Displaying items by tag: valmet

Valmet to supply an Advantage NTT tissue production line to Sofidel S.p.A in Poland

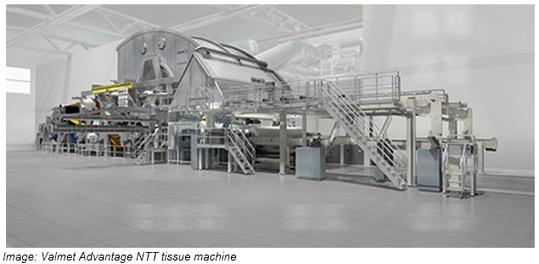

Valmet will supply a complete automated tissue production line to Sofidel's Delitissue mill in Ciechanóv, Poland. The delivery includes an Advantage NTT 200 tissue production line, stock preparation equipment and automation system.

The order was included in Valmet's 2015 orders received. The value of the order is not disclosed.

Sofidel and Valmet have a long history in working together and Valmet has previously delivered eleven tissue lines to Sofidel mills in various countries in Europe. The up-coming new line in Poland is the first Valmet Advantage NTT tissue technology based line in Sofidel's machine fleet. Start-up of this new line is scheduled for fourth quarter 2017.

"We see this as an investment of the future for several reasons. Sustainable production with low energy and fiber consumption is a success factor where the new line fits well in line with our targets to reduce environmental impact. The energy and fiber saving Valmet Advantage NTT technology will support Sofidel's environmental strategy. The Advantage NTT technology also allows us to take next step into the premium quality segment and differentiate our product offering in the tissue market," says Luigi Lazzareschi, CEO of Sofidel

"We share a long history with Sofidel, and are proud that they have selected our Advantage NTT technology for their path forward. We are facing an increasing interest in this technology from all markets, due to its flexibility to produce both conventional and premium products with low energy and fiber consumption. And we are convinced that it will be a success also for Sofidel," says Jan Erikson, Vice President, Sales, Valmet.

Technical information of the delivery

The new tissue machine will have a design speed of 1,800 m/min in textured mode and 2,000 m/min in plain mode. The production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of supply comprises a complete tissue production line including an Advantage NTT tissue machine, with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including, an AirCap hood with Air system, WetDust system and a SoftReel B reel. Valmet will also deliver detailed mill engineering, stock preparation equipment as well as an automation package including DCS (distributed control) and QCS (quality control) systems.

About the customer Sofidel S.p.A

The Sofidel Group is the second largest European manufacturer of tissue paper (paper products for sanitary and domestic use) and the sixth largest in the world. It was founded 50 years ago and today boasts 27 subsidiaries in 13 countries - Italy, Spain, Sweden, The United Kingdom, Belgium, France, Croatia, Germany, Poland, Romania, Greece, Turkey and the USA. It has about 5500 employees and a consolidated turnover of € 1,809 million (2015) and a capacity of over a million tonnes a year.

For further information, please contact:

Jan Eriksson, Vice President Sales Valmet Tissue Mills Business Unit, tel. +46 705 17 14 90

Johan Björn, Sales Manager, Valmet Tissue Mills Business Unit, tel. +46 703 17 12 16

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply paper machine wet end rebuild for Khanna Paper Mills in India

Valmet will supply a paper machine wet end rebuild to Khanna Paper Mills Private Limited located in Amritsar, India. The main targets of the rebuild are to improve end product quality, increase production and add paper grades by extending the basis weight range. The start-up of the rebuilt paper machine PM 5 is scheduled for the first quarter of 2017.

The order is included in Valmet's first quarter 2016 orders received. The value of the order is not disclosed. A project of this type and scope is typically valued at approximately EUR 5-7 million.

