Ianadmin

Valmet receives repeat order for a new Advantage DCT tissue production line from Papel San Francisco in Mexico

Valmet will supply an Advantage DCT 100TS tissue production machine to Papel San Francisco in Mexico. The new machine will be installed at the company's mill in Mexicali and start-up is planned for the second half of 2017.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed

Continuation of good cooperation

The new tissue line will fulfill Papel San Francisco's need of new capacity for standard tissue products. Valmet has previously delivered three tissue machines to the company. Two Advantage DCT machines started up in 2006 and 2009 and one Advantage NTT started up in 2013 which fulfills the company's demand of textured tissue.

"Our previous installations are running very well. The Advantage DCT machines are operating at high speed and made the world speed record of 2160 m/min already in 2009. The Advantage NTT machine has reached record high production capacity in conventional mode and the textured products are well received on the market. Due to the need to increase our capacity of standard tissue we decided to go for the cost and energy efficient Advantage DCT technology equipped with the Advantage ViscoNip press," says Dario Palma y Meza Espinoza, Operational Director, Papel San Francisco.

"Our relationship withPapel San Francisco is a showcase for how a supplier and customer cooperate to achieve continuous performance improvements with a win-win result. During the years Papel San Francisco has managed to break several records regarding speed and operation performance. Our relationship is built on respect, strong trust and cooperation with professional and technical focus," says Jan Larsson, Sales Director North America, Tissue Mills Business Unit, Valmet.

Technical information about the delivery

The new tissue machine will have a width of 2.8 m and a design speed of 2,200 m/min and will add 30,000 tons tissue paper per year to Papel San Francisco's current production of toilet tissue, kitchen towels and napkins.

Valmet's scope of delivery will comprise an Advantage DCT 100TS tissue machine. The machine will be equipped with OptiFlo headbox and cast alloy Yankee cylinder. The machine will also be featured with the well proven Advantage tissue technology including ViscoNip press, AirCap hood and WetDust dust system. Start-up and commissioning are also included in the delivery.

About the customer Papel San Francisco

Papel San Francisco started up their first tissue machine in 1980. In the past 35 years the company has grown steadily and are today operating five tissue machines with a yearly capacity of 150 000 tons of tissue products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Resolute Announces Downtime at Kénogami (Quebec) Paper Mill

Resolute Announces Downtime at Kénogami (Quebec) Paper Mill Due to Ongoing Government Support of Port Hawkesbury (Nova Scotia) Mill

Resolute Forest Products Inc. (NYSE: RFP) (TSX: RFP) has just announced the temporary closure of its Kénogami (Quebec) supercalendered paper mill from June 23 to July 4, 2016. The 11 days of downtime, impacting 184 employees at the operation, is in large part attributable to the ongoing market disruption caused by measures taken by the former provincial NDP Government in Nova Scotia and the former Conservative Government of Canada in support of the Port Hawkesbury (Nova Scotia) paper mill.

Resolute has consistently raised concerns with government officials, including at the Canadian federal level, that special measures of support discriminated in favor of Port Hawkesbury and resulted, among other damages, in the permanent closure of Resolute's Laurentide (Quebec) paper mill in the fall of 2014. As a result, late last year, Resolute filed a Notice of Arbitration with the Canadian Federal Government under the North American Free Trade Agreement (NAFTA).

Resolute has consistently raised concerns with government officials, including at the Canadian federal level, that special measures of support discriminated in favor of Port Hawkesbury and resulted, among other damages, in the permanent closure of Resolute's Laurentide (Quebec) paper mill in the fall of 2014. As a result, late last year, Resolute filed a Notice of Arbitration with the Canadian Federal Government under the North American Free Trade Agreement (NAFTA).

"In light of today's announcement, I reach out again to Canadian International Trade Minister Freeland urging her to address the competitive disadvantage in which supercalendered manufacturers, such as Resolute, find themselves today. We are in the untenable position of dealing with a dual set of consequences: unfair government support of Port Hawkesbury here in Canada, and retaliatory, protectionist actions by U.S. authorities," stated Richard Garneau, President and Chief Executive Officer. "At least as far as the U.S. part of the problem is concerned, it is essential that Canada ensure the formation of a fair and equitable Chapter 19 Panel under NAFTA to rectify the injustice visited upon Resolute by the U.S. Department of Commerce."

