Ianadmin

Valmet to deliver a quality control system to Tembec Tartas SAS in France

Tembec's specialty dissolving pulp mill in Tartas, France, has ordered a Valmet IQ quality control system (QCS) and an expansion of its existing Valmet DNA distributed control system (DCS) for its pulp dryer. By complementing its current control system with this investment, the mill is targeting to improve process stability and reduce lost time during transition phases such as start-ups, breaks and speed changes. Start-up of the new QCS is scheduled for October 2016.

The order was included in Valmet's second quarter 2016 orders received. Typically the order value of this kind of automation system deliveries is below EUR one million.

The order was included in Valmet's second quarter 2016 orders received. Typically the order value of this kind of automation system deliveries is below EUR one million.

"We decided to change our DCS and QCS according to our obsolescence management plan. The choice was done between our existing supplier and Valmet. We chose Valmet because of better reactivity and potential quality benefits," says Ludovic Berdinel, Project Department Director at Tembec Tartas SAS.

"The mill was convinced about our capability to improve their pulp dryer performance through our automation solution and process skills," says Boris Hosteins, Sales Manager, France & North Africa, Automation, Valmet.

Technical details about the delivery

Replacing an obsolete third-party QCS, Valmet's delivery includes a Valmet IQ scanner with basis weight and moisture sensors, machine-direction controls and reporting. Valmet IQ is a comprehensive quality monitoring and control system. The solution combines all of the key elements of a QCS system from measurements, controls and profilers to condition monitoring and machine vision into one scalable system. Guaranteed compatibility between different generation Valmet products helps to future-proof investments and maximizes the effectiveness of existing equipment.

Valmet will also expand the mill's Valmet DNA distributed control system that has controlled the pulp dryer processes for the past four years. The delivery includes additional 650 I/Os to replace outdated programmable logic controllers.

Information about the customer Tembec Tartas SAS

Tembec Tartas SAS is the leader in production of specialty cellulose used in consumer-oriented industries such as cosmetics, pharmaceuticals, packaged foods and construction. Its parent company Tembec is a large, diversified and integrated forest products company which stands as the global leader in sustainable forest management practices. The company's principal operations are located in Canada and France.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Cyprium Partners Announces New Investment in Paper Machinery Corporation

Cyprium Partners, a non-control private equity firm, is pleased to announce its new subordinated debt investment in Paper Machinery Corporation (PMC). The capital was used to facilitate an acquisition of the business by a newly formed Employee Stock Ownership Plan (ESOP) from the Baumgartner family. The selling shareholders, Donald Baumgartner and John Baumgartner, will continue to serve on the company’s board of directors.

Founded in 1947 and headquartered in Milwaukee, Wisconsin, PMC is a manufacturer of complex, high-speed forming machines and ancillary equipment utilized by paper and packaging companies to produce paper cups, paperboard canisters, and custom paperboard packages. PMC machines are installed in over 40 countries around the world with each machine built, configured, and equipped according to customer specifications. See www.papermc.com.

Founded in 1947 and headquartered in Milwaukee, Wisconsin, PMC is a manufacturer of complex, high-speed forming machines and ancillary equipment utilized by paper and packaging companies to produce paper cups, paperboard canisters, and custom paperboard packages. PMC machines are installed in over 40 countries around the world with each machine built, configured, and equipped according to customer specifications. See www.papermc.com.

“Cyprium is very excited to support the Baumgartner family in its sale of PMC to its employees,” said Leland Lewis, a Managing Partner at Cyprium Partners. “Cyprium’s experience with ESOP transactions and multi-generational businesses made this a natural fit for both PMC and Cyprium.”

In addition, Dan Kessler, a Partner at Cyprium, stated “This is a tremendous opportunity for the more than 250 employees of PMC who have been rewarded for their years of dedication with ownership in the Company. We look forward to working with the senior management team of Luca Dellomodarme, Scott Koehler and Michael Kazmierski to continue PMC’s success.”

About Cyprium Partners

Cyprium Partners is a private equity firm focused on non-control (minority ownership) investments. Cyprium utilizes a combination of subordinated debt, preferred stock, and/or common stock to enable privately-held businesses, entrepreneurs, and management teams to achieve their financial and strategic objectives. With offices in Cleveland, New York, and Chicago, the firm invests $10 million to $60 million per transaction in U.S. and Canadian companies with $8 million or more of EBITDA. Learn more about Cyprium Partners at www.cyprium.com.