Signing ceremony in Finland on February 8th 2016. In front from left: Mikko Osara, Vice President, Paper Mills, Valmet and Varun Jain, CEO, Khanna Paper Mills. Behind from left: Kari Lamminmäki, Product Manager, Forming sections, Valmet, Nandkumar DM, General Manager, Sales & Technical Support, Valmet and Arun Sharma, Senior General Manager, Khanna Paper Mills.

Valmet's delivery includes rebuild of forming section into Valmet OptiFormer Hybrid as well as headbox measurement, inspection and service and press section runnability improvements.

"Khanna Paper Mills decided to invest in new, high technology regarding the upcoming rebuild of PM5. We selected Valmet as a supplier of the rebuild due to their ability to provide solutions that are flexible also for future needs. After the rebuild we will have flexibility to make also packaging grades according to future market demands," says Varun Jain, CEO of Khanna Paper.

"Valmet offers key technologies for challenging rebuilds. Forming technologies are good demonstrations of our core know-how. Modern forming technologies help our customers to achieve better formation, higher end product quality and significantly decrease energy consumption," says Petri Paukkunen, Vice President, Paper Mills Sales and Marketing, Valmet.

Technical details

Valmet OptiFormer Hybrid with shoe and blade technology uses a unique dewatering technology to boost the output quality and capacity of both new and rebuilt paper machine over a broad range of machine speeds and basis weights. It enables easy operation within a wide operating window, superior and controllable dewatering and improved paper quality, especially formation. It also delivers a potential for fiber cost savings.

The 7060-mm-wide (wire) PM 5 produces newsprint and uncoated woodfree (WFU) grades with the basis weight range of 45 - 80 g/m2. The design speed for the rebuilt machine parts is 1250 m/min.

See Varun Jain's, Khanna Paper CEO, interview about the rebuild investmant below

Information about the customer Khanna Paper Mills Private Limited

Khanna Paper Mills Private Limited (KPML) manufactures quality paper, newsprint and board for domestic consumption. It has been operating for a little over four decades. KPML produces annually around 380,000 tons of board, newsprint and writing & printing paper. KPML is among the top five paper companies in India and is also the first paper mill in India to produce high quality writing and printing paper from 100% deinked woodfree recovered paper.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply a paper machine wet end rebuild for Sappi's Kirkniemi mill in Finland

Valmet will supply a paper machine wet end rebuild for the Kirkniemi mill of Sappi Finland Operations Oy in Finland. The start-up of the rebuilt machine is scheduled for the fourth quarter of 2016.

The order is included in Valmet's first quarter 2016 orders received. The value of the order is not disclosed. A project of this type and scope is typically valued at approximately EUR 10-15 million.

"We have worked with Valmet for a long time, and the cooperation has been very good. Valmet is familiar with our paper machine and they know its potential. These are important factors when choosing a supplier. We wanted to have a reliable partner with good technical solutions," says Martti Savelainen, Mill Manager from Sappi.

"This new project is the third major rebuild for Sappi (Alfeld PM 2and Gratkorn PM 11) in just a few years. Our personnel is very familiar with the Kirkniemi machine, and our knowhow on the process and technical solutions are optimal for printing grades. By combining our experience and expertise, we were able to come up with a solution that met the customer's targets well, and we are pleased that Sappi chose Valmet for this rebuild project," says Petri Paukkunen, Vice President, Paper Mills Sales and Marketing, Valmet.

Information about the customer Sappi

Sappi is a global company focused on providing dissolving wood pulp, paper pulp and paper-based solutions to its direct and indirect customer base across more than 100 countries. Sappi produces approximately 5.7 million tons per year of paper, 2.4 million tons per year of paper pulp and 1.3 million tons per year of dissolving wood pulp.

Kirkniemi Mill has been a front runner in developing light-weight publication papers for demanding end-uses. Today, the mill's three paper machines produce coated papers for heat set web offset printing to customers around the world.

