Displaying items by tag: valmet

Valmet to supply two spray moisturizer systems to SAICA's corrugated board converting plants in Spain and France

Valmet will supply two Valmet IQ Moisturizer systems to SAICA's corrugated board converting plants in El Prat, Spain, and Beaulac, France. By installing Valmet's advanced moisturizing technology in their corrugators, SAICA's plants will be able to reduce corrugated board warping and consequently reduce waste and improve productivity in their converting processes.

The order was included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A moisturizer is usually valued below EUR 1 million. The deliveries will take place during the third quarter of 2016.

The order was included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A moisturizer is usually valued below EUR 1 million. The deliveries will take place during the third quarter of 2016.

"After many years of successful experiences working together with Valmet's automation solutions on paper production, Saica Group celebrates Valmet movement towards the introduction of automation technology on corrugators to ensure board quality as well as line production efficiency. The collaboration of the two companies' innovation technology teams is resulting on reliable control systems working on line and this order is a proof of our satisfaction," says Federico Asensio, Saica Group, Director, R&D and innovation.

"Entering paper and board converting with the Valmet IQ quality control solutions is one of Valmet's growth initiatives. We have earlier supplied a moisturizer system to SAICA's converting plant in Viana, Spain. A repeat order from SAICA is now proof that we are on the right track for delivering proven, value-adding quality control solutions also for the converting industry," states Jari Almi, Director, Quality Management Solutions, Automation, Valmet.

Technical information about Valmet IQ Moisturizer

Valmet's delivery includes two Valmet IQ Moisturizers that are part of the Valmet IQ product family for monitoring and optimizing process performance and end product quality.

Valmet IQ Moisturizer is a moisturizing system with applications for moisture cross-direction profiling, warp (curl) control and smooth moisture level increase. It features an air atomized micro droplet spray nozzle, a linear water control valve and excessive spray mist removal system.

Information about the customer SAICA

SAICA Group has three business areas: paper mills (Paper), collection of recyclable materials (Natur) and corrugated paper pack containers (Pack). The consolidated sales figures of the Spanish company for year 2015 were EUR 2,378 million. SAICA Group is a leading company in Europe in the manufacturing of containerboard paper, corrugating board with a capacity of almost 2.5 million tons of paper and more than 2.400 million square meters of corrugated board. The company has more than 8,800 employees at present in Spain, France, Italy, Portugal, United Kingdom, Ireland and Turkey.

Valmet receives repeat order for a new Advantage DCT tissue production line from Papel San Francisco in Mexico

Valmet will supply an Advantage DCT 100TS tissue production machine to Papel San Francisco in Mexico. The new machine will be installed at the company's mill in Mexicali and start-up is planned for the second half of 2017.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed

Continuation of good cooperation

The new tissue line will fulfill Papel San Francisco's need of new capacity for standard tissue products. Valmet has previously delivered three tissue machines to the company. Two Advantage DCT machines started up in 2006 and 2009 and one Advantage NTT started up in 2013 which fulfills the company's demand of textured tissue.

"Our previous installations are running very well. The Advantage DCT machines are operating at high speed and made the world speed record of 2160 m/min already in 2009. The Advantage NTT machine has reached record high production capacity in conventional mode and the textured products are well received on the market. Due to the need to increase our capacity of standard tissue we decided to go for the cost and energy efficient Advantage DCT technology equipped with the Advantage ViscoNip press," says Dario Palma y Meza Espinoza, Operational Director, Papel San Francisco.

"Our relationship withPapel San Francisco is a showcase for how a supplier and customer cooperate to achieve continuous performance improvements with a win-win result. During the years Papel San Francisco has managed to break several records regarding speed and operation performance. Our relationship is built on respect, strong trust and cooperation with professional and technical focus," says Jan Larsson, Sales Director North America, Tissue Mills Business Unit, Valmet.

Technical information about the delivery

The new tissue machine will have a width of 2.8 m and a design speed of 2,200 m/min and will add 30,000 tons tissue paper per year to Papel San Francisco's current production of toilet tissue, kitchen towels and napkins.

Valmet's scope of delivery will comprise an Advantage DCT 100TS tissue machine. The machine will be equipped with OptiFlo headbox and cast alloy Yankee cylinder. The machine will also be featured with the well proven Advantage tissue technology including ViscoNip press, AirCap hood and WetDust dust system. Start-up and commissioning are also included in the delivery.