About Resolute Forest Products

Resolute Forest Products is a global leader in the forest products industry with a diverse range of products, including market pulp, wood products, tissue, newsprint and specialty papers. The company owns or operates over 40 pulp, paper, tissue and wood products facilities in the United States, Canada and South Korea, as well as power generation assets in Canada and the United States. Marketing its products in close to 80 countries, Resolute has third-party certified 100% of its managed woodlands to internationally recognized sustainable forest management standards. The shares of Resolute Forest Products trade under the stock symbol RFP on both the New York Stock Exchange and the Toronto Stock Exchange.

Resolute has received regional, North American and global recognition for its leadership in corporate social responsibility and sustainable development, as well as for its business practices. Visit resolutefp.com for more information.

Verso Announces Future Leadership Transition

Dave Paterson will become Chairman of the Board when Verso Emerges from Bankruptcy and will Step Down as President and Chief Executive Officer when Verso Finds his Successor.

Verso Corporation (OTCPink: VRSZQ) has just announced that David J. Paterson, the President and Chief Executive Officer and a director of the company, will become the Chairman of the Board of Verso immediately upon its emergence from its pending Chapter 11 bankruptcy proceeding. In addition, Mr. Paterson has informed Verso's board of directors that he intends to step down as the company's President and Chief Executive Officer when Verso finds his successor, but until then, he intends to continue to serve in this role. Though there is no set timetable for Mr. Paterson's departure, both Verso and he intend for the transition to occur in short order, with the objective that the new President and Chief Executive Officer be in place to guide Verso as soon as practicable after it emerges from bankruptcy. Verso has engaged a search firm and is actively seeking a successor to Mr. Paterson.

Verso Corporation (OTCPink: VRSZQ) has just announced that David J. Paterson, the President and Chief Executive Officer and a director of the company, will become the Chairman of the Board of Verso immediately upon its emergence from its pending Chapter 11 bankruptcy proceeding. In addition, Mr. Paterson has informed Verso's board of directors that he intends to step down as the company's President and Chief Executive Officer when Verso finds his successor, but until then, he intends to continue to serve in this role. Though there is no set timetable for Mr. Paterson's departure, both Verso and he intend for the transition to occur in short order, with the objective that the new President and Chief Executive Officer be in place to guide Verso as soon as practicable after it emerges from bankruptcy. Verso has engaged a search firm and is actively seeking a successor to Mr. Paterson.

"Dave Paterson has been a stalwart as Verso's President and Chief Executive Officer over the past four years," said Scott Kleinman, Verso's Chairman of the Board. "During this period of unprecedented upheaval in the printing and writing papers industry, Dave has provided insightful vision and steady, reliable leadership for Verso. His contributions in managing a business with constrained liquidity have been particularly valuable and appreciated as Verso has dealt head on with the financial challenges of our industry and company. Due in no small measure to Dave's substantial efforts, Verso now is poised to emerge from a fully consensual Chapter 11 reorganization as a stronger competitor with a financially sustainable capital structure. We take great comfort in the knowledge that while Dave soon will be giving up his day-to-day responsibilities as the President and Chief Executive Officer of Verso, he will remain with the company as my successor as the Chairman of the Board upon Verso's emergence from bankruptcy."

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

Valmet invests in press felt production

Valmet develops its paper machine clothing production plant in Tampere, Finland by investing in press felt production. The investment is done in order to improve the product technology and production capacity of seamed press felts for the paper, board, tissue and pulp drying machines.

The investment includes a new wide weaving loom, updating of some existing weaving looms and a new fiber opening and blending machinery. The total value of the investment is several million euros and the investment project will be finalized during the first quarter of 2017.

Seamed felts improve safety and efficiency

The investment is done in order to meet the growing market needs as customers are willing to move away from endless felts in older machines. The seamed felt market is growing, especially in North America, where over 70% of the felts used in paper and board machines are endless. Also in Europe, the market of seamed felts is growing. The change from endless felts to seamed ones improves occupational safety and production efficiency at mills.The seamed felt installation is faster and takes much less manpower than installing an endless felt.