For further information, please contact:

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills, Valmet, tel. +358 40 744 8182

Pekka Turtinen, Senior Sales Manager, Sales and Marketing, Paper Mills, Valmet, +358 40 770 7649

Valmet supplied folding boxboard production line for Metsä Board Husum mill started up in Sweden

Valmet supplied coated board production line for Metsä Board, part of Metsä Group, has started up at the company's Husum mill in Sweden. The new machine produces high-quality folding boxboard with an annual capacity of 400,000 tons with a basis weight range of 185 - 350 g/m2.

"During the project Valmet has operated professionally and we are satisfied with their ability to deliver. We also trust that the new production line will come up to our expectations," says Ari Kiviranta, SVP, Production and Technology in Metsä Board.

Valmet supplied coated board production line for Metsä Board has successfully started up at the company's Husum mill in Sweden. The design of the machine is based on Valmet's modular OptiConcept M production lines.

"Metsä Board is well known for its high-quality, lightweight folding boxboards, used widely in packaging globally. Thanks to the new production line and our recent product development, we are now able to respond to demand better than ever before," comments Mika Joukio, CEO of Metsä Board.

About Valmet's delivery

This new machine with an off-coater process underlines that Valmet has vast know-how and masters the technique of coated board. Valmet's delivery included a board machine featuring the latest modular design of headboxes, forming section and press section, as well as a rebuild of the off-machine coater, winder and the roll wrapping line. The wet end area of the machine is based on innovative OptiConcept M frame construction without the need for cantilever beams for fabric changes.

"We are very happy about the start-up of this new production line and the overall fluent cooperation with Metsä Board. With this project we have expanded Valmet's OptiConcept M family to cover also coated board production. Technologies and know-how related to coated board are one of our strategic focus areas in Valmet", says Sami Anttilainen, Vice President, Technology of Paper Mills, Valmet.

Information about the customer Metsä Board

Metsä Board is a leading European producer of folding boxboards and white linerboards made from fresh forest fibres. Its lightweight paperboards are developed as the perfect fit for consumer goods, retail-ready and food service packaging. The pure fresh forest fibres Metsä Board uses are a renewable resource, traceable to origin in northern forests. The global sales network of Metsä Board supports customers worldwide, including brand owners, converters and merchants. In 2015, the company's sales totalled EUR 2.0 billion, and it has approximately 2,600 employees. Metsä Board, part of Metsä Group, is listed on the NASDAQ OMX Helsinki.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply fourth tissue production line to Fine Hygienic

Valmet has been awarded a repeat order of an Advantage DCT 200TS tissue production line to Fine Hygienic Holding (FHH), one of Nuqul Group's companies. The new line, including a complete delivery package from stock preparation equipment to rewinder, will be installed at FHH premises at Al Nakheel mill in Abu Dhabi and is planned to commence operation on the first quarter of 2017.

The order is included in Valmet's fourth quarter 2015 orders received. The value of the order is not disclosed.

The long partnership between FHH and Valmet goes back to 1988. Three Valmet tissue machines have already been installed at the FHH mills - Al Bardi Paper Mill and Al Sindian Paper Mill in Egypt and Al Snobar Paper Mill in Jordan.

"We at Fine Hygienic Holding, do not only look for technology when choosing our suppliers, but for forging strong long-term partnership that will enable us to grow together. Our long-term relationship with Valmet and their Advantage tissue technology convinced us that we will have the best conditions to meet the market's challenging requirements for high quality facial tissue produced with lowest possible energy consumption," says Hani Nuqul, the Chief Officer of Strategic Industries at FHH.

"We are proud to work in partnership with FHH and fulfill their demand of a complete package of tissue making equipment from stock preparation to rewinder. We are excited to be part of their expansion plans and together we will make this project a benchmark in the tissue market," says Jan Erikson, VP Tissue Sales at Valmet.

Technical information of the delivery

The new tissue machine will have a width of 5.6 meters and a design speed of 2,200 m/min. The new line will add 60,000 tons of high quality tissue per year to the company's current production of bath, facial, napkin and towel tissue for consumers in the Middle East.

