Ianadmin

A.Celli Paper_Ecosystem Tour

Come see our perfect Ecosystem at ’iT’s Tissue’ 2015!

A.Celli Paper has concentrated its most recent R&D activity on the reduction of energy consumption, an important aspect of the paper industry whose ultimate goal is safeguarding the environment. This reduced environmental impact is foundational to be able to answer increasingly stringent norms on emissions, and it is reflected also on direct and tangible economic benefits, certainly an important market aspect and a major sales tool. And how is the company doing this? First of all by guiding customers in the choice of new equipment, avoiding over-dimensioned machines to deal with extreme and rather improbable market situations. Additionally, a series of machinery specific for the entire process line – from stock preparation to the tissue machine – applicable both on new systems and on existing plants, in the latter case with very interesting ROI.

The ability of A.Celli Paper to offer complete turn-key plants, taking charge of every aspect for their setting-up, represents for customers a guarantee of the quality of the project and of the respect for schedules. An ability matured in the course of the company’s 70 years of experience in serving the paper industry and assured by the expertise of its qualified technicians.

Particular attention is reserved to consolidating our acknowledged leadership in the field of winders through continuous technical evolution of the product, integrated with roll handling equipment. The 700 winders sold are the result of A.Celli’s acknowledged and consolidated position founded on building reliable, high-performance machines focusing on safety, energy savings, safeguarding the environment and on supplying a complete service that goes beyond winding to encompass also handling. A firmly rooted legacy that has given rise to a new generation of winders that we invite you to see first-hand, together with the new Iridium® printing technology, at the forthcoming iT’s Tissue 2015 event.

Ence-Navia selects GL&V for Pulp Mill Rebuild

![]() Ence-Navia is a leading producer of eucalyptus pulp in Europe. The pulp mill, located in Spain is part of the Ence Group and produce up to 500,000 tonnes of high-quality ECF pulp.

Ence-Navia is a leading producer of eucalyptus pulp in Europe. The pulp mill, located in Spain is part of the Ence Group and produce up to 500,000 tonnes of high-quality ECF pulp.

The pulp made at Ence-Navia is highly sought after by the specialty paper industry due to the good quality wood and high quality processes used to obtain excellent quality used for decorative paper, multilayer paper and other special papers.

GL&V was chosen to be the supplier of all technologies used for this rebuild. The collaboration between GL&V and Ence-Navia will boost the mill production and reduce the usage of chemicals used for bleaching. GL&V will supply a new hot chlorine dioxide stage (DualD) and rebuild the Screen room. Fredrik Björck at GL&V explains “These improvements will enable the mill to run higher quality pulp at reduced operating cost and lower environmental impact.”

As GL&V are focusing on innovation and provide technologies that generate energy and cost saving opportunities this upgrade is in perfect alignment with our strategies.

The rebuild will be done in several stages, commencing in June 2015. The project is set to be completed during spring 2016.

Contact GL&V for further information:

Fredrik Björck, Manager Chemical Pulping Sales, Sweden

Tel: +46 (0)54 770 5708

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Futura redraws the boundaries with Andromeda

Andromeda is a complete new converting solution, two years in development at FuturaLab, which redraws the boundaries for tissue roll products converting for the benefit of customers.

Andromeda is a complete new converting solution, two years in development at FuturaLab, which redraws the boundaries for tissue roll products converting for the benefit of customers.

The Andromeda Showcase at Futura during It’s Tissue, June 22-26, will represent an opportunity for the industry to understand why Andromeda is such a radical step changer, and to become closely acquainted with its details.

In all the key areas of process continuity, overall equipment effectiveness, safety, productivity, layout, manpower reduction and finished product quality, Andromeda sets a new benchmark.

VP of International Operations Piero Ceccon said: “Andromeda is clearly a better way to make roll products. Its innovations draw on the experiences and lessons of the past 13 years since Futura was born, and of the multi-disciplinary team at Futura whose knowledge and wisdom goes far further back than that.”

