Ianadmin

P&G Takes Bold Step Toward Total Renewable Energy with New Biomass Plant

Scrap wood to create 100% of the steam needed to run one of Company’s largest paper manufacturing facilities

P&G aims to one day run all of its manufacturing facilities on renewable energy. Now, we have taken a big stride in that direction by announcing an agreement to develop a 50-megawatt biomass plant that will help run our Bounty paper towel & Charmin toilet tissue plant in Albany, Georgia USA.

The biomass plant will turn scrap wood into steam and electricity, providing 100% of the steam we need to make Bounty and Charmin. What’s more, the incoming biomass will provide up to 60-70% of the site's overall energy needs.

Here's an infographic that shows how the biomass plant will work (click to see full size):

Here's an infographic that shows how the biomass plant will work (click to see full size):

When it opens in 2017, the biomass plant will significantly increase our use of renewable energy, moving us closer to our goal of obtaining 30% of our total energy from renewable sources by 2020 and 100% one day in the future.

We currently get 8% of our energy from renewable sources including wind, solar, geothermal and biomass. This new project will get us nearly halfway to our 2020 goal.

“As this project enables us to operate one of our largest global plants with a renewable energy source, it will reduce the environmental footprint of two leading brands, Bounty and Charmin. We see this as a win for our business, consumers, partners and the environment.”

Martin Riant, P&G Executive Sponsor of Sustainability and Group President, Global Baby and Feminine & Family Care

The project has been in the works for nearly two years, and has included more than a dozen partners. The $200-million plant will be built, owned and operated by Constellation, a leading retail supplier of power, natural gas and energy products and services, and a subsidiary of the Exelon Corporation.

In addition to steam for P&G, the plant also will create electricity that Constellation will sell to local utility Georgia Power, who will then share it with residents across the state. Several local, state and federal officials and other companies also supported the project.

“This is a Connect+Develop project on steroids,” said P&G’s Global Business Development Manager Bob Bourbon, who helped structure the partnerships to make the project a reality.

The new plant will replace an aging biomass boiler that has been providing about 30 percent of the total energy needed to run the Albany site for the last 34 years. “We’ve been committed to biomass for generations. This project takes us to a heightened level of commitment and benefit,” said Len Sauers, Vice President, Global Sustainability.

emtec at Future. Forum Paper in Austria

Process Optimization within the Paper, Board and Tissue Production

On May 20th and 21st, emtec Electronic GmbH will participate at the “Future. Forum Paper” – the Austrian Paper Conference with trade show for pulp and paper industry in Graz.

During the two days emtec will present different testing instruments by which the process from the production of the pulp to the conversion to the finished product can be controlled and guided in the right direction to get an efficient process and the best possible quality with the lowest possible costs.

In the wet end it is extremely important to have detailed information about the charges of particles in the pulp suspension, which can be determined by the CAS Charge Analyzing System. Also important is the knowledge about the surface charge of the pulp fibers, which can be measured with the FPA Fiber Potential Analyzer. Furthermore, emtec Electronic developed a new Online measuring device FPO Fiber Zeta Potential Analyzer Online, which measures the Zeta Potential of fibers directly in the process and delivers reliable and necessary information concerning the efficiency of chemicals in the process immediately.

In addition to the wet end, it is necessary to get an idea of the quality of the base paper after the production and of the finished product after converting. The EST12 Surface & Sizing Tester is one of the equipment for determining important paper surface properties such as hydrophoby and sizing as well as the porosity and pore structure, which have influences on the printability, coatability, and glueability.

Especially for tissue and nonwoven products, the TSA Tissue Softness Analyzer gives reliable and objective information about the real softness, smoothness/roughness, stiffness as well as the final hand feeling.

Another innovative device is one of the latest developments: the ACA Ash Content Analyzer. It allows the fast and accurate determination of the total mineral filler content as well as the percentage content of the individual filler components of paper and board. It is a useful alternative to the traditional combustion method.

Xerium Schedules First Quarter 2015 Conference Call

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, today announced that it plans to release its financial results for the first quarter of 2015 after the close of regular market trading on Monday, May 11, 2015.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, today announced that it plans to release its financial results for the first quarter of 2015 after the close of regular market trading on Monday, May 11, 2015.

The Company plans to hold a conference call on the following morning:

| Date: | Tuesday, May 12, 2015 | |

| Start Time: | 9:00 a.m. Eastern Time | |

| Domestic Dial-In: | 1-844-818-4921 | |

| International Dial-In: | 1-484-880-4582 | |

| Passcode: | 31324661 | |

| Webcast: |

To participate on the call, please dial in at least 10 minutes prior to the scheduled start.

Presentation viewing details:

A live audio webcast, in addition to the materials used in the presentation, will be available in the investor relations section of the company's website at www.xerium.com/investorrelations. To access the live audio webcast, please click on the earnings call event link that will appear on the investor relations home page.

An archive of the webcast and presentation materials will also be available after the call by clicking on the "Archived Webcasts" link that appears on the left hand side of the company's investor relations homepage at www.xerium.com/investorrelations.

ABOUT XERIUM TECHNOLOGIES

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 26 manufacturing facilities in 12 countries around the world, Xerium has approximately 3,100 employees.

Source: Xerium Technologies, Inc.

Xerium Technologies, Inc.

Cliff Pietrafitta, Investor Relations

919-526-1444

This email address is being protected from spambots. You need JavaScript enabled to view it.

Engineered softwood could transform pulp, paper and biofuel industries

Scientists have demonstrated the potential for softwoods to process more easily into pulp and paper if engineered to incorporate a key feature of hardwoods. The finding, published in this week's Proceedings of the National Academy of Sciences, could improve the economics of the pulp, paper and biofuels industries and reduce those industries' environmental impact.

John Ralph, Great Lakes Bioenergy Center (GLBRC) plants leader and University of Wisconsin–Madison professor of biochemistry

"What we've shown is that it's possible to pair some of the most economically desirable traits of each wood type," says John Ralph, the Great Lakes Bioenergy Research Center's (GLBRC) plants leader and a University of Wisconsin-Madison professor of biochemistry.

According to Ralph, altering what once was the hard and fast distinction between softwoods and hardwoods — which process into largely separate product streams — could create opportunities for the multi-billion dollar industries that process biomass for profit.

Like most plants, hardwood trees such as birch or poplar contain lignin, the notoriously hard-to-process "glue" that lends plant tissues their structure and sturdiness. Lignin is derived from binding molecules called G- and S-monomers, with S-monomers producing a simpler and more easily degradable lignin. As hardwoods contain both G- and S-monomers, they have traditionally been prized for their relatively easy processing into pulp or paper.

Like most plants, hardwood trees such as birch or poplar contain lignin, the notoriously hard-to-process "glue" that lends plant tissues their structure and sturdiness. Lignin is derived from binding molecules called G- and S-monomers, with S-monomers producing a simpler and more easily degradable lignin. As hardwoods contain both G- and S-monomers, they have traditionally been prized for their relatively easy processing into pulp or paper.

Softwoods such as pine or spruce, on the other hand, derive their lignin from G-monomers only, producing a lignin that is much harder to degrade and which renders softwoods more difficult to process. Their industrial advantage, however, is their long fibers, which are particularly well suited for use in making strong paper products such as shipping containers and grocery bags. In addition, the sugar found within softwoods converts more easily and in higher volume to ethanol, making softwoods a potentially superior feedstock for biofuels.

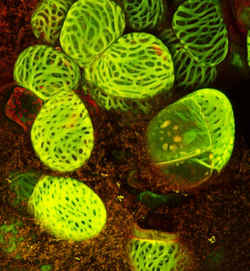

Ralph and a team of collaborators, including first author Armin Wagner from Scion, one of New Zealand's Crown Research Institutes, and GLBRC's Fachuang Lu, used a model called the "tracheary element" (TE) system to prove that it's possible to engineer conventionally long-fibered softwoods to contain the easier-to-process lignin found in hardwoods.

The TE system induces suspension-cultured cells to make secondary cell walls representative of those found in real wood fibers. In this study, the researchers transformed cells from softwood pine within the TE system by introducing genes for two key enzymes known to produce lignin in flowering plants, showing that the resulting softwood was capable of making and incorporating the S-monomers needed to produce a hardwood-type lignin in its cell wall.

Next, the researchers will attempt to use the same approaches to engineer actual softwood plants to produce S-monomers and S/G lignins. The transition from model to plant is highly anticipated.

"If we could implement this in real plantation softwoods, we could decrease the intensity of pre-treatment processes and increase yields across a variety of industries," Ralph says. "But there's a tangible environmental benefit as well: processing biomass faster and more efficiently cuts out a significant amount of waste and energy."

The research was funded partially by GLBRC, one of three Department of Energy Bioenergy Research Centers created to make transformational breakthroughs that will form the foundation of new cellulosic biofuels technology.

—Krista Eastman

emtec at ANEX & SINCE 2015

Softness Evaluation: An Introduction to the Nonwoven-Market

emtec Electronic at the ANEX & SINCE 2015 in Shanghai, China

The company emtec Electronic will participate at the “ANEX & SINCE 2015” in Shanghai, China from 13th to 15th of May. The event will be a combination of the Asia Nonwovens Exhibition and Conference (ANEX) and the Shanghai International Nonwovens Conference and Exhibition (SINCE). The company emtec will be present at booth no. V21 together with Shanghai Forest & Paper Scientific Instrument – its representative for China.

At the exhibition booth emtec will present its TSA – Tissue Softness Analyzer, which was developed for the tissue industry, but is also applicable in the nonwoven sector. The device allows the optimization of the production and converting process, the quality control from supplied products, and also the quality assurance during the production and converting process. Furthermore, the TSA can be used in the R&D to develop new products and to improve existing products.

At the exhibition booth emtec will present its TSA – Tissue Softness Analyzer, which was developed for the tissue industry, but is also applicable in the nonwoven sector. The device allows the optimization of the production and converting process, the quality control from supplied products, and also the quality assurance during the production and converting process. Furthermore, the TSA can be used in the R&D to develop new products and to improve existing products.

The TSA – Tissue Softness Analyzer gives reliable and objective information about the real softness, smoothness/ roughness, stiffness as well as the final hand feeling. The availability of these three parameters opens a huge amount of chances for the optimization of the production and converting processes.

More information about the device and its application will be given by Mr. Alexander Gruener in his presentation “TSA: A new method for Process Optimization, QA and R&D in Nonwovens Production and Converting.” on Wednesday, 13th May at 10:05 am.

Södra raises price of hardwood pulpwood

Södra is replacing the contracting premium for hardwood pulp that has been in place since 10 February with a corresponding price increase of SEK 25 per m3sub effective as of 15 April.

Södra is replacing the contracting premium for hardwood pulp that has been in place since 10 February with a corresponding price increase of SEK 25 per m3sub effective as of 15 April.

The mild and wet winter, in combination with the clearing of storm-felled wood, have led to a weaker flow of hardwood at the same time as demand for the material is favourable. The price increase applies to hardwood pulp and sawable hardwood.

Södra's offer for hardwood remains strong, providing the basis for a high level of activity at the hardwood mill," says Håkan Larsson, President, Södra Skog.

For further information, please Contact:

Håkan Larsson, President of the Södra Skog business area.

Tfn: +46 (0) 499-159 81

Inapa creates brand song with sounds from the team and operations

Inapa, one of the leading paper merchants in Europe, launched today a new brand song, the first element of an audio branding project developed with the sound agency Índigo to celebrate the 50th anniversary of this Portuguese company founded in 1965.

To get a more authentic outcome, this “sonic identity” was created based on real sounds from Inapa operations. The technical team recorded dozens of sounds sourced directly from the company’s machines and equipment, like paper cutting machines, forklifts, warehouse robots, printers and packaging machineries, among others. These sounds were used as the pulse of the brand song, being its rhythmic basis. For the final output, the teams were invited to participate providing the voices and instrumental talent to the brand song.

To achieve this result, the project started with the creation of a task force with team members from the different countries where Inapa operates. The goal was to guarantee the representation of different cultural visions in order to get to a solid sound approach able to illustrate Inapa’s values: client intimacy, commitment, excellence, leadership and sustainability.

In the second phase we analyzed different types of sounds and sound moods to evaluate how they represented the core values, reducing the aesthetical bias of music evaluation.

As the Group is in different geographies that speak several languages, the sonic identity has no lyrics but has a human element that reinforced the importance of people, team work, intimacy and commitment.

“Our activity is directly linked to our senses – textures, odors and vibrant colors – and the sound is an extension, connecting our teams at an emotional level, wherever they are”, states José Morgado, CEO of Inapa Group. “This project was an additional motivation to think about our positioning and core values and how we wanted to translate them into sound. In our 50th anniversary this is our way to honor the past, celebrate the present and, especially, inspire the future”.

Credits:

- Project Management – Hugo Rua, Fernando Rente, Manuel Faria;

- Production Manager – Manuel Faria;

- Composition – José H. Afonso;

- Sound Technician – Miguel Lima;

About Inapa Group

Inapa is one of the leading paper merchants in Europe, with annual sales above 900 million Euros. Established in 1965, Inapa is the only paper and pulp Portuguese company with multinational operations being also the only listed company in the paper distribution sector in Europe.

With a team of 1500 employees, Inapa Group operates in 9 countries – Germany, France, Spain, Portugal, Switzerland, Belgium, Luxembourg, Turkey and Angola – holding a leading position in all these markets.

Valmet launches new IQ Process and Quality Vision solution

Valmet launched its next generation machine vision solution, Valmet IQ Process and Quality Vision, at PaperCon 2015 event in Atlanta. The new solution contains the key elements of advanced process and quality vision system; Valmet IQ Web Inspection System and Valmet IQ Web Monitoring System. It features a number of new advanced solutions combined with high-resolution matrix-cameras providing the sharpest quality images that allows the pulp and paper producers to see the defects that have never been seen before.

Valmet IQ Web Inspection System

"Our process knowledge combined with spearhead machine vision technology now provides tangible benefits to pulp and paper producers. The solution optimizes both end product quality and line efficiency. It allows customers to increase machine speed while simultaneously reducing disturbances. It is not only the pixel size that matters, it is possible to really see the difference," says Jari Almi, Director, Quality Management Solutions, Valmet.

The Web Inspection System detects quality defects and flaws across the entire width of the sheet, pinpointing any issues in real-time. The Web Monitoring System is designed to monitor production and web break events, seamlessly tracing them back to their root causes.

Valmet IQ Web Monitoring System

Both functionalities have a common, simple and easy-to-use user interface. All Valmet IQ solution components are based on our extensive process knowledge and experience in the pulp & paper industry, and backed up by our expert services.

For further information, please contact:

Jari Almi, Director, Quality Management Solutions, Automation business line, Valmet. Tel: +358 40 764 7512

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

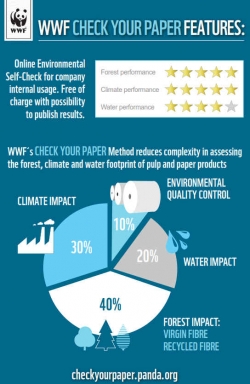

WWF´s “Environmental Self-check” –a free and confidential service for pulp and paper producers

With today’s launch of the online Environmental Self-check, WWF provides an improved service to pulp and paper manufacturers globally for company internal usage. The five online steps to check the environmental footprint of pulp and paper brands can be filled out confidentially. The Environmental Self-check is a new feature of WWF´s Check Your Paper, a public database of brands with high environmental standards (checkyourpaper.panda.org)

With today’s launch of the online Environmental Self-check, WWF provides an improved service to pulp and paper manufacturers globally for company internal usage. The five online steps to check the environmental footprint of pulp and paper brands can be filled out confidentially. The Environmental Self-check is a new feature of WWF´s Check Your Paper, a public database of brands with high environmental standards (checkyourpaper.panda.org)

“WWF wants to offer an additional service to producers to support continual improvement efforts. With the Environmental Self-check we encourage companies to test their products with our method and verify their environmental performance. Companies can download their scores for company internal usage and discussions without any cost or obligations,” said Emmanuelle Neyroumande, Pulp and Paper Global Manager, WWF International “Of course we encourage them to also publish their scores subsequently, to show leadership in transparency.”

The Environmental Self-check is based on a method which reduces the complexity of assessing the forest and manufacturing footprint of pulp and paper products. Previously called “Scorecard”, it was developed upon request by and with support of large buyers, and in consultation with scientists, NGOs and producers. The Check Your Paper method is already being used across regions and for different products. WWF now also encourages the use of the method in supplier screening tools, for example those of retailers and other large buyers of pulp and paper.

The public Check Your Paper database has further a new focus on featuring pulp and paper products with high environmental standards and a low forest, water and climate footprint. As part of the improved Check Your Paper, WWF will offer more opportunities for transparent leaders in the sector to get public recognition for published brands. All third party audited brands will automatically participate in the Environmental Paper Awards 2016 which will be issued for Best Environmental Performance paper

brands and the most transparent producers.

Rod Taylor, Director Forests for Life Programme, WWF International said “At a time of increasing interest in supply chain risks worldwide, the Check Your Paper Method offers an opportunity for suppliers and buyers to work together to reduce their environmental footprint.”

For further information:

Helma Brandlmaier, Senior Advisor Strategic Communications and Knowledge Management, WWF International Tel: +43676842728219 This email address is being protected from spambots. You need JavaScript enabled to view it.

Check Your Paper (checkyourpaper.panda.org) has been designed as a user-friendly tool to help paper purchasers and manufacturers to evaluate their environmental footprint. With the help of the Check Your Paper scheme, also responsible merchants and other distributors can verify and demonstrate the quality of the products they sell. This scheme aims to channel paper consumption and production towards alternatives with the least harmful environmental impacts. It focuses on a limited number of major impacts related to the health and vitality of humans and ecosystems, including:

- forest impacts through wood harvesting

- greenhouse gas emissions

- water pollutants

- wastes

CYP is based on parameters and the rating system of the WWF Paper Scorecard that was initially launched 2007. The parameters and criteria were updated early 2010, with substantial input from more than 30 key paper sector players, including number of globally largest paper manufacturers, paper merchants, paper buyers and non- governmental organisations from Europe, North America, Latin America and Africa.

Rating categories on Check Your Paper are defined as follows:

- Excellent 90-100%: These products have an excellent environmental performance.

- Very good 80-89%: These products have a very good environmental performance.

- Good 60-79%: These products have a good environmental performance.

- Fair (lower than 60%): These products are on the right path and showcase the transparency of the producer/merchant.

About WWF

WWF is one of the world’s largest and most respected independent conservation organizations, with over 5 million supporters and a global network active in over 100 countries. WWF's mission is to stop the degradation of the earth's natural environment and to build a future in which humans live in harmony with nature, by conserving the world's biological diversity, ensuring that the use of renewable natural resources is sustainable, and promoting the reduction of pollution and wasteful consumption.

WWF´s Forests for Life Programme has a long standing track record working with companies. Check Your Paper is part of WWF’s global Forests for Life Programme´s efforts to motivate continual improvement in the forest products sector and to promote sustainable consumption For more information, visit www.panda.org/forests

Billerudkorsnäs:- Best quarterly performance ever

CEO Per Lindberg comments on the development during Q1 2015:

“We are proud to report our best quarter so far in our short history as BillerudKorsnäs. Our operating profit in the quarter reached a level of SEK 698 million and the operating margin was over 12%.”

THE RESULT

The financial performance for the first quarter this year was very strong. On top of a very strong operating result, our operating cash flow was excellent, SEK 733 million, and we have further improved our net debt/equity ratio which is now down to 0.57. Return on capital employed is improving and closing in on our 13% target, but still rounded to 11% and hence we are above all our financial targets except ROCE. Of course, no planned maintenance shutdowns and a weakened SEK had a significant positive impact on the quarter, but I am still very pleased. The one area where we in Q1 fall a little short is volume growth as compared to last year. But keeping in mind that the beginning of last year was exceptional and that production and delivery volume ramp-up rarely is linear, I am still confident in our ability to reach our longer-term growth targets.

The financial performance for the first quarter this year was very strong. On top of a very strong operating result, our operating cash flow was excellent, SEK 733 million, and we have further improved our net debt/equity ratio which is now down to 0.57. Return on capital employed is improving and closing in on our 13% target, but still rounded to 11% and hence we are above all our financial targets except ROCE. Of course, no planned maintenance shutdowns and a weakened SEK had a significant positive impact on the quarter, but I am still very pleased. The one area where we in Q1 fall a little short is volume growth as compared to last year. But keeping in mind that the beginning of last year was exceptional and that production and delivery volume ramp-up rarely is linear, I am still confident in our ability to reach our longer-term growth targets.

MARKET OUTLOOK

The overall market has been stable during the quarter. We expect the stability to continue with quite good demand and little changes in local prices. The pulp price in USD seems to have peaked, but the relative strength of the USD versus other currencies have compensated for the USD nominated price fall.

The relatively high pulp price contributes both to stability and to our own profitability. However, the high pulp cost pressures unintegrated production capacity in the Euro-zone and Sweden. We also see some competitors being forced to take action due to profit squeeze. Meanwhile, and on the balance, we now have a slightly more positive market outlook for our business areas Packaging Paper and Containerboard than we previously expected, whereas the Consumer Board market continues to be stable.

Looking in further detail we can see that within the MF segment in Packaging Paper increased competition pressures local prices and we have not been able to utilise our full capacity during the quarter. This was expected and will most likely continue. On the other hand, the brown sack paper segment shows strength and is trending more positively than expected. Within Containerboard, the fluting segment is currently very strong, with strong order books and we may be looking at price hikes during Q2. In the liner segment competition continues to increase with increased capacity on the market. Even if prices have been kept quite stable during the quarter, white liner continues to be somewhat of a concern.

STRATEGY

I feel that we have prepared the company well both financially and operationally to be ready to take an additional step towards becoming the leading player in the primary fibre packaging market. Our mid-term strategic target is to grow the company organically with 3-4% per year until 2018. This requires debottleneck investments, and several decisions have already been made and I expect more to come. Looking beyond mere organic growth, we have by now strengthened our balance sheet enough to also consider additional growth by acquisitions or significant investments. However, shareholder value will not be compromised and any such step will be subject to utmost scrutiny.

Our mission is to challenge conventional packaging for a sustainable future. In order to emphasize the importance of sustainability we are partnering with the Tara expedition. We share the vision of a future where plastics floating in the oceans are a memory only, and what brings us together is that we constantly seek new answers to sustainability challenges. We want to be active in driving the development towards a more sustainable future, and several lessons from this cooperation will be fed into our own product development.

For further information, please contact:

Per Lindberg, President and CEO 46 (0)8 553 335 00

Susanne Lithander, CFO, 46 (0)8 553 335 00

BillerudKorsnäs – Packaging manufacturers and brand owners are offered added value in the form of brand-strengthening, productivity-boosting and environment-enhancing packaging solutions. BillerudKorsnäs has a world-leading market position within primary fibre-based packaging paper. The company has annual sales of around SEK 21billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com