Valmet's scope of delivery will comprise a complete tissue production line featuring stock preparation systems, an Advantage DCT 200TS tissue machine and a Focus Rewinder line. The tissue machine is equipped with an OptiFlo II TIS headbox and a cast alloy Yankee cylinder. It will also feature the well proven Advantage tissue technology including a ViscoNip press, and AirCap hood and a SoftReel reel. Services as installation advisory, training, start-up and commissioning are also included in the delivery.

Information about the customer Fine Hygienic Holding

Fine Hygienic Holding is a leading company in the hygiene industry and one of Nuqul Group's companies, founded in 1952 and has grown over the years to become a leading group embracing a number of ventures in the Middle East and North Africa. Fine Hygienic Holding is the sole company that uses SteriPro sterilizing technology, a unique sterilization process that eliminates germs. The company is keen on introducing high quality products in local and international markets.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet's new calendering technology introduced at Stora Enso's Ingerois Board Mill

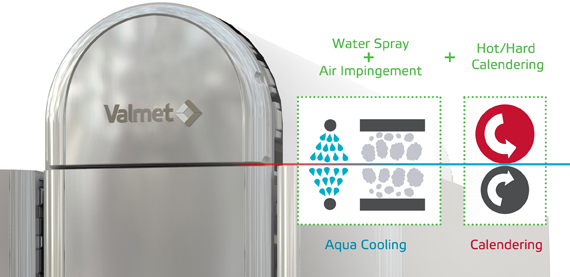

Valmet's new aqua cooling calendering technology has been taken into use first time at customer site at Stora Enso Ingerois Board Mill in Finland. Stora Enso decided to modernize the precalender of its board machine BM 4 to improve the quality of the produced board and lighten the board - i.e. increase its bulk - without compromising its properties. BM 4 produces folding boxboard for the consumer packaging industry.

The new aqua cooling technology has now been successfully used in production for a few months. The technology has made it possible to lower the basis weight of the end product at BM 4 while maintaining the functional and visual properties of the board.

"The new aqua cooling technology enables developing and optimizing the machine's operating method to achieve bulk saving potential. This brings significant energy and raw material savings throughout the value chain of the product," says Taisto Nevalainen, Mill Director of Stora Enso's Ingerois Board Mill.

"Cooperation with Stora Enso was excellent from the very first contact to the start-up and the whole process was exceptionally fast. Using the new aqua cooling equipment in practice has confirmed the earlier results from our pilot machine. Installation of the equipment itself went well, and thanks to its compact structure, the equipment fits in perfectly despite the narrow space available," says Mika Viljanmaa, development manager from Valmet's Paper Mills Business Unit.

A result of focused R&D work

Valmet focuses in its research and development work on three areas: 1) ensuring advanced and competitive technologies and services, 2) enhancing raw material, water and energy efficiency, and 3) promoting renewable materials. The now introduced aqua cooling technology focuses especially on improving the material and energy efficiency in paper and board making process.

The idea of aqua cooling is that the paper web is cooled down by evaporating moisture from the web. The effect can be enhanced by adding a small amount of water on the web surface before cooling. The cooler the web is before it reaches the calender, the more quality improvement and raw material savings can be obtained.

Aqua cooling calendering: www.valmet.com/aquacooling

Information about the customer Stora Enso

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Stora Enso's aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. Stora Enso employs some 27 000 people in more than 35 countries, and the sales in 2014 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki and Stockholm.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

For further information, please contact:

Mika Viljanmaa, Development Manager, Paper Mills Business Unit, Valmet, tel. +358 40 846 7078 / This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet to supply new high consistency bleaching system to Rottneros pulp mill in Sweden

Valmet will deliver a new high consistency bleaching system to Rottneros pulp mill in Sweden.

Valmet will deliver a new high consistency bleaching system to Rottneros pulp mill in Sweden.

