Ianadmin

Sonoco's Menasha, Wis. Paper Plant Receives Bronze Sustainability Star Award

Sonoco one of the largest diversified packaging companies, has recognized U.S. Paper Mills Corp.'s facility in Menasha, Wis., with a Bronze Sustainability Star Award for the plant's successful efforts to achieve a 26 percent waste reduction.

The plant achieved this significant waste reduction by recovering fiber from the waste streams in the pulping process and reducing moisture content in its waste stream by optimizing equipment. The fiber recovery component alone reduced waste by 50-60 tons per month.

The plant achieved this significant waste reduction by recovering fiber from the waste streams in the pulping process and reducing moisture content in its waste stream by optimizing equipment. The fiber recovery component alone reduced waste by 50-60 tons per month.

"Our primary goal was to recover fiber from the waste streams in the pulping process, and it has paid off," said Troy Huebner, plant manager. "Overall, 58 percent of the plant's waste reduction is a direct result of material that is reconsumed back into processes, reducing the waste stream significantly. Our waste reduction strategy has streamlined operations, reduced waste and cut costs."

Administered by Sonoco Recycling, the Company's recycling business, the Sonoco Sustainability Star Awards program is comprised of three tiers:

- Gold recognizes facilities that have achieved 99% landfill diversion.

- Silver is awarded to facilities achieving 95% landfill diversion, and

- Bronze recognizes facilities that have made significant waste reduction achievements, such as drastically reducing their waste streams or implementing a new composting system.

A recycling leader with locations and expertise worldwide, Sonoco Recycling annually collects more than 3 million tons of old corrugated containers, various grades of paper, metals and plastics. In addition, the Company has experts who provide secure, reliable and innovative recycling solutions to residential and commercial customers. Currently, Sonoco Recycling operates five material recovery facilities (MRFs) serving more than 125 communities in which curbside-collected residential and commercial materials are processed. The Company also operates recycling programs which identify waste reduction opportunities that reduce operating expenses for many of the largest consumer product companies in the United States.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and display and packaging services. With annualized net sales of approximately $5.0 billion, the Company has 20,800 employees working in more 330 facilities in 34 countries, serving many of the world's best known brands in some 85 nations. Sonoco is a proud member of the 2014/2015 Dow Jones Sustainability World Index. For more information on the Company, visit our website at www.sonoco.com.

The forest and paper industry is lagging behind in digital customer experience

Several industries are adopting more and more digital channels for customer service. Research conducted by Tieto shows that most of European forest and paper industry companies do not take this change seriously and have exaggerated their expertise know-how in this area.

Digital customer experience management is not at the heart of European forest and paper industry: a mere 24% of all respondents believed that this could bring added value to business operations. Developing customer loyalty and production efficiency were considered to be most important in the recent Tieto study.

Digital customer experience management is not at the heart of European forest and paper industry: a mere 24% of all respondents believed that this could bring added value to business operations. Developing customer loyalty and production efficiency were considered to be most important in the recent Tieto study.

Self-evaluation shows that the forest and paper industry does not see itself as lagging behind. The respondents were asked to classify their company either as an innovator, a forerunner, a follower or as lagging behind; a clear majority (61%) saw themselves in the first two groups.

According to the research, forest and paper industry invests a mere 10-19% of the budget into developing digital customer experience. This is significantly less when compared to retail or finance industries. Diverse placement of investments is also problematic: more than half of the respondents were unable to say, which budget line covers customer experience-related projects in their own company.

Customer Experience is perceived to be better than it is

According to the research, a significant share (71%) of forest and paper industry companies has already invested in customer experience management.

Active customer experience-related projects deal with optimising adaptability in the distribution chain, customer service personnel training for service culture and sales, and predicting customer needs according to behavioural models and analytics.

When asked about their own companies’ investment for customer experience development, Swedish ventures have larger expectations for success as compared to other countries. 80% of Swedish respondents considered their venture to be an innovator or forerunner. This opinion was shared by 60% of Norwegian, German and Austrian respondents. Finnish respondents placed clearly lower (52%), despite the fact that Finland has most likely invested more into customer experience development than the counterparts.

