Ianadmin

Valmet to supply a defibrator system to Action Group in India

Valmet will deliver a new defibrator system to Action Group, in India. The defibrator is an essential part of Action Group's new fiberboard line being built, and it will produce 28 tons per hour bd (bone dry) fiber. The start-up of the system is scheduled to be in September 2017.

The order was included in Valmet's second quarter 2016 orders received. An order with this scope of supply is usually valued in the range EUR 1.5-5 million.

"We have compared the different refiner alternatives available in the market and found that Valmet's defibrator is the most suitable choice for our line," says Mr. Vivek Jain, Director at Action Group.

"The defibrator to be delivered is specially designed for production levels up to 32 tons per hour, which is perfect in this case. The customer has two existing fiberboard production lines, and this is the first defibrator system from Valmet. The fiberboard market is growing in India, and Action Group is the second customer during 2016 that has chosen Valmet as preferred supplier," says Leif Sundberg, Sales Manager at Valmet.

Valmet's defibrator system

The delivery to Action Group includes a Valmet EVO-56 Defibrator system. The defibrator system is an essential part in a fiberboard line. Valmet's defibrators are known for their reliability and provide high-quality, homogenous fiber material. The material from Valmet's system has a minimum of shives and low fines content, which is a prerequisite for successful fiberboard production.

About the customer Action Group

The Action Group is a 44 year old conglomerate with a leading presence in the footwear, steel & power, chemicals, real estate, health care and electronics industries in India. The company's headquarter is located in Udyog Nagar, New Dehli, in India. Action. Action Tesa, part of the Action Group, is one of the largest companies in fiberboard business in India and their products are mainly used for floors, door skins and furniture.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

All aboard! Next stop: the future!

PCMC (Paper Converting Machine Company Italia S.p.A.), international leader in the design and manufacture of paper converting machines headquartered in Diecimo (Lucca) and part of the US multinational Barry-Wehmiller, is inaugurating its new facilities in Fornaci di Barga.

The business activities of a company with a history that began back in 1919, when PCMC - today strong of a turnover that exceeds 50 million euro - culminates today in this new production site, symbol of innovation and of the company’s potential for growth in the future. The premises will allow check-outs of 4 converting lines simultaneously, for a production capacity of 36 lines per year, together with a space for the administration, production and sales departments. And the official inauguration of the new plant is scheduled for Wednesday, October 12th with a very special event that merges the tradition of the the past with the technology of the future. An event dedicated to the about 1000 people working in the company and their families, customers, guests coming from the world over, with a special focus on the young generations part of the PCMC family. Almost 100 years of history keeping not profits, not the product, but people and their talents at the center of everything.

Spurred by the corporate motto “People Care Moves our Company”, the event is centered on the talents protagonists of PCMC’s development throughout the years.

Together with the ribbon cutting ceremony, another inauguration will take place: the street dedicated to William Austin Chapman, founder of Barry-Wehmiller, which will bear his name.

And to celebrate the event and mark the company’s roots in tradition, participants will be taken to Fornaci di Barga on a steam train! A time machine that, like the history of PCMC, goes back a long way and is headed straight into the future.

About PCMC

Paper Converting Machine Company (PCMC) has been specializing for over 90 years in the design and manufacture of converting machinery for the tissue, nonwovens and flexographic printing industries. Its tissue converting product line includes laminating, printing, embossing, perforating and packaging equipment to produce multi-ply bathroom tissue and household towels, table napkins, and away-from-home rolled products. The nonwovens converting line produces a variety of consumer products, including wet wipe disposable cloths.

In addition, the company is a major manufacturer of multi-substrate flexographic presses, providing numerous printing options for the flexible packaging industry. The offer includes also machine rebuild and upgrade packages to improve the performance of existing equipment. PCMC is headquartered in Green Bay, Wi (USA), while its operations for Europe, Asia and Latin America are coordinated by PCMC Italia Spa, which is headquartered in Lucca, Tuscany - the veritable heart of the global Tissue business. PCMC is part of Barry-Wehmiller Companies, Inc., based in St. Louis (Missouri), a world-leading supplier of packaging, corrugating, and paper converting technology, as well as engineering consulting services across a broad spectrum of industries, employing more than five thousand associates around the globe.

