Ianadmin

Mapal appoints Strand Hanson, prepares for AIM float

![]() Mapal Green Energy, developers of the innovative floating fine bubble aeration system (FFBA) for wastewater treatment, has appointed Strand Hanson in preparation for an AIM float in early summer this year. The brokers are Beaufort Securities.

Mapal Green Energy, developers of the innovative floating fine bubble aeration system (FFBA) for wastewater treatment, has appointed Strand Hanson in preparation for an AIM float in early summer this year. The brokers are Beaufort Securities.

Mapal Group, as the post float company will be known, has a rapidly developing reputation across a number of industry sectors, with over 40 sites live worldwide. In the UK, interest to date has been centered around the water utilities, where the company has successfully sold in projects to Thames Water, United Utilities and Anglian Water. The company has also reported interest from the pulp and paper, agriculture, food and beverages and petro chemicals sectors, all of which generate wastewater requiring a biological aeration treatment process.

In its regulation of the UK water industry, the implementation of the latest Ofwat Asset Management Plan (AMP6) in April of this year has perhaps presented the company with it biggest opportunity to date. Ofwat now requires water utilities to focus on the total operating cost of plant, which now includes maintenance and energy usage, not just the initial capital cost, as was previously the case.

The Mapal technology is well placed to address this new regulatory hurdle. Floating fine bubble aeration approaches the challenge of waste water biological aeration by marrying the strengths of surface aeration technology – easy to install and accessible for maintenance - with the efficiency which is derived from sub surface fine bubble aeration systems. With no moving parts generating friction and driving high energy consumption, a key benefit for users of Mapal’s system is its dramatically reduced energy and maintenance bills.

Earlier this year, the company was shortlisted for the 2015 Environment and Energy Awards.

For details of Mapal Green Energy’s floating fine bubble aeration technology, please visit http://www.mapal-ge.com

Mapal Green Energy pioneered the concept of floating fine bubble aeration (FFBA)as a more efficient means of treating waste water for both utility companies and industry applications.

Tests around the world have shown that in some cases, compared to surface aeration, a plant’s energy consumption can be reduced by up to 70% using the Mapal system,.

With over 40 installations worldwide, Mapal's floating fine bubble aeration technology has been proved to meet and exceed stringent effluent quality parameters including the reduction of : BOD5, TSS, COD, Tkn and Ammonia.

In the UK, the system is being used by Anglian Water, Thames Water and United Utilities.

Mapal’s innovative equipment floats on the surface, so wet and live installation is the norm, which makes for a very fast changeover of plant and a minimal downtime. The units are made from robust stainless steel, so have a long life and as a modular system, the installation can be added to or reduced quickly and easily. Thus far, their largest UK installation is designed to handle a flow rate of up to 10,450m3/day in wet weather.

The Mapal technology can be adapted for aggressive and hazardous liquids and is therefore suitable for application across a wide range of industry sectors where a solution based on aeration is required. Liquid waste from the paper, food and beverages, petro chemicals, agriculture and other industries can all be treated.

Södra increases price for softwood pulp in Europe to USD 870 per tonne

Due to low global softwood pulp stocks and solid demand, Södra will increase its market price for NBSK in Europe to USD 870, effective from June 1st 2015.

Due to low global softwood pulp stocks and solid demand, Södra will increase its market price for NBSK in Europe to USD 870, effective from June 1st 2015.

For further information, please contact:

Magnus Björkman, President of Södra Cell International, +46 70 265 75 22

Henrik Wettergren, Sales Director Europe, +46 73 069 70 12

Resolute Enters Into New ABL Credit Facility

Resolute Forest Products Inc. has announced that it has entered into a new five-year credit agreement for a senior secured asset-based revolving credit facility with an aggregate lender commitment of up to $600 million at any time outstanding, subject to borrowing base availability based on specified advance rates, eligibility criteria and customary reserves. This facility replaces the company's previous $665 million senior secured asset-based revolving credit facility, originally dated as of December 9, 2010, which was simultaneously terminated.