About the customer Papel San Francisco

Papel San Francisco started up their first tissue machine in 1980. In the past 35 years the company has grown steadily and are today operating five tissue machines with a yearly capacity of 150 000 tons of tissue products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet invests in press felt production

Valmet develops its paper machine clothing production plant in Tampere, Finland by investing in press felt production. The investment is done in order to improve the product technology and production capacity of seamed press felts for the paper, board, tissue and pulp drying machines.

The investment includes a new wide weaving loom, updating of some existing weaving looms and a new fiber opening and blending machinery. The total value of the investment is several million euros and the investment project will be finalized during the first quarter of 2017.

Seamed felts improve safety and efficiency

The investment is done in order to meet the growing market needs as customers are willing to move away from endless felts in older machines. The seamed felt market is growing, especially in North America, where over 70% of the felts used in paper and board machines are endless. Also in Europe, the market of seamed felts is growing. The change from endless felts to seamed ones improves occupational safety and production efficiency at mills.The seamed felt installation is faster and takes much less manpower than installing an endless felt.

"This investment gives us the necessary assets to further develop our leading technology for the growing and demanding seamed felt market. It also ensures our capacity for the coming years to deliver felts that respond to customer needs for optimized production performance. This is also an investment in Valmet's renewed services approach," says Jari Stålhammar, Vice President, Fabrics, Services Business Line at Valmet.

For further information, please contact:

Jari Stålhammar, Vice President, Fabrics, Services Business Line, Valmet, tel. +358 40 5014239

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet renews its services approach

Valmet has renewed its services offering and unified its way to serve to enable better customer experience and growth in the services business.

"Our vision is to become the global champion in serving our customers. We constantly challenge ourselves to improve both our services offering and also the way we actually meet our targeted customer service level. After adding automation and related services to our offering in 2015, the natural next step was to start unifying our services offering and way to serve our customers. We see that our new approach, called "Shared Journey Forward", is a concrete step towards our vision," says Pasi Laine, President and CEO of Valmet.

After the renewal, Valmet's whole services offering is easy to understand and to choose from. The services are restructured under three categories: reliability services, performance services, and new technology upgrades. Furthermore, Valmet develops further its global expertise network and way to serve the customers both online and close by.

The core commitments Valmet is making to its customers are keeping safety as number one priority, being close to the customers, serving customers with solutions meeting their needs and having people to whom customers can trust.

"The commitments we give to our customers reflect also our priorities. We never compromise safety and continuously develop our safety culture and procedures. Being close to customers means both that we are globally present with over 100 service centers and we utilize industrial internet in helping our customers remotely. We listen to our customers in order to find the best solution for particular customer needs and we work hard every day to earn our customers' trust," says Jukka Tiitinen, President of Services Business Line.

Valmet's services offering is built to improve reliability and performance of customers' processes and also bring in new technology to keep the processes up-to-date in the changing business environment.

"In addition to strong individual services products our solutions are built to bring concrete benefits to our customers. Our reliability services keep the equipment and processes running smoothly. We can even take responsibility for maintenance and on-site services and inventory management. With performance services our customers can achieve reduced energy and raw material costs, reduced process variability, optimized quality and production, and enhanced environmental performance. Furthermore, adding new technology to the process at the right time keeps production competitive and helps to take the production to the next level," describes Jukka Tiitinen Valmet's renewed services offering.

For further information, please contact:

Jukka Tiitinen, Business Line President, Services, Valmet, tel. +1 404 433 0937

Petri Lakka, Vice President, Services Development, Valmet, tel. +358 40 521 1087

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Fatal accident at Valmet's project site in Sweden

On Thursday, June 2, 2016 a serious workplace accident occurred in Valmet's installation activities in the pulp mill expansion project at Södra Cell's Värö mill in Sweden. An employee of Valmet's subcontractor was seriously injured in a lifting operation and later died in hospital whilst receiving treatment for injuries sustained during the accident.

"Our thoughts are with the deceased's family and colleagues. We have informed the personnel working with the project on site and are giving them the needed support. Valmet is committed to protecting the health, safety and environment (HSE) of our people, customers, partners and the communities where we operate. Everyone has the right to a safe work environment. Investigation of the accident has been started and corrective actions will be implemented to continuously improve our processes and routines to ensure safety," says Stefan Mattsson from Valmet.