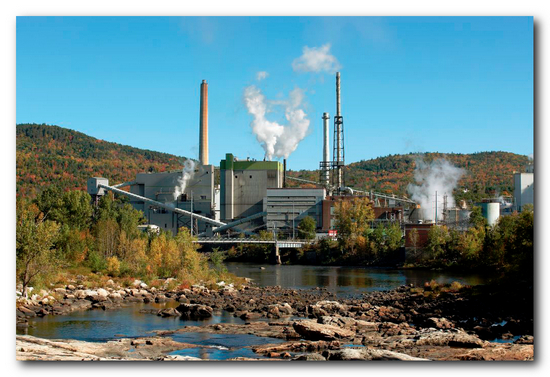

Valmet's advanced boiler control application for optimized combustion successfully commissioned at Catalyst Paper's Rumford Mill in Maine, USA

Valmet's advanced boiler control application for optimized combustion has been successfully commissioned at Catalyst Paper's Rumford Mill in Maine, USA. The new combustion management application optimizes the performance of the paper mill's fluidized bed boiler units 6 and 7.

"Valmet's experts have been able to provide us with a cost effective solution that has demonstrated concrete improvements in overall boiler control and have helped us to obtain considerable reduction in process variation," says Scott Alley, Utilities General Superintendent, Rumford Mill, Catalyst Paper.

Catalyst Paper's Rumfort Mill

The application has been integrated into the mill's existing automation system. It enables the mill to improve boiler steam output control and optimize limestone use, steam output variability and grid temperature variability. Additionally, it's now possible to operate both boiler units in fully automatic control for varying compositions of coal and biofuel. The application also provides the tools to improve operational uniformity across shifts.

"Valmet DNA FBB Combustion Manager is a powerful tool to control combustion variables simultaneously," says David Eapen, Performance Improvement Engineer, Automation, Valmet.

Valmet's delivery included a complete Valmet DNA FBB Combustion Manager application, engineering, boiler base control logic enhancements, commissioning, tuning and training. Valmet also provided a Valmet DNA Fuel Power Compensator application that compensates for disturbances caused by fuel quality and amount variations by regulating fuel feeding respectively.

"The project to implement Valmet's advanced boiler controls at the Rumford Mill was a big success. From initial control logic design, to hardware and software commissioning, to operator training, Valmet performed as promised," says Steve Day, Process Control Engineer and Project Manager, Rumford Mill, Catalyst Paper.

Technical information about Valmet's solution

Valmet DNA FBB Combustion Manageris an advanced control application for the optimized combustion of both bubbling and circulating fluidized bed boilers. The purpose of the application is to protect the combustion process against variations in production, fuel amount, fuel quality and combustion circumstances. As a result, DNA FBB Combustion Manager provides several environmental, operational and financial benefits, including a stabilized combustion process, increased boiler efficiency, a wider boiler operation range, minimized flue gas oxygen content as well as minimized NOx and CO emissions.

Valmet DNA Fuel Power Compensator is based on the estimation of fuel power input to the boiler. No additional sensors or transmitters are needed. The application calculates the fuel power online and compensates it by regulating the fuel flow accordingly. Valmet DNA Fuel Power Compensator is especially applicable for combusting multiple fuels with different fuel-specific heat values. A combustion process with changing solid fuel mixtures or a single fuel with varying dryness can also benefits from the application.

The solution is part of Valmet's Industrial Internet offering that makes the customer's processes more efficient.

Information about the customer Catalyst Paper

Catalyst Paper manufactures diverse printing papers and market pulp. Its customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has an annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

First Advantage NTT tissue production line in USA successfully started up at von Drehle Corporation's Natchez mill in USA

The von Drehle Corporation is the first tissue maker in the USA to produce tissue with Valmet's innovative Advantage NTT technology. The new line was started up at the company's mill in Natchez, Mississippi, USA.