Resolute Forest Products Inc. has announced that it has entered into a new five-year credit agreement for a senior secured asset-based revolving credit facility with an aggregate lender commitment of up to $600 million at any time outstanding, subject to borrowing base availability based on specified advance rates, eligibility criteria and customary reserves. This facility replaces the company's previous $665 million senior secured asset-based revolving credit facility, originally dated as of December 9, 2010, which was simultaneously terminated.

"We took advantage of our strong financial position and attractive market conditions to replace the ABL with a facility that gives us more flexible terms and conditions, improves pricing, extends maturity and immediately lowers our cost of capital," said Jo-Ann Longworth, senior vice president and chief financial officer. "This facility will support Resolute as we continue to execute on our growth and diversification initiatives for the future."

The $600 million facility includes a $450 million tranche available to Resolute's U.S. borrowers and its Canadian borrowers, as well as a $150 million tranche available only to its U.S. borrowers, in each case subject to the borrowing base availability of those borrowers. The facility includes a $60 million swingline sub-facility and a $200 million letter of credit sub-facility. The credit agreement also provides for an uncommitted ability to increase the revolving credit facility by up to $500 million, subject to certain terms and conditions.

As of today, the facility is completely undrawn, with the exception of approximately $37 million of undrawn ordinary course letters of credit. The new credit agreement contains customary covenants, representations and warranties and events of default for asset-based credit agreements of this type. As with the facility that it replaces, the company's obligations under the facility are guaranteed by certain material subsidiaries and they are secured by first priority liens on accounts receivable, inventory and related assets.

The facility is provided by a syndicate of nine banks, with Bank of America, N.A., as U.S. administrative agent and collateral agent, and Bank of America, N.A. (through its Canada branch), as Canadian administrative agent. Bank of America Merrill Lynch and Bank of Montreal arranged the facility as joint lead arrangers and joint bookrunners; Barclays Bank and Wells Fargo also acted as joint lead arrangers and joint bookrunners.

Troutman Sanders LLP and McCarthy Tétrault LLP represented Resolute.

About Resolute Forest Products

Resolute Forest Products is a global leader in the forest products industry with a diverse range of products, including newsprint, specialty papers, market pulp and wood products. The company owns or operates some 40 pulp and paper mills and wood products facilities in the United States, Canada and South Korea, and power generation assets in Canada. Marketing its products in close to 80 countries, Resolute has third-party certified 100% of its managed woodlands to at least one of three internationally recognized sustainable forest management standards. The shares of Resolute Forest Products trade under the stock symbol RFP on both the New York Stock Exchange and the Toronto Stock Exchange.

Resolute and other member companies of the Forest Products Association of Canada, as well as a number of environmental organizations, are partners in the Canadian Boreal Forest Agreement. The group works to identify solutions to conservation issues that meet the goal of balancing equally the three pillars of sustainability linked to human activities: environmental, social and economic.

Resolute is proud to be ranked by Corporate Knights as one of Canada's Best 50 Corporate Citizens for 2014. In addition, the company and Richard Garneau, president and chief executive officer, have been named to Canada's Clean50. And in January 2015, Resolute was awarded The New Economy magazine's global Clean Tech Award for best forestry and paper solutions.

SOURCE Resolute Forest Products Inc.

For further information: Investors: Rémi G. Lalonde, Vice President & Treasurer, 514 394-2345, This email address is being protected from spambots. You need JavaScript enabled to view it.; Media and Others: Seth Kursman, Vice President, Corporate Communications, Sustainability and Government Affairs, 514 394-2398, This email address is being protected from spambots. You need JavaScript enabled to view it.

