Ian Melin-Jones

James Cropper steps into Pantherella partnership

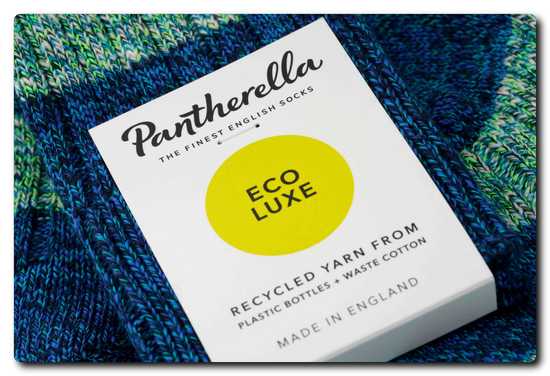

Britain’s finest sockmaker Pantherella has partnered with bespoke papermaker James Cropper to launch new packaging for its luxury sock range that speaks to its ‘Eco Luxe’ credentials and new brand identity.

Having first opened its factory doors in Leicester over 80 years ago, at the time trading as ‘Midlands Hosiery’, Pantherella now supplies more than 750,000 pairs of socks every year to leading luxury retailers and department stores around the globe. Timeless designs, luxurious yarns - from filament silk to Sea Island cotton - and fine-linked toe seams make Pantherella socks the finest in the world.

The partnership with James Cropper was developed following Pantherella’s first rebrand since 1937. Working with Michael Johnson of Johnson Banks, one of the most highly respected graphic designers in the UK, Pantherella landed on a refined colour palette of black and white. This brand palette became the driver behind the beautiful packaging designed and created using paper from James Cropper’s flagship ‘Vanguard’ range and can be found across all of the Pantherella sock collections.

Speaking on the partnership, Jamie Bartle, James Cropper’s creative design lead said: “We’re delighted to be working with this brilliant and much-loved British brand. Pantherella shares many of our values at James Cropper including a strong commitment to our heritage, cutting edge design and sustainable innovation.

“The new sock rider ticket showcases the capability of our flagship paper, Vanguard, and enables Pantherella to communicate how luxury can be achieved through simple and elegant design cues.”

On the new packaging, Justin Hall, chief executive of Pantherella said: “As a luxury brand on stage at some of the world’s most iconic stores, our packaging needs to marry our philosophy of Provenance, Design and Quality. James Cropper’s Vanguard range offered us the best of both worlds; premium quality paper, with the sustainability credentials our stakeholders now want to see us embracing.

“The new packaging will play a key role in communicating the story behind our rebrand to consumers, in which we want to strike a balance between the old and the new.”

James Cropper’s Vanguard collection offers smooth uncoated papers and boards available in a wide range of pastel and intense colours.

About James Cropper

James Cropper is a prestige paper innovator based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers.

Throughout 174 years of high-quality paper production, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

James Cropper is a member of the Paper Cup Recovery & Recycling Group (PCRRG), a cross-industry group that exists to develop collection and recycling opportunities for paper cups and identify and support solutions that sustainably transform used paper cups into a valuable resource. For more information, visit www.pcrrg.uk

About Pantherella

Established as the finest English sock maker since 1937, Pantherella has long been the choice of undeniably stylish men and women around the world. Made from the most luxurious fibres, Pantherella socks are made using a specialised knitting machine in their fifth-generation family owned factory in Leicester. Featuring their trademark fine-linked toe seam, a technique Pantherella is globally recognised for; quality and attention to detail are at the heart of the brand. With a core philosophy of provenance, design and craftsmanship, every Pantherella customer receives the finest excellence.

Please view the latest look books and brochures here: www.pantherella.com/brochure

Valmet introduces a full range of Industrial Internet solutions to pulp, board, paper, tissue and energy producers

Valmet introduces a full range of new, data-driven Industrial Internet solutions to pulp, board, paper, tissue and energy producers. The Valmet Industrial Internet (VII) solutions combine advanced monitoring and prediction applications, Advanced Process Controls (APC), dynamic process simulators and remote services from Valmet Performance Centers into comprehensive solutions that provide tangible benefits to customers.