This is Valmet's third tissue machine delivery to von Drehle. Since earlier von Drehle operates two Advantage DCT tissue lines in the Cordova mill, North Carolina in the USA. The Advantage NTT technology is designed for maximum production flexibility, energy efficiency as well as enhanced product quality.

"We are very pleased with the equipment and systems as well as the support provided by Valmet to us and our contractors, both in the past and continuing", says Joe Pankratz, Vice President of Manufacturing, von Drehle Corporation.

"We are delighted to announce our first Advantage NTT start up in USA. This is the fourth successful NTT start-up since the first machine start-up in 2013. We want to thank von Drehle for the good cooperation and team effort to make this project a success and a benchmark in the industry. This high capacity NTT installation will provide von Drehle with excellent flexibility and capability for a wide product quality range in its operations for years to come," says Soren Eriksson, Sales Director, Tissue Mills Business Unit, Valmet.

Technical information

The new tissue machine has a width of 2.6 m and a design speed of 2,000 m/min in plain mode and 1,800 m/min in textured mode. The raw material for the new line is recycled fiber and the production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of delivery comprised a complete tissue production line including an Advantage NTT 100HS tissue machine. The tissue machine is equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It also features the Advantage tissue technology including, an AirCap hood and a SoftReel L reel. Furthermore, the delivery included an automation package with process control system. Valmet was also responsible for installation supervision, training and commissioning as well as product development support.

About the customer von Drehle Corporation

The von Drehle Corporation, established in 1974, is based in Hickory North Carolina, USA and currently operates tissue mills in Cordova, Maiden, Memphis and Las Vegas. The company provides quality towel, tissue and dispenser products for the Away From Home market in North America.

For further information, please contact:

Tom Morse, Mill Sales Manager Valmet Tissue North America, +1 225 772 4991

Soren Eriksson, Account Sales Manager Valmet Tissue North America +1 404 242 8845

Jan Eriksson, Vice President Sales Valmet Tissue Mills Business Unit, tel. +46 705 17 14 90

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply an extensive board machine rebuild for Arkhangelsk in Russia

Valmet will supply an extensive board machine and automation rebuild for Arkhangelsk Pulp & Paper Mill (PPM) in Russia. The project for the board machine 2 (BM 2) is a continuation to the pre-engineering project executed by Valmet earlier this year.

The order is included in Valmet's thirdquarter of 2016 orders received. The value of the order will not be disclosed. The value of an order of this type is typically valued around EUR 50-60 million. The rebuild is a part of Arkhangelsk's investment project "Reconstruction of board department" with total value of 8.8 billion rubles (about EUR 125 million).

Arkhangelsk Pulp & Paper Mill in Novodvinsk, Russia

The delivery will include a new Valmet OptiConcept M board machine wet end, a number of improvements to the drying section, a completely new dry end and a machine control system upgrade. Target of the rebuild is to increase production by 30%. The start-up of the rebuilt machine is scheduled for the second half of 2018.

"Valmet's OptiConcept M board making linefocuses on low operating costs combined with energy-efficient and flexible production of high-quality board grades. We have a number of excellent references verifying the targeted outcome. Furthermore, our uniquely wide scope of offering differentiates us from the competitors. The project continues our good cooperation with Arkhangelsk - we have earlier delivered several pulp and paper technologies to them, latest being the pulp mill upgrade and two modern refiner lines," says Vesa Simola, EMEA Area President of Valmet.

Technical details of the delivery

Valmet's extensive board machine and automation delivery for the rebuild includes pulpers for broke collection, equipment for approach flow systems for top and back plies, two OptiFlo Fourdrinier headboxes, OptiFormer Multi forming section, OptiPress Linear press section, a start-up package of paper machine clothing, dryer section rebuild, OptiCalender Compactcalender, OptiReel reel, automatic transfer rails,OptiWin Drum two-drum compact winder and related air systems. The automation upgrade comprises Valmet IQ quality measurement system, Valmet DNA process control system and a moisturizer. The delivery will also include a semi-automatic reels spool return system and a roll conveying system.

