Ianadmin

Sonoco Donates $50,000 to Hurricane Matthew Relief

Sonoco (NYSE:SON), one of the largest diversified global packaging companies, has donated $50,000 to the American Red Cross to aid in Hurricane Matthew relief efforts in the Southeast.

Sonoco has been headquartered in Hartsville, S.C., since its inception in 1899, and about 2,000 of its employees currently call South Carolina home. Sonoco’s Hartsville headquarters and manufacturing operations were impacted by the storm, as were locations in Florida, Georgia and North Carolina, and many of its employees, their families and their friends are facing hardships after the historic hurricane.

Sonoco has been headquartered in Hartsville, S.C., since its inception in 1899, and about 2,000 of its employees currently call South Carolina home. Sonoco’s Hartsville headquarters and manufacturing operations were impacted by the storm, as were locations in Florida, Georgia and North Carolina, and many of its employees, their families and their friends are facing hardships after the historic hurricane.

“We have all been touched by Hurricane Matthew over the past several days,” said Jack Sanders, president and CEO of Sonoco. “Like during the historic floods just one year ago, as we rebuild, I have no doubt that the resiliency and faith of our citizens will continue to shine through this crisis.”

“Thanks to generous donors, like Sonoco, all Red Cross disaster assistance is free,” said Louise Welch Williams, regional chief executive officer of the American Red Cross, Palmetto SC Region. “From shelters, food and emotional support, to working with families to help them with their long-term recovery, the Red Cross provides comfort and support after a disaster through the generosity of businesses and individuals.”

Sonoco asks other companies and individuals throughout the region to support hurricane recovery efforts by donating and volunteering with the American Red Cross and other agencies. To donate to the relief efforts, visit www.redcross.org/SC.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. With annualized net sales of approximately $5 billion, the Company has 20,800 employees working in more than 330 operations in 35 countries, serving some of the world’s best known brands in some 85 nations. For more information on the Company, visit our website at www.sonoco.com.

About the American Red Cross:

The American Red Cross shelters, feeds and provides emotional support to victims of disasters; supplies about 40 percent of the nation's blood; teaches skills that save lives; provides international humanitarian aid; and supports military members and their families. The Red Cross is a not-for-profit organization that depends on volunteers and the generosity of the American public to perform its mission. For more information, please visit redcross.org/SC or follow us on Twitter @RedCrossSC.

Global Process Automation To Present At Rockwell Automation Event

The team at Global Process Automation is pleased to announce that Daniel Lee, VP of Operations, will speak at the Process Solution’s User Group, an event hosted by Rockwell Automation.

Mr. Lee will be speaking about Global Process Automation’s experience-- completing multiple concurrent DCS migrations to PlantPAx with a major pulp and paper client. By implementing a “Rock-solid” system, the client was able to realize a number of benefits to their business including: reduced life-cycle costs, increased effectiveness in troubleshooting, and the ability to make faster decisions thanks to the availability of more data.

Mr. Lee will be speaking about Global Process Automation’s experience-- completing multiple concurrent DCS migrations to PlantPAx with a major pulp and paper client. By implementing a “Rock-solid” system, the client was able to realize a number of benefits to their business including: reduced life-cycle costs, increased effectiveness in troubleshooting, and the ability to make faster decisions thanks to the availability of more data.

Mr. Lee’s position as VP of Operations with Global Process Automation puts him in a unique position to speak on DCS migrations as well as many other topics related to industrial process control, automation, data acquisition, visualization, and process automation.

Along with business development, operational management, and customer relations management, Mr. Lee is integral to custom system design, layout, scheduling, and engineering support for large control system projects.

Global Process Automation (GPA), headquartered in Wilmington NC with regional offices in Pryor, OK; Nashville, TN and Little Rock, AR is a recognized leader in process automation, control and information systems. GPA has been involved in the pulp and paper, life science, and specialty chemical industries for over 20 years. Working with many leading DCS platforms, GPA has designed, engineered, integrated, and migrated many legacy DCS systems to modern platforms-- which are needed in today’s ever-changing manufacturing environment. GPA’s staff of over 35 engineers, many of which are factory trained, bring years of process control experience to all facets of automation projects. Also, with a strong IT staff that understands the unique needs of process control, GPA is able to provide its clients with leading edge solutions in data analytics, networking, data center design, virtualization, and cyber security.