"Our thoughts are with the deceased's family and colleagues. We have informed the personnel working with the project on site and are giving them the needed support. Valmet is committed to protecting the health, safety and environment (HSE) of our people, customers, partners and the communities where we operate. Everyone has the right to a safe work environment. Investigation of the accident has been started and corrective actions will be implemented to continuously improve our processes and routines to ensure safety," says Stefan Mattsson from Valmet.

Valmet has initiated an incident investigation, in co-operation with the customer and contractor. The incident is also under investigation by the police and the Swedish Work Environment Authority.

For further information, please contact:

Stefan Mattsson, Vice President, Fiber Processing Business Unit, Valmet, tel. +46 70 653 38 18

Bertel Karlstedt, President, Pulp and Energy, Valmet, tel. +358 10 676 3026

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply an extensive board machine rebuild for ITC Bhadrachalam mill in India

Valmet will supply an extensive board machine rebuild and automation solution for machine and quality control to the ITC Bhadrachalam mill in India. The rebuilt production line (PM1) is planned to produce high-quality lightweight coated board with a wide range of produced grades. The start-up of the rebuilt machine is scheduled for the fourth quarter of 2017.

The order is included in Valmet's second quarter 2016 orders received. Typically, a project of this type and scope is valued at EUR 30 - 40 million.

"ITC has been the pioneer in Indian paper industry for introducing folding box board of international quality standards. Our investment in a state of the art paperboard machine PM 4 from Valmet way back in 1997 changed the experience of Indian printing industry. Selecting Valmet as partner for the new PM1 rebuild project is in line with our focus on enhancing the customer experience while aligning with the philosophy of "triple bottom line" i.e. for improved environmental, economic and social factors. With the support from Valmet, we will be introducing globally best available technology into this machine. I am sure that our customers are going to benefit immensely out of this project," says Sanjay Singh, CEO of ITC Paperboards and Specialty Papers Division.

"Long term relationship with the customer forms a solid base for this project - another machine PM 4 at the site is Valmet-delivered and Bhadrachalam values it as their flagship board machine. Energy and raw material savings were among the most important issues that were discussed in the negotiations of this new rebuild project. High quality furnish combined with our latest technology and automation and with the competence of ITC personnel give a good base for enabling an excellent end product. The rebuild will enable ITC to be among the best folding boxboard producers globally when it comes to lightweighing or improving bulk - leading directly to raw material savings," comments Petri Paukkunen, Vice President, Sales and Marketing from Valmet.

Technical information about the delivery

Valmet's delivery for the ITC Bhadrachalam PM1 board making machine rebuild includes all the key technologies from headbox to reel and automation for machine and quality control. The machine features number of leading technologies delivered exclusively by Valmet.

OptiFlo Fourdrinierheadbox,OptiFormer MultiFourdrinier forming section andOptiPress Linearshoe press with linear web run are important in high-quality board production. They enhance e.g. the end product surface and strength properties and productivity. Compared to other coated board machines in India, the machine is not equipped with Yankee cylinder, which often limits production. In the calendering section, a new type of a calender from Valmet OptiCalender Compact delivers reliable calendering results.

Valmet DNAmachine control andValmet IQquality control systems give accurate and reliable real-time data, which enables the optimizing of the entire production process and the end product quality.

The 4250-mm-wide (wire) PM 1 will produce mainly cup board, but also solid folding box board (FBB), bleached board (SBS) and art board grades with the basis weight range of 150 - 320 g/m2. The design speed for the rebuilt machine parts is 600 m/min.

Information about the customer ITC

ITC Paperboards and Specialty Papers Division is among the leaders in the paper and paperboard business with solutions to meet a diverse cross-section of packaging and communication needs. With emphasis on harnessing state-of-the-art technology, the company has emerged as the largest manufacturer of packaging and graphic boards in South Asia. Unit Bhadrachalam has seven machines with production annual capacity of 405,000 tons (TPA) of paperboard and 140,000 TPA of specialty boards.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply upgrades for recovery boiler and evaporation line at Södra Cell Mönsterås pulp and paper mill in Sweden

Valmet will supply Södra Cell Mönsterås pulp and paper mill in Sweden a recovery boiler upgrade and an evaporation line upgrade. The delivery is scheduled for the fall 2016.

The order was included in Valmet's first quarter 2016 orders received. The value of the order is not disclosed. The value of an upgrade of this scope is usually valued below EUR 6 million.

"Recovery boilers need consistent upgrades at regular intervals. This kind of upgrade needs to be done due to the erosion and corrosion of the recovery boiler tubes based on third party inspection evaluation findings. We have been a trusted services partner for this replacement work with Södra Cell Mönsterås for several years and we are happy to continue good co-operation with them," says Marcus Grundevik, Sales and Project Manager from Valmet.