"The customer valued the fact that there is no need for cantilevering beams with OptiConcept M and that there are only minor changes required for the foundations. Space requirement will also be smaller compared to the traditional wet end concepts. The 'plug and play' feature of OptiCalender Compact wasalso appreciated by the customer," comments Senior Sales Manager Pekka Turtinen from Valmet.

The 7,000 mm wide (wire) BM2 produces fluting and kraftliner grades with a basis weight range of 90 - 200 g/m2. The design speed for the new parts is 1,000 m/min. The annual production will be about 330,000 tonnes.

Information about the customer Arkhangelsk PPM

Arkhangelsk PPM (APPM) is one of the leading pulp and paper mills in Russia and Eastern Europe focusing on pulp, board and paper production. Austrian Pulp Mill Holding GmbH is the owner of the mill. Pulp production of the mill is 850.000 tons and corrugated board production 500.000 tons.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Toscotec’s new technological facility for large-diameter Steel Yankee Dryers opens its doors.

Toscotec pursues its investment strategy in order to enhance its strength in the tissue and paper industry. Inspired by its trust in innovation and a custom-oriented spirit, the company - pioneer and world leader in the Steel Yankee Dryer market - opens the new facility dedicated to the complete production cycle of TT SYDs.

The architectural heart of the facility is the central hall that houses all the stages of the production line: 180m long, 40m wide overall and up to 18m high. From metalworking and precision mechanical processing to thermal treatment in a 10m x 10m oven, all the tests and stamps are made on site according to European (PED), American (ASME), Chinese (CSEI) and Japanese (JIS) regulations. The new center also houses technical and production offices, as well as a conference room and lounge for customers.

The facility is located in Massa, 50 km from Lucca, a location chosen for its easy seaport access for quick overseas shipments.

The new center marks a breakthrough in Steel Yankee Dryer manufacturing and has a clear aim: to increase efficiency and ensure the best product worldwide, allowing Toscotec to further enhance its leadership role in technological innovation.

Customer visits will be organized during MIAC 2016 . For more information, please write to: This email address is being protected from spambots. You need JavaScript enabled to view it.

AMETEK LAND releases gas analyser for gas oil, utilities, cement, glass, paper, refineries, pipelines

AMETEK Land, the leading industrial combustion efficiency and environmental pollution emissions monitoring specialist, announces a number of enhancements to its Lancom 4 Portable Gas Analyser to improve usability and provide attractive features as standard.

Now available as a free download, Lancom 4’s innovative data acquisition software, Insight, is a powerful tool that allows users to interface their analyser with a PC for remote control and data logging. Insight offers graphing and analysis tools for data visualisation and reporting purposes, providing even easier access to data. Communications between Insight and the user’s PC requires a USB-RS232 interface converter, which is now supplied with every Lancom 4 for quick and easy set up.

In addition, Lancom 4 now includes Wake and Sleep functions, allowing measurements and data logs to be recorded over an extended period, and a rugged Carry Case, ensuring that the instrument is protected at all times when in use. All are now supplied as standard at no extra charge.

Upgrading to Lancom 4 also has been made much easier. Hardware items, such as external printers or analogue output modules, can be simply plugged in, with no firmware configuration needed. This means that these items can be fitted in the field, avoiding the need to return the instrument to the factory.

Derek Stuart, Global CE Product Manager for AMETEK Land, said: “We are continually innovating within our ranges to ensure that we can deliver the most advanced features and software to our customers. Our aim is to provide even greater access to the most-accurate information to make gas data analysis as comprehensive as possible.”

Lancom 4 is renowned as the world’s most versatile and accurate portable flue gas analyser for checking or testing a boiler system or pollutant process. It has the capability to monitor up to 9 different gases, a total of 17 measurement parameters with one instrument as well as the ability to data log up to 250,000 records.

Widely used across industries including gas CHP (Combined Heat and Power) plants, utilities, cement kilns, glass, paper mills, pipelines and refineries, the Lancom 4 is known for its convenience and ease of use. The user simply switches on the analyser, allows it to complete an automatic zero calibration, and it is ready for use.

