Ian Melin-Jones

Valmet to supply the final stage of forming section rebuild to Stora Enso’s Skoghall Mill in Sweden

Valmet will supply the final stage of its four-stage forming section rebuild to Stora Enso’s Skoghall Mill in Sweden. The target of Valmet’s four-stage development project is to further improve production capabilities of the Stora Enso Skoghall Mill forming section.

The latest order is included in Valmet's orders received of the first quarter 2020. The value of the order will not be disclosed.

The latest order is included in Valmet's orders received of the first quarter 2020. The value of the order will not be disclosed.

“Innovation and continuous long-term development describe well our cooperation with Valmet. Together we came up with a solution that fulfils our targets for this upgrade project,” says Marie Morin, Mill Director from Stora Enso.

“Stora Enso Skoghall Mill is committed to long-term development of its machines. This type of cooperation is based on trust and openness and we look forward to successfully conclude the last phase of this project,” says Kirsi Peltola, Sales Manager from Valmet.

Valmet supplied the first stage in 2017 and has since then upgraded other parts of the forming section step-by-step on an annual basis. The last stage of the rebuild will be started up at the end of year 2020.

Information about the customer Stora Enso

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. The company employs some 26,000 people in more than 30 countries. Skoghall Mill in western Sweden is a modern world-class producer of cartonboard for demanding consumer packaging and printing purposes, including liquid packaging and dry foodstuffs board.

Toscotec and Sofidel to co-present Sofidel America’s new integrated Tissue Mill in Inola, Oklahoma, at Tissue World Miami.

Toscotec will be at Tissue World Miami 2020 Booth D-20 to showcase its innovative Tissue Technology including the Energy-Savings solutions customized for Sofidel America.

On March 13 at 1:00 pm, Sofidel’s Vice Chief Technical Officer Davide Mainardi and Toscotec’s Sales Director Marco Dalle Piagge will jointly present “Energy Efficient Solutions for Sofidel America: a Case Study”, which offers a detailed analysis of this new integrated tissue mill from a sustainability perspective.

The presentation will focus on Toscotec’s scope of supply that included Detailed Process Engineering of the plant and layout (“Inside the Box”) to cut energy consumption and ensure top efficiency in the use of thermal and electrical energy. In particular, Toscotec’s design focused on the energy recovery from the Tissue Machine Drying Section and Auxiliary Systems, Process Optimization, as well as on the reduction of water consumption and Virgin Fiber usage.

Toscotec will also take part in the following events of the Tissue World Miami Conference:

On March 10, at 1:00 pm, John Holton, Technical Support Toscotec North America, will moderate the Yankee Dryer Workshop titled “Troubleshooting and Problem Solving” and will deliver a presentation on the subject of “Overview of Yankee Diagnostics”.

On March 11, at 2:10 pm, Toscotec Technical Director Paolo Raffaelli will take part in the Senior Management Symposium’s Panel Discussion “Business Resilience in the '20s: Technological, Liability, and Human Resource Challenges”.

The Toscotec teams of North America and Toscotec Italy will be at Booth D-20 from Wednesday, March 11, through Friday, March 13.

ANDRITZ successfully starts up PrimeLineTM W6 tissue machine at Arkhbum Tissue Group in Russia

International technology Group ANDRITZ has successfully started up the PrimeLineTM W6 tissue machine, including stock preparation, re-evaporation plant, hall-ventilation, automation, and electrification, at Arkhbum Tissue Group LLC in Vorsino (Kaluga region), Russia.

The ANDRITZ tissue machine – with a design speed of 2,100 m/min and a paper width of 5.6 m – produces high-quality facial, toilet, napkin, and kitchen towel grades made of 100% virgin pulp. The combination of a 16 ft. PrimeDry Steel Yankee and the latest PrimePress XT Evo shoe press technology enables a high drying capacity and achieves remarkable cost savings and operational flexibility compared to systems with conventional presses and cast Yankee dryers. The re-evaporation system that feeds energy back to the production process enables additional savings.

Successful start-up of the ANDRITZ PrimeLineTM W6 tissue machine with PrimePress XT Evo shoe press at Arkhbum Tissue Group LLC in Russia. Photo: ANDRITZ

Successful start-up of the ANDRITZ PrimeLineTM W6 tissue machine with PrimePress XT Evo shoe press at Arkhbum Tissue Group LLC in Russia. Photo: ANDRITZ

The scope of supply also included stock preparation with an approach flow system. The centerpiece of the stock preparation line is the ANDRITZ Papillon refiner, which treats fibers gently in the cylindrical refining zone in order to achieve superior fiber properties at low energy consumption. ANDRITZ also provided process pumps, piping, instrumentation, electrification and automation as well as on-site services.