"This investment gives us the necessary assets to further develop our leading technology for the growing and demanding seamed felt market. It also ensures our capacity for the coming years to deliver felts that respond to customer needs for optimized production performance. This is also an investment in Valmet's renewed services approach," says Jari Stålhammar, Vice President, Fabrics, Services Business Line at Valmet.

For further information, please contact:

Jari Stålhammar, Vice President, Fabrics, Services Business Line, Valmet, tel. +358 40 5014239

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

WEPA Lille S.A.S. (France) has signed a contract with PMPower for TM#11 recovery boiler steam system delivery

In February 2016, WEPA signed a contract with PMPower for a recovery boiler system delivery of TM#11 in its Mill in Lille (France).

PMPower is one of PMP’s (Paper Machinery Producer) divisions, responsible for energy solutions for both tissue and paper mills. PMPower supports PMP’s business partners globally offering its own, new products within:

• dryer hoods & steam & condensate systems,

• energy recovery systems,

• mist removal systems,

• wet dust removal systems,

• building ventilation systems.

WEPAs TM#11 will be supplied with state-of-the-art new technological items provided by PMPower. The project driving force is modern technology that ensures energy savings solutions following global trends. PMPower’s scope of delivery includes the delivery, installation and commissioning of a recovery boiler system for the TM#11. The new system will perform steam generation of 1,2 t/h and will guarantee a high level of availability and permanently adhere to the guaranteed performance values. The erection and start-up are scheduled for June 2016.

WEPAs TM#11 will be supplied with state-of-the-art new technological items provided by PMPower. The project driving force is modern technology that ensures energy savings solutions following global trends. PMPower’s scope of delivery includes the delivery, installation and commissioning of a recovery boiler system for the TM#11. The new system will perform steam generation of 1,2 t/h and will guarantee a high level of availability and permanently adhere to the guaranteed performance values. The erection and start-up are scheduled for June 2016.

About WEPA:

WEPA can look back on over 65 years of history. With competence and reliability, the company has become the third largest hygiene paper manufacturer in Western Europe since the founding in 1948. The family owned group with eleven plants in five European countries is run from its headquarter in Arnsberg, Germany. More than 3,000 motivated employees produce approximately 720,000 tons of toilet paper, kitchen towels, hankies, facials, hand towels, napkins and industrial rolls each year. (learn more: www.wepa.de)

About PMP:

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 29 countries. Company with headquarters in Jelenia Góra, Poland, owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching a new logo & visual identity. (learn more: www.pmpgroup.com)

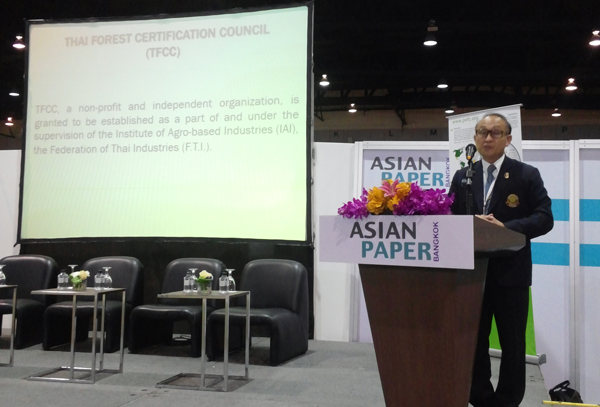

PEFC at Asian Paper Bangkok

Thailand announces their application to PEFC for membership and we highlight the opportunities of certification in Asia and beyond – Asian Paper Bangkok 2016 was a busy few days!

Thailand announces their application to PEFC for membership and we highlight the opportunities of certification in Asia and beyond – Asian Paper Bangkok 2016 was a busy few days!

“Accelerating demand for legal and sustainable timber represents both opportunities and challenges for the world's forest's, specifically in Asia,” said Ben Gunneberg, CEO of PEFC International, as he spoke at the Certification, Environment and Sustainability session on the first day of Asian Paper.

“Certification must adapt to the constantly shifting sands of needs of people. We need to ensure that sustainable forest management equally balances the environmental, social and economic pillars of sustainability, we need to find common ground between global demand side requirements and local supply side expectations," Mr. Gunneberg explained.