Technical information of the delivery

Valmet's delivery includes replacement of several recovery boiler and evaporation line parts and additionally a new concentrated non-condensable gases (CNCG) burner system.

As part of this upgrade the evaporation line 2 will be equipped with new Valmet TUBEL heating surface area in one of the effects. In a Valmet TUBEL Concentrator liquor is evaporated on the outside of the tubes for easy on-line washing and to avoid chemical or mechanical off-line washing.

Södra Cell Mönsterås pulp mill, Photo Södra/Ola Åkeborn

About the customer Södra Cell

Södra is Sweden's largest forest-owner association, with more than 50,000 forest owners as its members. Södra is also an international forest industry Group, with operations based on processing its members' forest products.

For further information, please contact:

Marcus Grundevik, Sales and Project Manager, Energy Sales and Services Operation, EMEA, Valmet, tel. +46 73 030 74 51

Fredrik Vedin, Product Sales Manager EVAPS, Recovery Systems, Valmet, tel. +46 706 45 23 55

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mill, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply recausticizing upgrade to Arkhangelsk Pulp and Paper mill in Russia

Valmet will deliver a recausticizing upgrade to Arkhangelsk Pulp and Paper mill in Novodvinsk, Russia. The upgrade includes both technology and automation deliveries. Arkhangelsk Pulp and Paper is rebuilding the plant to increase capacity and replace obsolete equipment. The start-up of the delivery is scheduled for the fall 2017.

The order was included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. An upgrade with this scope of supply is usually valued below EUR 10 million.

The order was included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. An upgrade with this scope of supply is usually valued below EUR 10 million.

"The project is the second stage of bleached pulp production upgrade in order to increase the capacity. The first stage included the replacement of old drum washers and installation of three Valmet TwinRoll presses was successfully completed in 2015. The goal of the rebuild is to increase white liquor production, which will be followed by installation of an oxygen delignification plant in the future. The obsolete equipment will be replaced as well during the project", says Pavel Smirnov, Deputy Chief Engineer of the Arkhangeslk Mill.

"The rebuild will make possible to increase the capacity of the plant and reduce the considerable maintenance that is required today. The delivery is especially exciting since it is the first time we deliver our new generation lime mud disc filter - OptiDisc. The design will increase work safety and ensure mill runnability", says Thomas Malmqvist, Sales Manager at Valmet.

Technical details about the delivery

The delivery includes technology for the recausticizing plant consisting of cooling, slaking, white liquor filtration and lime mud washing & drying. In addition to main machinery and auxiliary equipment, the order also includes automation instruments related to machinery motors and a DCS process control system. The new design of the lime mud disc filter gives access to bearings and seals from outside the vessel, which makes maintenance easier and improves safety. With the new design the lifetime of the main shaft is doubled.

About the customer Arkhangelsk Pulp and Paper

Arkhangelsk Pulp and Paper Mill is one of the leading wood chemical mills in Europe. Its main shareholder is Pulp Mill Holding GmbH. The company is the major container board manufacturer and one of the leaders in Russian pulp production. The company specializes on production of bleached sulfate pulp, board including uniliners, different paper grades, and copy-books.

For further information, please contact:

Thomas Malmqvist, Sales Manager, Pulp & Energy Business Line, Valmet tel. +46 54 14 23 87.

Valmet launches new sustainability action plans for 2016-2018

Valmet has defined new action plans for its sustainability agenda for 2016-2018. The action plans include detailed actions and targets for each sustainability focus area. The new action plans were defined based on an extensive agenda review conducted in early 2016.

Valmet defined the sustainability agenda initially in early 2014, and has systematically worked to implement the actions set for each of its focus areas. The agenda is called Sustainability360º and it takes a comprehensive approach to sustainability in our operations. The agenda focuses on five core areas: sustainable supply chain; health, safety and environment; people and performance; sustainable solutions, and corporate citizenship.

Valmet defined the sustainability agenda initially in early 2014, and has systematically worked to implement the actions set for each of its focus areas. The agenda is called Sustainability360º and it takes a comprehensive approach to sustainability in our operations. The agenda focuses on five core areas: sustainable supply chain; health, safety and environment; people and performance; sustainable solutions, and corporate citizenship.