The two-day Process Solutions User Group will be held November 7th & 8th at the Georgia World Congress Center in the Georgia Ballroom, building C, in Atlanta Georgia. This two-day event provides an excellent opportunity for professionals in the process industry around the world to share information and learn about the latest process automation technologies from Rockwell Automation. For more information visit www.psug.rockwellautomation.com.

You can reach Global Process Automation by calling 877-848-5166, emailing This email address is being protected from spambots. You need JavaScript enabled to view it. or visiting www.global-business.net

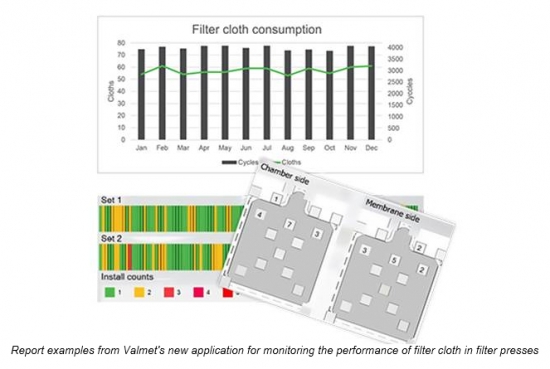

Valmet launches world's first application for monitoring filter cloth performance

Valmet launched its newest Industrial Internet application at the FILTECH exhibition in Cologne, Germany on October 11, 2016. The application is used for monitoring the performance of filter cloth in filter presses. The application has been piloted in customer filtration processes with good results, and the first customer orders have been received with implementation still in 2016.

Pending on the size of the process, a filtration process may consume thousands of filter cloths per year. By gathering information with RFID technology, the application can analyze the performance of filter cloths and filters.

"We are able to utilize the information on cloth lifetimes, the reasons for cloth removal and cloth consumption to optimize the whole filtration process. In addition, this information helps process operators to better monitor the filter itself," explains Sanna Uusitalo, Product Manager, Filtration at Valmet.

Seeing inside the filtration process contributes to savings

Valmet's application is based on special equipment and RFID tags that submit information to be used in the follow-up and analysis of the whole filtration process. An optimal process leads to remarkable savings.

"Savings can be achieved through planned maintenance and reduced filter downtime. The filter cloths and filters will be developed further as more information is gathered about their performance. The application also enables remote support from our filtration experts. By enabling us to see inside the process, the application helps us and our customers to optimize the whole filtration process," Uusitalo continues.

RFID technology has been in use for decades, but Valmet is the first to utilize it for filter cloths. Valmet has developed the application in co-operation with customers and filter manufacturers. At this stage, the application is first being used in the mining industry, but there are already plans to broaden its use to filtration processes in the pulp and paper industry.

The application and its use is demonstrated at the FILTECH exhibition in Cologne, Germany, October 11-13, 2016.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Lenzing invests EUR 100 mn in pulp production

The Lenzing Group will expand and modernize its existing dissolving wood pulp production at the sites in Lenzing/Austria and Paskov/Czech Republic. At a press meeting in Vienna, Lenzing CEO Stefan Doboczky announced a total investment program of EUR 100 mn, approximately EUR 60 mn of it in Lenzing and almost EUR 40 mn in Paskov. Additional new capacities of around 35,000 tons will be added over the next 2.5 years.

“With these investments, we are taking another step in the implementation of our new corporate strategy sCore TEN,” said Stefan Doboczky. “We aim to increase our own dissolving wood pulp production from currently 56% to 75% of the group’s requirements for the production of botanic cellulose fibers by the end of the decade. The modernization will lead to more efficiency of our plants. The upgrade and expansion of our bio-refinery setup will underline Lenzing’s leadership as the most sustainable fiber producer.”

“With these investments, we are taking another step in the implementation of our new corporate strategy sCore TEN,” said Stefan Doboczky. “We aim to increase our own dissolving wood pulp production from currently 56% to 75% of the group’s requirements for the production of botanic cellulose fibers by the end of the decade. The modernization will lead to more efficiency of our plants. The upgrade and expansion of our bio-refinery setup will underline Lenzing’s leadership as the most sustainable fiber producer.”

Lenzing’s bio-refinery concept is based on using only certified wood from countries in Western and Central Europe. It is an essential part of Lenzing’s mission to turn CO2 and sunlight into high value fibers, as it ensures that 100% of the wood components are used to produce fibers, bio-chemicals and bio-energy. This investment is also an essential part of Lenzing’s quality strategy, as the high quality of our botanic fibers depends on the quality of the dissolving wood pulp.

In August 2016, Lenzing announced a capacity expansion for specialty fibers of 35,000 tons by mid-2018. Roughly EUR 70mn will be invested in the site in Heiligenkreuz/Burgenland and approximately EUR 30 mn in Lenzing/Upper Austria as part of this project. The new pulp investment program will be implemented in addition to these investments.

These investments are yet another long-term commitment of the Lenzing Group to the Austrian production sites. In the next 2.5 years, Lenzing will therefore invest a total of EUR 160 mn in Austria. Lenzing is thus once again one of the leading industrial investors in Austria.

The Lenzing Group

The Lenzing group is a world market leader headquartered in Austria, with production sites in all major markets as well as a worldwide network of sales and marketing offices. Lenzing supplies the global textile and nonwovens industry with high-quality, botanic cellulose fibers. Its portfolio ranges from dissolving pulp to standard and specialty cellulose fibers.

Lenzing quality and innovative strength set global standards for cellulose fibers. With 78 years of experience in fiber production, the Lenzing Group is the only company worldwide combining the manufacturing of all three cellulose fiber generations on a large scale under one roof – from the classic viscose to modal and the lyocell fiber TENCEL®.

The success of the Lenzing Group is based on its consistent customer orientation together with its leadership in innovation, technology and quality. Lenzing is committed to the principles of sustainable management and very high environmental standards. In addition to its core business of fibers, the Lenzing Group also operates in the field of engineering and plant construction.

Charmin Makes It Easier For Consumers To Choose Responsibly Sourced Toilet Paper

New On-Pack Seal Communicates Charmin’s Partnership with Forest Stewardship Council and Rainforest Alliance

Charmin has taken the next step in supporting responsible forest management by achieving Forest Stewardship Council® (FSC®) certification in its tissue paper products. This month, Charmin also launched its newest tissue product innovation, Charmin Essentials, and with it the launch of FSC and Rainforest Alliance certification of Charmin Ultra Strong and Ultra Soft family of tissue products. Consumers can now find the FSC and Rainforest Alliance CertifiedTM seals on-pack, further solidifying its efforts and commitment to responsible papermaking by sourcing one hundred percent of the virgin fiber sourced for its products from responsibly managed sources.

Charmin has taken the next step in supporting responsible forest management by achieving Forest Stewardship Council® (FSC®) certification in its tissue paper products. This month, Charmin also launched its newest tissue product innovation, Charmin Essentials, and with it the launch of FSC and Rainforest Alliance certification of Charmin Ultra Strong and Ultra Soft family of tissue products. Consumers can now find the FSC and Rainforest Alliance CertifiedTM seals on-pack, further solidifying its efforts and commitment to responsible papermaking by sourcing one hundred percent of the virgin fiber sourced for its products from responsibly managed sources.

“P&G knows that it is important to preserve our world’s forests to ensure a future for our planet. That’s why we partner with the Forest Stewardship Council and the Rainforest Alliance to help us ensure that the tree fibers used in our products, like Charmin, come from responsibly managed forests while still delivering the superior product experience our consumers expect,” said John Brase, Vice President, Family Care. “This campaign is one piece of our overall efforts to support and raise awareness of the protection of forests and FSC. Now, when consumers purchase Charmin and see the FSC and Rainforest Alliance Certified seals, they can “enjoy the go” now and for generations to come.”

P&G reached this milestone, in part, by tapping into the World Wildlife Fund Global Forest & Trade Network's expertise in sourcing fiber from well-managed forests that protect wildlife habitat and the air and water upon which we all depend.

“We applaud P&G for putting the FSC label on its product, which sends a strong message about the importance of responsible forest management,” said Corey Brinkema, president of the Forest Stewardship Council US.

Today’s consumers want to be environmentally friendly and Charmin is proud to share information and insights on its approach to responsible papermaking to empower its consumers to do the same to make informed decisions. Consumers will now find in-depth sustainability webpages to learn more about what P&G is doing to keep environmental impact top of mind for their favorite products.

“By sourcing from responsibly-managed forests, P&G sets an example of environmental and social responsibility for other companies, and for their customers,” said Richard Donovan, senior vice president and president of forestry, the Rainforest Alliance.

To learn more about Charmin’s environmental commitments and progress, please visit the Charmin Sustainability Page.

About Charmin

Charmin has been America's most popular toilet paper for more than 25 years. In the U.S., P&G offers Charmin Ultra Soft and Charmin Ultra Strong - premium two-ply toilet paper; Charmin Basic - a one-ply toilet paper; Charmin Sensitive - with gentle and soothing lotion with a touch of aloe & vitamin E; Charmin Essentials – a long-lasting toilet paper. For more information on Charmin, visit http://www.charmin.com. See label code: FSC® C100701.

About Rainforest Alliance

The Rainforest Alliance is an international nonprofit organization working around the world since 1987 to conserve forests and natural resources while advancing sustainable livelihoods. Rainforest Alliance is focused on transforming forestry, agriculture and tourism, collaborating with foresters, farmers, businesses and workers to build strong forests and healthy communities, protect habitat, and rebalance the Earth, with the vision of a world where planet and people prosper together. The Rainforest Alliance is a founding member of Forest Stewardship Council and is a certifying body for products that carry the FSC seal. To learn more about the Rainforest Alliance, visit www.rainforest-alliance.org.

About Forest Stewardship Council®

The Forest Stewardship Council is an independent nonprofit organization that promotes environmentally sound, socially beneficial, and economically prosperous management of the world’s forests. FSC was created in 1993 to help consumers and businesses identify products from well-managed forests. FSC sets standards by which forests are certified, offering credible verification to people who are buying wood and wood products. More than 5,000 companies and nearly 170 million acres of forestland are certified under FSC standards in the United States and Canada. For more information visit www.fsc.org.

ANDRITZ successfully starts up second tissue machine with steel Yankee for St. Croix Tissue, USA

International technology Group ANDRITZ has successfully completed the start-up of the second of two supplied PrimeLineTM W8 tissue machines with steel Yankees at the St. Croix tissue mill in Maine, USA.

The machine has a design speed of 2,000 m/min and a width of 5.6 m. The Yankee is manufactured entirely of steel and has a diameter of 18 ft. It enables efficient drying at minimized energy costs and safe operation. As a special feature, the Yankee’s design enables the option of production with shoe press.

The ANDRITZ tissue twins at the St. Croix tissue mill in Maine. “Photo: ANDRITZ”.

Both machines – the first of the two tissue machines started production in the second quarter of 2016 – have an aggregate capacity of 126,000 t/y for the production of hygienic papers and napkin tissues.

‘We have had a good experience with ANDRITZ, they are a proven supplier,’ says Arvind K. Agarwal, CEO of International Grand Investment Corp., the parent company of St. Croix Tissue. ‘We have considerable confidence in their technology and reliability. The start-up of the two PrimeLine machines was outstanding and the ability of the machines to produce high-quality tissue with excellent formation is allowing us to convert a commodity product into a value-added product.’

This successful start-up again confirms ANDRITZ PULP & PAPER’s position as one of the global market leaders for supply of complete tissue production lines, key components, and services.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,700 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

Global pulpwood prices were up in the 2Q/16 after having declined for seven consecutive quarters

Wood fiber costs currently account for almost 60% of the cash costs when manufacturing wood pulp. Prices for both wood chips and pulplogs have trended downward for a long time, but this came to an abrupt halt in the 2Q/16 when the softwood price index rose 2.3% and the hardwood price index increased 3.7% from the 1Q/16, according to the latest Wood Resource Quarterly.

The wood fiber costs for the world’s pulp industry had trended downward for almost five years until this year when both the softwood and hardwood fiber price indices jumped in the 2Q/16. The two indices rose because price increases were seen for wood chips and pulplogs in practically every major market around the world.

The wood fiber costs for the world’s pulp industry had trended downward for almost five years until this year when both the softwood and hardwood fiber price indices jumped in the 2Q/16. The two indices rose because price increases were seen for wood chips and pulplogs in practically every major market around the world.

The Softwood Wood Fiber Price Index (SFPI) was up 2.3% from the 1Q/16 to US$89.63/odmt in the 2Q/16, as reported in the Wood Resource Quarterly (WRQ). This was the first quarter-over-quarter increase since early 2014. A combination of a weaker US dollar and higher wood fiber prices in the local currencies in Western Canada, France, Brazil and Germany, were the main reasons for the higher SFPI this quarter.

The Hardwood Wood Fiber Price Index (HFPI) was up 3.7% from the 1Q/16 to US$86.86/odmt, which was also the first increase in almost two years. The biggest price increases (in US dollars) occurred in Russia, Brazil, Chile, Australia and Eastern Canada.

Despite the recent price increase, current price levels for wood fiber are close to the lowest they have been in almost ten years in nominal terms. Wood fiber costs currently account for approximately 58% of the cash costs when manufacturing pulp on a global basis, according to Fisher International. Of the 16 major pulp-producing regions around the world tracked by the WRQ, pulpmills in Japan have the highest wood fiber cost percentage of close to 70%, while Russian mills have the lowest wood cost share of just below 40%.

The historically low wood fiber costs are, of course, very good news for the world’s pulp and paper industry. With market pulp prices currently being slightly below their ten-year averages, the wood costs as a percentage of the market pulp price (NBSK and EBK) are close to their lowest levels in almost 15 years.

Note. The Global Wood Fiber Price Index is a weighted average of delivered wood fiber prices for the pulp industry in all regions tracked by the publication Wood Resource Quarterly. These regions together account for 85-90% of the world’s wood-based pulp production capacity. The price is based on current quarter average prices, and country/regional wood fiber consumption data. The global average price for softwood and hardwood is calculated in nominal US$ per oven-dried metric ton (odmt) of wood fiber.

Global lumber, sawlog and pulpwood market reporting is included in the 52-page quarterly publication Wood Resource Quarterly (WRQ). The report, which was established in 1988 and has subscribers in over 30 countries, tracks sawlog, pulpwood, wood chip, lumber and pellet prices, trade and market developments in most key regions around the world. To subscribe to the WRQ, please go to www.woodprices.com

MIAC opens its doors! This 12.13.14 October in Lucca/Italy! (23rd edition!)

270 Exhibitors, 5000 Visitors: this is MIAC in Lucca (Italy)! Visiting MIAC means obtaining a full overview of the technology and equipment available to the paper industry sector thanks to the constant participation of the leading companies in the sector which present the latest developments in machines, systems and avant-garde solutions to improve the management of the various stages in the paper production cycle.

During the 3 days of Exhibition take place 4 International Conferences, offering very interesting content and studied to provide professional and dynamics information to the participants coming from all over the world.

The paper industry and the district of Lucca

The paper industry in Italy boasts significant numbers: 165 Paper Mills, 20,000 workers, almost 9,000,000 tonnes of paper and cardboard produced every year, with a turnover of 6.8 billion Euros (the volume of production places Italy in the first 4 positions to European level).

Lucca is the only officially acknowledged “Paper District” in Europe: over 140 Paper Mills and Converters, 6,500 workers, 2,000,000 tonnes of paper and cardboard produced (tissue paper and corrugated cardboard), with a turnover of 3.5 billion Euros. Lucca is also home to major companies that supply technologies, machinery and services to the paper industry sector, with a turnover of more than 2,600 million Euros and over 8,000 workers!

In Europe, Lucca is the number one spot for tissue production (24% market share), Italy is also one of the leader countries in the corrugated cardboard sector. But Lucca is not only synonymous with the Paper Industry! It is also one of the major tourist destinations in Italy, and is sure to charm the Visitors of MIAC with its beautiful city Walls, Towers and Squares.

Praxair Signs Long-Term Oxygen Supply Agreement with Brazilian Pulp Producer Fibria

Praxair, Inc. (NYSE: PX), through its Brazilian subsidiary White Martins, has signed a long-term agreement expanding its supply of oxygen to Fibria Celulose S/A (NYSE: FBR) in Três Lagoas, Brazil. Fibria is the world’s largest producer of eucalyptus pulp, exporting the product to customers in more than 40 countries.

![]() Through its Horizon 2 Project, Fibria is expanding its Três Lagoas facility, located in the state of Mato Grosso do Sul. The expansion is expected to be completed in late 2017. Praxair’s new plant, also expected to start up in late 2017, is designed to increase Fibria’s productivity and support the company’s expansion of this site. Fibria currently has global annual production capacity of 5.3 million tons of eucalyptus pulp and is seeking to increase its capacity to 7.25 million tons annually. Fibria’s expansion will demand an additional 160 tons per day of oxygen, for use in the pulp delignification stage, also known as pre-bleaching pulp.

Through its Horizon 2 Project, Fibria is expanding its Três Lagoas facility, located in the state of Mato Grosso do Sul. The expansion is expected to be completed in late 2017. Praxair’s new plant, also expected to start up in late 2017, is designed to increase Fibria’s productivity and support the company’s expansion of this site. Fibria currently has global annual production capacity of 5.3 million tons of eucalyptus pulp and is seeking to increase its capacity to 7.25 million tons annually. Fibria’s expansion will demand an additional 160 tons per day of oxygen, for use in the pulp delignification stage, also known as pre-bleaching pulp.

“White Martins is proud of the strong relationship we have built with Fibria throughout the years while serving their industrial gas needs at the Três Lagoas and Aracruz plants in Brazil,” said Domingos Bulus, president of Praxair South America. “We look forward to supporting the continued expansion of Fibria in Brazil and around the world by delivering reliable service and value-creating applications technologies.”

“As the global leader in the eucalyptus pulp market, Fibria is known for its operational excellence,” said Júlio Cunha, director of engineering for the Horizon 2 Project. “That is why we have selected serious and committed suppliers that can support the growth and sustainable development of the company.”

About Praxair

Praxair, Inc., a Fortune 300 company with 2015 sales of $11 billion, is a leading industrial gas company in North and South America and one of the largest worldwide. The company produces, sells and distributes atmospheric, process and specialty gases, and high-performance surface coatings. Praxair products, services and technologies are making our planet more productive by bringing efficiency and environmental benefits to a wide variety of industries, including aerospace, chemicals, food and beverage, electronics, energy, healthcare, manufacturing, primary metals and many others. More information about Praxair, Inc. is available at www.praxair.com.

About Fibria

The world leader in eucalyptus pulp production, Fibria strives to meet the growing global demand for forestry products in a sustainable manner. With production capacity of 5.3 million tons of pulp per year, it has industrial units in Aracruz (Espírito Santo), Jacareí (São Paulo) and Três Lagoas (Mato Grosso do Sul), as well as in Eunápolis (Bahia), where it operates Veracel in a joint operation with Stora Enso. Fibria has 969,000 hectares of forests, with 568,000 hectares of planted forests, 338,000 hectares of environmental preservation and conservation areas and 63,000 hectares to be used for other uses. The pulp manufactured by Fibria is exported to more than 40 countries. In May 2015, Fibria announced the expansion of its Três Lagoas unit, which will receive a new line with annual pulp production capacity of 1.95 million tons and is slated for startup in the beginning of the fourth quarter of 2017. For further information please visit: www.fibria.com.br/en/

Xerium Celebrates 1000th Press Felt Shipped From Its Kunshan, China Plant

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently celebrated the shipment of its 1000th press felt from its new state-of-the-art machine clothing plant located in Kunshan, China.

This world-class press felt plant was designed and built to exacting best-practice standards over a 3 year period by a team of industry veterans from Europe, North America and China. It is the newest press felt plant in the world and shipped its first press felt in Q3 2015.

Xerium is now routinely producing its press felt solutions locally for customers in China and the Asia-Pacific region. The company is proud to announce that the 1000th press felt was produced for Jiangsu Bohui Paper Machine 1. The Kunshan, China plant is equipped to serve the largest and most complicated pulp, paper, paperboard, and tissue machines in the world.

Kunshan produces leading products known as Flomaxx, Strata, Huyspeed, Impact, Huyperm, and Huystar. These premium products are known for exceptional performance in the tissue, paperboard, paper, and fiber cement industries and help manufacturers make higher quality products, with reduced operating costs, and longer product lives.

Xerium’s Kunshan plant is located in the heart of the Yangtze River paper-making region of China, at the very center of the largest papermaking region in the world. Prior to the Kunshan plant, Xerium served this region of the world mainly as an exporter of products made in Europe. Xerium has significantly increased its competitive position with this plant and is now closely partnering with customers in China and the rest of Asia. Xerium has a multi-year plan to continue expanding the scope of machine clothing production in Kunshan. It is underway right now with an expansion to make forming fabrics in Kunshan.

“We are delighted to celebrate this important milestone for the Kunshan plant. We have the right processes and a strong Six Sigma certified team. We are proud that our customers are having great success when they use these high-performance press felts on their machines. We use the latest designs, best materials, and most modern manufacturing processes in the world,” said Mr. Harold Bevis, President and Chief Executive Officer of Xerium. “Customers have really embraced Kunshan as a new local source of high-value press felts. They now depend on us every day to help them achieve their goals.”

About Xerium (NYSE:XRM)

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 30 manufacturing facilities in 13 countries, approximately 500 patents, and approximately 3,000 employees.