"By working through a bottom-up approach, by convening all interested parties at both national and international levels in ongoing dialogues, PEFC is well placed to build a bridge between local and global and to advance an understanding of sustainability that we all can feel comfortable with," Mr. Gunneberg highlighted.

Alongside Ben’s ‘fireside chat’ with other forestry experts to address sustainable forestry, realizing dollars and the value of sustainability, we also had our PEFC booth at the heart of the Asian Paper to provide information, initiate debate and raise awareness throughout the two day conference.

Spotlight on Thailand.

With so much progress under foot in Thailand towards enhancing the legal and sustainable trade and production in the wood-based and forest sector, PEFC and Federation of Thai Industries (FTI) co-hosted a special afternoon session within Asian Paper to shine the spotlight on Thailand.

With so much progress under foot in Thailand towards enhancing the legal and sustainable trade and production in the wood-based and forest sector, PEFC and Federation of Thai Industries (FTI) co-hosted a special afternoon session within Asian Paper to shine the spotlight on Thailand.

During the event, dozens of stakeholders came together celebrate progress in developing the Thai national certification system and to share perspectives for enhancing the sustainability of the Thai forestry sector through PEFC certification.

“Now that the Thailand Forest Certification Council is officially registered within FTI we have completed all the requirements and look forward to becoming a member of PEFC,” announced Dr. Nihkom, Chair of the TFCC. “Joining PEFC’s international alliance will give Thailand prominence and recognition for all the work we are doing to advance sustainability within our country.”

“I would like to congratulate all the stakeholders who have worked so hard over the past years to achieve this significant step towards the PEFC endorsement of a Thai Forest Certification System,” said Mr. Gunneberg, as he made the announcement. “We look forward to welcoming Thailand as a National member once they have been voted in by our PEFC members.”

The announcement follows an important development on 11 May when the Ministry of Natural Resource and Environment, the Ministry of Industry Thailand, and Ministry of Agriculture and Cooperatives came together to form the Institute Agro-based Industry (IAI) under FTI. It was acknowledged that the Institute will be responsible for running the Thailand Forest Certification Council.

Neenah Announces European Distribution Center in the Netherlands

New facility will serve as distribution hub for best-selling printing and packaging papers

As part of an overall expansion initiative to provide worldwide distribution as well as meet specific needs of large, global accounts, Neenah Paper have just announced the opening of its new European Distribution Center in Utrecht, Netherlands.

As part of an overall expansion initiative to provide worldwide distribution as well as meet specific needs of large, global accounts, Neenah Paper have just announced the opening of its new European Distribution Center in Utrecht, Netherlands.

This new facility, managed by the C. van Heezik Group will serve as a local European resource for some of Neenah’s most popular and best-selling brands in Europe. Neenah will immediately stock select Environment® Papers and Neenah® Folding Board, the premium lines from Neenah most often specified by designers for print and packaging products overseas. This announcement comes during Drupa (http://drupa.com), the world's leading trade show for graphic and industrial print.

“The location for Neenah’s new European Distribution Center was strategically selected for three reasons,” said Chris Schneider, Sr. International Marketing and Logistics Manager. “First, the city of Utrecht is centrally located within Netherlands and larger Europe, already a well-known transport hub. Second, this particular location enables Neenah to better service its US-based global accounts who produce a large amount of print and packaging locally in Europe. Finally, Neenah has a strong, local logistics partner that we know and trust.”

The new facility enables the timely, efficient, and cost effective operations of Neenah throughout Europe, as well as room for expansion. Schneider adds, “This is an exciting time for Neenah to solidify our position as a global provider of premium packaging papers for our key customers, with the capability to deliver anywhere within Europe.”

About Neenah

For more than 100 years, Neenah Paper (NYSE: NP) has been an innovative leader in the creation and manufacturing of papers for premium writing, text, cover, digital, packaging and specialty needs. The Neenah signature portfolio, including market-leading brands such as ASTROBRIGHTS®, CLASSIC®, ENVIRONMENT®, and ROYAL SUNDANCE® Papers now includes SUEDETEX® and TOUCHÉ®. The company also offers envelopes in thousands of unique colors, finishes and styles. Neenah Packaging provides unique and sustainable packaging papers, boards and labels as well as custom solutions for premium and luxury packaging. Neenah is committed to developing relevant mobile and online technologies including Neenah Cabinet™ for iPad, iPhone and Android. With multiple manufacturing facilities in Wisconsin, prime importance is also placed on recycled and alternative fiber products through the Neenah Green initiative. For more information on Neenah call (800) 558-5061. Follow Neenah on Twitter: @neenahpaper; subscribe to the Neenah Facebook page; or visit Against the Grain, Neenah’s blog for designers, printers and paper-lovers.