CEO Fabio Boschi added: “Andromeda represents the strong belief we have in the ability of technology to benefit our customers. It is about refusing to accept the status quo and having faith in the vision of dedicated engineers and designers.”

BASF to sell its global paper hydrous kaolin business to Imerys

BASF has signed a contract to sell its global paper hydrous kaolin (PHK) business to Imerys, a leader in mineral-based specialty solutions for industry, based in Paris, France. In September 2014, BASF announced its plan to evaluate strategic options for its PHK business.

BASF has signed a contract to sell its global paper hydrous kaolin (PHK) business to Imerys, a leader in mineral-based specialty solutions for industry, based in Paris, France. In September 2014, BASF announced its plan to evaluate strategic options for its PHK business.

- BASF to focus on kaolin for industrial applications

- Transaction includes a production site in Wilkinson County, Georgia, United States

- BASF will toll for Imerys during a short transition period post-closing to ensure continued supply for customers

The divestiture is subject to approval by the relevant merger control authorities. Closing of the transaction is expected to take place during the third quarter of 2015. The parties have agreed not to disclose the financial details of the transaction.

Imerys will purchase the global PHK business including a production site for milling in Wilkinson County, Georgia. Overall, 190 positions will be affected globally. BASF will work with affected employees to help locate other employment opportunities within the company or to provide the appropriate transition support.

In step with BASF’s strategy to actively manage its portfolio, this divestiture allows the kaolin business to focus on its leading position in the industrial segments. In addition, BASF will continue producing kaolin for process catalysts.

“We are taking an important step to improve the competitiveness of our kaolin business and further sharpen our focus on growth and core businesses,” said Dr. Shane Porzio, Vice President, Global Business Management of Kaolin for BASF. “We will work closely with Imerys to ensure a smooth transition for customers.”

BASF will toll for Imerys and provide other services during a short transition period to ensure continuity of supply for customers.

About BASF

At BASF, we create chemistry – and have been doing so for 150 years. Our portfolio ranges from chemicals, plastics, performance products and crop protection products to oil and gas. As the world’s leading chemical company, we combine economic success with environmental protection and social responsibility. Through science and innovation, we enable our customers in nearly every industry to meet the current and future needs of society. Our products and solutions contribute to conserving resources, ensuring nutrition and improving quality of life. We have summed up this contribution in our corporate purpose: We create chemistry for a sustainable future. BASF had sales of about €74 billion in 2014 and over 113,000 employees as of the end of the year. BASF shares are traded on the stock exchanges in Frankfurt (BAS), London (BFA) and Zurich (AN). Further information on BASF is available on the Internet at www.basf.com.

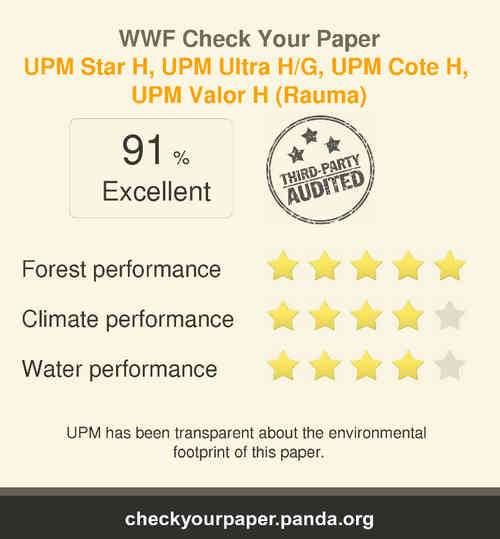

UPM papers meet the highest environmental standards in WWF’s Check-your-paper tool

WWF’s Check-your-paper (CYP) tool is a public database for pulp and paper products with high environmental standards. The CYP method focuses on a limited number of environmental parameters including how well forests supplying fibre are managed, use of recycled fibre, fossil CO2 emissions, waste going to landfills and water pollution from mills.

UPM has been part of CYP since the very beginning and one of the first companies to rate papers in the tool. The used method is simple but not simplistic and has been developed and fine-tuned by WWF since 2007, in cooperation with scientists, paper buyers, producers and non-governmental organisations (NGOs).

