Ianadmin

UPM Shotton Paper Mill achieves five year milestone without Lost Time Accident

UPM Shotton, based on Deeside, North Wales, has achieved a new landmark in UPM safety performance. The last recorded Lost Time Accident (LTA) suffered by a UPM employee on site was on 5th July 2011, giving the mill five years of LTA-free operation.

Shotton, a producer of 100% recycled newsprint is the first UPM manufacturing unit, globally, to reach this milestone. The parent company UPM-Kymmene launched its ‘Safety First’ campaign in 2011 with the aim of raising awareness of the responsibility for all. UPM Shotton employees make more than 4000 safety observations per year in their drive improve and weekly Safety ‘Talks’ are held for the whole workforce as well as visitors and contractors on site.

Mr David Ingham with Rhys Jones, Safety Representative, Unite

David Ingham, General Manager at UPM Shotton commented: “Sustaining this high level of safety performance is a world class achievement by UPM Shotton’s employees. We have continuously focused our time and energy to keeping everyone safe at Shotton.”

He added: This success is built on a sound foundation of management commitment to safety and employees’ commitment to keeping each other safe.I am personally proud of your achievement.”

The production facility employs around 200 persons and operates a paper machine, materials recovery facility and a biomass combined heat power plant on its site in North Wales.

UPM Shotton is part of UPM Paper ENA which is a member of the UPM-Kymmene Corporation. The paper mill produces 100% recycled newsprint from recovered newspapers and magazine from the UK domestic recycling supply chain. The mill started operations in 1985 and has a single paper production line, a renewable power plant and a £17m materials recovery facility. It employs approximately 200 persons.

UPM Paper - UPM is the world's leading producer of graphic papers and a supplier of a wide product range that includes magazine, newsprint, fine and speciality papers. UPM believes in the future of print and its effective coexistence with digital media.

UPM’s paper business consists of two distinct business areas located at the centre of their market: UPM Paper ENA (Europe & North America) and UPM Paper Asia. Together these two businesses employ around 11 000 papermakers - www.upmpaper.com

Mohawk Announces Organizational Changes and Promotions

Mohawk, North America’s largest privately-owned manufacturer of fine papers, envelopes and specialty substrates for commercial and digital printing, is pleased to announce the following organizational changes and promotions.

Mohawk, North America’s largest privately-owned manufacturer of fine papers, envelopes and specialty substrates for commercial and digital printing, is pleased to announce the following organizational changes and promotions.

Ted O’Connor has been named Senior Vice President and General Manager, Mohawk Envelope and Converting. In this new role, Ted leads Mohawk’s sales and marketing efforts for envelopes, while working closely with manufacturing and supply chain teams to enhance Mohawk’s rapidly growing envelope and converting businesses. Previously, Ted served as Senior Vice President, Sales, responsible for sales of fine paper across North America.

Melissa Stevens has been promoted to Senior Vice President, Sales for Premium Paper. In this new role, Melissa will leverage her expertise in sales process management to drive sales and business development efforts for Mohawk’s core premium paper business across North America. Previously, Melissa served as Vice President, Sales.

Beth Reardon has been promoted to Sales Director, East, overseeing business development efforts and field sales activities in the Midwest, Mid Atlantic and Northeast Regions of the U.S.

Nancy Dutch has been promoted to Sales Director, West, overseeing business development efforts and field sales activities in the West and South Central regions of the U.S.

Becky Thomas has been promoted to National Accounts Manager, New England, overseeing business development efforts for Mohawk’s core paper, social stationery and packaging businesses.

ABOUT MOHAWK

Mohawk is North America’s largest privately-owned manufacturer of fine papers and envelopes which are preferred for commercial and digital printing, photo specialties, packaging and high-end direct mail.

Mohawk fine papers and envelopes include the signature brands Mohawk Superfine® and Strathmore®, as well as proprietary treatments Inxwell® and i-Tone®. With a culture of innovation, Mohawk’s business model now extends beyond paper manufacturing into new areas of growth, including specialty digital substrates and wide format ink jet materials. Mohawk remains committed to an 85 year heritage of bringing the most innovative and beautiful materials to the design and print communities.

As a leader in environmentally and socially responsible business practices, Mohawk was the first U.S. manufacturer of commercial printing papers to match 100% of its electricity with wind power renewable energy credits and the first U.S. premium paper mill to shift toward carbon neutral production. Many products within Mohawk’s portfolio of recycled papers are certified by Green Seal and the Forest Stewardship Council (FSC).

Mohawk is a fourth-generation, family-owned and operated business based in Cohoes, New York, with global sales and operations located throughout North America, Europe and Asia. For more information, please visit www.mohawkconnects.com.

Fibria in Fortune’s list of companies that are helping to change the world

Fibria, a Brazilian forestry company and the world's leading eucalyptus pulp producer, was recognized by American magazine Fortune (of the Time Inc. group) as one of the companies that are helping to create a better world. The magazine prepares the annual list “Change The World”, which ranks 50 companies from around the world that most create positive social impacts through their strategies, operations and innovations. Fibria is the only pulp and paper company to be included in this year’s ranking.

“Fibria understands that healthy business growth depends not just on economic and financial aspects but also on social and environmental aspects. We believe in shared value and having our principle recognized by entities with global credibility is reason for celebration,” said Marcelo Castelli, CEO at Fibria.

“Fibria understands that healthy business growth depends not just on economic and financial aspects but also on social and environmental aspects. We believe in shared value and having our principle recognized by entities with global credibility is reason for celebration,” said Marcelo Castelli, CEO at Fibria.

Among the 50 companies that are helping to change the world, Fibria ranked 14th. According to Fortune, one of the highlights at Fibria is the Forest Savings program, which completed 25 years of activities last year. The project includes rural producers in the forestry business through a partnership with the company, which helps in the creation of forests by providing seedlings, technical assistance and the necessary inputs for cultivation, while the producers are responsible for managing the forests.

“We are glad to see a program of such importance for Fibria as a reference in the Fortune list. By including local producers in the company’s supply chain, Fibria generates shared value, combining the company’s success with the prosperity of local communities,” said Maria Luiza de Oliveira Pinto e Paiva, the Sustainability, Corporate Relations and Communications Officer at Fibria.

Currently, 1,685 producers from 164 cities in the states of Espírito Santo, Bahia, Minas Gerais and São Paulo participate in the program, which covers a total area of 67,000 hectares. Around 30% of the wood supplied to the Fibria unit in Espírito Santo comes from local producers participating in the Forest Savings program.

Fortune’s “Change The World” list recognizes companies with revenues of over US$1 billion that made a positive social impact through activities that are part of their business strategy. Nominations are made by executives, academics and NGOs, which are followed by a detailed assessment by the magazine in partnership with FSG, a nonprofit consulting firm, Shared Value Initiative, a global platform that seeks business solutions for social challenges, and Professor Michael E. Porter from the Harvard Business School.

Assessment of the companies takes into consideration the measurable social impact, business results and the level of innovation.

The complete list is available at http://for.tn/2bhiwAg #ChangeTheWorld

Ulf Larsson appointed Executive Vice President of SCA

Effective immediately, SCA’s Board of Directors has appointed Ulf Larsson, current President of SCA Forest Products and a member of the Executive Management Team, Executive Vice President of SCA. This is in addition to his current assignments.

Ulf Larsson started at SCA in 1992. Ulf has a BSc Forestry, Swedish University of Agricultural Sciences, Umeå, Sweden. He has held several leading positions within SCA Forest Products.

Ulf Larsson started at SCA in 1992. Ulf has a BSc Forestry, Swedish University of Agricultural Sciences, Umeå, Sweden. He has held several leading positions within SCA Forest Products.

NB: This information is information that SCA is obliged to make public pursuant to the EU Market Abuse Regulation or the Securities Markets Act. The information was submitted for publication, through the agency of the contact person set out below, at 07:30 CET on August 24, 2016.