ANDRITZ successfully starts up tissue machine with steel Yankee for Doubletree Paper Mills, USA

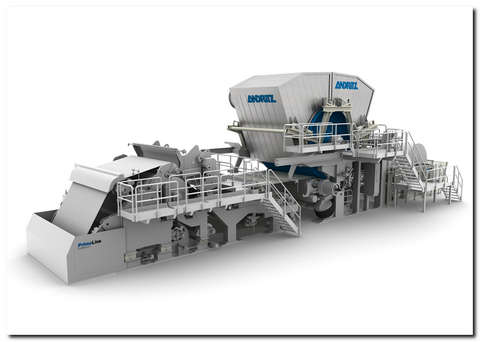

International technology Group ANDRITZ has successfully completed start-up of the PrimeLineCOMPACT tissue machine with steel Yankee supplied to Doubletree Paper Millsʼ Gila Bend mill in Arizona, USA. The machine has a design speed of 2,100 m/min and a width of 2.6 m. The Yankee is manufactured entirely of steel and has a diameter of 4.8 m.

The ANDRITZ PrimeLineCOMPACT tissue machine PHOTO: Andritz

ANDRITZ supplied the tissue machine on an EPC basis, including the crescent former, the complete stock preparation plant, and automation systems.

For further information, please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of almost 25,000 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, production equipment for biofuel (second generation), biomass torrefaction equipment, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

MM Packaging Austria concentrates folding carton production on Vienna site

MM Packaging Austria with two sites, Vienna and Gunskirchen, Upper Austria, will concentrate its production on the larger facility in Vienna until year-end, securing its future as a high-performance site.

MM Packaging Austria with two sites, Vienna and Gunskirchen, Upper Austria, will concentrate its production on the larger facility in Vienna until year-end, securing its future as a high-performance site.

The Gunskirchen plant currently employs 135 employees. Approximately one quarter of the workforce will be offered continued employment in Vienna. Talks with the Works Council are already in progress. A social plan will be elaborated.

For further information, please contact:

Stephan Sweerts-Sporck, Investor Relations, Mayr-Melnhof Karton AG, Brahmsplatz 6, A-1040 Vienna

Tel.: +43 1 501 36-91180, Fax: +43 1 501 36-191195

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it., Website: http://www.mayr-melnhof.com

Stora Enso utilizes Metso's valve know-how in its Varkaus Mill rebuild in Finland

Metso will supply altogether hundreds of valves for Stora Enso's conversion of the Varkaus Mill fine paper machine in Finland to light-weight containerboard. In addition, Metso has carried out an installed base audit of its valves in the recycled fiber plant. The analysis ensures applicability and future performance of the valves in the rebuild. Metso also takes care of the spare part inventory services to the mill.

The valve delivery contains Metso's Neles® ball valves, V-port segment valves and triple eccentric Neldisc® butterfly valves for on-off and control applications. The control valves are equipped with Metso's ND9000 series intelligent valve controllers, which have capability for advanced performance follow-up. They also allow predictive maintenance planning activities.

In the installed base audit of its valves conducted in the recycled fiber plant in Varkaus, Metso analyzed the applicability of the valves for the plant's process and made recommendations for future maintenance needs. Properly scheduled maintenance activities with the spare part inventory services support mill availability, process performance and enhance risk control.

"Stora Enso and Metso have a long-term relationship in the Varkaus Mill. We are pleased that Stora Enso counts on our expertise to meet their valve solutions needs. In addition to the valve supply contract, the results of Metso's audit ensure that they can utilize the existing valve equipment in the containerboard machine, and the necessary maintenance measures can be foreseen and scheduled. Our spare part inventory services ensure that critical parts are available for them. This will bring cost savings and will ensure optimum process efficiency," emphasizes Marko Lindeman, Sales Director, Pulp and Paper industry in Finland, Metso.

Metso and Stora Enso have a long-term relationship. Metso's flow control solutions are contributing to Stora Enso's process efficiency at several plants globally.

The order was included in Metso's first-quarter 2015 and 2014 fourth-quarter orders received. The values of the orders are not disclosed. The rebuilt containerboard machine is scheduled to start up during the fourth quarter of 2015.

Leading flow control offering and service solutions to pulp and paper customers

Metso has a long track record of delivering engineered performance and reliability to the pulp and paper industry. Metso is the market leader in control and on-off valves for pulp and paper customers globally - about 75% of the world's pulp flows through Metso's valves. Additionally, Metso is one of the leading suppliers of intelligent valve controllers.

