in the future.

"Valmet's strong R&D infrastructure is built around our 16 own R&D centers and pilot facilities. We have over 400 R&D professionals around the globe and around 1,800 protected inventions. As a result of our R&D work, we have continuously improved our products and services and brought new innovations to market. With this new position we aim to create an even more focused R&D process and portfolio, and accelerate the commercialization of new innovations," says Juha Lappalainen, Senior Vice President of Valmet's Strategy and Operational Development.

Ari Saario moves to this new position from Valmet's Pulp and Energy business line's R&D function. He has a strong background in technology and R&D from Oilon, Metso and Valmet. He has versatile experience of more than 10 years in research and technology development, R&D team leadership and R&D funding.

For further information, please contact:

Ari Saario, Director, Research & Development (as of Jan 18, 2016), Valmet, tel. +358 50 590 2046

Juha Lappalainen SVP, Strategy and Operational Development, Valmet, tel. +358 50 523 8708

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet-supplied OptiConcept M board making line started up at Pratt Industries in the USA

Pratt Industries' Valmet-supplied containerboard production line, PM 16, successfully came on stream on October 04, 2015 at their greenfield paper mill in Valparaiso, Indiana, USA. This is Valmet's first OptiConcept M installation in North America.

"PM 16 is one of the industry's most efficient paper mill, employing 120 people to make 370,000 tons a year - twice the productivity of many competitor mills. It is the world's most environmentally-friendly paper mill and a showcase for the latest in 21st Century paper-making technology," says Anthony Pratt, Global Chairman of Pratt Industries.

Valmet OptiConcept M board making line is designed to use less water, electricity and raw materials. "That's important not only for our environment but also for our customers who realize the importance of sustainable packaging." says Pratt.

The Valmet OptiConcept M containerboard production line started up on October 4, 2015 for Pratt Industries at the Valparaiso mill in Indiana, USA.

About Pratt Industries

Pratt is America's 5th Largest corrugated packaging company and the world's largest, privately-held 100% recycled paper and packaging company, with more than 5200 highly-skilled employees dedicated to the environment and sustainability. Pratt was founded in the USA some 25 years ago and, since then, has shown dramatic growth with sophisticated manufacturing facilities in more than 20 states.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Further information, please contact:

Tuomo Rämö, Senior Project Manager, Paper Mills, Valmet, tel. +358 40 748 8513

Mike Gray, Area Vice President, North America, Valmet, tel. +1 920 738 8542

The Board of Directors of Valmet resolved on continuing the long term incentive plan for key employees

The Board of Directors of Valmet has decided to continue the share based incentive program for Valmet's key employees approved in December 2014. The aim of the program is to combine the objectives of the shareholders and the key employees in order to increase the value of the company, to commit the key employees to Valmet, and to offer them a competitive reward plan based on holding the company's shares.

The Board of Directors of Valmet has decided to continue the share based incentive program for Valmet's key employees approved in December 2014. The aim of the program is to combine the objectives of the shareholders and the key employees in order to increase the value of the company, to commit the key employees to Valmet, and to offer them a competitive reward plan based on holding the company's shares.

The program approved in 2014 includes three discretionary periods, which are the calendar years 2015, 2016 and 2017. The Board of Directors of Valmet shall decide on the performance criteria and targets in the beginning of each discretionary period. The potential reward of the program from the discretionary period 2016 is based on EBITA % improvement and orders received growth % of the stable business, that is, the Services and Automation business lines. The potential reward of the plan from the discretionary period 2016 will be paid partly as Valmet shares and partly in cash in 2017. The proportion to be paid in cash is intended to cover taxes and tax-related costs arising from the reward to the key employee. As a rule, no reward is paid, if the key employee's employment or service ends before the reward payment.

As part of the share based incentive program members of the Valmet Executive Team shall have a possibility to receive a matching share reward for the discretionary period 2016 provided that he or she owns or acquires Valmet shares up to a number determined by the Board of Directors by December 31, 2016. Reward receipt is tied to the continued employment or service of the Valmet Executive Team member upon reward payment.

The reward of the plan may not exceed 120 percent of the key employee's annual total base salary. The shares paid as reward may not be transferred during the restriction period, which will end two years from the end of the discretionary period. Should a key employee's employment or service end during the restriction period, as a rule, he or she must gratuitously return the shares given as reward to Valmet.