"Forest and paper industry is not in the forefront of customer experience development, thus the research responses paint an overly rosy picture. This might be due to the fact that comparisons are drawn with the respondents’ own industry or another industry, instead of comparing with retail, for example, where development has progressed further", explains Tieto sales director Jaakko Vilén.

Leaders Need to Understand the Need for Change

The same research also shows that the importance of customer experience is not understood in top management: a clear majority of management-level respondents (62%) did not consider customer experience to be important for business operations.

"The forest and paper industry has traditionally focussed on developing high-end production, logistics and supply chain; service has not been viewed as a competitive advantage. Customer loyalty is high on the management's list of priorities according to this research, but its relation to customer service and experience is either not seen or is dismissed. Companies do not take advantage of digitalisation potential; however, competitive advantage on global markets is gained through innovative methods. The industry desperately needs brave frontrunners ", explains Vilén.

Jaakko Vilén does note that change is in the air, as the development projects highlighted in the research do focus on the right issues. Promising examples are online services that are offered to forest owners by larger forest and paper industry companies, the use of analytics for customer data processing, and initial experiments with online shop applications for pulp and paper sales. Various solutions learned from online trading ease transactions and provide customers of the forest and paper industry opportunities for monitoring delivery.

104 decision makers from Finland, Sweden, Norway, Germany and Austria were interviewed for this research conducted by Tieto Marketvisio.

Read the research: https://www.tieto.com/sites/default/files/atoms/files/tieto_forest_cem_report_en.pdf

For further information, please contact:

Jaakko Vilén, Sales Director, Tieto Forest, jaakko.vilen[at]tieto.com, tel. +358 50 373 9302

Tieto is the largest IT services company in the Nordics providing full lifecycle IT services. We also provide global product development services for companies in the communications and embedded technologies arena. Through industry insight, technology vision and innovative thinking, Tieto proactively strives to inspire and engage its customers in finding new ways of accelerating their business.

Building on a strong Nordic heritage, Tieto combines global capabilities with local presence. Headquartered in Helsinki, Finland, Tieto has over 13 000 experts in more than 20 countries. Turnover is approximately €1.5 billion. Tieto’s shares are listed on NASDAQ in Helsinki and Stockholm. www.tieto.com

International Paper Agrees to Sell Carolina® Coated Bristols Brand

International Paper (NYSE: IP) has announced it has reached a definitive agreement with MeadWestvaco Corporation (MWV) to sell the Carolina® coated bristols brand. The sale is expected to close April 30, 2015. Terms of the sale were not disclosed.

International Paper's decision to sell the Carolina brand was a result of its plans to convert the Riegelwood N.C., Mill to 100 percent fluff and softwood pulp production, thereby eliminating the manufacturing capability to produce the brand. "We recognize that Carolina is a leading brand valued by our merchants, printers, graphic designers and other customers," said Mike Amick, senior vice president, North America Papers & Pulp and Consumer Packaging. "MWV has a long history producing coated bristols for the commercial print market and we view them as a strategic fit to acquire the Carolina brand." Carolina is a preferred coated bristols brand used in a variety of applications like greeting cards, book covers and marketing collateral.

International Paper's decision to sell the Carolina brand was a result of its plans to convert the Riegelwood N.C., Mill to 100 percent fluff and softwood pulp production, thereby eliminating the manufacturing capability to produce the brand. "We recognize that Carolina is a leading brand valued by our merchants, printers, graphic designers and other customers," said Mike Amick, senior vice president, North America Papers & Pulp and Consumer Packaging. "MWV has a long history producing coated bristols for the commercial print market and we view them as a strategic fit to acquire the Carolina brand." Carolina is a preferred coated bristols brand used in a variety of applications like greeting cards, book covers and marketing collateral.

Both companies are committed to a seamless transition to ensure the ongoing quality and reliable performance which customers value and expect. "Taking care of our customers throughout this transition is a top priority," said Amick.