Lancom 4 has fully built-in data capture and storage of measurement data, plus a USB connection to download the data to a PC, along with free-to-download Insight data acquisition and analysis software for on-site record keeping, analysis and reporting.

Extremely compact and portable, the Lancom 4 weighs only 6 kg / 15 lb and can easily be carried around a plant, even allowing trouble-free access to remote locations via ladders or gantry work. It is also highly robust and ideal for daily use in harsh industrial environments.

For further information on the Lancom 4 visit https://www.landinst.com/products/lancom-4-portable-gas-analyser and for additional information on the Insight software package, visit https://www.landinst.com/products/insight-data-acquisition-analysis-software

AMETEK Land (www.landinst.com) is a business unit of AMETEK, Inc. a leading global manufacturer of electronic instruments and electromechanical devices. AMETEK Land designs and manufactures a wide range of instruments for industrial non-contact temperature measurement, combustion efficiency and environmental monitoring.

Södra’s pulp mill in Värö now among the largest in the world

The equipment is in place and production has now commenced. Södra’s new pulp mill in Värö was officially inaugurated on Friday 30 September. "We are delighted to announce that production is under way. Our focus in the immediate future will be on ramping up the production rate," said Gunilla Saltin, Business Area President of Södra Cell.

Södra is investing a total of SEK 6 billion (around half a billion USD) to expand for the future. Some SEK 4 billion has been invested in the pulp mill in Värö. The expansion is now complete and will result in an increase in pulp production capacity from today’s 425,000 tonnes to 700,000 tonnes annually. The mill will thereby become one of the world’s largest, most modern and energy-efficient mills for the production of softwood sulphate pulp.

"The expansion is an important part of our strategy and a necessary move if we are to develop our operations. The paper pulp market is growing globally, and we will now have the opportunity to meet this demand and to continue growing together with our customers. We already deliver high-quality pulp to several different customer segments, which we will now be able to develop even further. This expansion will allow us to further strengthen our market-leading position and remain our customers’ preferred supplier," said Lars Idermark, President and CEO of Södra.

Additional services in the forest industry

The investment in Värö is part of Södra’s Group strategy. The expansion is a prerequisite for generating long-term value for Södra’s members and for its pulp customers in the global market.

"The forests owned by Södra’s members provide the company with a stable, sustainable source of fibre which Södra intends to develop to the full to keep pace with customers’ increasing demands. In the short term, the focus is on making sure the startup tonnage is brought up to premium quality as smoothly and quickly as possible," said Gunilla Saltin, Business Area President of Södra Cell.

Södra was founded in 1938 and is the largest forest-owner association in Sweden, with a membership of more than 50,000 forest owners. We engage in modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. Through value-generating relationships and a long-term approach, Södra is leading the way for the next generation of forestry.

Valmet to supply a rewinder to Roto-cart in Italy

The Italian tissue converting company Roto-cart Spa has selected Valmet as supplier for their new rewinder to be installed at the greenfield converting plant in Castelminio di Resana in Italy. The new site will be one of the biggest in the country.

The order was included in Valmet's second quarter 2016, orders received. The new Focus Reelite 20 ENS rewinder is planned to be in operation during the first quarter of 2017.

"Our target is to always invest in cutting-edge technology to be able to fulfill our customers' and consumers' requirements. Roto-cart has served this business for 35 years and we immediately recognized the Focus electromechanical rewinder's ability to provide outstanding paper properties preservation," says Giuliano Gelain, CEO of Roto-cart Spa.

"The Valmet Focus with offline printers has a long record of successful installations and we are excited to be part of Roto-cart's expansion plans and support their production of excellent tissue products," says Massimiliano Corsini, Vice President, Rewinder Technology, Valmet.

Valmet Focus Rewinder

Technical information

The new installation includes a Valmet Focus Reelite 20 ENS Rewinder with two unwind stands. The machine is pre-disposed for the installation of an offset printer. The offset printer can be by-passed. In by-pass mode the rewinder has a design speed of 1,800 m/minute depending on the paper characteristics and winding spool diameter. With the offset printer in operation the design speed is 900 m/min. Installation supervision services are included in the scope of supply.