The plan is directed to approximately 80 people. The rewards to be paid on the basis of the plan are in total an approximate maximum of 850,000 shares in Valmet.

Further information, please contact:

Pasi Laine, President and CEO, Valmet, tel. +358 10 672 0001

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +358 10 672 0007

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Juha Lappalainen appointed SVP, Strategy and Operational Development at Valmet

Mr. Juha Lappalainen (MSc. Eng., born 1962) has been appointed Senior Vice President, Strategy and Operational Development at Valmet as of January 4, 2016. Juha Lappalainen will succeed Kari Saarinen, who was appointed Valmet's CFO in November. In his new position as SVP, Strategy and Operational Development, Juha Lappalainen will be a member of Valmet's Executive Team and report to President and CEO Pasi Laine.

Mr. Juha Lappalainen (MSc. Eng., born 1962) has been appointed Senior Vice President, Strategy and Operational Development at Valmet as of January 4, 2016. Juha Lappalainen will succeed Kari Saarinen, who was appointed Valmet's CFO in November. In his new position as SVP, Strategy and Operational Development, Juha Lappalainen will be a member of Valmet's Executive Team and report to President and CEO Pasi Laine.

Juha Lappalainen has been employed by Valmet since 2013, and is currently working as Vice President, Procurement. He has a strong, international background in global telecommunications with versatile experience in sales, technology and business development, and in leading strategic projects including mergers and acquisitions.

"It is a pleasure to welcome Juha Lappalainen to our Executive Team to develop our operations forward. As company we have taken big leaps regarding strategy execution, procurement, quality, and health and safety results. I am convinced that under Juha's leadership we will continue to strengthen these areas further," says Pasi Laine, President and CEO of Valmet.

For further information, please contact:

Pasi Laine, President and CEO, Valmet, tel. +358 10 672 0001

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet-delivered TwinRoll press installed at Södra Cell's Mönsterås pulp mill in Sweden

A Valmet-delivered TwinRoll Evolution press was successfully installed at Södra Cell's Mönsterås pulp mill in Sweden during the yearly shutdown in the end of September. This is the 85th TwinRoll Evolution press Valmet has delivered since the model was launched in 2009.

"The new wash press will play an important role in our process to secure a grade of pulp that meets customer requirements and to achieve improved availability," says Olof Hellström, one of Södra's project managers.

Fast commissioning

Lars Harrysson, project leader at Södra, said that the installation and commissioning were highly successful, and that the schedule was maintained throughout the project. "Everything has worked out, and everyone has done their utmost to get the new press installed and running," says Harrysson.

"The shutdown in Mönsterås was well planned which created the best possible conditions and enabled the efficient installation. Slightly more than one day after the start-up the press was up and running in nominal production of soft wood pulp, with a dryness that was well above the promised. The training was an important piece in the success. Committed and interested operators enabled a quick knowledge transfer," says Mikael Johansson, Project Manager at Valmet.

Information about the customer Södra Cell and the Mönsterås mill

Södra is an economic association with a membership base of about 51,000 forest owners in southern Sweden. Södra has built up a considerable production of paper pulp, wood products and biofuels. Södra employs about 3,500 people and has three business areas Södra Skog, Södra Cell and Södra Wood. Södra Cell is one of the largest players in the world in the area of softwood pulp and operates three pulp mills in Sweden: Mörrum, Mönsterås and Värö.

Södra Cell Mönsterås is Södra's biggest pulp mill with a capacity of 750,000 tonnes per year of pulp. In addition to electricity, the mill delivers district heating to the municipality of Mönsterås and to Södra's sawmill in the area. Furthermore, the mill supplies tall oil for biodiesel. Södra is in a period of substantial investments and plans to invest more than 30 million euros in the pulp mill in Mönsterås during 2015 and 2016. This will lead to more efficient energy usage and increase productivity at the mill.

For further information, please contact:

Mikael Johansson, Project Manager, Pulp and Energy Business Line, Valmet tel. +46 70 653 3807

Valmet to supply key technology to SCA's Östrand pulp mill expansion project in Sweden

Valmet has received a major order to deliver cooking, fiber line and evaporation plant to SCA's Östrand pulp mill located in Timrå, Sweden. This delivery is part of SCA's investment to upgrade the production of bleached softwood kraft pulp at the Östrand mill from today's capacity of 430,000 tons to 900,000 tons per year. The last start-up of the renewed pulp mill is scheduled for May 2018.