This is the first step in a larger rebuild project, called Agenda 500, at the mill. The longtime goal is to increase both availability and the total production volume of Rottneros two pulp mills to reach a capacity of 500,000 ton per year.

Planned delivery time for the bleaching system is in July 2016.The order is included in Valmet's fourth quarter 2015 orders received. The value of the order will not be disclosed. Typically an order of this scale is valued at around euro 2-4 million.

"In our investment project we aim to increase capacity and lower our chemical consumption. We have had a long and good relation with Valmet over the years, which is one of the reasons for choosing them as supplier," says Nils Hauri, Production Manager at Rottneros mill.

"Valmet's bleaching system offers high availability with low operational cost, including energy and chemical consumption and maintenance costs. We are convinced that this bleaching system will live up to all expectations in this project," says Johan Eurenius, Sales Manager at Valmet.

Details about the delivery

Valmet's delivery includes machinery and erection, training, commissioning and start-up services. The new high consistency bleaching system consists of a chemical mixer and a bleaching tower, two washing stages with screw presses and mc pumps. This project aims to lower the peroxide consumption, increase capacity and keep maintenance costs to a minimum.

About the customer Rottneros

Rottneros produces market pulp and has an annual production capacity of just under 350,000 tonnes of pulp, produced at two mills in Sweden. In 2014 Rottneros employed around 250 people, the majority in Sweden and had sales amounting to approximately SEK 1.5 billion. Rottneros' shares have been listed on what is now Nasdaq Nordic, Stockholm since November 1987.

For further information, please contact:

Johan Eurenius, Sales Manager, Fiber Processing, Pulp and Energy Business Line, Valmet, tel. +46 70 592 55 29

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

The Nomination Board of Valmet's proposal for the composition and remuneration of the Board of Directors

Proposal for the composition of the Board of Directors

The Nomination Board of Valmet proposes to the next Annual General Meeting, which is planned to be held on March 22, 2016, that the number of members of the Board of Directors until closing of the Annual General Meeting 2017 will be eight and that

The Nomination Board of Valmet proposes to the next Annual General Meeting, which is planned to be held on March 22, 2016, that the number of members of the Board of Directors until closing of the Annual General Meeting 2017 will be eight and that

- Bo Risberg, Mikael von Frenckell, Lone Fønss Schrøder, Friederike Helfer and Rogerio Ziviani are re-elected as Board members,

- Aaro Cantell, Jouko Karvinen and Tarja Tyni are elected as new Board members.

The Nomination Board proposes that Bo Risberg is re-elected as the Chairman of the Board and Mikael von Frenckell is re-elected as the Vice-Chairman of the Board.

Erkki Pehu-Lehtonen, Member of the Board of Directors of Valmet, has informed Valmet's Nomination Board that he will not be available in the election of the Board of Directors in the next Annual General Meeting. Erkki Pehu-Lehtonen (born 1950) has served as a member of Metso's Board of Directors 2010-2013, and he has served as a member of Valmet's Board of Directors since the demerger (December 31, 2013).

The Nomination Board notes, that a personnel representative will participate as an invited expert in Board meetings within the limitations imposed by the Finnish law. The new Board of Directors will invite the personnel representative as its external expert in its organizing meeting after the Annual General Meeting.

"I am very pleased with the diversity of the knowhow and experience that the nominees for the Board of Directors possess. These requirements, forming part of the principles on diversity agreed for Valmet, were high on the Nomination Board's agenda in the procedure preparing the proposal for the Board composition", says Kari Järvinen, the Chairman of the Nomination Board.

Proposed new Members of the Board of Directors

Aaro Cantell is an entrepreneur and Chairman of the Board in Normet Group Oy since 2005. He has previously worked at Fenno Management Oy and Finnish Innovation Fund Sitra, among others. Aaro Cantell is currently Chairman of the Board of Normet Group Oy, VTT Technical Research Centre of Finland Ltd and Affecto Oyj, and Member of the Board of Federation of Finnish Technology Industries.