VII solutions are tailored for each customer industry

The new VII solutions have been created for the specific needs of pulp, board, paper, tissue and energy producers. The purpose is to efficiently utilize data and Valmet’s expertise to reduce energy consumption, improve chemical and environmental efficiency, optimize pulp and paper quality, increase process reliability, maximize production and enable efficient management of the customer’s equipment fleet.

Performance Centers and Valmet Customer Portal are key elements of the VII solutions

Remote services from Valmet’s eight Performance Centers are a key part of the VII solutions. The Performance Centers make Valmet’s expertise easily available for customers through remote connections and tools.

Customers can collaborate with Performance Center experts, access the Industrial Internet applications, follow-up their Key Performance Indicators and see performance reports via Valmet Customer Portal.

Customers can collaborate with Performance Center experts, access the Industrial Internet applications, follow-up their Key Performance Indicators and see performance reports via Valmet Customer Portal.

“Our customers’ needs have been the starting point of developing these data driven Industrial Internet solutions. We have integrated our process, automation and services know-how and extensive Industrial Internet application portfolio into a value-added solution offering. Ultimately, the aim is to empower our customers to move toward autonomous plants or mills, which will result in significantly more efficient production processes and operations. We want to engage our customers in a dialogue with data to move their performance forward,” says Jari Almi, Vice President, Industrial Internet, Automation business line, Valmet.

New Forests to Purchase Tasmanian Plantations from Norske Skog

Australia-based international forestry investor New Forests has agreed to purchase the Tasmanian plantations of a local subsidiary of Norwegian pulp and paper company Norske Skog. The purchase includes a net plantation area of more than 18,000 hectares of radiata pine in the south of Tasmania and an agreement for timber sales to the Boyer Mill, which continues to be operated by Norske Skog.

The purchase is made on behalf of the New Forests Australia New Zealand Forest Fund 3 (ANZFF3), a closed-end comingled forestry fund focused on sustainable timber plantations in Australia and New Zealand. Mark Rogers, New Forests’ Managing Director for Australia and New Zealand noted, “This acquisition is a good outcome for New Forests’ ANZFF3 and its investors, who are seeking a diversified exposure to the mature, professionally managed timberland markets of Australia and New Zealand. The purchase brings added geographic and market diversity to the fund, which will also benefit from a secure, long-term offtake agreement to the local mill.”

The purchase is made on behalf of the New Forests Australia New Zealand Forest Fund 3 (ANZFF3), a closed-end comingled forestry fund focused on sustainable timber plantations in Australia and New Zealand. Mark Rogers, New Forests’ Managing Director for Australia and New Zealand noted, “This acquisition is a good outcome for New Forests’ ANZFF3 and its investors, who are seeking a diversified exposure to the mature, professionally managed timberland markets of Australia and New Zealand. The purchase brings added geographic and market diversity to the fund, which will also benefit from a secure, long-term offtake agreement to the local mill.”

The plantations have traditionally serviced around two-thirds of the Boyer Mill supply. Through a long-term pulpwood supply agreement, ANZFF3 will supply 360,000 tonnes annually to the mill, commencing at completion of the transaction. Existing contracts related to the plantation estate, including forest harvesting and haulage, will transfer with the sale.

New Forests’ Matt Crapp is Director of Operations for ANZFF3 and will oversee the transition of the plantation management upon settlement, expected in mid-2020. Crapp explained, “New Forests has strong ties throughout the Tasmanian plantation industry and will appoint a reputable and experienced property manager to oversee day-to-day operations. We anticipate opportunities for current Norske Skog forest management staff to gain employment under the new property management arrangement.”

Crapp continued, “We also look forward to bringing the estate into the broader New Forests’ portfolio, where we emphasise long-term management strategies that seek to align financial value with improving productivity, promoting forest health and resilience, and ensuring that forest management contributes to local economic, environmental, and social objectives.”

About New Forests

New Forests is a sustainable real assets manager offering leading-edge strategies in responsible forestry with more than AUD 5.4 billion in AUM across a global portfolio of nearly 1 million hectares of forestry and conservation investments. As global demand for resources grows, there is a need to increase productivity while ensuring the conservation of the world’s remaining natural forests. New Forests seeks to create investment strategies that provide lasting solutions to this challenge. Through responsible management of forests and other real assets, we create shared benefit for investors and local communities alike. New Forests has international reach, with offices and assets in Australia, New Zealand, Southeast Asia, and the US. This gives us a global perspective combined with local expertise that allows us to understand and manage our assets more effectively. To learn more, visit www.newforests.com.au.