International Paper's coated paperboard and printing papers businesses are strategic to the company's global portfolio. "The sale of Carolina captures the brand's value, and positions the remaining coated paperboard products to support our customers' strategic growth in the food service and packaging markets. The company's commercial print portfolio, which includes the Hammermill®, Accent® Opaque, Williamsburg Offset and the Springhill® brands, will continue to be a strategic part of the company and a valued part of merchant product portfolios," said Amick.

About International Paper

International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging along with uncoated papers and pulp. Headquartered in Memphis, Tenn., the company employs approximately 58,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2014 were $24 billion. For more information about International Paper, its products and stewardship efforts, visit www.internationalpaper.com.

International Paper to Expand Fluff Pulp Capacity

Company to Convert N.C. Mill, Streamline Coated Paperboard Business

![]() International Paper (NYSE: IP) has announced plans to invest $135 million to expand fluff pulp production at its Riegelwood N.C. Mill. The investment will convert the mill to 100 percent fluff and softwood pulp production, adding an incremental 400,000 tons of capacity, with ongoing flexibility to shift between the two products. When the conversion is complete, the company will have the capability to produce up to 1.4 million tons annually of high-quality fluff. The new fluff pulp capacity is expected to ramp up mid-year 2016.

International Paper (NYSE: IP) has announced plans to invest $135 million to expand fluff pulp production at its Riegelwood N.C. Mill. The investment will convert the mill to 100 percent fluff and softwood pulp production, adding an incremental 400,000 tons of capacity, with ongoing flexibility to shift between the two products. When the conversion is complete, the company will have the capability to produce up to 1.4 million tons annually of high-quality fluff. The new fluff pulp capacity is expected to ramp up mid-year 2016.

"The investment at Riegelwood proactively repositions assets to serve our customers in the growing global fluff pulp market and best positions International Paper to increase shareholder value," said Mark Sutton, chairman and CEO, International Paper.

Fluff pulp, which is projected to grow globally at an annual rate of 3 to 4 percent, is used in a variety of applications including baby diapers, feminine hygiene and adult incontinence products. "This new capacity will support the growth of IP customers across the globe," said Mike Amick, senior vice president, North American Papers & Pulp and Consumer Packaging. "Riegelwood is ideally located with access to fiber and proximity to shipping ports critical for supplying a global customer base." With the current expertise at Riegelwood, combined with world-class pulp operations in Franklin, Va., Georgetown, S.C. and Pensacola, Fl., International Paper is set to build on its proven track record of success in the fluff pulp market.

As a result of the Riegelwood Mill conversion to 100 percent fluff and softwood pulp, the company will reduce its coated paperboard capacity by 350,000 tons, sell the Carolina® brand to MeadWestvaco (MWV), and focus the business on supplying customer demand in the food service and packaging markets. The sale of the Carolina business, which represents the majority of the coated paperboard volume reduction, is expected to close April 30, 2015. Terms of the sale were not disclosed. Carolina is a premier coated bristols brand used in a variety of applications including greeting cards, book covers and marketing collateral. The sale captures the brand's value, supports International Paper's plans to expand fluff pulp production at Riegelwood and streamlines and strengthens its coated paperboard business.

"International Paper's printing papers and coated paperboard businesses remain strategic to the company and these moves capture value while allowing for strategic repositioning and growth," Amick said. International Paper is well positioned to support current and future coated paperboard customer demand from its two world-class mills in Texarkana, Texas, and Augusta, Ga.

About International Paper

International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging along with uncoated papers and pulp. Headquartered in Memphis, Tenn., the company employs approximately 58,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2014 were $24 billion. For more information about International Paper, its products and stewardship efforts, visit www.internationalpaper.com

Voith BlueLine machines successful in operation

In the paper industry there is a demand for innovations that reduce operating costs and help conserve resources in the production process. Voith developed its BlueLine range to meet both these requirements. Strong sales in the two years following the market launch of this product range confirm that this approach is appreciated in the industry.

In the paper industry there is a demand for innovations that reduce operating costs and help conserve resources in the production process. Voith developed its BlueLine range to meet both these requirements. Strong sales in the two years following the market launch of this product range confirm that this approach is appreciated in the industry.