Jouko Karvinen was the CEO of Stora Enso Oyj between 2007 and 2014. From 2002 to 2006 he was the CEO of the Medical Division of Royal Philips and before that held several executive positions within ABB Asea Brown Boveri Ltd. Jouko Karvinen is currently Member of the Board of Nokia Oyj and SKF AB, Member of Foundation and Supervisory Boards of IMD business school, Lausanne, Switzerland, and Member of International Advisory Board of Komatsu Corporation of Japan.

Tarja Tyni works as Senior Vice President, Corporate Clients and Business Development in Mandatum Life Insurance Company Limited since 2008. She has previously held several positions within Investment Banking of Nordea Group and its predecessors. Tarja Tyni is also Chairman of the Board of Innova Oy and Mandatum Life Investment Services, and Member of the Board of Euroben Life & Pension Limited.

Proposal for the remuneration of the Board of Directors

The Nomination Board proposes to the Annual General Meeting that the annual remuneration payable to the members of the Board of Directors to be elected at the Annual General Meeting for the term until the close of the Annual General Meeting in 2017 be as follows:

- EUR 100,000 for the Chairman of the Board,

- EUR 60,000 for the Vice Chairman of the Board and for the Chairman of the Audit Committee,

- EUR 48,000 for each Board member.

In addition, the Nomination Board proposes that a meeting fee in the amount of EUR 700 shall be paid for those members whose place of residence is in Nordic countries, EUR 1,400 for those members whose place of residence is elsewhere in Europe and EUR 2,800 for those members whose place of residence is outside of Europe for the Board meeting attended, including the meetings of the committees of the Board of Directors.

The Nomination Board proposes to the General Meeting that as a condition for the annual remuneration the members of the Board of Directors are obliged, directly based on the Annual General Meeting's decision, to use 40 percent of the fixed annual remuneration for purchasing Valmet shares from the market at a price formed in trading at Nasdaq Helsinki's stock exchange list and that the purchase will be carried out within two weeks from the publication of the Interim Review for the period January 1, 2016 to March 31, 2016.

The Nomination Board

Kari Järvinen (Managing Director, Solidium Oy)acted as the Chairman of the Nomination Board. The members the Nomination Board were Martin Oliw (Partner, Cevian Capital AB), Roger Hagborg (Investment Advisory Professional, Triton), Risto Murto (CEO, Varma Mutual Pension Insurance Company) and Bo Risberg as an expert member in his capacity as the Chairman of the Board of Directors of Valmet.

Valmet's Board of Directors will include these proposals into the notice of the Annual General Meeting of 2016, which is estimated to be published on February 9, 2016.

Further information, please contact:

Kari Järvinen, Chairman of Valmet's Nomination Board, tel. +358 40 548 3995

Rasmus Oksala, General Counsel, Valmet, tel. +358 10 672 0026

Publishing of Valmet's Financial Statements Review 2015 on February 9, 2016

Valmet's Financial Statements Review 2015 will be published on Tuesday, February 9, 2016 at approximately 12:00 noon Finnish time (EET). The stock exchange release and presentation material in Finnish and in English will be available at that time on Valmet's website at www.valmet.com/investors.

Valmet's Financial Statements Review 2015 will be published on Tuesday, February 9, 2016 at approximately 12:00 noon Finnish time (EET). The stock exchange release and presentation material in Finnish and in English will be available at that time on Valmet's website at www.valmet.com/investors.

News conference for analysts, investors and media

Valmet will arrange a news conference in English for investment analysts, investors, and media on Tuesday, February 9, 2016 at 2:00 p.m. Finnish time (EET). The news conference will be held at Valmet Head Office in Keilaniemi, Keilasatama 5, 02150 Espoo, Finland. President and CEO Pasi Laine and CFO Kari Saarinen will be presenting at the news conference.