"Our systematic execution of the previous action plans has led to many concrete results. We have for instance established Valmet-wide processes for managing the sustainability of our supply chain, improved occupational safety year by year and realized a significant increase in employee engagement. On top of this, Valmet has been recognized as one of the world's sustainability leaders in Dow Jones Sustainability Index. As we have now reached many of our current targets, this was a natural phase to review the agenda and define actions for the next three years," says Anu Salonsaari-Posti, SVP, Marketing, Communications and Sustainability at Valmet.

In 2016-2018, special focus continues on ensuring a globally sustainable supply chain and continuous improvement of safety culture. More information on the agenda and roadmaps is available at www.valmet.com/sustainabilityagenda

Comprehensive sustainability reporting

Valmet strives to have globally consistent and transparent management and reporting practices so that all its stakeholders can reliably assess the company's sustainability performance and development. Valmet reports annually on its sustainability performance according to the Global Reporting Initiative (GRI). The company also reports to selected third-party sustainability ratings. In 2015, Valmet was included in the Dow Jones Sustainability Index (DJSI) for the second consecutive year. Valmet also reported to CDP's Climate Change program with a score of 97/100.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

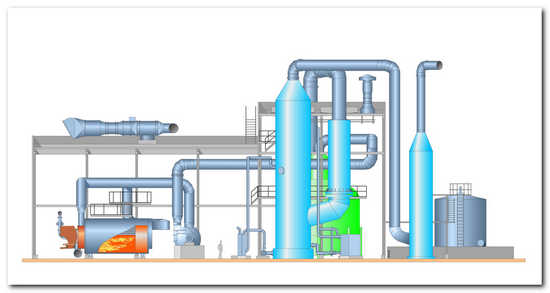

Valmet to supply a sulfuric acid plant to the Metsä Group bioproduct mill in Äänekoski, Finland

Valmet will supply a sulfuric acid plant to Metsä Group's bioproduct mill in Äänekoski for in-house sulfuric acid production. By means of the new sulfuric acid plant of its own the bioproduct mill can utilize the chemicals in the odorous gases of the pulp manufacturing process. This will help to reduce the wastewater load considerably. The start-up of the plant is scheduled for the third quarter of 2017.

Valmet's delivery is part of Metsä Group's sulfuric acid plant investment that is valued at roughly EUR 20 million. The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed.

"The sulfuric acid plant producing process chemicals from sulfur compounds from odorous gases is a remarkable step towards closed chemical circulation and further improves the environmental performance of the bioproduct mill," says Timo Merikallio, Project Director of bioproduct mill at Metsä Group.

"More efficient utilization of the raw materials and putting circular economy into practice within the industry increases the need for new innovations. The sulfuric acid plant technology that will be delivered to Äänekoski is developed by Valmet. We have developed also multiple new biotechnology processes for pulp and energy industries including lignin and bio-oil production," says Risto Hämäläinen, Director, Environmental Systems at Valmet.

Technical information about the delivery

The order includes a sulfuric acid plant developed by Valmet. The plant consists of a concentrated non-condensable gas (CNCG) incinerator and a sulfuric acid converting plant. The production capacity of the plant will be approximately 35 tons of sulfuric acid per day.This will be the world's first larger scale sulfuric acid plant that will be in operation at a pulp mill.

The new plant will enable the bioproduct mill to become nearly self-sufficient in sulfuric acid, as the odorous gases produced in the pulping process can be converted into sulfuric acid. This will bring significant environmental advantages. The amount of sulfate lead to the mill's effluent treatment plant will be reduced and the sulfate load in the nearby waterways will be smaller compared to the current mill in Äänekoski. The CNCG incineration plant can be used as a back-up boiler for producing process steam by incinerating CNCG, tall oil pitch or liquid methanol.

Information about the customer Metsä Group

Metsä Group is a responsible forest industry group whose products' main raw material is renewable wood from sustainably managed northern forests. The company focuses on tissue and cooking papers, fresh forest fibre paper-boards, pulp, wood products, and wood supply and forest services. Metsä Group's sales totalled EUR 5 billion in 2015, and the company employs approximately 9,600 people. The Group operates in some 30 countries. Metsäliitto Cooperative is the parent company of Metsä Group and is owned by approximately 116,000 Finnish forest owners.

For further information, please contact:

Risto Hämäläinen, Director, Environmental Systems, tel. +358 40 505 2001

Timo Merikallio, Project Director, Bioproduct mill, Metsä Group, tel. +358 50 598 9342

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.