Metso has strong pulp and paper industry expertise in valve solutions, and its comprehensive value-added services improve customers' process efficiency. Metso's flow control offering and services for the pulp and paper industry focus on three main areas: solving technical and process issues, improving business performance, and managing a business area. Today Metso has more than 40 valve and field device service centers worldwide.

Metso's valve technology centers and valve production facilities are located in Finland, the United States, Germany, China, South Korea, India and Brazil.

Stora Enso in brief

Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wood and paper. Our aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 27 000 people in more than 35 countries, and our sales in 2014 were EUR 10.2 billion. Stora Enso shares are listed on NASDAQ OMX Helsinki (STEAV, STERV) and Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market.

Metso is the world's leading industrial company in the mining and aggregates industries and in the flow control business. Our knowledge, people and solutions help drive sustainable improvements in performance and profitability in our customers' businesses.

Metso has an uncompromising attitude towards safety. Our products range from mining and construction equipment and systems to industrial valves and controls. Our solutions are delivered and supported by decades of process knowledge and a broad scope of services backed by a global footprint of over 90 service centers, thousands of service employees, and an extensive logistics network.

Metso is listed on the NASDAQ OMX Helsinki, Finland. In 2014, Metso's net sales totaled EUR 3.7 billion. Metso employs approximately 14,000 industry experts in more than 50 countries. Expect results.

www.metso.com, www.twitter.com/metsogroup

For further information, please contact:

Marko Lindeman, Sales Director, Pulp and Paper industry in Finland, Flow Control, Metso, Tel. + 358 20 483 6008, Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Jussi Ollila, Vice President, Global Marketing and Communications, Metso Corporation, Tel. +358 20 484 3212, Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Welcome to the May-June issue of Pulp Paper & Logistics.

Welcome to the May-June issue of Pulp Paper & Logistics. Over the past few weeks we heard the news of mill closures here in the UK. First was the announcement from Aylesford Newsprint that it had applied to go into administration with the loss of nearly 300 jobs and more recently we also had news from Tullis Russell Group that its papermaking subsidiary Tullis Russell Papermakers Limited had also been placed into administration by its directors.

Welcome to the May-June issue of Pulp Paper & Logistics. Over the past few weeks we heard the news of mill closures here in the UK. First was the announcement from Aylesford Newsprint that it had applied to go into administration with the loss of nearly 300 jobs and more recently we also had news from Tullis Russell Group that its papermaking subsidiary Tullis Russell Papermakers Limited had also been placed into administration by its directors.

This only highlights that papermakers in Europe continue to feel the pressure of declining demand and increasing energy costs coupled with raw materials trading at higher prices, all of which continue to drive mill owners to achieve the best productivity from machinery and equipment already in place, rather than upgrade.

In contrast, the tissue and packaging sector is on the up, with news of some significant orders for new machinery in recent months that highlight this growth area. There is also growing pressure on wood as a sustainable raw material and with authorities increasingly using wood as a source of energy the pressure on paper makers will continue. Read more about this in our sister publication Forest & Bioenergy Review ( www.forestbioenergyreview.com ).

For those of you who are going to the Zellcheming show in Frankfurt, Germany (30 June – 2 July) do not forget that you can register prior to the show at www.mesago.de/en/ZEX/For_visitors/Welcome/index.htm. If you want to arrange a meeting with Vince Maynard of Pulp Paper & Logistics magazine (email: This email address is being protected from spambots. You need JavaScript enabled to view it. ) or Ian-Melin Jones of Pulp-Paperworld.com (email: This email address is being protected from spambots. You need JavaScript enabled to view it. ) get in touch as soon as possible. Don’t forget your after-show activities so if you need to just chill out you can always visit O’Reilly’s Frankfurt, which offers both great beer and food (oreillys.com/frankfurt.html). See you there.