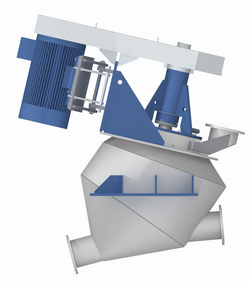

In the meantime, more than 40 IntegraGuard headbox screens have been sold. The machine head geometry was flow-optimized to keep the flow velocity through the screen consistent and low, which prevents strings and deposits. Thanks to the new improved head piece of the screen, the energy requirement of IntegraGuard could be reduced and pulsation minimized. As a result, energy efficiency and paper quality are improved.

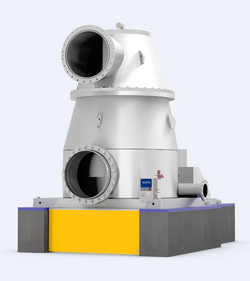

The most successful machine in the BlueLine range to date is the IntensaMaXX pulper detrashing machine, which has now had over 50 installations. This rugged machine has an asymmetric housing that prevents tail formation and stringing, so that even stock containing a lot of contamination does not cause problems in operation. In the IntensaMaXX, the reject is discharged in a downwards direction, ensuring reliable removal of all contaminants. IntensaMaXX can be used in all LC and HC pulping systems for recovered paper. Another advantage of the IntensaMaXX is its low energy consumption.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

ABB successfully delivers global Collaborative Production Management system to KPAQ’s Kraft Paper Mill in Louisiana

Global “Order to Cash” solution providing flexibility and enhanced production performance

ABB, the leading power and automation technology group has successfully delivered a Collaborative Production Management (CPM) system to KPAQ Industries, LLC at their mill located in St. Francisville, Louisiana.

KPAQ’s new CPM system has been integrated to their existing ERP system, various production systems and accounting systems allowing KPAQ to fully utilize ABB’s cpmPlus solutions for sales/order management, production planning, production management, decision support and product tracking.

As a result, KPAQ will now be able to streamline their entire operation as all mill functions will be handled in one comprehensive system allowing a single point of access to all pertinent production data. The system will also be able to efficiently scale to correspond with KPAQ’s production growth and potential expansion.

“We had a highly customized system that did not fit our current work environment. The configurable architecture that ABB provides will allow for all the tools and reporting needed for decision making and efficient action,” stated Jeff Rake, KPAQ COO.

ABB’s Collaborative Production Management (CPM) solutions integrate various manufacturing systems, providing real-time visibility, execution, tracking, reporting, and optimizing of manufacturing processes.

The ABB Global CPM Product provided to KPAQ has been proven to reduce “order-to-cash” time for customer’s manufacturing operations, improve throughput, reduce inventory and optimize business processes.

ABB personnel from the United States, Finland and the Czech Republic collaborated extensively with the KPAQ project team over the scheduled eight month transition to successfully install the comprehensive Global Product and position KPAQ to begin operations in November 2014 with the new CPM system in place.

ABB (www.abb.com) is a leader in power and automation technologies that enable utility, industry, and transport and infrastructure customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in roughly 100 countries and employs about 140,000 people.

Iggesund further reduces carbon emissions

Iggesund Paperboard’s Swedish pulp and paperboard production facility, Iggesund Mill, reduced its fossil carbon dioxide emissions by 86 per cent from 2013 to 2014 from what was already a low level. The reduction is partly due to the investment in a new recovery boiler, which was completed in 2012.

“It always takes time to fine tune a new piece of equipment and we’ve also made some smaller investments to optimise our return from the recovery boiler,” explains Olov Winblad von Walter, Manager of Iggesund Mill. “Now we’re getting close to achieving the potential we expected.”

“It always takes time to fine tune a new piece of equipment and we’ve also made some smaller investments to optimise our return from the recovery boiler,” explains Olov Winblad von Walter, Manager of Iggesund Mill. “Now we’re getting close to achieving the potential we expected.”

The mill’s environmental improvements are not limited to carbon dioxide. Emissions of sulphur have also been cut by 82 per cent, nitrogen oxides by 19 per cent and particulates by 90 per cent – all compared with 2011, which was the last year the old recovery boiler was operating. A conscious decision on operating strategy and investments in process stages that previously used fossil fuel oil have also contributed to the radical reductions in air-borne emissions.

Iggesund Mill is not the only component of the Holmen Group to succeed with its environmental work. Between 2013 and 2014 carbon dioxide emissions per tonne of manufactured paperboard and paper products within the Group were cut from 123 kilos to 67 kilos. This is almost 50 per cent and demonstrates clearly that the Group has taken yet another step to reduce the climate impact of its own operations.

In recent years the Holmen Group has received a number of awards for its sustainability work. In 2014 Iggesund was given the Bio Strategy of the Year award by the industry organisation PPI. The Holmen Group was also included on the Carbon Disclosure Project’s list of the 187 global companies that are leaders in the battle to tame the climate threat.

“We’re very satisfied with this year’s outcome and I believe we’ve thereby strengthened our position as a leader in sustainability efforts,” comments Lars Strömberg, Director of Sustainable and Environmental Affairs at Holmen.

In 2013 Iggesund also commissioned a biomass CHP plant at the company’s Workington Mill in the UK. By switching its energy source from fossil fuel to biomass in a single step, the mill eliminated almost all the fossil carbon emissions from its production process. At Iggesund Mill in Sweden, bioenergy supplied 99.1 per cent of the energy used in the production process during 2014. Today the emissions from all paperboard production within the Holmen Group are within a few tenths of one per cent of being fully fossil free.

“Our strategy of investing in fossil-free technology at the mills in Sweden and the UK have been decisive steps in our sustainability work,” Strömberg emphasises. “The fact that we’ve been rewarded with top positions in various rankings and indexes proves that active work with energy and climate issues gives us a credibility that also strengthens our brands.”

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Further information:

Staffan Sjöberg

Public Relations Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund Paperboard

SE-825 80 Sweden

Tel: +4665028256

Mobile: +46703064800

www.iggesund.com

ANDRITZ to supply new press section at Iggesund Paperboard, Workington, England

International technology Group ANDRITZ has received an order from Iggesund Paperboard to install a complete press section for the board machine 2 at the Workington mill, England. Start-up is scheduled for the second quarter of 2016.

ANDRITZ will deliver a turnkey new press section, including a PrimePress X shoe press and a new PrimeFeeder for tail threading from press section to dryer section. The scope of supply also includes a new press pulper, field instrumentation, machine control systems, electrification, and new press section drives. The new press section will increase production capacity and improve energy efficiency, runability, and product quality.

The Workington mill produces high-performance paperboard used for consumer packaging and graphical products.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of almost 25,000 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, production equipment for biofuel (second generation), biomass torrefaction equipment, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

For further information, please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

European paper industry partners with Pöyry

The Confederation of European Paper Industries (CEPI) is pleased to announce a new partnership with Pöyry. The partnership will allow CEPI and Pöyry to work more closely together, particularly in the areas of innovation and bioeconomy. In addition, it will reinforce Pöyry’s presence both at the European Paper Week as well as other events organised by CEPI.

The Confederation of European Paper Industries (CEPI) is pleased to announce a new partnership with Pöyry. The partnership will allow CEPI and Pöyry to work more closely together, particularly in the areas of innovation and bioeconomy. In addition, it will reinforce Pöyry’s presence both at the European Paper Week as well as other events organised by CEPI.

Pöyry is an international consulting and engineering company providing services across the full project lifecycle and helping to solve the challenges faced by the world’s toughest industries. By becoming a CEPI Partner, Pöyry joins Buckman, Omya and Voith. “We are very excited to have Pöyry on board and we very much look forward to a fruitful collaboration”, says CEPI Director General Marco Mensink.

CEPI’s partnership programme is currently open to machine and chemical suppliers active in the pulp, paper or board industry with a direct link to paper manufacturing. It was first launched in 2011 and aims at exchanging technical information and expertise as well as promoting common interests.

For more information, please contact Annie Xystouris at This email address is being protected from spambots. You need JavaScript enabled to view it. mobile: +32(0)486 243 642.