European paper and board production follows the EU economy downward trend in 2019

|

Sappi Europe to increase prices for Woodfree Coated and Woodfree Uncoated paper grades by 5-8% for all European markets.

Decreasing profitability combined with further cost increases makes a 5-8% price increase in all Sappi’s European markets unavoidable. This increase affects WFC and WFU sheets and reels and is valid as per the 14th of April 2020. Your local sales office representative will contact you with further market related details.

Decreasing profitability combined with further cost increases makes a 5-8% price increase in all Sappi’s European markets unavoidable. This increase affects WFC and WFU sheets and reels and is valid as per the 14th of April 2020. Your local sales office representative will contact you with further market related details.

About Sappi

Sappi is a leading global provider of sustainable woodfibre products and solutions, in the fields of Dissolving wood pulp, Printing papers, Packaging and speciality papers, Casting and release papers, Biomaterials and Bio-energy. As a company that relies on renewable natural resources, sustainability is at our core. Sappi European mills hold chain of custody certifications under the Forest Stewardship Council™ (FSC™) and the Programme for the Endorsement of Forest Certification™ (PEFC™) systems. Our papers are produced in mills accredited with ISO 9001, ISO 14001, ISO 50 001 and OHSAS 18001 certification. We have EMAS registration at 8 of our 10 mills in Europe.

Sappi Europe SA is a division of Sappi Limited (JSE), headquartered in Johannesburg, South Africa, with 12,500 employees and 18 production facilities on three continents in nine countries, 37 sales offices globally, and customers in over 150 countries around the world.

Learn more about Sappi at www.sappi.com

ANDRITZ to supply complete pulp mill to UPM in Uruguay

International technology group ANDRITZ was selected by UPM, headquartered in Helsinki, Finland, to supply energy-efficient and environmentally leading equipment and processes for all main process islands in fiber production and chemical recovery for their new pulp mill to be built near Paso de los Toros in central Uruguay.

This world-class eucalyptus pulp mill will have an annual production capacity of 2.1 million tonnes and is scheduled for start-up in the second half of 2022.

The core equipment supplied by ANDRITZ will originate largely from Finland and thus will have a significant positive employment impact on employment for ANDRITZ’s staff there as well as on the ANDRITZ workshops where a large part of the core equipment for this contract will be manufactured.

UPM will build a eucalyptus pulp mill with a production capacity of 2.1 million tonnes in Paso de los Toros, Uruguay. ANDRITZ will deliver all pulp production and power generating equipment as well as chemical recovery technologies for the mill. © UPM

UPM will build a eucalyptus pulp mill with a production capacity of 2.1 million tonnes in Paso de los Toros, Uruguay. ANDRITZ will deliver all pulp production and power generating equipment as well as chemical recovery technologies for the mill. © UPM

The ANDRITZ scope of supply includes the following:

- A complete Wood Processing Plant maximizing utilization of various eucalyptus species.

- The world’s largest single-line Fiberline, including state-of-the-art LoSolids continuous cooking with efficient heat recovery and unique washing and bleaching technology based on DD-Washers, all contributing towards high-quality pulp, highest operational time, and low chemical consumption, thus having lowest environmental impact.

- A new and innovative EvoDry Pulp Drying System with two energy-efficient pulp drying lines based on the high-capacity Twin Wire Former technology.

- An energy-efficient black liquor Evaporation Plant with a tailor-made process solution resulting in high availability and increasing the overall production and efficiency of the plant.

- The HERB Recovery Boiler features energy-efficient flue gas cooling and feed water preheating technologies to maximize steam production for power generation. The state-of-the-art HERB Recovery Boiler is designed for extended operating periods.

- A biomass Power Boiler based on high-quality ANDRITZ EcoFluid Bubbling Fluidized Bed (BFB) technology. The scope of supply includes a biomass-fired boiler with flue gas cleaning and other auxiliary equipment. The Power Boiler also supplies steam for the mill during start-up. The fuels used are bark, harvesting residues and sludges from the mill.