This successful start-up confirms ANDRITZ’s strong position as one of the global market leaders for supply of complete tissue production lines, key components, and services.

Valmet to supply cooking and fiberline to Tamil Nadu Newsprint and Papers Ltd. in India

Valmet will deliver cooking and fiberline to Tamil Nadu Newsprint and Papers Ltd. (TNPL) for their unit 2, located in Mondipatti in the Trichy District, India. The site has a 200,000 tons per year multilayer board machine, which has been in operation since 2016. The new pulp mill will have a capacity of 165,000 tons per year of bleached hardwood kraft pulp and the start-up is planned for the first quarter of 2021.

The order is included in Valmet’s orders received of the fourth quarter 2019. The value of the order will not be disclosed. An order with this scope of supply is usually valued in the range of EUR 20-30 million.

Valmet has a long-term relationship with TNPL. Valmet has previously supplied two fiberlines based on hardwood and bagasse respectively to their unit 1, located in Kagithapuram in the Karur District, India.

Managing Director and the mill management team of TNPL together with Valmet’s sales management team

Managing Director and the mill management team of TNPL together with Valmet’s sales management team

“Valmet’s technology is proven to meet TNPL’s strict requirements for low water consumption and raw material efficiency, which have special importance in this region. Since the launch of our latest third generation continuous cooking system in late 2018, we have been well received by the market and this order is yet another acknowledgment of that. Furthermore, this will be Valmet’s first modern reference in India for a continuous digester system, so we are proud and grateful to be a part of the project together with TNPL,” says Eva Engelfeldt, Senior Sales Manager, Fiber Processing Business Unit, Valmet.

“The unit 2 is a leading manufacturer of pulp and paper board in India. The new pulp mill with Valmet’s cooking and fiberline technology will further strengthen our ambition to maintain the leading position,” says S J Varadarajan, General Manager (Projects), TNPL. “The Valmet fiberline brings the latest technology to the TNPL Unit 2 with thrust on water conservation and environment protection. This fiberline will go a long way in making the operations of our unit 2 profitable,” says S V R Krishnan, Executive Director (Operations), TNPL.

Information about Valmet’s delivery

The scope of Valmet’s supply includes main equipment and process design for continuous cooking, deknotting, screening, brown stock washing, oxygen delignification, a three stage ECF bleaching and DNCG systems including pressure vessels, instruments and pumps.

Information about Tamil Nadu Newsprint and Papers Ltd.

Tamil Nadu Newsprint and Papers is situated at Kagithapuram in the Karur District of the Tamil Nadu province in India. The company produces newsprint and printing & writing papers using hardwood and bagasse as the primary raw materials.

James Cropper appoints Global Luxury Packaging Lead

James Cropper, one of the world’s most innovative papermakers, has appointed Tricia Hartmann as its first global luxury packaging lead for Speciality Papers.

Tricia joins to build awareness of James Cropper’s expertise in the luxury sector across the international market. With strong technical expertise in printing, paper and packaging, she will be responsible for the development of the luxury packaging offer; driving the take-up of the business’ bespoke services including Tailor Made papers and services, through growing its international partnerships with luxury brands.

Tricia Hartmann James Cropper’s Tailor Made service combines world-leading colour-matching and sustainable fibre innovation expertise with post-production capabilities such as embossing, varnishing and laminating. It not only offers brands such as Burberry and Hallmark high-quality and beautiful unique papers, it also enables them to embed purpose driven credentials and communicate brand DNA and story through their packaging.

Tricia Hartmann James Cropper’s Tailor Made service combines world-leading colour-matching and sustainable fibre innovation expertise with post-production capabilities such as embossing, varnishing and laminating. It not only offers brands such as Burberry and Hallmark high-quality and beautiful unique papers, it also enables them to embed purpose driven credentials and communicate brand DNA and story through their packaging.

Joining from Arjowiggins Creative Papers, Tricia previously spent ten years driving business development in luxury packaging across Europe and Asia.

Nick Barnes, Director at James Cropper said: “Tricia’s extensive knowledge of the international luxury packaging market and her passion for sustainability make her the perfect fit to drive forward our expansion on the international stage.