United States Paper (Except Newsprint) Market 2016

United States Paper (Except Newsprint) Market 2016 - Analysis And Forecast to 2020: U.S. Dominated in Global Imports of Paper Accounting an for 11% Share - Research and Markets

Research and Markets has announced the addition of the "U.S. Paper (Except Newsprint) Market - Analysis And Forecast to 2020" report to their offering.

![]() The report provides an in-depth analysis of the U.S. paper (except newsprint) market. It presents the latest data of the market size and volume, domestic production, exports and imports, price dynamics and turnover in the industry. In addition, the report contains insightful information about the industry, including industry life cycle, business locations, productivity, employment and many other crucial aspects. The Company Profiles section contains relevant data on the major players in the industry.

The report provides an in-depth analysis of the U.S. paper (except newsprint) market. It presents the latest data of the market size and volume, domestic production, exports and imports, price dynamics and turnover in the industry. In addition, the report contains insightful information about the industry, including industry life cycle, business locations, productivity, employment and many other crucial aspects. The Company Profiles section contains relevant data on the major players in the industry.

The U.S. dominated in global imports of paper (except newsprint), accounting an for 11% share (based on USD). Germany (10%), the United Kingdom, and France (6%, each) followed. In 2015, U.S. paper (except newsprint) imports totaled 5.4 billion USD, which was 0.4 billion USD (7%) less than the year before.

From 2007 to 2015, U.S. paper (except newsprint) imports showed negative dynamics. After the period of relative stability of 2007-2008, imports plunged noticeably by nearly 22% and stood at this level for five years, until they dropped again in 2015. There was an annual decrease of -4.0% throughout the analysed period.

U.S. imports have not shown any signs of recovery. They have to grow another 38% in order to reach the pre-recession level of 2007. Despite this, the U.S. remains one of the most attractive destinations for overseas suppliers.

Canada was the main supplier of paper (except newsprint) into the U.S., accounting for 39% of total U.S. imports in 2015. Finland held second place in the ranking with an 11% share, followed by Germany (8%) and the Republic of Korea (7%).

Net U.S. imports of paper (except newsprint) showed a downward trend over the period under review. In 2015, this industry still ran a significant trade deficit of 2.3 billion USD.

Product coverage:

- Bleached bristols and clay-coated, uncoated freesheet, cotton fiber, special industrial, packaging, and industrial converting papers

- Construction paper

- Disposable diapers and similar disposable products, made in paper mills

- Sanitary tissue paper products, made in paper mills

- Paper (except newsprint) mills

Key Topics Covered:

1. Introduction

2. Executive Summary

3. Market Overview to 2020

4. Domestic Production 2008-2015

5. Imports 2007-2015

6. Exports 2007-2015

7. Competitive Landscape

8. Company Profiles

- Appvion

- Blue Ridge Paper Products

- Cellu Tissue Holdings

- Clearwater Paper Corporation

- Crane & Co.

- Cycle Link (USA)

- Expera Specialty Solutions

- Hollingsworth & Vose Company

- International Paper Company

- Kamilche Company

- Kapstone Paper and Packaging Corporation

- Kimberly-Clark Corporation

- Longview Fibre Paper and Packaging

- Mondi Bags USA.

- Neenah Paper

- New-Indy Containerboard

- Newpage Holding Corporation

- Nice-Pak Products

- P. H. Glatfelter Company

- Pratt Industries (USA)

- SDW Holdings Corporation

- Sca Americas

- Sca Tissue North America

- Simpson Investment Company

- Verso Paper Holdings

- Verso Paper Management

- Wausau Paper Corp.

For more information about this report visit http://www.researchandmarkets.com/research/frpbvp/u_s_paper

Sonoco Announces Price Increase for All Uncoated Recycled Paperboard Products

Sonoco (NYSE:SON) has just announced that it will raise the price for all grades of uncoated recycled paperboard (URB) products by $40 to $60 per ton depending on grade, effective with shipments in the United States and Canada, beginning October 3, 2016.

“It is critically important in a mature business, such as our paper business, to run our operations efficiently and provide a return that justifies continued investment,” said Palace Stepps, director of sales and marketing for Sonoco’s North America paper business. “The increase is necessary to capture generally higher operating costs so we can continue providing high-quality, value-adding products to our customers.”