- A complete White Liquor Plant. The new recausticizing plant includes efficient green liquor filtration with LimeGreen filters – producing clean green liquor and minimizing waste to landfill. The new lime kiln plant includes two lime kilns with high-efficiency ANDRITZ LimeCools.

ANDRITZ also delivered UPM’s first pulp mill in Uruguay, which was started up in 2007 in Fray Bentos. © ANDRITZ

ANDRITZ also delivered UPM’s first pulp mill in Uruguay, which was started up in 2007 in Fray Bentos. © ANDRITZ

This major order once again confirms the excellent and long-term business relationship between ANDRITZ and UPM. ANDRITZ also supplied a complete pulp mill in Fray Bentos, Uruguay, which was started up successfully in 2007 and is now owned by UPM.

Valmet to deliver defibrator system to Qinzhou Lvyuan Wood in China

Valmet will supply a Defibrator™ system and a Steam Separator PV system to Qinzhou Lvyuan Wood Co., Ltd. in China. The start-up of the system is planned for spring 2020.

The order was included in Valmet’s orders received of the fourth quarter 2019. The value of the order will not be disclosed.

Qinzhou Lvyuan project is a new investment of Lvyuan Group to expand its production and diversify its product range. The project is located in Guangxi autonomous region. In recent years, Guangxi has actively developed the forestry industry, expanded the industrial chain and built industrial clusters.

"We studied the equipment configuration of this project and compared several suppliers on their equipment performance parameters and actual use conditions in detail. After that, we chose Valmet to provide us the related fiber preparation equipment, which included the new generation of defibrator system and steam recovery system. It will enable an environmental production with lowest operation cost and the best fiber quality,” says Xu Zhaohui, Chairman of Lvyuan Group.

"Valmet’s employees are real professionals in fiber technology, and they are very hardworking and dedicated. Valmet provided us professional technical support and services to ensure the success of our project," says Wang Zhenhua, Qinzhou Lvyuan Wood Project Manager.

Leif Sundberg, Sales Manager, Pulp and Energy business line, Valmet, shaking hands with Xu Zhaohui, Chairman of Lvyuan Group

Leif Sundberg, Sales Manager, Pulp and Energy business line, Valmet, shaking hands with Xu Zhaohui, Chairman of Lvyuan Group

“This is an important prestige order for Valmet, since it is the first time Lvyuan group buys from us. The delivery will give us important references in China and Asia,” says Leif Sundberg, Sales Manager, Pulp and Energy, Valmet.

Information about Valmet’s delivery

Valmet’s scope of supply includes the newly released Defibrator Gen2 EVO 56 system and the Valmet Steam Separator PV. Valmet's defibrators are known for their reliability and provide homogenous fiber material of highest quality. The Steam Separator PV recovers process steam from the blow line that can be reused for preheating of the chips. This will reduce the fresh steam consumption significantly. This delivery will provide the highest performing and most energy efficient fiberboard front-end system on the market.

Information about the customer Qinzhou Lvyuan Wood Co., Ltd.

Qinzhou Lvyuan Wood Co., Ltd. was founded in 2001 and is one of the large-scale MDF manufacturers in China with annual production capacity of more than 750,000 cubic meters.

It has four subsidiaries, which are located in Zhejiang, Guangdong, Fujian, and Anhui province, and four production lines, including three production lines with an annual output of 200,000 cubic meters, and one imported production line with an annual output of 150,000 cubic meters.

Sappi Europe initiates consultations regarding the future of Paper Machine 2 at its Stockstadt mill Germany

Sappi’s strategy recognises the leadership position of the company in graphic papers markets and the need to strengthen its position in these markets to deliver maximum value to the company. The continuing and accelerating structural drop in demand for coated papers in Europe and elsewhere has made it impossible for Sappi Europe to fill its capacities adequately and to be sufficiently profitable in its current form. Importantly the current unfavourable market situation is caused by factors that are beyond Sappi’s control.

Taking these market conditions into account, Sappi has undertaken a thorough review of its European production assets. It has concluded that the least disruptive way to adjust its capacity in line with market demand would be to operate fewer machines. Exhaustive analysis indicates that the preferred option to achieve this would be to relocate the entire production output of Paper Machine 2 at Stockstadt mill (some 240,000 tpa of coated graphic paper) to other Sappi paper machines in Europe.