Today, UPM has 23 paper product groups rated in the CYP tool. All of them are third-party verified. The results vary from good to excellent, the majority being very good or excellent.

"UPM has shown the importance it gives to transparency and environmental performance by publicly disclosing the environmental impact of several of its uncoated and coated papers on WWF’s Check Your Paper. WWF invites pulp and paper producers to join WWF Environmental Paper Award 2016 by listing their papers on CYP," states Emmanuelle Neyroumande, Manager, Forest Product Consumption & Footprint, WWF International.

UPM’s customers are increasingly interested in sustainability of papers. UPM offers product declarations and environmental data, like Paper Profiles, for all products as a tool to provide customers with information on the sustainability of products and the supply chain.

“We promote transparency in our activities and consider WWF’s Check-your-Paper as one good way to increase it. The tool helps customers to identify the most environmentally sound paper products. We have cooperated with WWF to develop the tool and this work continues.” says Päivi Rissanen, Director, Environment and Responsibility, UPM Paper ENA.

Read more: www.upmpaper.com

http://checkyourpaper.panda.org/

Environmental Paper Award 2016

For further information, please contact:

Päivi Rissanen, Director, Environment and Responsibility, UPM Paper ENA, tel. +358 (0) 40 743 0306

UPM, Media Desk

tel. +358 (0) 40 588 3284

Mon–Fri from 9:00–16:00

This email address is being protected from spambots. You need JavaScript enabled to view it.

UPM leads the reformation of the bio and forest industries. We are building a sustainable future in six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve a global base of customers. We employ approximately 20,000 people and our annual sales are approximately EUR 10 billion. UPM's shares are listed on NASDAQ OMX Helsinki. UPM – The Biofore Company – www.upm.com

UPM Paper ENA (Europe & North America) is the world’s leading producer of graphic papers, serving customers in Magazine Publishing & Advertising, Merchants, Home & Office, and Newspaper Publishing. A leader in sustainable and high performance papers, UPM Paper ENA’s production is located in Finland, Germany, the United Kingdom, France, Austria, and the United States. With headquarters in Germany, UPM Paper ENA employs approximately 9,000 people. To learn more about UPM Paper ENA visit: www.upmpaper.com

WWF is one of the world’s largest and most respected independent conservation organisations, with almost five million supporters and a global network active in more than 100 countries. WWF’s mission is to stop the degradation of the earth’s natural environment and to build a future in which humans live in harmony with nature, by conserving the world’s biological diversity, ensuring that the use of renewable natural resources is sustainable, and promoting the reduction of pollution and wasteful consumption.

Crown Princess Victoria meets SCA’s female team in Portugal

In conjunction with her visit to Portugal, Crown Princess Victoria will meet SCA and its professional team of female sailors, Team SCA, which is participating in the Volvo Ocean Race.

An announcement was made in August 2014, that Crown Princess Victoria would be godmother for Team SCA and the team’s boat. On June 4 and 5, the Crown Princess will meet the team again in SCA’s pavilion at the Race Village in Lisbon.

“We are honored that Crown Princess Victoria will visit our fantastic female sailors here in Portugal. The Crown Princess is a role model for many women across the globe. I am also proud that our female sailors – through their professionalism, strong team spirit and positive attitude – have inspired and continue to globally motivate many people,” says Magnus Groth, CEO of SCA.

Team SCA is the only team in the Volvo Ocean Race comprising only women. The start was in October 2014 in Alicante, Spain and the finish is expected to take place in Gothenburg in June 2015. One of the reasons that SCA chose to enter a female team was the company’s belief that all women across the world should have the same opportunities as men to participate in society – socially, educationally and professionally.

“We are delighted that Crown Princess Victoria of Sweden will be visiting us during our stop in Lisbon. SCA has given us a unique opportunity to participate in this race and having the Crown Princess as the Godmother of our crew and boat is an enormous honor. Her visit will further strengthen our motivation as we enter the remaining legs,” says Dee Caffari, Team SCA.