“We look forward to drawing on her insight and experience to continue to strengthen our offering to luxury brands across the globe.”

Speaking on her appointment Tricia Hartmann said: “Thanks to its position as a leading innovator in the luxury paper and packaging space for almost two centuries, James Cropper has firmly established itself as the leading solution to many international luxury brands, providing the paper for their shopping bags and their boxes.

“As we continue to see the drive towards a circular economy reaching brands and consumers in the luxury space, the demand for sustainable solutions like James Cropper’s CupCyclingTM and COLOURFORM is ever increasing. And the global market is responding as such.

“It’s an exciting time to be joining a business with such a great legacy of innovation in sustainability, and to be a part of its journey to becoming a leading player in the global luxury market”.

Tricia is based in Paris and will be growing James Cropper’s global team with a focus on partnerships in the premium packaging space across Europe, Asia and the USA.

New ABB actuator launches, helping improve efficiency, safety and product quality

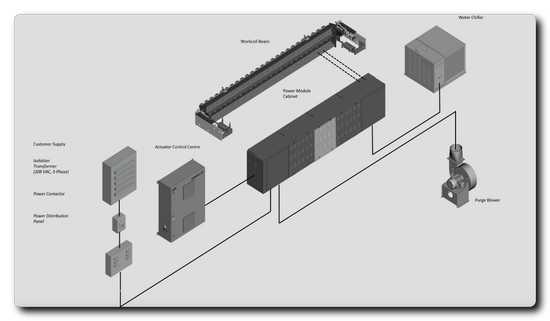

New Induction xP Plus is the paper industry’s most targeted, efficient and flexible induction heating actuator system for cross-direction (CD) caliper and gloss profile control

Technology leader ABB today announces the launch of its Induction xP Plus actuator for paper and packaging manufacturers seeking a powerful, efficient, rapid-acting and safe method for controlling caliper on paper machines calenders.

Induction xP Plus rapidly ensures efficient heating up to 100 kW/meter in a highly-targeted area, providing unmatched flexibility for power density and heating zone width. It is the only caliper profiling system available with hybrid control zone configurations of 60 mm, 75 mm or 120 mm, enabling customers to target higher precision heat distribution at the edges, where it is often critical, as well as increasing heat density to get on spec quicker—even after sheet breaks.

“Induction xP Plus significantly enhances our offering as the only actuator featuring ABB’s unique power module technology, hybrid zones for targeted heat distribution and flexible layout configurations,“ said ABB product manager, Frank Condra. “The specification is developed to maximize paper quality and productivity, but crucially, includes an off-machine power module, enabling Induction xP Plus to meet the most stringent industrial safety requirements.”

An evolution of ABB’s highly-regarded Induction xP actuator, the new Induction xP Plus uses ABB’s uniquely efficient fixed frequency/soft switching technology which, in tandem with a lower voltage design, ensures negligible switching losses and lower stresses on electronic components. Induction xP Plus also features serial communications to the power modules, a three-phase power bus distribution system and advancements in the mower module and workcoil. These features combine to deliver the lowest CD caliper variation and associated improvements in reel build, while also providing the best sheet finishing for gloss, smoothness, and printability.

ABB’s Induction Profiler is an integral part of the ABB Ability™ Quality Management System, which is based on industry-leading ABB Ability™ System 800xA. By utilizing advanced measurement, control strategies and high-performance algorithms, ABB caliper and gloss control minimizes caliper and gloss variations under any operating conditions.

Mondi Group benefits from efficient ordering processes via the integrated Voith Paper Webshop

Since the Voith Paper Webshop was launched in 2017 the number of users has risen continuously. Worldwide, more than 96 companies are already using the newly developed online tool from Voith’s digital portfolio. The Mondi Group, which has more than 100 production facilities in 30 countries worldwide, is now also relying on Voith’s simple, time-saving and cost-saving ordering processes.

- Personalized access with seamless integration into ERP system simplifies procurement of replacement parts

- High data quality with pre-populated spare parts lists, order history and operating instructions

- Improved paper machine efficiency and reduced downtimes due to easy-to-plan purchasing processes with order tracking

In the past, Mondi purchasing staff had used electronic catalogs to order replacement parts, raw materials or office supplies. However Wolfgang Stramitzer, who headed the project in his capacity as Project Manager Procurement Excellence at Mondi, stresses that the webshop developed by Voith has little in common with the eProcurement processes previously used: “Thanks to the wealth of extra services like 24/7 availability or order tracking, the webshop offers significantly more benefits. For me it is an outstanding model that further improves the efficiency of our Group.” For example, order tracking allows Mondi to see exactly when an order will arrive. Necessary downtimes can be planned precisely and kept as short as possible. At the same time, the availability of the machine is increased.