Taking these market conditions into account, Sappi has undertaken a thorough review of its European production assets. It has concluded that the least disruptive way to adjust its capacity in line with market demand would be to operate fewer machines. Exhaustive analysis indicates that the preferred option to achieve this would be to relocate the entire production output of Paper Machine 2 at Stockstadt mill (some 240,000 tpa of coated graphic paper) to other Sappi paper machines in Europe.

To this end, Sappi Europe has today begun a process of consultation with the competent employee representatives at Stockstadt mill. The task at hand is to identify viable alternatives for Paper Machine 2.

Berry Wiersum, CEO of Sappi Europe commented: “We fully recognise and commend the enormous efforts, both past and present, that employees and the management of Stockstadt mill have undertaken to reduce costs in order to earn better margins. Despite these relentless efforts the situation will not improve in the foreseeable future. We very much regret that we are confronted with this situation and hope that the consultation period can be used to find jointly socially acceptable solutions. At the same time, it is imperative that we not lose sight of the overall objective of improving the competitiveness of Stockstadt mill and securing its future.”

The mill currently employs 760 people, of which up to 150 positions may be impacted by the consultations. Sappi stands ready to provide the required support and to implement the decisions reached as a result of the consultation process.

Veolia to deliver key chemical removal technology to leading global pulp producer

Veolia Water Technologies will support a major expansion of a mill in Brazil by providing a turnkey chloride removal system designed to optimize the processing of wood-derived pulp used in the making of cellulose fibers.

Eucalyptus forests grow faster in Brazil than in almost any other region of the world. Many of these national wood resources are increasingly used for dissolving wood production that meets the fast-growing demand from apparel brands for making textiles with renewable fibers instead of synthetic ones. On the back of this trend, one of the world’s largest pulp producers is expanding its dissolving wood pulp operations in Brazil to convert the cellulose of hardwood forests into the raw material to produce not only staple fibers (rayon-grade) or viscose filament yarns but also specialty fibers used in the manufacturing of a wide variety of pharmaceutical and food products.

The pulping production uses a washing and cleaning process to increase the purity of the pulp. The resulting product of this process is a liquid stream that is rich in organics for energy production. This liquor, however, requires careful management and removal of chemicals to avoid the undesired build-up of chloride and potassium in the recovery cycle, which if left uncontrolled, can create corrosion and boiler fouling.

The pulping production uses a washing and cleaning process to increase the purity of the pulp. The resulting product of this process is a liquid stream that is rich in organics for energy production. This liquor, however, requires careful management and removal of chemicals to avoid the undesired build-up of chloride and potassium in the recovery cycle, which if left uncontrolled, can create corrosion and boiler fouling.

To prevent significant boiler capacity losses and increased operating costs, Veolia will treat 650 tons per day of precipitator ash. Based on advanced crystallization technology, HPD® Enhanced Chloride Removal Process (ECRP™) will be integrated into the project to yield the best control of sodium recovery and chloride removal steps.

“Veolia is proud of enabling substantial chemical savings at yet another world-class pulping project in Brazil. Recycling inputs and cutting waste while making pulping operations more productive and sustainable are at the heart of our technologies. We are pleased to make pulping processes more resource-efficient in Brazil and all over the world” stated Jim Brown, CEO, Veolia Water Technologies Americas.

The benefits of purging chloride and potassium residuals in the recovery cycle are not limited only to the economic boost of lower operating costs and improved steam generation in the recovery boiler. Equally important, ECRP’s recovery of soda chemicals from the mother liquor also makes environmental gains by protecting the health of wildlife and waterways through limited emissions of sulfur compounds and minimized losses of sulfate salts.

Through the continuous improvements in HPD® evaporation and crystallization systems, Veolia helps global producers make pulping operations safer, cleaner and more efficient to further reduce their environmental impacts and create economic value through the responsible management of closed-loop industrial processes.

Toscotec fires up its 200ᵗʰ TT SYD

Toscotec has successfully started up its 200ᵗʰ Steel Yankee Dryer at César Iglesias Group’s mill in Santo Domingo, Dominican Republic.