SCA has undergone a major journey of transformation in recent years, completing a number of acquisitions and divestments around the world. Participation with the female Team SCA in the Volvo Ocean Race plays a key role in this journey, namely, to increase global awareness of SCA and its brands. As part of this initiative, SCA has carried out local CSR projects linked to health and hygiene. One example is the education of young girls and women about hygiene and menstruation in partnership with the UN agency, the Water Supply and Sanitation Collaborative Council (WSSCC).

Follow Team SCA on www.teamsca.com

The attached images of the Crown Princess Victoria and Team SCA is from August 2014.

For additional information please contact:

Linda Nyberg, VP Media Relations, +46 8 788 51 58

Karl Stoltz, Media Relations Manager, +46 8 788 51 55

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Environmental impact assessment program for Finnpulp's new softwood pulp mill to be launched

![]() Finnpulp Oy has submitted an environmental impact assessment program to the North Savo Centre for Economic Development, Transport and the Environment regarding the pulp mill project in Sorsasalo, Kuopio. The assessment program includes Finnpulp Oy's plans on the various implementation alternatives for the mill project and a plan (working program) on the environmental impacts to be assessed and the implementation methods of the assessment.

Finnpulp Oy has submitted an environmental impact assessment program to the North Savo Centre for Economic Development, Transport and the Environment regarding the pulp mill project in Sorsasalo, Kuopio. The assessment program includes Finnpulp Oy's plans on the various implementation alternatives for the mill project and a plan (working program) on the environmental impacts to be assessed and the implementation methods of the assessment.

The annual production capacity of this pulp mill, designed specifically to produce raw materials for the tissue and packaging board industries, is 1.2 million tons. In addition, it will produce bioelectricity and wood-based biochemicals such as tall oil and turpentine. It is estimated that the mill will use roughly 6.7 million cubic meters of wood raw material per year.

In addition to the construction and operation of the pulp mill itself, the assessment procedure will cover the essential auxiliary activities required by the mill such as road and rail connections and the power transmission network.

The assessment program will be available online for the duration of the assessment process at www.ymparisto.fi/finnpulpyva. The assessment program will also be available at the Kuopio council house, the Siilinjärvi municipal office and the North Savo ELY Centre as of the 9th of June, 2015. The public event relating to the assessment program will be held at the Kuopio council house's council hall on the 16th of June, 2015 at 6:00pm.

More information on the project and the assessment process

From the project manager:

Pirkko Seitsalo, Pöyry, tel. +358 10 332 4325, This email address is being protected from spambots. You need JavaScript enabled to view it.

Timo Piilonen, Finnpulp Oy, tel. +358 50 598 9310, This email address is being protected from spambots. You need JavaScript enabled to view it.

From the coordinating authority:

Juha Perho, the North Savo ELY Centre, tel. +358 295 026 836, This email address is being protected from spambots. You need JavaScript enabled to view it.

Catalyst Paper named one of Canada's top corporate citizens

Catalyst Paper has announced that it has been named for the ninth consecutive year as one of the Best 50 Canadian Corporate Citizens by Corporate Knights, "the magazine for clean capitalism", which reports on corporate sustainability and transparency and produces numerous indices, including Canada's Best 50 Corporate Citizens.

Catalyst Paper has announced that it has been named for the ninth consecutive year as one of the Best 50 Canadian Corporate Citizens by Corporate Knights, "the magazine for clean capitalism", which reports on corporate sustainability and transparency and produces numerous indices, including Canada's Best 50 Corporate Citizens.

"We are proud to be recognized for our long-term commitment to environmental sustainability and stewardship," said Joe Nemeth, President and CEO. "We voluntarily produced our first Sustainability Report in 1993 and have strived ever since in our commitment to sustainability through efforts at certified fibre sourcing and chain of custody, manufacturing efficiency, green-energy generation and making paper products responsibly."