For Markus Wenzl, Head of Procurement at the Mondi Neusiedler facility, the webshop is also an important tool for the maintenance of the system. “The webshop offers a high quality of data and simple and secure access to replacement parts. In addition, information like pre-populated spare parts lists, customized packages and the ordering history help us keep production running,” says Wenzl.

In the Voith Paper Webshop, papermakers are able to purchase Voith products and services quickly and easily.

In the Voith Paper Webshop, papermakers are able to purchase Voith products and services quickly and easily.

A further key to the success of the webshop is the personalization of access, which makes the ordering process much simpler. Item numbers in the webshop correspond with Mondi item numbers. In addition, the system stores the details of the specific wear and spare parts for each of the customer’s paper machines. Because paper machines have a high degree of individualization, this function allows significant acceleration of the ordering process. Purchasing staff no longer need to select a product in a catalog from a number of variants but will directly find the right parts for the respective machine. Moreover, a lot of information on the machine, from the original delivery to the ordering history and operating instructions are integrated into the personalized section of the Voith Paper Webshop.

Seamless integration of the Voith Paper Webshop into Mondi’s purchasing system enables optimized processes and reduces administration effort. At the Mondi Group, the integration of the webshop into the SAP Ariba platform will take place in the first quarter of 2020. Currently, the webshop is still integrated into an existing Mondi catalog system via an OCI interface and is being used in the Neusiedler pilot paper mill in Hausmening, Austria. The sharing of all documents important for the ordering process, like order and order confirmation, is already being done fully automatically and electronically, also via SAP Ariba. Currently, the project teams are working on processing the data for the remaining Mondi subsidiaries. In all cases the secure exchange of data is of course guaranteed.

The Voith Paper Webshop is tailored precisely to the needs of customers. “Usually, the supplier comes and shows us what it has. Voith, on the other hand, asked us what we need,” says Markus Wenzl. This willingness to listen to the customer was a characteristic of the entire project and a further key to implementation. The Mondi Group’s extensive experience with eProcurement also helped. “It was fun to work with Mondi. You really noticed that the company has a lot of experience in eProcurement and therefore knows exactly what is needed to make this kind of project a success for both parties,” says Björn Kleigrewe, Project Manager from the Voith Webshop Team. Wolfang Stramitzer adds: “Of course there were always challenges. But thanks to Voith’s willingness to pursue new approaches we were always able to find a sustainable solution.”

Verso Corporation Completes Sale of Androscoggin and Stevens Point Mills

Verso Corporation has just announced that it has completed the sale of its Androscoggin Mill, located in Jay, Maine, and its Stevens Point Mill, located in Stevens Point, Wisconsin, to Pixelle Specialty Solutions LLC ("Pixelle").

"We are pleased to have completed the sale of our Androscoggin and Stevens Point mills to Pixelle," said Verso Chief Executive Officer Adam St. John. "After the transaction, we will continue to be a debt-free company with significant manufacturing and financial flexibility, well positioned to enhance our competitive market position, effectively respond to industry trends and take advantage of low-risk, high-return opportunities that should create long-term value for all of our stakeholders."

"With the sale of the Stevens Point and Androscoggin mills, we will now focus on the growth and enhancement of our pulp and packaging products as well as the specialty products produced at our remaining mills," said Verso President Mike Weinhold. "Our experienced, knowledgeable employees combined with our flexible manufacturing capabilities and unmatched commitment to innovation, product performance and service position Verso as a supplier of choice in North America and beyond."

"With the sale of the Stevens Point and Androscoggin mills, we will now focus on the growth and enhancement of our pulp and packaging products as well as the specialty products produced at our remaining mills," said Verso President Mike Weinhold. "Our experienced, knowledgeable employees combined with our flexible manufacturing capabilities and unmatched commitment to innovation, product performance and service position Verso as a supplier of choice in North America and beyond."

Verso is a leading North American producer of graphic and specialty papers, packaging and pulp. The Company's Duluth, Escanaba, Quinnesec and Wisconsin Rapids mills have a combined annual production capacity of 2 million tons of paper.