Information about the customer Roto-cart

Roto-cart is an integrated tissue company with two converting units and one paper mill and thirty five years of experience. Their products are present in the Italian and European markets under their own and private label brands. Thanks to high technological avant-garde lines and the certifications of business quality FSC and ISO 9001, Roto-cart has chosen to specialize in the "premium quality" range of products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Baldwin brings new Flexo portfolio of optimized LED UV, IR-drying and automatic cleaning systems to US market

Baldwin will showcase its new portfolio of optimized LED UV curing, IR-drying and automatic cleaning systems, specifically designed for the US Flexo industry, at SuperCorr in Orlando, October 17th - 20th. With 40 years of experience and many thousands of systems installed worldwide, Baldwin is considered a leading global supplier of process automation equipment.

Baldwin’s Flexo portfolio offers these systems that can be installed separately or as a complete system:

Baldwin’s Flexo portfolio offers these systems that can be installed separately or as a complete system:

LED curing uses 50% less power

The UVed LED UV technology represents the latest in solid state LED curing technology and offers over 50% reduction in power consumption in an ultra-compact UV lamphead. Lightweight, it is designed for the requirements of corrugated LED printing with instant ON/OFF, minimal heat, zero ozone and width switching.

Optimized IR-drying enhances color definition

The FlexoDry2 dryer is specifically developed for corrugated Flexo printing presses, reducing energy consumption by up to 30% over traditional IR dryers, with the use of patented Diamond IR lamps. The dramatically-improved drying capability enhances color definition and reduces or eliminates marking, while allowing full-speed printing. The system offers an integrated hot air knife with temperature control, which provides better surface drying. The FlexoDry2 comes with an integrated light curtain as standard and an optional Camera Vision System. Multiple light beams increase lamp head coverage and improve safety through the use of linear transmitters.

Automated cleaning enhances print quality and improves worker safety

The Flexo Cleaner Brush enhances print quality by removing hickies and/or cleaning and drying the printing plates within three to four minutes, offering more uptime which leads to higher press output and a cleaner environment. Hickey picker cleaning removes fibers, debris and fine layers of ink. No manual cleaning or skin contact with wash agents reduce work related injuries. Plate cleaning is completed without de-coupling the press, improving operator safety. The Flexo Cleaner Brush system is designed to completely eliminate substrate fiber accumulation, to avoid negative impact on the print image quality.

The Flexo Clean Pick system consists of a traversing cloth wash head that picks up hickies and fibers from the Flexo plates during printing. Different cleaning modes available are spot cleaning, constant cleaning or intensive cleaning. No manual cleaning or skin contact with wash agents reduce work-related injuries. With a dry cloth, the system lightly touches the plate and removes hickies without the need to stop the press, enhancing quality and productivity without creating waste. With a wetted cloth, the system can perform an even deeper cleaning of the plates if required.

“We are excited to offer our new, advanced Flexo printing portfolio to the US Flexo market. The feedback from our European customers has been overwhelming as our products continue to improve their production performance and print quality, unlocking new potential for their business,” said Peter Hultberg, Baldwin Chief Commercial Officer.

“The entire Baldwin equipment project on my new corrugated Flexo press was executed without any issues and the performance has exceeded my expectations, particularly with respect to energy consumption,” commented Niall Diamond, Production Manager at Diamond Corrugated, who purchased the complete Flexo system in 2016 to enhance production.

About Baldwin Technology, Inc.

Baldwin Technology Company, Inc. is a leading global supplier of process automation equipment and related consumables for the printing, packaging and other industrial segments, e.g. technical textiles, chip and fiberboard, film extrusion and many more. Baldwin offers its customers a broad range of market-leading technologies, products and systems that enhance the quality of industrial produced products with focus on improving the economic and environmental efficiency of the production process. Baldwin is headquartered in St. Louis, Missouri. With 600 team members, the company has operations strategically located in 9 countries, on 14 sites, all around the globe to support product distribution, global sales and service infrastructure. For more information, visit www.baldwintech.com.