In the next issue for July-August 2015 we will be covering paper recycling/deinking and associated technologies, water management and treatment, and drying technology. Submissions should be with us by the end of June.

Vince Maynard

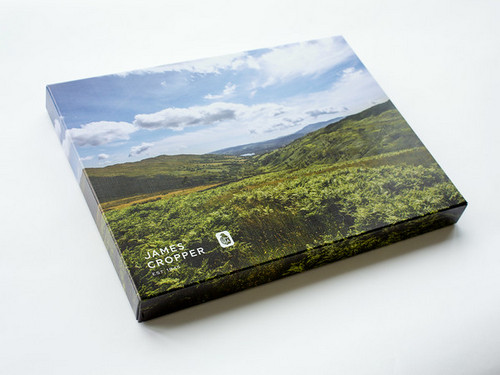

James Cropper - Quick win for wall art

James Cropper Paper’s innovative direct print, no-adhesive, instant wall art product, Khora is awarded Best Special Application Substrate at the European Digital Press Association Awards in Cologne.

Turning a photograph into instant wall art was made effortless with the launch of Khora by James Cropper Paper in September 2014, allowing image makers of all backgrounds to put print-ready art directly onto a no-adhesive, no-fixings, no-fuss display box. The innovation has taken less than a year to receive its first industry plaudits, with an award from the European Digital Press Association (EPA).

Presented in front of an international audience of paper and printing specialists on Wednesday 20 May at the FESPA 2015 print technology exhibition in Cologne, Germany, Khora was named as the year’s Best Special Application Substrate. Opening up the possibility for an image to be taken from a camera to a professional box presentation in five minutes, the product was recognised by judges for its versatility, convenience and permanence. The EDP jury commented “Developed by British boutique paper mill James Cropper. It uses the firm’s high-quality archival paper to ensure long-lasting high quality results that meet the most demanding artist and gallery requirements, while being simple to assemble needing no glue, tape or staples”.

Supplied flat for digital inkjet printing, the pre-scored product offers immaculate reproduction from high-resolution image files. The quick and easy ‘lock-in’ construction, completed by one person, uses fold-in tabs to create a canvas-like box structure ready for hanging direct from the printer, without the need for further processing. The high-definition, conservation-standard board offers sharp and long-lasting print results on both water-based dye and pigment inkjet systems.

Watch the high speed construction of Khora here: https://vimeo.com/104613857

Geoff Leech, Art and Digital Director for James Cropper Paper, said on receiving the award: “Khora is a new and exciting product and for it to be recognised as such by the printing industry so soon after its launch is testament to its great potential. Convenience and exceptional quality are two things that image makers – whether private photographers or commercial designers – are calling on us to provide, and with Khora we believe we have delivered exactly that. Product development is a day-in day-out activity at James Cropper Paper and we’re grateful that the hard work that has gone into making Khora so special has been acknowledged.”

The EPA Awards are presented by the industry body in association with a number of global media outlets. The Federation of Global Screen and Digital Printing Trade Associations holds the FESPA trade exhibition every year to showcase the work of the biggest names in printing innovation, from textile printing to automotive body wraps.

To find out more about James Cropper Paper and the art and design projects they support, please visit: www.jamescropper.com

Tullis Russell Papermakers Limited (in administration) - Update

Blair Nimmo and Tony Friar were appointed as Joint Administrators of Tullis Russell Papermakers Limited on 27th April 2015.

Blair Nimmo and Tony Friar were appointed as Joint Administrators of Tullis Russell Papermakers Limited on 27th April 2015.

The Joint Administrators had set a closing date for indicative offers for the business and assets of 12pm on 18th May 2015, but unfortunately no offers were received.

Prior to entering administration, Tullis Russell Papermakers had been widely marketed for sale by its parent company, Tullis Russell Group Limited. The Group had approached 64 parties worldwide, but unfortunately this process proved to be unsuccessful.

Following their appointment, the Joint Administrators contacted these parties to establish whether they wished to acquire the business and assets, but the parties reconfirmed their position and did not pursue any interest.