The Company will promptly announce how it plans to utilize no less than $225 million and up to $282 million of the net cash proceeds from the transaction for the benefit of stockholders. Verso also plans to utilize a portion of the net cash proceeds in 2020 to reduce its remaining unfunded pension liability.

Houlihan Lokey acted as financial advisor to the Company and Akin Gump Strauss Hauer & Feld LLP acted as legal counsel to the Company in connection with the transaction.

Petr Domin was appointed Chairman of the Management Board and CEO of Slovenian paper mill Vipap Videm Krško

The shareholders of an important European paper producer, Slovenian company Vipap Videm Krško, appointed Petr Domin the Chairman of the Management Board and CEO in November 2019. “My task is to ensure further development of the company, prepare a strategy leading to strengthening the market position in Central and Southeastern Europe and increase company´s profitability,“ stresses Petr Domin, new CEO of Vipap Videm Krško. “Vipap celebrated its 80th anniversary last year. When our followers celebrate a centenary, I want them to confirm, that we have done a good job here,“ adds Domin.

New owner of company is an investor association RIDG Holding, which purchased the paper mill last November from Czech Ministry of Finance, holder of 96.5% of shares. “Lately Vipap stagnated and literally lived from day to day. Petr Domin, during his time in office of Huhtamaki Group, doubled the profit,“ says Pavel Svoreň for stakeholders of RIDG Holding, part of PORTIVA investment group and adds: “Petr Domin´s task is to prepare the strategy to provide significantly profitable functioning of the company.“

Petr Domin joined Jipap, which later became a part of the Huhtamaki Group, in 1990 as an operator. At the end of 2018 left Huhtamaki as an Executive Vice President of Fibre Packaging division. During his time in office held the positions of Country CEO of Czech Republic (2005 to 2006), Norway (2006 to 2008) and Northern Ireland (2008 to 2009). Domin has created a system of the production KPI´s, which later spread within whole Huhtamaki Group division. As an Executive Director of European division of Fibre Packaging, Domin created the employees´ career development and education systems. Holding a position of Executive Vice President, personally managed the introduction of company´s CSR and was responsible for Huhtamaki Oy business strategy.

Petr Domin (53 yrs.) is married and has four children. He graduated in the field of paper and cellulose technology at the University of Pardubice and in 2005 got his MBA at Nottingham Trent University. In his free time he enjoys sports. In addition to athletics, he also likes golf and watching rally races, in which he used to participate as a co-driver during the Czech Championship competitions. “In sports I do, I always look for something that this activity can inspire me in people and company management,“ says Petr Domin and adds: “In the rally, the co-driver and the driver form a team. One without the other cannot win the race and at the same time they must absolutely trust, that each of them will do their part of the job with precision. This is exactly how I work with my team in the company.“

Metsä Board’s emissions reduction targets meet the most ambitious goals of the Paris Agreement

Metsä Board, the leading European producer of premium fresh fibre paperboards and part of Metsä Group, has had its emissions reduction targets approved by the Science Based Targets initiative as being consistent with the levels required to meet the goals of the Paris Agreement. The targets, covering greenhouse gas emissions from Metsä Board’s operations (Scopes 1 and 2), are in line with reductions required to limit global warming to 1.5°C. Metsä Board has committed to reduce by 100% its absolute Scope 1 and 2 GHG emissions by 2030 from a 2016 base year. Scope 1 covers greenhouse gas emissions caused by the company’s own production and Scope 2 refers to purchased energy.

Metsä Board’s target for reducing the emissions from its value chain (Scope 3) also meet the SBTi’s criteria for ambitious value chain goals and are thus in line with current best practices. Metsä Board commits that 70% of its non-fibre suppliers and downstream transportation suppliers by spend will set science based targets by 2024.

“Last year we announced our new, ambitious sustainability targets for 2030. One of these is to achieve fossil free mills by 2030 with zero fossil CO2 emissions. Now we are making the next big commitment to do our share in reducing the consequences of climate change,” says Mika Joukio, CEO of Metsä Board.

The Science Based Targets initiative defines and promotes best practice in science-based target setting and independently assesses companies’ goals. Science-based targets are emission reduction targets set in line with the latest climate science requirements needed to meet the goals of the Paris Agreement. The Science Based Targets initiative (SBTi) is a collaboration between CDP, the United Nations Global Compact, World Resources Institute (WRI) and the World Wide Fund for Nature (WWF).