Webcast

The news conference can also be followed through a live webcast at www.valmet.com/webcasts. The live webcast starts at 2:00 p.m. (EET) and a recording of the webcast will be available shortly after the event at the same address.

Conference call

It is also possible to take part in the news conference through a conference call. Conference call participants are requested to dial in at least five minutes prior to the start of the conference, at 1:55 p.m. (EET), at +44 1452 560304. The participants will be asked to provide the following conference ID: 25632403.

During the webcast and the conference call, all questions should be presented in English. After the webcast and the conference call, media has a possibility to interview the management in Finnish.

The event can also be followed in Twitter at www.twitter.com/valmetir.

Further information, please contact:

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +359 10 672 0007

For media: Anu Salonsaari-Posti, Senior Vice President, Marketing & Communications, Valmet, tel. +358 10 672 0033

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply grade conversion rebuild for Kruger Packaging in Trois-Rivières, Québec, Canada

Valmet will modernize a paper machine (PM10) at the Kruger paper mill in Trois-Rivières (Québec), Canada. Currently producing newsprint, PM10 will be rebuilt using some of the most advanced containerboard manufacturing and automation technology to produce 360,000 metric tonnes (MT) per year of 100% recycled lightweight and high strength linerboard. The rebuilt production line will start up in 2017.

Valmet will modernize a paper machine (PM10) at the Kruger paper mill in Trois-Rivières (Québec), Canada. Currently producing newsprint, PM10 will be rebuilt using some of the most advanced containerboard manufacturing and automation technology to produce 360,000 metric tonnes (MT) per year of 100% recycled lightweight and high strength linerboard. The rebuilt production line will start up in 2017.

The order is included in Valmet's fourth quarter 2015 orders received. The value of the order is not disclosed. The value of paper machine rebuilds depends on the scope of the delivery. This kind of rebuild is typically valued around EUR 30 million.

"Kruger selected Valmet based on its innovative technology and track record of successful rebuilds, as well as their knowledge of North American recycled linerboard requirements," declared Project Manager, Christian Lemay of Kruger Packaging L.P.

Modernization project will generate significant growth opportunities

The solution for this ~8.4-meter-wide (wire) machine will be fully modernized from headbox to winder to produce linerboard with industry-leading high strength to basis weight properties, and with sheet formation and surface characteristics suitable for high-quality graphic printing for corrugated box plants.

In addition to the machinery improvements, the delivery will includeValmet DNA automation system with remote servicing capabilities for machine and process control as well as MD/CD controls. Valmet will deliver also Valmet IQ Dilution Profiler that contributes to improved sheet quality and minimized variability. To be delivered Valmet Pulp Analyzer will provide fast and precise online updates of key fiber and papermaking furnish properties.

"To be able to reach the targets, grade conversion modernizations require thorough expertise. Valmet is one of the few suppliers who can design, manage and deliver this kind of vast grade conversion projects. Additionally, Valmet's pilot plant played a substantial role since we could demonstrate the technologies to the customer in real life conditions," says Mike Gray, Valmet's Area Vice President in North America.

Information about the customer Kruger Packaging L.P.

Kruger Packaging L.P. is a Canadian manufacturer of containerboard and packaging products made from recycled fibers. The company currently operates one containerboard mill in Montreal (Québec), as well as two packaging plants in LaSalle (Québec) and Brampton (Ontario). Founded in 1904, its parent company, family-owned Kruger Inc., is also a major producer of publication papers, tissue products, renewable energy, cellulosic biomaterials, and wines and spirits. In addition, Kruger Inc. is a leading paper and paperboard recycler in North America.

Further information, please contact:

Mike Gray, Area Vice President, North America, Valmet, tel. +1 920 738 8542

Jari Siitonen, Sales Director, Paper mills, Valmet tel. +358 40 765 7406

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki