Ianadmin

Sonoco Announces Price Increase on Recycled Paperboard in U.K.

Sonoco-Alcore S.a.r.l. has just announced it will raise prices by £40 per tonne on all recycled paperboard grades sold in the United Kingdom. The price change will be effective with shipments on or after August 15, 2016.

"This price increase is in direct response to rising raw material costs," said Phil Woolley, director, Paper Europe. "We will continue to monitor market conditions to determine if additional pricing actions will be required in other European markets."

"This price increase is in direct response to rising raw material costs," said Phil Woolley, director, Paper Europe. "We will continue to monitor market conditions to determine if additional pricing actions will be required in other European markets."

Sonoco Alcore S.a.r.l. is wholly-owned by Sonoco (NYSE:SON) and operates 29 tubes and cores plants and four paperboard mills in Europe, including the Company's uncoated recycled paperboard mill in Stainland, U.K.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. With annualized net sales of approximately $5 billion, the Company has 20,800 employees working in more than 330 operations in 34 countries, serving some of the world's best known brands in some 85 nations. Sonoco is a proud member of the 2015/2016 Dow Jones Sustainability World Index. For more information on the Company, visit our website at www.sonoco.com

This announcement is distributed by NASDAQ OMX Corporate Solutions on behalf of NASDAQ OMX Corporate Solutions clients.

The issuer of this announcement warrants that they are solely responsible for the content, accuracy and originality of the information contained therein.

Source: Sonoco Products Company

SATU Laboratory among finalists of a global Pulp & Paper innovation competition

Estonian startup company SATU Laboratory has come out with an innovative product called Gel Wipe, designed for cleaning and moisturising anal area. What makes it innovative is that you can use it with nearly any kind of toilet paper without worrying that the paper might break. In addition, it does not clog pipes or pollute the environment when deposited in the environment. Gel Wipe was designed by Estonians and chosen among the six finalists of the prestigious innovation competition called Pulp and Paper International.

Siim Saat, the CEO of SATU, says that today, many people still find it strange to use gel when wiping, but he believes that the product will find a place in the bathrooms of everyone who appreciates hygiene. “There are two major downsides to wiping with dry paper – firstly, it damages your skin, and secondly, it does not yield good results in terms of hygiene. You can also use water to clean yourself up after going to the toilet, but that is a more bothersome process and water also dries out skin. Hopefully, Gel Wipe can make a lot of people feel better and more comfortable,” added Saat.

Siim Saat, the CEO of SATU, says that today, many people still find it strange to use gel when wiping, but he believes that the product will find a place in the bathrooms of everyone who appreciates hygiene. “There are two major downsides to wiping with dry paper – firstly, it damages your skin, and secondly, it does not yield good results in terms of hygiene. You can also use water to clean yourself up after going to the toilet, but that is a more bothersome process and water also dries out skin. Hopefully, Gel Wipe can make a lot of people feel better and more comfortable,” added Saat.

SATU’s Gel Wipe is one of the six finalists competing for the Pulp and Paper International prize in the Tissue-Innovation category. Winners will be announced in November during a formal gala in Brussels.

Information about the competition: http://events.risiinfo.com/ppi-awards/awards/award-finalists

Further information:

Siim Saat

CEO

SATU Laboratory

Phone: +372 507 0089

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

James Cropper remembers Somme victims with paper tribute

British master papermaker James Cropper plc paid tribute to the victims of the Battle of the Somme by providing the paper for thousands of special bleuet flowers, which accompanied the signature red poppies at the recent centenary commemoration.

The event took place at the Thiepval Memorial in France on 1 July, 100 years on from the first day of the infamous World War One assault. It saw attendees – which included TRH The Prince of Wales and Duchess of Cornwall, TRH The Duke and Duchess of Cambridge and HRH Prince Henry of Wales – don the blue flowers alongside their red poppies, while thousands of the bleuets were scattered across the site.

Organised by the UK and French Governments, in partnership with the Commonwealth War Graves Commission and The Royal British Legion, the service saluted the one million casualties sustained on both sides during the 141-day battle. The Thiepval Memorial stands in commemoration to the missing of the Somme: the 72,000 men that have no known grave.

The bleuet de France is the symbol of memory and solidarity in France for veterans, victims of war, widows and orphans and is the country’s equivalent to the British and Canadian remembrance poppy.

Phil Wild CEO at James Cropper, said: “We’ve worked with the Royal British Legion for many years now, providing the paper for the signature red poppies, and it’s a cause that’s very close to our hearts. To have played a part in such an important tribute to those we lost a century ago by developing the paper bleuets was an honour.

“It was particularly powerful to see the poppies and bleuets shower the site together as a poignant mark of respect to the brave soldiers from both Britain and France who fought for their countries.”

To find out more about James Cropper, visit www.jamescropper.com

Centenary of the Battle of the Somme from James Cropper on Vimeo.

About James Cropper

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

About Technical Fibre Products (TFP)

As well as paper products, James Cropper plc also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors. For further information visit: www.jamescropper.com and www.tfpglobal.com.

About James Cropper 3D Products

With James Cropper 3D Products, James Cropper plc has created the next generation of sustainable moulded paper packaging. Available in a wide variety of colours and with a naturally tactile finish, the product has a clear focus on quality and is design-engineered to suit all packaging needs. Features to improve product value and packaging integrity, such as personal embossing, natural hinges and cut-outs, enhance brand impact. All packaging products are recyclable and made from 100 per cent renewable natural fibres.

Xerium Introduces 2 New Roll Cover Technologies; EnerSoft TS for Tissue Machines and ProGloss for Calender Roll Applications

Xerium Technologies, Inc., a leading global provider of industrial consumable products and services, recently launched 2 new roll cover product families; EnerSoft TS – a new generation polyurethane roll cover technology specifically engineered for demanding tissue pressure rolls positions, and ProGloss – a new advanced technology composite roll cover for calender applications.

New ProGloss Composite Calender Roll Technology Engineered for Improved Gloss and Longer Life (Graphic: Business Wire)

EnerSoft TS combines advanced polyurethane materials technology, innovative venting patterns, and proprietary roll manufacturing techniques to deliver maximum machine performance and reduced energy consumption, with consistent performance over the life of the cover. EnerSoft TS is available in several hardnesses for virtually any pressure roll application.

ProGloss composite roll covers utilize the latest innovative composite technology to deliver the industry’s leading combination of wear resistance, impact resistance, and durability while generating best-in-class gloss levels for all calender applications. ProGloss covers incorporate newly developed epoxy matrix and filler materials enabling improvements in gloss sustainability, cover life, and barring resistance while maintaining extreme resistance to damage.

New EnerSoft TS Roll Cover Technology for Tissue and Toweling Machines provides Enhanced Machine Performance with Reduced Energy Consumption (Graphic: Business Wire)

More information about EnerSoft TS and ProGloss technology is available at http://www.xerium.com/.

“We are very pleased to introduce these two new roll technologies. EnerSoft TS - builds upon our highly successful Rebel polyurethane technology with yet another pace-setting innovation for demanding tissue applications,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “And our new ProGloss portfolio of composite calender roll covers provide the ideal set of options for our customers that depend on critical calender operations. Once again, our roll cover development team has demonstrated its leadership in roll cover technology and have delivered high-performance covers that help our customers run their machines more reliably, and more efficiently, with improved product quality and reduced energy consumption.”

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 30 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

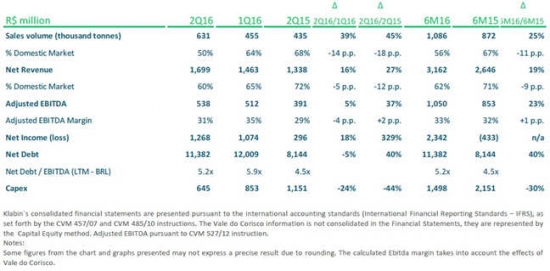

Klabin launches sales of pulp from its Puma Unit and posts EBITDA growth of 37% in 2Q16

Klabin, Brazil’s largest packaging paper producer and exporter and leading manufacturer of corrugated board packaging and industrial bags, reported its 20th straight quarter of growth, with adjusted EBITDA (earnings before interest, tax, depreciation and amortization) in the second quarter of 2016 of R$538 million, or 37% higher than in the second quarter of 2015. Net revenue including wood sales amounted to R$1,699 million, advancing 27% on the prior-year period.

- Adjusted EBITDA amounted to R$538 million in the second quarter of 2016, an increase of 37% from the same period of 2015.

- Net sales revenue in the second quarter advanced 27% on the prior-year period to R$1,699 million.

- In March, Klabin successfully commissioned its Puma Unit in Ortigueira, Paraná. Pulp production continued to ramp up during the quarter, with sales corresponding to 50% of the mill’s nominal capacity.

The second-quarter results benefitted from the commencement of pulp sales by the Puma Unit, which marked a new phase in the Company’s growth. The unit’s operations are ramping up within the established learning curve and contributed 181,000 tons to pulp sales volume in the period, with 165,000 tons of hardwood pulp and the remainder softwood pulp, generating revenue of R$286 million.

Klabin’s sales volume in the second quarter amounted to 631,000 tons (excluding wood), or 45% higher than in the same period last year. In addition to the additional pulp volume in the period, the Company registered 4% growth in sales of paper and packaging, which reached 450,000 tons. This growth was supported by the expansion in production capacity, the debottlenecking actions carried out in 2015 and the flexibility of its product mix, which allows production to be directed to various different markets.

Export volume in the quarter corresponded to 50% of total sales volume, compared to 32% in the second quarter of 2015. The increase is explained by the growth in paper exports and, especially, by the start of pulp sales.

Capital Expenditure

Klabin invested R$649 million in the second quarter of year, with the highlight the investment of R$505 million in the new pulp mill in Ortigueira, Paraná. Capital expenditure to sustain the industrial operations came to R$99 million. Meanwhile, R$34 million was allocated to the forestry operations and R$11 million to special projects and capacity-expansion projects.

Financial Highlights

About Klabin

Klabin is Brazil's largest paper producer and exporter and the leading manufacturer of paper and board for packaging, corrugated board packaging, industrial bags and timber in logs. Founded in 1899, it has 15 industrial units in Brazil and one in Argentina. Klabin is organized into four business units: Forestry, Pulp, Paper (paperboard, kraft paper and recycled) and Packaging (corrugated board and industrial bags).

Management of the company is entirely oriented towards sustainable development, in the pursuit of integrated and responsible growth that combines profitability, social development and a commitment to the environment. Klabin has been included in the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (BM&FBovespa) since 2014. It is also a signatory to the United Nations Global Compact and the Brazilian Pact to Eradicate Slave Labor, and seeks suppliers and business partners that adopt the same values of ethics, transparency and respect for the principles of sustainability.

Learn more at www.klabin.com.br

Mondi welcomes 1400 visitors to its house of paper solutions at Drupa

Mondi is looking back at a highly successful Drupa 2016 where the company showcased its innovative offer as the one-stop paper manufacturer for the professional printing industry. Among Mondi’s many highlights were a paper house illustrating the comprehensive paper solutions Mondi offers featuring a paper art gallery, live print runs of the new high-speed inkjet paper NEUJET® and a cutting-edge 3D printer using BIO TOP 3®.

Mondi Uncoated Fine Paper presented its wide range of professional paper solutions at the Drupa fair in Düsseldorf, Germany from 31 May to 10 June. As a one-stop paper manufacturer, Mondi offers sustainable paper solutions for all printing technologies and needs.

Johannes Klumpp, marketing & sales director Mondi Uncoated Fine Paper, explains, “We have had a very successful Drupa! On the one hand, we have proudly exhibited our professional print portfolio and have had interesting discussions with around 1400 customers. On the other hand, we have learned more about trends in printing technologies with our OEM partners.”

A house made of paper

Klumpp points out that “One of the highlights of the booth at Drupa was the Mondi ‘paper house’ reflecting Mondi’s one-stop paper manufacturer approach.” In this house, visitors could feel at home, be well taken care of, discover the creative environment of an art gallery and personally experience a variety of paper haptics. The house consisted of panels covered with natural-shaded BIO TOP 3® next and the high-white DNS® premium as well as an attractive grey shade of Mondi’s tinted paper. In the upstairs area Mondi’s customers could withdraw from the hectic rush of the trade show routine – much like in a living room. On the ground floor a dedicated art gallery opened up a whole new world for visitors who could admire different art objects reflecting the duality of the whole booth between the rational and the emotional world. Furthermore, visitors were invited to experience the different shades and haptics of Mondi papers with touchpads on the house. “All of these details combined the approach that people are in touch with Mondi products every day and that our paper can do much more than one would expect,” adds Klumpp.

Sustainable. Every day.

A tree made of wood and paper reflected Mondi’s clear sustainability commitment. For Mondi, sustainability makes good business sense hence is one of its key drivers and was also a key topic for Drupa. All Mondi uncoated fine paper branded products are part of Mondi’s Green Range, meaning that they are FSC® or PEFC™ certified, 100% recycled or totally chlorine free bleached (TCF). Mondi continually invests in making its mills and production plants as energy efficient and sustainable as possible. Customers have the best paper solutions combined with proven, environmentally sound production – every day.

NEUJET® – bringing high-speed inkjet paper to a new level

The NEUJET® portfolio was presented at Drupa with live print runs on an Océ ColorStream 3700 Z high-speed digital inkjet printing press by Canon. NEUJET® represents Mondi’s next generation of high-speed inkjet papers and visitors were especially impressed by the smooth surface and vivid colours on NEUJET® silk. The portfolio is optimised for medium to heavy colour direct mails, graphic arts and book printing applications. NEUJET® is offered in two quality levels, standard and premium, and two surface finishes, matte and silk, closing the gap to coated offset printing.

PERGRAPHICA® design papers attract attention

PERGRAPHICA® - Mondi’s design paper range called ‘Paper for Perfectionists’ - caught a lot of attention at Drupa. Customers could assure themselves that it fulfils the most demanding requirements for sophisticated and elegant printed documents. The printed samples and attractive marketing materials for PERGRAPHICA® showed the variety of options: two textures (Rough and Smooth), three shades (High White, Classic and Natural) and six grammages between 90 and 300 g/m2. Produced in Austria and FSC® and EU Ecolabel certified, it is sold through a network of long-term distribution partners Europapier (Austria and CEE), Papierunion/Inapa Group (Germany), Burgo Distribuzione (Italy), and Double V (Russia).

3D print as highlight at Drupa and at the Mondi booth

Mondi has partnered with Mcor, an innovative manufacturer of the world’s most affordable, full-colour, safe and eco-friendly 3D printers, on the development of paper optimised for Mcor 3D printers. At Drupa Mondi featured the recently launched Mcor ARKe printing full colour paper 3D models – printing with Mondi’s BIO TOP 3® next. BIO TOP 3® next is an off-white uncoated hybrid printing paper ensuring high impact reproductions that catch attention. The paper is extremely versatile and meets the highest requirements: it combines an elegant look with an extensive environmental profile. Produced totally chlorine free (TCF), the paper retains a natural uncoated feel with an off-white shade and has been found to be optimally suited for Mcor 3D printers. Mcor ARKe uniquely employs the global-standard ICC colour map to provide the industry’s most accurate, photorealistic colour 3D. Dr Conor MacCormack, co-founder & CEO of Mcor concludes: “This year the Drupa show truly brought the 2D and 3D printing worlds together. 3D printing using Mondi’s BIO TOP3® next paper delivers high quality colour models at a low price and it is eco-friendly and safe.”

Customer focused innovation – every day

Another highlight of the professional print portfolio were the hybrid printing papers providing flexibility in the printing technology used and high print quality all at once. “We are strongly committed to continuously developing our portfolio serving our customers’ needs. At the same time, we adapt our papers to the technology developments in the professional printing industry,” explains Johannes Klumpp. “Mondi and the Neusiedler mill are well known for innovative, high quality papers produced in a sustainable way. Our clear dedication to quality leadership is demonstrated in one of our latest innovations in our premium hybrid segment.” Under the slogan “one quality – one mill – one look”, Mondi Neusiedler sets a new quality reference guaranteeing hybrid offset, preprint and laser printing. Professional printers, creative agencies and end users will benefit from consistent print quality and one shade from 50 – 400 g/m² with DNS® premium, MAESTRO® extra and IQ premium.

We are Mondi: IN TOUCH EVERY DAY

At Mondi, our products protect and preserve the things that matter.

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are located in central Europe, Russia, North America and South Africa. We offer over 100 packaging and paper products, customised into more than 100,000 different solutions for customers, end consumers and industrial end uses - touching the lives of millions of people every day. In 2015, Mondi had revenues of €6.8 billion and a return on capital employed of 20.5%.

The Mondi Group is fully integrated across the packaging and paper value chain - from managing forests and producing pulp, paper and compound plastics, to developing effective and innovative industrial and consumer packaging solutions. Our innovative technologies and products can be found in a variety of applications including hygiene components, stand-up pouches, super-strong cement bags, clever retail boxes and office paper. Our key customers are in industries such as automotive; building and construction; chemicals; food and beverage; home and personal care; medical and pharmaceutical; packaging and paper converting; pet care; and office and professional printing.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc, under the ticker code MNDI.

For us, acting sustainably makes good business sense and is part of the way we work every day. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

ANDRITZ to deliver recycled paper plant and PM approach to Pro-Gest Group, Italy

International technology Group ANDRITZ has received an order from the Italian Pro-Gest Group to deliver the complete waste paper processing plant and approach system for its new paper machine in Mantova, Italy.

The ANDRITZ FibreGuard LC pulping and detrashing system will be installed in both recycled paper lines. PHOTO: Andritz

ANDRITZ will deliver the OCC (old corrugated containers) line for the top ply; MW (mixed waste) line for the back ply; paper machine approach system including Shortflow Deaeration; as well as the broke handling, fiber recovery, and reject handling systems. The scope of supply also includes engineering, erection supervision, start-up, commissioning, and training. Start-up is scheduled for September 2017.

The state-of-the-art equipment supplied by ANDRITZ fits perfectly with Pro-Gest’s requirements for high-speed paper production. The paper machine is targeted to produce 550,000 tons of fluting per year from 100% waste paper.

Owned by the Zago family, Pro-Gest is Italy’s leading vertically integrated producer of packaging in corrugated board, active in all fields, from the collection of raw materials to packaging production. The Group also includes an integrated tissue manufacturing division, featuring the full range of high quality products.

Pro-Gest is active in eight Italian regions with 22 production sites, employs over 1,000 people, and generated a consolidated turnover of EUR 450 million in 2015.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

ANDRITZ to supply new FibreFlow drum pulping system to SAICA, Spain

International technology Group ANDRITZ has received an order from S.A. Industrias Celulosa Aragonesa (SAICA) to supply a FibreFlow drum pulping system for its paper mill in El Burgo de Ebro, Spain.

ANDRITZ FibreFlow drum FFD pulping system “Photo: ANDRITZ”.

ANDRITZ will supply a latest-generation FibreFlow drum FFD - including the complete feeding and dewiring system - for a new OCC line. The state-of-the-art ANDRITZ pulping system ensures high fiber yield from various waste paper streams and reliable operation. The convincing results of specific trials on the industrial-scale drum pulper at the ANDRITZ pilot plant in Graz, Austria, as well as ANDRITZ's 40 years of experience in drum pulping with more than 200 FibreFlow drum installations worldwide were decisive for SAICA to place the order with ANDRITZ.

The scope of supply also includes complete erection, start-up and commissioning, and training. Start-up is scheduled for September 2017.

SAICA Group is the leading European company for the production of recycled paper for corrugated cardboard, with an annual production of 2.5 million tons of paper. With locations in Spain, Italy, Portugal, the UK, Ireland, and Turkey, the group has more than 8,000 employees and is divided into four business areas: recycled paper production for corrugated cardboard (Paper), recyclable materials recovery (Natur), production of corrugated packaging (Pack), and flexible packaging (Flex). In 2015, consolidated sales of the multinational group amounted to 2,378 million euros.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

Increased Popularity of Paperboard Packaging to Emerge as a Key Driver for the Paper Manufacturing Market in Romania Until 2020

Technavio analysts forecast the paper manufacturing market in Romania to register a slow growth, posting a CAGR of close to 2% during the forecast period, according to their latest report.

The research study covers the present scenario and growth prospects of the paper manufacturing market in Romania for 2016-2020. To calculate the size of the paper manufacturing market in Romania, the report considers volumes generated in the 12 trailing months and the revenue generated from the manufacture of paper and paper products by manufacturers in Romania.

The research study covers the present scenario and growth prospects of the paper manufacturing market in Romania for 2016-2020. To calculate the size of the paper manufacturing market in Romania, the report considers volumes generated in the 12 trailing months and the revenue generated from the manufacture of paper and paper products by manufacturers in Romania.

Technavio chemicals and materials analysts highlight the following four factors that are contributing to the growth of the paper manufacturing market in Romania:

- Increased popularity of paperboard packaging

- Recyclable and cost-effective nature

- Increased demand from organized retail sector

- Growth of processed food industry

Increased popularity of paperboard packaging

Paperboards can be folded, are lightweight and strong, and are resistant to lasers used in high-speed automated filling. High-quality printing on paperboard packaging can enhance the aesthetic appeal of packaged goods and their sales, and this has led to retailers opting for this type of packaging. The popularity of paperboard packaging is also on the rise due to 30% of companies focusing on redesigning their existing packaging to make it more attractive, and it is easy and convenient to come up with eye-catching designs and shapes using paperboards. Paper and paperboards are also versatile in terms of the variety of products that can be packaged using these materials.

According to Chandrakumar Badala Jaganathan, a lead analyst at Technavio for research on textile, fiber, and composites, “The demand for paperboard containers has led to demand for corrugated paper, which is used to wrap these containers to enhance the safety of packaged products. Manufacturers in the market are focusing on enhancing their portfolio of paperboard packaging products to capture growth opportunities.”

Recyclable and cost-effective nature

The concept of recycling is gaining popularity due to environmental awareness. Consumers prefer paperboard packaging as it can be recycled easily and is biodegradable. “The manufacture of paper requires less electricity compared to plastic. This leads to energy efficiency and savings. Also, the cost-effective nature of paperboard is fueling the demand for paperboard packaging, as it costs 30% - 35% less than plastic,” adds Chandrakumar.

Increased demand from organized retail sector

Organized retailing refers to the retailing of different categories of products, including ready-to-cook food products, under one roof. Consumers purchase groceries, including frozen and chilled food products, from these stores. These items are generally packed in paper or paperboard containers. This has led to increased demand for these containers, as they are safe, durable, and eco-friendly. With the growth of the organized retail sector and an increase in consumer demand for frozen and chilled food products, the demand for paperboard packaging is also expected to increase during the forecast period. Hence, manufacturers in the market are focusing on channel strategies that involve the organized retail sector to capture a greater market share.

Growth of processed food industry

Demand for processed food, convenience food, and fast food is on the rise. The packaging needs to be safe, durable, and eco-friendly, as it can enhance the shelf life of these products. The packaging also needs to be lightweight, flexible, and convenient to carry and use. This has led to the development of innovative paperboard packaging solutions being developed by manufacturers of packaging products.

Browse Related Reports:

- Global office stationery and supply market 2015-2019

- Global Paper and Paperboard Container and Packaging Market 2016-2020

- Global stationery and cards market 2015-2019

-

About Technavio

Technaviois a leading global technology research and advisory company. The company develops over 2000 pieces of research every year, covering more than 500 technologies across 80 countries. Technavio has about 300 analysts globally who specialize in customized consulting and business research assignments across the latest leading edge technologies.

Technavio analysts employ primary as well as secondary research techniques to ascertain the size and vendor landscape in a range of markets. Analysts obtain information using a combination of bottom-up and top-down approaches, besides using in-house market modeling tools and proprietary databases. They corroborate this data with the data obtained from various market participants and stakeholders across the value chain, including vendors, service providers, distributors, re-sellers, and end-users.

Technavio Presents Key Manufacturers and Their Competitive Landscape in the Paper Manufacturing Market in Turkey from 2016-2020

Technavio has announced the key manufacturers in their recent paper manufacturing market in Turkey report until 2020. The report also presents the manufacturer landscape and a corresponding database of the key manufacturers involved in the production of paper. In addition, the report discusses the major drivers influencing market growth, and the challenges faced by manufacturers and the market as a whole. It also examines key emerging trends, and their influence on current and future market scenarios.

Competitive vendor landscape

The paper manufacturing market in Turkey is characterized by the presence of diverse international and regional manufacturers. However, as international players have already established their footprint in the market, regional manufacturers are finding it increasingly difficult to compete with them, especially on aspects such as quality, technology, and pricing. The competitive environment in this market will likely intensify further with an increase in product and service extensions, technological innovations, and mergers and acquisitions. International players are expected to grow inorganically by acquiring regional and local players.

The paper manufacturing market in Turkey is characterized by the presence of diverse international and regional manufacturers. However, as international players have already established their footprint in the market, regional manufacturers are finding it increasingly difficult to compete with them, especially on aspects such as quality, technology, and pricing. The competitive environment in this market will likely intensify further with an increase in product and service extensions, technological innovations, and mergers and acquisitions. International players are expected to grow inorganically by acquiring regional and local players.

Chandrakumar Badala Jaganathan, a lead analyst at Technavio for research on textile, fiber, and composites, says, “Manufacturers in the market compete based on parameters such as pricing, quality, innovation, flexibility, and speed of delivery. The focus is shifting from low cost production to innovation-based production. Apart from developing new technologies, manufacturers also have to keep abreast of emerging technologies that can have a bearing on their product lines.”

The report also states that manufacturers in the market face intense competition from products manufactured in China. This is true particularly in the case of segments such as paper stationery. However, a considerable amount of government supports in the form of incentives, such as tax exemptions for small and medium-sized manufacturers operating in this segment, and the implementation of schemes encouraging education (leading to increased consumption of paper stationery by educational institutions) will present growth opportunities for manufacturers.

Request for sample report: http://goo.gl/6a1oO8

Some of the key manufacturers in paper manufacturing market in Turkey are:

Company

| Description | |||

| Mondi Tire Kustan | Manufacturer and supplier of packaging paper, uncoated fine paper, and converted packaging products | ||

| Hayat Kimya Sanayi | Leading player in FMCG and manufacturer of tissues, household cleaning products, and baby and adult diapers | ||

| Alkim Kagit | Manufacturer of paper with a product portfolio including offset paper, coated paper, office paper, and special editions | ||

| Dunapack Dentaş | Provider of corrugated packaging solutions | ||

| Kahramanmaras Kagit | Manufacturer of commercial paper, corrugated cardboard, testliner and fluting paper, and core boards | ||

| Aktul Kagit | Manufacturer of tissue paper and semi-finished rolls with brand names such as Komili Konfor and Komili Yuvam | ||

| İpek Kağıt | Leading manufacturer of tissue paper | ||

| Olmuksan International Paper | Manufacturer of packaging materials such as corrugated boxes and cardboards of various types based in the US | ||

| Simka Kagit | Manufacturer of paper from recycled paper and paperboard | ||

| Sun-ka Kagit ve Karton | Manufacturer of cardboards from recycled waste paper | ||

| Mopak Kagit | Manufacturer of paper, cardboard, office paper, and notebooks | ||

| Levent Kagit | Leading manufacturer of paper in Turkey with a portfolio including pulp paper, napkin paper, toilet paper, and towel paper | ||

| Kartonsan | Manufacturer of cardboard products | ||

| Akasan-Adana Kagit | Provider of packaging solutions | ||

| Halkali Kagit | Producer of paperboard | ||

| Marmara Kagit | Producer of paper-based packaging products | ||

| Oyka Kagit | Producer of paper-based packaging products | ||

| Viking Kagit | Producer of products such as paper towels and paper-based toiletries | ||

| Eka Kagit | Producer of kraft and tissue paper | ||

|

Source: Technavio |

|||

Browse Related Reports:

- Global Pulp Market 2016-2020

- Global Specialty Paper Market 2015-2019

- Global Recycled Paper Packaging Market 2015-2019

About Technavio

Technavio is a leading global technology research and advisory company. The company develops over 2000 pieces of research every year, covering more than 500 technologies across 80 countries. Technavio has about 300 analysts globally who specialize in customized consulting and business research assignments across the latest leading edge technologies.

Technavio analysts employ primary as well as secondary research techniques to ascertain the size and vendor landscape in a range of markets. Analysts obtain information using a combination of bottom-up and top-down approaches, besides using in-house market modeling tools and proprietary databases. They corroborate this data with the data obtained from various market participants and stakeholders across the value chain, including vendors, service providers, distributors, re-sellers, and end-users.