CEPI aisbl - The Confederation of European Paper Industries

The Confederation of European Paper Industries (CEPI) is a Brussels-based non-profit organisation regrouping the European pulp and paper industry and championing industry’s achievements and the benefits of its products. Through its 18 member countries (17 European Union members plus Norway) CEPI represents some 515 pulp, paper and board producing companies across Europe, ranging from small and medium sized companies to multi-nationals, and 940 paper mills. Together they represent 23% of world production.

About Pöyry

Pöyry is an international consulting and engineering company. We serve clients globally across the energy and industrial sectors and provide local services in our core markets. We deliver management consulting and engineering services, underpinned by strong project implementation capability and expertise. Our focus sectors are power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry has an extensive local office network employing about 6,000 experts. Pöyry's net sales in 2014 were EUR 571 million and the company's shares are quoted on NASDAQ OMX Helsinki (Pöyry PLC: POY1V).

Website: http://www.poyry.com/

Endress+Hauser Introduces Turbimax CUS52D Turbidity Sensor

Turbidity sensor provides fast, laboratory-quality measurements in real-time for the entire water purification process and many other process applications. Its hygienic design also makes it suitable for applications in food and beverage.

Endress+Hauser introduces the Turbimax CUS52D turbidity sensor for process water filtration and other industrial process turbidity conditions. The Turbimax CUS52D performs laboratory-quality turbidity measurements without the need for extensive bypass installations, avoiding costly product or water losses.

The sensor measures turbidity from 0.000 to 4000 NTU with accuracy of 2% of measurement ±0.01 NTU at process temperatures from -4 to 185 °F with a detection limit of 0.0015 NTU. The sensor measures turbidity in accordance with ISO 7027

The Turbimax CUS52D’s surface minimizes the build-up of biofilms and particulates. The ability to operate at high pressures (up to 145 psi) makes suppressing air bubbles possible. For bypass operation an optional air bubble trap catches smaller air bubbles. In particularly challenging cases, the CYR52 ultrasonic cleaning system can be installed on a flow cell or even right on the existing pipe to prevent and remove surface contamination and bubbles without direct product contact.

The Turbimax CUS52D is available in immersion, flow cell and in-line versions. The immersion model can be installed in open channels and basins, while the stainless steel hygienic in-line model can be inserted directly into pipes. The Turbimax CUS52D can be used at the raw water inlet of any plant and the outlet of process filtration and clarification. The Turbimax CUS52D is well suited to filter monitoring, filter backwashing and all stages of industrial water purification. With available 2” triclamp the CUS52D is also well adapted to hygienic food and beverage processes in brewing, spirits, soft drink, dairy and others. Its fast response time of less than 1 second means it can also perform very well as a primary process variable (PV) in control applications.

The sensor uses the 90° light scattering principle in accordance with the ISO 7027 standard. The optical signals from the sensor are continuously monitored and tested for plausibility. In the case of discrepancies, an error message is sent via the transmitter.

A smart solid state reference for the Turbimax CUS52D allows the sensor to be verified and calibrated before insertion into the process without the use of liquid standards. As a result, neither employees nor processes come into contact with any harmful liquid standards such as Formazin, which are typically used for field calibration. The solid state references are matched to each sensor for maximum calibration accuracy, are simple to use, and provide consistent, reliable and clear results.

For more detailed technical information on the Turbimax CUS52D turbidity sensorplease go to the product page at: www.us.endress.com/cus52d

About Endress+Hauser

Endress+Hauser is one of the largest instrument manufacturers in the United States’ industrial automation industry – specializing in automation solutions for the Chemical, Food & Beverage, Oil & Gas, Water and Wastewater, Life Sciences, Power and Energy, Primaries, and Pulp and Paper Industries. Endress+Hauser, a Switzerland based company, first began operations in the U.S. in 1970. Since that time, Endress+Hauser has continued to invest in its U.S. operations - investing an average of 10% of its annual revenue into its infrastructure.

For more information, please visit www.us.endress.com .

Contact: Crystal Hunt

Senior Public Relations Manager

Endress+Hauser, Inc.

Office:317-535-1306

Mobile: 317-439-6426

Fax: 317-535-2171

This email address is being protected from spambots. You need JavaScript enabled to view it.