Karl Stoltz, Media Relations Manager, +46 8 788 51 55

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo, Vinda and Zewa. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2015 amounted to approximately SEK 115bn (EUR 12.3bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Voith Receives Further Order from Lee & Man for Two Tissue Machines

Voith signed a contract in June 2016 with Lee & Man Paper Manufacturing Limited to provide it with two tissue machines in Dongguan. The move is not only a continuation of the previous successful cooperation between Lee & Man and Voith, but also a consolidation of Voith's strong position in the global tissue machine market.

![]() The location for the TM11 and TM12 is in Dongguan, China. The start-up of these two tissue machines is expected to take place respectively in September and July of 2017. Lee & Man ordered its TM3, TM9 and TM10 machines from Voith, and the start-up of TM9 and TM10 will take place respectively in March and May of 2017. From March through to September in 2017, four tissue machines from Voith will start up in a row in Lee & Man’s mill, at the pace of one machine every other two months. This exciting scenario is built upon great customer trust, which Voith has earned over many years of high quality performance.

The location for the TM11 and TM12 is in Dongguan, China. The start-up of these two tissue machines is expected to take place respectively in September and July of 2017. Lee & Man ordered its TM3, TM9 and TM10 machines from Voith, and the start-up of TM9 and TM10 will take place respectively in March and May of 2017. From March through to September in 2017, four tissue machines from Voith will start up in a row in Lee & Man’s mill, at the pace of one machine every other two months. This exciting scenario is built upon great customer trust, which Voith has earned over many years of high quality performance.

The TM11 and TM12 machines have a working width of 5,600 mm, a design speed of 2,200 m/min and a maximum operating speed of 2,000 m/min. Each of these two tissue machines will produce 60,000 tons of household paper from virgin fiber annually. The scope of supply includes stock preparation, approach, broke handling, a white water system and the tissue machine. It features the perfect combination of a NipcoFlex T shoe press to offer remarkable energy savings, a 5.5 meter steel Yankee dryer which can enhance drying efficiency by optimizing the heat transfer and a high-performance steam hood to guarantee paper quality with a lower energy consumption. Moreover, the technically mature Voith automation package including DCS, MCS and QCS forms an integral part of the order.

Voith has always been committed to meet the requirements of the paper industry for lower energy and water consumption, less fiber usage and higher system availability. The signing of this contract has once again highlighted the strong regard for Voith’s innovative technology in the tissue paper industry.

Established in 1994, Lee & Man Paper Manufacturing Limited is one of the world’s leading paper manufacturers, mainly producing packaging paper and tissue paper with different grades and specifications. The company’s annual sales volume in 2015 was up to 525 million tons. The company currently has five factories in China, with a total of 6,500 employees.

About Voith Paper

Voith Paper is a Group Division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Verso Introduces Liberty® Coated Paper Promotion "Life, Liberty® and the Pursuit of Great Paper"

Promotion Features Liberty® Line's Aesthetics, Breadth and Flexibility for Commercial Printing Applications

Verso Corporation (NYSE: VRS), a leading producer of coated papers, has just introduced Life, Liberty® and the Pursuit of Great Paper, a new promotion for its Liberty® coated web paper line.

Liberty® is a No. 4 coated web paper that offers the widest range of basis weights in its class, from 38 lb. to 70 lb., and three finishes – gloss, dull and matte. It is designed to perform on web offset or rotogravure printing presses and is best suited for printing applications including publication covers, catalogs, magazines and retail inserts.

Liberty® is a No. 4 coated web paper that offers the widest range of basis weights in its class, from 38 lb. to 70 lb., and three finishes – gloss, dull and matte. It is designed to perform on web offset or rotogravure printing presses and is best suited for printing applications including publication covers, catalogs, magazines and retail inserts.

"Liberty® is a clean, white sheet that delivers just the right amount of contrast, making images and details really stand out," said Verso Brand Manager Tim Nordin. "Exceptional whiteness with great print gloss reproduces images with crisp aesthetics, excellent definition and print snap. The Life, Liberty® and the Pursuit of Great Paper promotion showcases these features through a variety of print demonstrations on Liberty® gloss, dull and matte. It also includes unprinted sample sheets of various basis weights and finishes as well as product features and specifications."

Verso Senior Vice President of Sales, Marketing and Product Development Mike Weinhold adds, "Liberty® has a long track record of excellent, consistent on-press performance with commercial and publication printers. Verso has a high degree of manufacturing system flexibility with multiple paper machines at mills located in the Midwestern and Eastern United States. This means we are able to make Liberty® on multiple machines resulting in better lead times, greater availability and faster deliveries."

To learn more about Verso's Liberty® product line, visit versoco.com.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. The FSC® trademark license code for Verso Corporation is FSC® C014984. For more information, visit us online at versoco.com.

Little Rapids Corporation Awards Voith to Supply New Tissue Machine for its Plant in Wisconsin (USA)

American specialty paper manufacturer Little Rapids Corporation has signed a contract with Voith Brazil to purchase a new tissue paper machine. This new machine will replace the existing PM3, located in Shawano, Wisconsin (USA).

![]() Besides significant improvement of paper quality, the new machine will produce 119 metric tons per day at a speed of 1,830 m/min. Except for the existing Yankee dryer, which will be reused, all other machine components will be new and based on Voith's machine model VTM3.

Besides significant improvement of paper quality, the new machine will produce 119 metric tons per day at a speed of 1,830 m/min. Except for the existing Yankee dryer, which will be reused, all other machine components will be new and based on Voith's machine model VTM3.

In addition to the new tissue machine and auxiliaries, Voith's scope of supply includes: stock preparation, approach flow system, steam box, dust and mist removal systems, DCS systems and field services.

The project is scheduled to start in the third quarter of this year and the start-up is expected for the end of 2017.

About Little Rapids Corporation

Little Rapids Corporation was founded by Charles Egan in 1947 and re-mains a family-owned business. The company’s core product lines serve the medical and beauty market segments, flexographic printing for a variety of packaging markets, and tissue, MG paper, and wet crepe paper for the specialty paper market. With headquarters and manufacturing facilities in Green Bay, the company, which employs 435, also has a paper manufacturing facility in Shawano, Wisconsin. In addition, the company donates to the region via the Little Rapids Corporation - Egan Family Foundation, a private foundation established by the Egan family in 1986 with the mission to fund charities in communities where Little Rapids Corporation has facilities.

About Voith Paper

Voith Paper is a Group Division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Prestige brands such as IBM take Paperworld China as an ideal platform to launch new products in China

Creative Pavilion inspires creativity

Running from 20 – 22 September, Paperworld China 2016 will gather famous brands to display and launch new products. The fair will showcase a wide range of products including stationery, office supplies, school & artist items and gifts. Prominent brands such as Dokumental, Online, Pilot, Senator and Zebra for writing instruments, Lyra, Nicker, Pebeo, Simbalion and Superstrong for artist supplies, as well as Easymate and Foldermate for organisation aids will attend Paperworld China. Among the exhibitors, visitors can also find iBeacard, IBM, Robotcheers and TPPS for office supplies, as well as Handscript, Kiky, Languo, Paperblanks and Uzhi for paper products and school products.

Running from 20 – 22 September, Paperworld China 2016 will gather famous brands to display and launch new products. The fair will showcase a wide range of products including stationery, office supplies, school & artist items and gifts. Prominent brands such as Dokumental, Online, Pilot, Senator and Zebra for writing instruments, Lyra, Nicker, Pebeo, Simbalion and Superstrong for artist supplies, as well as Easymate and Foldermate for organisation aids will attend Paperworld China. Among the exhibitors, visitors can also find iBeacard, IBM, Robotcheers and TPPS for office supplies, as well as Handscript, Kiky, Languo, Paperblanks and Uzhi for paper products and school products.

IBM, the world renowned brand for computer related hardware, is launching its toner cartridges in the Chinese market for the first time and using the fair to do so. At Paperworld China 2016, the company is expecting to meet business partners to launch its toner cartridges for HP laser printers in China. This imported product meets EU eco standards, and can offer high quality printing.

Robotcheers will also use Paperworld China as a platform to introduce their commercial-use robot, which is able to communicate with humans and can move around independently. The company is targeting to become an important intelligent robot developer, and is expecting its product to be widely used as a receptionist in commercial buildings, shopping malls, exhibitions, hotels as well as restaurants.

Creative Pavilion inspires creativity

Creative Pavilion is one of the special zones in Paperworld China 2016. The zone is dedicated to hobby and handicraft materials and tools. Targeting buyers from dealers, department stores, retailers and bookshops, important brands such as Brother, Hirakata, Kidstoyo and Rosie’s Studio will present creative ideas at the fair in this pavilion.

Pébéo, a French paint brand that has high standards on product safety and quality, is returning to the Creative Pavilion this year. At Paperworld China 2016, Pébéo will present the company’s new series “Mixedmedia”. This new drawing concept encourages artists to use two or more diverse painting materials and media to create an art piece. Tools and techniques for “Mixedmedia” will be introduced at the show.

Seminars are also arranged for hobby & crafts related topics such as soft clay and knitting. Among the speakers are Ms City, who will offer a seminar on ball-jointed doll, as well as Ms Yu-ming Wang presenting on pressed flower on behalf of the United Pressed Flower Art Society, Taiwan.

The 12th edition of Paperworld China will be held at the Shanghai New International Expo Centre. It is expected to welcome around 400 exhibitors and brands from 12 countries and regions. The show is jointly organised by Messe Frankfurt (Shanghai) Co Ltd, the China Chamber of Commerce for I/E of Light Industrial Products & Arts-Crafts and Guangzhou Foreign Trade South China Exhibition Corp Ltd.

For more information about the show, please visit www.paperworldchina.com or email: This email address is being protected from spambots. You need JavaScript enabled to view it..

Other shows under the Paperworld brand include:

- Hong Kong International Stationery Fair 9 – 12 January 2017, Hong Kong

- Paperworld28 – 31 January 2017, Frankfurt am Main

- Paperworld Middle East & Playworld Middle East

14 – 16 March 2017, Dubai

For more details about these fairs, please visit

www.global.paperworld.messefrankfurt.com

Background information on Messe Frankfurt

Messe Frankfurt is one of the world’s leading trade fair organisers, generating around €648 million in sales and employing 2,244 people. The Messe Frankfurt Group has a global network of 30 subsidiaries and 55 international Sales Partners, allowing it to serve its customers on location in 175 countries. Messe Frankfurt events take place at approx. 50 locations around the globe. In 2015, Messe Frankfurt organised a total of 133 trade fairs, of which more than half took place outside Germany.

Comprising an area of 592,127 square metres, Messe Frankfurt’s exhibition grounds are home to 10 exhibition halls. The company also operates two congress centres. The historic Festhalle, one of the most popular venues in Germany, plays host to events of all kinds. Messe Frankfurt is publicly owned, with the City of Frankfurt holding 60 percent and the State of Hesse 40 percent.

For more information, please visit our website at: www.messefrankfurt.com

Valmet to supply a moisturizer system to Zhejiang Dongda Paper in China

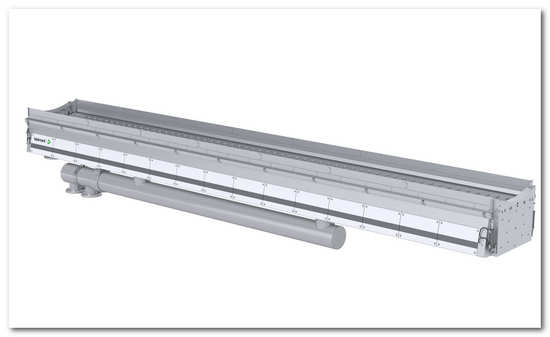

Valmet will supply a moisturizer system to Zhejiang Dongda Paper Co. Ltd. in Hangzhou, Zhejiang Province, China. The new solution, Valmet IQ Moisturizer, will enable the mill to improve board quality on its paper machine PM2.

The order is included in Valmet's second quarter 2016 orders received. The delivery will take place in September 2016.

"IQ Moisturizer is very important for our PM2. Before our decision, we visited another mill where it has been installed and were very impressed by its performance. We expect the solution to solve our current curl issue and help us to increase the machine speed to the targeted level," says Sun Guanfa, General Manager, Zhejiang Dongda Paper Co. Ltd.

"We have earlier supplied a Valmet DNA distributed control system, a Valmet IQ quality control system and a ValmetIQ Process and Quality Vision (PQV) system for Zhejiang Dongda Paper's PM2, and the mill has been very satisfied with their good performance and stable runnability. IQ Moisturizer will now provide the mill with easy and fast curl control without any other curl control measures," says Guo Zhutuan, Sales Director, Automation, Valmet.

Technical information about Valmet IQ Moisturizer

Valmet IQ Moisturizer is a moisturizing system with applications for moisture cross-direction profiling, curl control and smooth moisture level increase. It features an air atomized spray nozzle, a linear water control valve and a mist removal system.

The solution is part of the Valmet IQ product family for monitoring and optimizing process performance and end product quality.

Information about the customer Zhejiang Dongda Paper Co. Ltd

Zhejiang Dongda Paper Co. Ltd is a major producer of coated white cartonboard and paper in Zhejiang Province. The company was founded in 1999, and its annual production capacity is 400,000 tons.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Paula H.J. Cholmondeley Joins Board Of Directors Of KapStone Paper And Packaging Corporation

KapStone Paper and Packaging Corporation (NYSE: KS) ("KapStone") has just announced that the Board of Directors elected Paula H.J. Cholmondeley as a director of the company, effective August 11, 2016. Ms. Cholmondeley joins the Board of Directors as a Class B director with a term expiring at the annual meeting of stockholders in 2017. KapStone increased the number of its directors from eleven to twelve.

Ms. Cholmondeley, age 69, is the founder and chief executive officer of The Sorrel Group, LLC, a corporate governance consulting company. She currently serves as an independent trustee of Nationwide Mutual Funds and as a member of the board of directors of Terex Corporation and Bank of the Ozarks, Inc. Previously, she also was the vice president and general manager of Specialty Products at Sappi Fine Paper North America, a producer of coated wood-free paper and related products, and served seven years in various financial roles at International Paper Company. Additionally, she is a part-time faculty member of the National Association of Corporate Directors. Ms. Cholmondeley graduated from Howard University with a B.A. in Accounting and earned an M.S. in Accounting from The Wharton School at the University of Pennsylvania.

Ms. Cholmondeley, age 69, is the founder and chief executive officer of The Sorrel Group, LLC, a corporate governance consulting company. She currently serves as an independent trustee of Nationwide Mutual Funds and as a member of the board of directors of Terex Corporation and Bank of the Ozarks, Inc. Previously, she also was the vice president and general manager of Specialty Products at Sappi Fine Paper North America, a producer of coated wood-free paper and related products, and served seven years in various financial roles at International Paper Company. Additionally, she is a part-time faculty member of the National Association of Corporate Directors. Ms. Cholmondeley graduated from Howard University with a B.A. in Accounting and earned an M.S. in Accounting from The Wharton School at the University of Pennsylvania.

About KapStone

Headquartered in Northbrook, Illinois, KapStone Paper and Packaging Corporation is the fifth largest producer of containerboard and corrugated packaging products and is the largest kraft paper producer in the United States. KapStone has 4 paper mills, 22 corrugated converting facilities, 65 distribution centers, and approximately 6,300 employees.