Valmet has received a major order to deliver cooking, fiber line and evaporation plant to SCA's Östrand pulp mill located in Timrå, Sweden. This delivery is part of SCA's investment to upgrade the production of bleached softwood kraft pulp at the Östrand mill from today's capacity of 430,000 tons to 900,000 tons per year. The last start-up of the renewed pulp mill is scheduled for May 2018.

The order is included in Valmet's fourth quarter 2015 orders received. The value of the order is not disclosed.

In SCA's press release on December 2, 2015 SCA's project director Ingela Ekebro explained about the goals of the project: "The new pulp mill will have world class technology. We are going to produce pulp with top quality, while our environmental performance is the best achievable and we are going to do it with a cost efficiency that allows us to successfully compete with other pulp suppliers worldwide."

"This major agreement with SCA is a strong continuation of Valmet's and SCA's long term cooperation and an important achievement for our pulp technology business. The project has a significant employment impact to Valmet in Sweden, since a significant part of the equipment to be delivered in this project, will be engineered and produced in our Swedish units," says Bertel Karlstedt, President, Pulp and Energy Business Line, Valmet.

The estimated employment impact of the order is about 150 man years mainly in Sweden. A large part of the order will be delivered from Valmet's Swedish units: the cooking plant from Karlstad, fiber line from Sundsvall, and evaporation plant from Gothenburg.

Valmet has earlier delivered both pulp and tissue technology to SCA and has also extensive services contracts with SCA. The most recent delivery was the new Compact Cooking G2 for the SCA Obbola kraftliner mill.

Details about Valmet's delivery

Valmet's delivery includes a Compact Cooking G2 together with a TwinRoll press based fiber line for both ECF and TCF pulp production at a capacity of 2,850 air dry tons per day (adt/d). The evaporation plant consist of 7 effects with a TUBEL superconcentrator for high dry solids and has a capacity of 1,150 tons of evaporated water per hour. The total package is optimized for superior water and energy efficiency.

Information about the customer SCA

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. The company's sales are conducted in about 100 countries under many strong brands, including the leading global brands. As Europe's largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm

For further information, please contact:

Stefan Mattsson, Vice President, Fiber Processing Business Unit, Valmet, tel. +46 70 653 38 18

Bertel Karlstedt, President, Pulp and Energy, Valmet, tel. +358 10 676 3026

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet started up new coaters at Mayr-Melnhof Kolicevo board machine in Slovenia

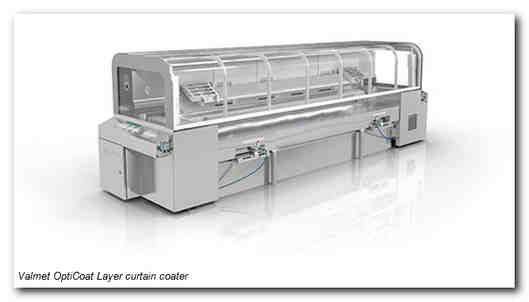

Valmet has successfully started up new coating technology, featuring multilayer curtain coating, at Mayr-Melnhof Kolicevo board machine 3 (BM 3) in Slovenia. Valmet's delivery included a new OptiCoat Layer curtain coater with supply system and a new OptiCoat blade coater.

Compared to other curtain coating solutions OptiCoat Layer is compact in size and straightforward to install. This enables lower investment cost and shorter shut-down time. The start-up was very smooth, thanks to the pre-assembly and pre-testing. This and the good cooperation between Valmet and experienced Kolicevo mill resulted inhigh-quality production right after the start-up.

"The assembly was finished on time and the start-up was done by just pushing the button. We are happy that the high targets set for this project have been met. The cooperation with Valmet was very good, on an open base during the whole project and startup phase, preventing all possible disturbances, before they even could occur," says Technical Mill Manager Rado Kunavar from Mayr-Melnhof Kolicevo.

Benefits with curtain coating

Mayr-Melnhof has been using curtain coaters from different suppliers for several years. Due to the compact design of Valmet's coater, the coating trials performed in Järvenpää and the good cooperation during the sales phase, they decided to choose Valmet this time. The selected coating concept including the 2-layer curtain coating makes it possible to reduce coat weight resulting in cost savings.

OptiCoat Layer uses slide dye curtain coating, which enables versatile use of coating color substances and layer thicknesses. The method also provides flawless coating coverage. The supply system includes the necessary degassing equipment. Effective degassing is essential in curtain coating since even the smallest air bubbles affect the stability of the curtain.