“It is critically important in a mature business, such as our paper business, to run our operations efficiently and provide a return that justifies continued investment,” said Palace Stepps, director of sales and marketing for Sonoco’s North America paper business. “The increase is necessary to capture generally higher operating costs so we can continue providing high-quality, value-adding products to our customers.”

Sonoco is one of the largest producers of uncoated recycled paperboard in the United States and Canada, producing more than one million tons annually from 11 mills. For more information about Sonoco’s complete line of URB paper products, or to learn more about current pricing, please visit the Company’s website (www.sonoco.com) or contact the Company at 1-800-377-2692.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging and packaging supply chain services. With annualized net sales of approximately $5.0 billion, the Company has 21,000 employees working in more than 300 facilities in 34 countries, serving many of the world’s best known brands in some 85 nations. For more information on the Company, visit our website at www.sonoco.com.

United States Paper Bag And Coated And Treated Paper Market 2016

Research and Markets has announced the addition of the "U.S. Paper Bag And Coated And Treated Paper Market - Analysis And Forecast to 2020" report to their offering.

![]() The report provides an in-depth analysis of the U.S. paper bag and coated and treated paper market. It presents the latest data of the market size and volume, domestic production, exports and imports, price dynamics and turnover in the industry. In addition, the report contains insightful information about the industry, including industry life cycle, business locations, productivity, employment and many other crucial aspects. The Company Profiles section contains relevant data on the major players in the industry.

The report provides an in-depth analysis of the U.S. paper bag and coated and treated paper market. It presents the latest data of the market size and volume, domestic production, exports and imports, price dynamics and turnover in the industry. In addition, the report contains insightful information about the industry, including industry life cycle, business locations, productivity, employment and many other crucial aspects. The Company Profiles section contains relevant data on the major players in the industry.

The U.S. takes a 10% share (based on USD) of global paper bag and coated and treated paper exports, which put it in third place, following China (15%) and Germany (14%). In 2015, the U.S. exported 5,773 million USD, which was 1% over the previous year.

Outside of a significant drop of 2009, U.S. paper bag and coated and treated paper exports showed steady growth from 2007 to 2015. There was an average annual increase of +3.9% throughout the analysed period. As U.S. companies improved their positions on overseas markets, domestic manufacturers enjoyed a new growth driver.

From 2007 to 2015, the U.S. was a net exporter of paper bags and coated and treated paper. Prior to 2011, net U.S. exports of paper bags and coated and treated paper showed an upward trend. However, in 2011, they turned downward and decreased steadily through to the end of the period. In 2015, this industry still ran a significant trade surplus of 518 million USD.

Product coverage:

- Single-web paper, rolls and sheets, including waxed, for flexible packaging uses

- Multiweb laminated rolls and sheets, excluding foil, for flexible packaging uses

- Printing paper, coated at establishments other than where paper was produced

- Gummed products

- Pressure-sensitive products

- Wallcoverings

- Converted foil for nonpackaging applications

- Other coated and processed papers, excluding for packaging uses

- Gift wrap paper Specialty bags, pouches, and liners, coated and single-web paper

- Specialty bags, pouches, and liners, multiweb laminations and foil, excluding film-film

- Uncoated single-web paper grocers' bags and sacks and variety and shopping bags

- Shipping sacks and multiwall bags, all materials, excluding textiles

- Laminated aluminum foil rolls and sheets for flexible packaging uses (converting and printing or converting only)

- Pasted, lined, laminated, or surface-coated paperboard

- Paper bag and coated and treated paper manufacturing

Key Topics Covered:

1. Introduction

2. Executive Summary

3. Market Overview

4. Domestic Production

5. Imports

6. Exports

7. Competitive Landscape

8. Company Profiles

- Alpha Industries Management

- Atlas Agi Holdings.

- Avery Dennison Corporation

- Bemis Company

- Boise

- Coveris Flexibles US

- Coveris Key Holdings

- Curwood

- Duro Hilex Poly

- Jonah Brooklyn

- Mohawk Fine Papers

- Newpage Group

- Nitto Americas

- Packaging Dynamics Corporation

- Paperweight Development Corp.

- Printpack

- Printpack Enterprises

- Printpack Holdings

- Prolamina Corporation

- Sealed Air Corporation

- Shurtape Technologies

- Stm Industries

- Tetra Pak

- Westlake Polymers

For more information about this report visit http://www.researchandmarkets.com/research/xj9pdv/u_s_paper_bag

ANDRITZ to supply ATMP system to Volga, Russia

International technology Group ANDRITZ has received an order from JSC Volga in Balakhna, Nizhegorodskaya oblast, Russia, to deliver a complete state-of-the-art ATMP (Advanced Thermo-mechanical Pulp) line, which will process 100% spruce for the production of soft wood pulp. Start-up of the new line, which will be combined with existing equipment, is scheduled for 2019.

An ANDRITZ TX68 refiner will be installed as first refining

stage in the new ATMP system to be supplied to JSC Volga. “Photo: ANDRITZ”

The order comprises the supply of the chip washing system, pre-treatment equipment, an ANDRITZ TX68 high-speed high-consistency refiner as a first refining stage, two ANDRITZ TwinFlo low-consistency refiners as second refining stage, as well as the integration of an existing low-consistency refining system as third refining stage. The powerful TX68 with large refining zone delivers the highest throughput available in a single machine. The existing groundwood pulp reject system will be upgraded and integrated into the new ATMP system as reject line. The new ATMP plant will be the world's largest single-line thermo-mechanical pulping system for softwood with a capacity of 850 admt/d.

The advanced technological standard of the ANDRITZ mechanical pulping processes as well as the high reliability of the components were decisive for Volga to place the order with ANDRITZ.

JSC Volga is one of the leading newsprint manufacturers in Russia and Europe and solely uses TMP technologies for producing pulp which is fed to the newsprint paper machines. Volga's paper products are shipped to more than 60 countries worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

The largest TT SYD ever installed in Europe successfully started up at WEPA Cassino tissue plant, Italy.

The biggest European Steel Yankee Dryer for tissue production, a Toscotec TT SYD-18FT (5600mm wide), has been successfully started up at WEPA Cassino mill in Italy.

The PM3 rebuilding project was commissioned to Toscotec, WEPA’s long-term partner, continuing the process of investments in order to upgrade the plant and to achieve the best available technology in tissue making.

“High quality of product and energy saving were at the base of the project. WEPA is going to get more and more relevance in the European market. Cost Leadership and attention to consumers and customer needs, as well as sustainability in company management and production, is part of WEPA´s future strategy.” - says Bernhard Gross, Managing Director of WEPA Italia srl. “To avail ourselves of a skilled machinery specialist like Toscotec has been a big step forward to realize our strategy.”

The scope of the supply included also a double layer fully hydraulic TT Headbox-MLT with polished pipes and a Yankee steam & condensate removal system. All equipment was provided on a turn-key basis including engineering, supervision and installation.

About Toscotec

Toscotec is a turnkey supplier to the global tissue industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects, and individual machineries. Headquartered in Lucca, the nerve center of the Italian paper district, with offices in China and North America, the Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities. Key to the Group’s success is the engineering and R&D department, run by a team of highly qualified engineers. Toscotec currently employs approx. 180 people.

Stora Enso plans consolidation of corrugated packaging production in Finland

Stora Enso plans to consolidate manufacturing of corrugated packaging in Finland to its Lahti plant. The objective is to improve profitability and competitiveness by creating a centre of excellence for corrugated packaging in Lahti.

As part of the possible consolidation, Stora Enso would invest approximately EUR 19 million in new machinery and supporting infrastructure in Lahti, where the most important individual investment item is a new corrugator. The proposed project is planned to start in November 2016 and is expected to be finalised by the end of the first quarter 2018.

As part of the possible consolidation, Stora Enso would invest approximately EUR 19 million in new machinery and supporting infrastructure in Lahti, where the most important individual investment item is a new corrugator. The proposed project is planned to start in November 2016 and is expected to be finalised by the end of the first quarter 2018.

According to the plan, the Heinola Corrugated plant would be closed permanently and packaging manufacturing transferred to the Lahti plant. Co-determination negotiations will start within Lahti and Heinola corrugated plants.

“The plan to potentially consolidate our corrugated operations in Finland is largely driven by the need to improve profitability and strengthen our competitive edge. In addition to the planned investment, our strong infrastructure in Lahti would provide us with a world-class asset base to better serve our customers,” says Peter Torstensson, SVP and Head of Corrugated Nordics, Division Packaging Solutions.

The possible personnel reduction within the corrugated plants in Lahti and Heinola combined is about 60 persons. Decisions regarding the planned consolidation, closure and employee reduction will be taken after the co-determination negotiations have been concluded. The corrugated packaging production at the Kristiinankaupunki plant will be continued. The Heinola Fluting mill for containerboard will not be affected.

The plan will have a negative impact of approximately EUR 9 million which will be recorded as an item affecting comparability (IAC) in Stora Enso’s third quarter 2016 results.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people in more than 35 countries, and our sales in 2015 were EUR 10.0 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. storaenso.com

ANDRITZ to supply turnkey tissue production line to Bashundhara Paper Mills Limited, Bangladesh

International technology Group ANDRITZ has received an order from Bashundhara Paper Mills Limited, an enterprise of the Bashundhara Group, for supply of a turnkey tissue production line for its mill in Bangladesh. Start-up of the line, which will produce high-quality facial wipes, toilet paper, and napkins, is scheduled for the end of 2017.

ANDRITZ PrimeLineCOMPACT tissue machine “Photo: ANDRITZ”

The scope of supply includes the complete stock preparation, the tissue machine, as well as the complete automation and electrification. The PrimeLineCOMPACT VI tissue machine delivered by ANDRITZ will have a design speed of 2,100 m/min and a paper width of 2.85 m. The 16 ft. Yankee is made entirely of steel, thus enabling high and efficient drying performance. It will be manufactured at the ANDRITZ Steel Yankee Business Center in Foshan, China, which offers customers in Asia state-of-the-art manufacturing, local field service, and comprehensive quality management.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, production equipment for biofuel (second generation), biomass torrefaction equipment, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

Valmet to introduce a new quality management system for the self-adhesive laminating process

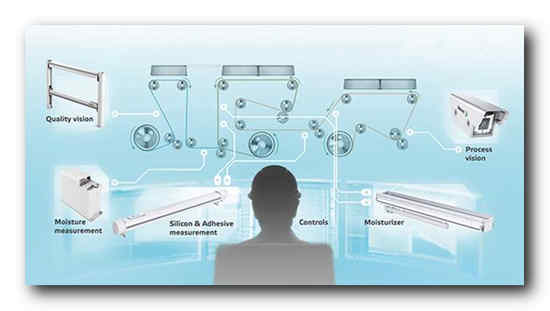

Valmet launched a new quality management system application at the Label Expo Americas exhibition which was held on September 13 - 15 in Rosemount, Illinois. New sheet quality measurements, innovative moisture profiling as well as web monitoring and inspection systems for self-adhesive laminating processes are now combined in the Valmet IQ quality control system.

Patented sensor technology

While adhesive coat weight control has been available for several years, successful control of the silicone release layer has lacked a suitable online sensor until now. The Valmet IQ Silicone and Adhesive Measurement is designed especially for demanding paper and self-adhesive laminating applications to measure silicone coated release liners. Mounted on a single sided scanning frame to provide continuous cross direction measurement profiles of the silicone coat weight, a second sensor after the adhesive application measures the adhesive coat weight. The accurate scan averages and high-resolution CD profiles measured by the new sensor provide a solid foundation for Valmet IQ's machine- and cross-direction silicone and adhesive controls.

Curl control with moisturizer sprayboom

The Moisturizer sprayboom is used to control final laminate curl and the moisture profile of the release liner to improve laminate uniformity and runnability. IQ Moisturizer sprays a fine mist to the paper in a controlled way, providing a very high degree of control and very fast response to quality destroying conditions.

Online quality control

Valmet IQ Process and Quality Vision (PQV) provides web inspection and monitoring tools for online defect inspection, detecting coating streaks and voids and video monitoring of key process operations. Defect inspection at unwinding, for instance, helps identify raw material problems like holes or other serious defects that can cause streaks and quality issues not originating in the laminating machine itself. Printing surface inspection at the reeler provides the final quality assurance step. Production and quality parameters can be easily monitored with the system providing a clear view into process and product quality at all times.

Comprehensive quality management with Valmet IQ

Valmet IQ is a quality management solution designed and built with the experience of thousands of system deliveries by Valmet over more than half a century. Designed for pulp, paper, board and tissue production, it is a customizable quality control, information and management solution that is now further developed for the converting industries such as corrugated board and self-adhesive laminates.

Labelexpo Americas

Labelexpo Americas 2016, the largest event for the label and package printing industry in the Americas, is held at the Donald E. Stephens Convention Center in Rosemont, a suburb of Chicago. Valmet will be exhibiting on stand 1559 in Hall B.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.