César Iglesias Technical Director, Jesús Feris Ferrús, commented: “Following three months of stable operation, we can confirm that our new steel Yankee dryer is delivering exceptional performances. We registered a 25% reduction of our overall thermal consumption including Yankee and Hoods. The TT SYD’s drying capacity is so high that we could significantly decrease the hoods temperature, thereby saving a substantial amount of energy. We also witnessed a great improvement of our tissue quality, in terms of hand feel and CD moisture profile. This led to an increase in our converting efficiency, which we estimate to be in the range of 10%.”

Since the first TT SYD was started up in the year 2000, this breakthrough innovation has come a long way. Toscotec’s TT SYD was the first Yankee dryer made of steel to come to the global market and it has since outclassed cast-iron Yankees to become the new technological standard of the tissue industry. Since then, TT SYD has had numerous imitation attempts, but none has reached its superior level of performance and the service experience which makes Toscotec the leading manufacturer of steel Yankee dryers worldwide.

With over 220 TT SYDs sold around the globe, Toscotec is by many magnitudes the world leading manufacturer of Steel Yankee Dryers; 200 cylinders currently operating all over the world is a notable milestone. These TT SYDs are running efficiently in more than 40 different countries across 5 continents, including over 110 cylinders in Asia and over 50 in Europe. The US market has only recently opened up to steel Yankees, and TT SYD sales have already reached over 10 units.

Out of the top 12 tissue producers in the world, 10 groups have recognised TT SYD’s superior energy efficiency and performance, and installed it at one or more of their production sites. These producers include Essity, APP, Hengan, Sofidel, WEPA, CMPC, Kruger and others who remain confidential.

Last year, Toscotec’s research and development launched the TT SYD’s third generation design. The first and second generation had been developed and continuously improved in 20 years of ongoing research, monitoring, and service of steel Yankees operating under very different conditions all across the globe. This accumulated expertise allowed for the development of TT SYD’s third product upgrade, where the height, width, and pitch of the internal ribs, as well as the shell thickness, attain an optimal geometry to maximize heat transfer efficiency without compromising safety or longevity. Toscotec’s R&D is also focusing on new innovations, including the Defender®, an internal surface treatment that ensures extraordinary resistance against corrosion and erosion. TT SYD’s operation stability, durability, and correct safety coefficient are all guarantees of its safety.

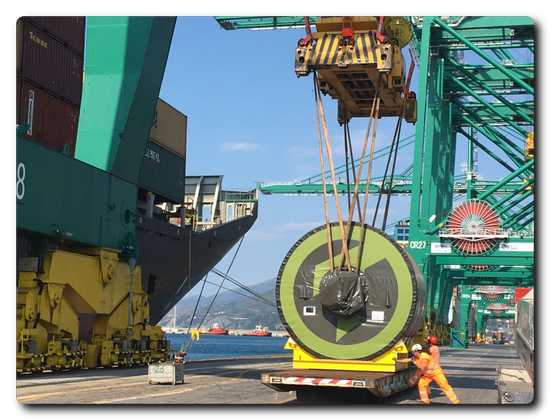

Moreover, in order to optimize the manufacturing process and shorten the delivery period, in 2012 Toscotec set up a manufacturing space specifically dedicated to the construction of its Steel Yankee Dryers. TT SYD Technology Lab is a highly technological and fully integrated 5,000 sqm plant, located just a few kilometers away from Massa’s maritime port, offering the logistical advantage of ensuring easy access to the seaport for large diameter Yankees.

Finally, beside TT SYD design advancements, Toscotec Service team has progressively and continuously upgraded the quality and accuracy of its Yankee dryer services, by relying on Toscotec’s extensive experience - the longest in the tissue industry - of steel Yankee engineering design, manufacturing, and service, in order to achieve optimal performance and infinite life.

The slowing down of the EU’s economy in 2019 - from 1.9% in 2018 to 1.1% in 2019 (Source: European Commission), combined with global instability and trade tensions, impacted the European paper and board consumption, which recorded a 4% decline.

The slowing down of the EU’s economy in 2019 - from 1.9% in 2018 to 1.1% in 2019 (Source: European Commission), combined with global instability and trade tensions, impacted the European paper and board consumption, which recorded a 4% decline.