A wider sales process was initiated with the Joint Administrators contacting approximately 200 parties.

Blair Nimmo, Joint Administrator and Head of Restructuring at KPMG in Scotland, said:

“The level of interest shown in the business and the outcome from Monday’s closing date is disappointing. The business continues to face considerable economic challenges as a result of weakening global demand for printed materials, rising raw material costs and the strengthening of Sterling against the Euro.

“We will now be working with the company’s remaining employees to continue to wind down operations and focus on realising the company’s assets.

“Unfortunately that will mean further redundancies but we will continue to work with government agencies to offer support to those affected.”

On appointment of the Joint Administrators’, 325 of Tullis Russell’s 474 staff were made redundant. While some work has been ongoing to meet existing customer orders, a further 21 employees have been made redundant while operations are being wound down.

About KPMG:

KPMG LLP, a UK limited liability partnership, operates from 22 offices across the UK with approximately 12,000 partners and staff. The UK firm recorded a turnover of £1.9 billion in the year ended September 2014. KPMG is a global network of professional firms providing Audit, Tax, and Advisory services. It operates in 155 countries and has 162,000 professionals working in member firms around the world. The independent member firms of the KPMG network are affiliated with KPMG International Cooperative ("KPMG International"), a Swiss entity. Each KPMG firm is a legally distinct and separate entity and describes itself as such.

Nalco Launches Next Generation of 3D TRASAR Technology for Cooling Water

Industry’s leading water management solution enhanced with more advanced interface and processing capabilities

Nalco, an Ecolab company, introduces the next generation of its industry-leading 3D TRASAR™ Technology for Cooling Water, featuring an upgraded interface and more advanced processing capabilities to efficiently manage more complex cooling water systems.

Nalco, an Ecolab company, introduces the next generation of its industry-leading 3D TRASAR™ Technology for Cooling Water, featuring an upgraded interface and more advanced processing capabilities to efficiently manage more complex cooling water systems.

“With increased demands on the world’s limited fresh water resources, today’s businesses are continually challenged to achieve greater productivity by using less water and energy, and extending the life of production assets”

“With increased demands on the world’s limited fresh water resources, today’s businesses are continually challenged to achieve greater productivity by using less water and energy, and extending the life of production assets,” said Pete Nassos, vice president of Marketing, Nalco. “The new 3D TRASAR Technology for Cooling Water platform meets the more complex water management needs of our customers.”

The 3D TRASAR system delivers the appropriate chemistry response to ensure a balanced, efficient and safe cooling system. Unique real-time monitoring, patented actives-based control technology, proprietary stress resistant chemistry and 24/7 information management capabilities detect, determine and deliver improved scale, corrosion and microbiological performance.

The enhanced 3D TRASAR platform provides the web-based performance metrics and operational assistance necessary for greater control of cooling water systems and the processes they impact. Featuring a more advanced controller with higher processing capabilities and improved diagnostics, the solution can monitor more dynamic processes and key performance indicators (KPIs) to improve production reliability, reduce downtime, increase water and energy savings, and enhance asset protection.

The new platform also is easier to use, with an improved user interface and navigation, seamless two-way communication and web-based monitoring and reporting. The System Assurance Center also has been expanded to effectively accommodate the more advanced monitoring capabilities of the new platform.

First introduced in 2004, 3D TRASAR technology is now in use at more than 28,000 locations throughout the world, helping a range of businesses conserve more than 400 billion gallons of water annually.

About Ecolab

Nalco is an Ecolab company. A trusted partner at more than one million customer locations, Ecolab (ECL) is the global leader in water, hygiene and energy technologies and services that protect people and vital resources. With 2014 sales of $14 billion and 47,000 associates, Ecolab delivers comprehensive solutions and on-site service to promote safe food, maintain clean environments, optimize water and energy use, and improve operational efficiencies for customers in the food, healthcare, energy, hospitality and industrial markets in more than 170 countries around the world. For more Ecolab news and information, visit www.ecolab.com.