"2-layer coating has been tested with dry edges, and equipment works as expected. It has proven to be very good that we chose the degassing system from Valmet. We are very pleased with it," says Production Manager Aljaz Hafner at Mayr-Melnhof Kolicevo.

Information about the customer Mayr-Melnhof Group and the Kolicevo mill

The Mayr-Melnhof Group's operations are entirely concentrated on the core business areas which are managed in two operative segments MM Karton and MM Packaging. MM Karton is the worldwide leading manufacturer of coated recovered cartonboard with a growing position in virgin fiber based board. The Division is composed of seven mills in Europe with a total annual production capacity of more than 1.6 million tons.

The recycling and virgin fiber based cartonboard grades are produced at the Kolicevo mill. Specializing in weights between 200 and 500 g / m², the products are used in particular for food packaging, cosmetics, pharmaceutical packaging and other high-quality applications.

Further information, please contact:

Michael Kremsner, Product Sales Manager, Paper Mills Business Unit, Valmet, tel. +43 1 7996255 83

Petri Paloviita, Product Manager, Coaters and Sizers, Paper Mills Business Unit, Valmet, tel. +358 40 5918622

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply press section technology for Marusumi Paper Co., Ltd. in Japan

Valmet will supply a paper machine rebuild to Marusumi Paper's Ohe mill in Japan. The rebuild includes a new press section utilizing Valmet's modern shoe press technology.

Valmet will supply a paper machine rebuild to Marusumi Paper's Ohe mill in Japan. The rebuild includes a new press section utilizing Valmet's modern shoe press technology.

The main target of the rebuild is to decrease energy consumption at the plant. The rebuilt machine will be started up during fourth quarter of 2016.

The order was included in Valmet's third quarter 2015 orders received. The value of the order is not disclosed.

"The trend in newsprint production has recently been towards lighter paper weights, driven by resource and energy savings. To further meet this lighter weight tendency, Marusumi Paper has decided to proceed with a press rebuild project in order to improve productivity and end product quality. We chose Valmet as a supplier for this rebuild for several reasons. The original supplier of the machine is Mitsubishi Heavy Industries, and Valmet has acquired the company's paper machinery technology. We have also had good experience with Valmet in an earlier project when installing a sizer for Ohe mill's PM 3 in 2005. We are expecting great performance from Valmet also with this project", says Toru Shinohara, Director and Mill Manager, Marusumi Paper Co., Ltd.

"Valmet can offer key technologies for challenging rebuilds, and pressing technology is one of our core know-how areas. Modern pressing technology can help our customers to achieve higher end product quality and significantly decrease energy consumption," says Petri Paukkunen, Vice President, Paper Mills Sales and Marketing, Valmet.

Key features of the delivery

Valmet's delivery includes a new center roll based press section with modern shoe press technology as well as related runnability solutions, new press section frames, installation, motors and electrification. The existing press section at PM 2 will be rebuilt into Valmet's OptiPress Center press section. With this tri-nip solution, the new 1st press, the 2nd press and the 3rd press shoe nip maximizes the dry content, decreases steam consumption and increases the wet strength of the paper.

The 9000-mm-wide (wire) PM 2 produces newsprint grades at the design speed of 1200 m/min.

About Marusumi Paper Co., Ltd.

Marusumi Paper Co., Ltd. is the Japanese paper making company which produces and sells paper products. The company was founded in 1919 with almost 100 years of history, and it is based in Ehime Prefecture, Japan.

Further information, please contact:

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills, Valmet, tel. +358 40 744 8182

Kazuhiko Endo, Director, Sales, Valmet Japan, tel. +81 (0)3 6744 3024

Valmet to supply a pulp cooking plant to Siam Cellulose's Ban Pong mill in Thailand

Valmet will deliver a pulp cooking plant to Siam Cellulose Co., Ltd's Ban Pong pulp mill in Ratchaburi, Thailand. The mill will produce 70,000 ton per year of eucalyptus pulp, and the start-up of the new cooking plant is scheduled to be in December 2016.

Valmet will deliver a pulp cooking plant to Siam Cellulose Co., Ltd's Ban Pong pulp mill in Ratchaburi, Thailand. The mill will produce 70,000 ton per year of eucalyptus pulp, and the start-up of the new cooking plant is scheduled to be in December 2016.

The order is included in Valmet's fourth quarter 2015 orders received. The value of the order will not be disclosed.