This year, Catalyst was one of 153 companies considered by Corporate Knights for its Best 50 list, and evaluated across 12 key performance indicators covering resource, employee and financial management, and from information that was disclosed voluntarily in Catalyst's public reports, financial filings and sustainability reports.

The honour reflects Catalyst's ongoing commitment and engagement with many partners and organizations to implement real sustainability and capacity-building initiatives. Our areas of work include helping protect the Great Bear Rainforest, developing transparency in reporting environmental impact, supporting growth of forest certification schemes, and supporting development and implementation of carbon reduction policies and practises.

About Catalyst Paper

Catalyst Paper manufactures diverse printing papers such as coated freesheet, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada.

SOURCE Catalyst Paper Corporation

For further information:

Graham Kissack, Sustainability Consultant, (250) 929-0123, or Eduarda Hodgins, Director Organization Development and Communications, (604) 247-4369

This information is being distributed to you by / Cette information vous est transmise par : Catalyst Paper Corporation

2nd Floor, 3600 Lysander Lane, Richmond, BC, V7B 1C3, Canada

www.catalystpaper.com

Pyrox and PyroxHigh: Voith launches new dryer fabrics onto the market

With Pyrox and PyroxHigh Voith is launching two new heat-resistant dryer fabrics onto the market. They are part of the CleanWeave family of dryer fabrics and were especially designed for dryer sections with moderately high temperatures. Pyrox fabrics are made from a blend of hydrolysis resistant PPS and abrasion resistant PET materials. Like the entire CleanWeave product family, Pyrox and PyroxHigh is produced from SynStron yarn, a material developed by Voith that is especially suited for the challenging conditions of the dryer section.

The proven weave structure of CleanWeave dryer fabrics is incorporated in Pyrox and PyroxHigh. It offers a low internal void volume and minimal yarn crossover points, ensuring contamination within the fabric to be reduced. The compact fabric structure simplifies cleaning of the surface to ensure constant permeability. All CleanWeave products from Voith have a stable, easy-to-clean fabric structure which is unique in the industry. This ensures that the fabric maintains close to its original air permeability, maximizing drying and sheet handling over its entire service life.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Xerium Introduces Aurora Corona Treater Roll Technology for Flexible Packaging Applications

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Aurora, a new advanced cover technology for corona treater positions on flexible packaging machines. Aurora Technology was specially engineered for high performance corona treater applications. Aurora operates well at highest dyne levels, while producing extremely uniform corona treatment, and is extremely resistant to roll cover burn-through. Aurora is built with superior dielectric strength, improved thermal conductivity, and superior volume resistivity, which in total provide flexible packaging producers improved machine performance, longer roll cover life and reduced energy consumption. Learn more about Aurora technology at http://www.xerium.com/news/xerium-news.aspx.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Aurora, a new advanced cover technology for corona treater positions on flexible packaging machines. Aurora Technology was specially engineered for high performance corona treater applications. Aurora operates well at highest dyne levels, while producing extremely uniform corona treatment, and is extremely resistant to roll cover burn-through. Aurora is built with superior dielectric strength, improved thermal conductivity, and superior volume resistivity, which in total provide flexible packaging producers improved machine performance, longer roll cover life and reduced energy consumption. Learn more about Aurora technology at http://www.xerium.com/news/xerium-news.aspx.

“Our objective is always to develop innovative product technology with measurable value for our customers. And we are very excited to see the benefits Aurora technology will deliver to the global flexible packaging industry.”

“We are delighted to introduce the new Aurora family of corona treater roll covers. This new generation technology which will help our customers achieve higher efficiency levels on their machines without roll cover burn through,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “Our objective is always to develop innovative product technology with measurable value for our customers. And we are very excited to see the benefits Aurora technology will deliver to the global flexible packaging industry.”

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 26 manufacturing facilities in 12 countries, two new plants under construction in 2 countries and employs approximately 3,100 employees.

Xerium Technologies, Inc.

Steve Cole, 336-260-4672

Director – Global Marketing

This email address is being protected from spambots. You need JavaScript enabled to view it.