"This will be our third cooking system from Valmet within 5 years, and after this Ban Pong installation, all our pulp production units in Thailand will have the same CompactCooking G2 system. The efficient utilization of raw material is vital from sustainability perspective and the pulp properties are excellent for our paper and packaging products," says Surasak Amawat, Managing Director, at Siam Cellulose Co., Ltd.

"We are very pleased to continue our successful cooperation with Siam Cellulose. The new cooking plant will replace the existing tube digesters and will utilize the raw material more efficiently, improve pulp quality, save chemicals and all in all improve the environmental performance of the mill", says Patrik Lidbäck, Sales Manager at Valmet.

Details about the delivery

The Valmet developed two-vessel CompactCooking G2 system has several benefits. It mainly consists of an ImpBin for impregnation and a digester for cooking of chips and is characterized by its simple, yet sophisticated design, a flexible system that is easy to operate. The ImpBin technology with its unique features enables higher kappa level still with low reject content. Using a 2-vessel design ensure well defined impregnation as well as cooking zones. Effective impregnation in combination with the benefits of the CompactCooking process produce pulps with high yield and excellent pulp quality.

Valmet has a long standing customer relationship with Siam Cellulose. This is the third CompactCooking system delivered to Siam Cellulose's mills in Thailand.

About the customer Siam Cellulose Co., Ltd. (SCL)

Siam Cellulose is a subsidiary of SCG Packaging and a leading producer of eucalyptus based pulp. SCG Packaging is the largest integrated paper and corrugated containers producer in ASEAN.

For further information, please contact:

Patrik Lidbäck, Sales Manager, Pulp and Energy Business Line, Valmet tel. +46 70 715 47 16.

Anil Purankar, Vice President, Pulp & Energy Business Line, Asia Pacific, Valmet tel. +66 81 723 6085.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to deliver its 200th online fiber analyzer to New-Indy Containerboard

New-Indy Containerboard, LLC will start to predict and control sheet strength with Valmet's fiber analyzer solution. The Valmet Pulp Analyzer, also known as Valmet MAP, and a Valmet Pulp to Paper Optimizer advanced process control solution will be installed at New-Indy Containerboard's 1,000 tons per day containerboard machine in Ontario, California, USA. The project will be implemented during the fourth quarter of 2015.

Photo of Valmet Pulp Analyzer - Valmet MAP

This will be the first 100% recycled furnish containerboard machine in the world to employ the prediction of important linerboard and corrugating medium sheet strength tests through online fiber analysis. It's also the 200th online fiber analyzer delivered by Valmet globally.

The order is included in Valmet's third quarter 2015 orders received. The value of the order is not disclosed.

Better prediction with modelling

Kris Anderson, Production Manager at New-Indy, explains the multiple benefits the mill staff foresees: "With strength prediction and model-based controls we expect that we will get more speed from the board machine and run lower basis weights, hence fiber savings on some grades. That is where the return of investment is. We will get a better model of our sheet strength properties and that will improve our quality variability in terms of STFI, Concora and Mullen tests. This modeling capability was a key factor in our decision to buy from Valmet."

Kevin VanPembrook, Valmet's North American Product Manager, says: "This order not only represents the 200th Valmet MAP sold since it was launched in 2005, but it is the first of our newly re-designed Pulp to Paper Optimizer Solution for low-consistency refining at the paper machine. This solution gives additional benefits for our customers, because it continuously predicts their final paper or board strength, and offers a multi-variable control platform to optimize it.

Technical details about the delivery

Valmet Pulp Analyzer's fiber imaging module is equipped with technology that enables the analysis of fiber fibrillation created during refining as well as many other fiber properties important for predicting board sheet strength tests. The fiber furnish samples are taken by Valmet SD 103 process sampling devices at multiple points in cycles of a few minutes. In addition, the analyzer is equipped with the CSF freeness module.

Valmet's Pulp to Paper Optimizer Solution is a multi-variable advanced process control that manages low-consistency refining conditions to consistently achieve final paper or board functional specifications.

For further information, please contact:

Kevin VanPembrook, Product Manager, Pulp&Paper Applications, North America, Automation, Valmet, Phone: +1 770 330 2102

Ismo Joensuu, Manager, Online Paper Analyzers Product Team, Automation, Valmet, Phone: +358 40 7006483

Valmet MAP product information: http://www.valmet.com/ValmetMAP

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.