Contact

Neenah: Jamie Saunders, 001-678-518-3222, This email address is being protected from spambots. You need JavaScript enabled to view it.

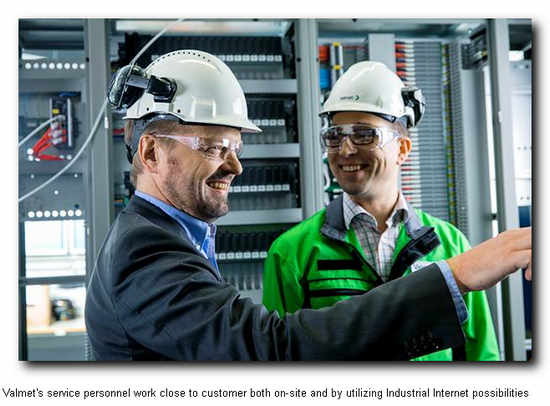

Valmet renews its services approach

Valmet has renewed its services offering and unified its way to serve to enable better customer experience and growth in the services business.

"Our vision is to become the global champion in serving our customers. We constantly challenge ourselves to improve both our services offering and also the way we actually meet our targeted customer service level. After adding automation and related services to our offering in 2015, the natural next step was to start unifying our services offering and way to serve our customers. We see that our new approach, called "Shared Journey Forward", is a concrete step towards our vision," says Pasi Laine, President and CEO of Valmet.

After the renewal, Valmet's whole services offering is easy to understand and to choose from. The services are restructured under three categories: reliability services, performance services, and new technology upgrades. Furthermore, Valmet develops further its global expertise network and way to serve the customers both online and close by.

The core commitments Valmet is making to its customers are keeping safety as number one priority, being close to the customers, serving customers with solutions meeting their needs and having people to whom customers can trust.

"The commitments we give to our customers reflect also our priorities. We never compromise safety and continuously develop our safety culture and procedures. Being close to customers means both that we are globally present with over 100 service centers and we utilize industrial internet in helping our customers remotely. We listen to our customers in order to find the best solution for particular customer needs and we work hard every day to earn our customers' trust," says Jukka Tiitinen, President of Services Business Line.

Valmet's services offering is built to improve reliability and performance of customers' processes and also bring in new technology to keep the processes up-to-date in the changing business environment.

"In addition to strong individual services products our solutions are built to bring concrete benefits to our customers. Our reliability services keep the equipment and processes running smoothly. We can even take responsibility for maintenance and on-site services and inventory management. With performance services our customers can achieve reduced energy and raw material costs, reduced process variability, optimized quality and production, and enhanced environmental performance. Furthermore, adding new technology to the process at the right time keeps production competitive and helps to take the production to the next level," describes Jukka Tiitinen Valmet's renewed services offering.

For further information, please contact:

Jukka Tiitinen, Business Line President, Services, Valmet, tel. +1 404 433 0937

Petri Lakka, Vice President, Services Development, Valmet, tel. +358 40 521 1087

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Stora Enso to close its Suzhou paper mill and to divest the site in China

Stora Enso has signed an agreement to divest the key assets of its Suzhou Mill in China, including the land-use rights and buildings, to the local government of Suzhou National New & Hi-tech Industrial Development Area (SND). During its 20 years of operation, the city of Suzhou has grown around the mill, making it difficult to develop and continue industrial operations at the current site. The cash consideration for the divestment of assets is approximately EUR 240 million.

Stora Enso has signed an agreement to divest the key assets of its Suzhou Mill in China, including the land-use rights and buildings, to the local government of Suzhou National New & Hi-tech Industrial Development Area (SND). During its 20 years of operation, the city of Suzhou has grown around the mill, making it difficult to develop and continue industrial operations at the current site. The cash consideration for the divestment of assets is approximately EUR 240 million.

The total gain on disposal to be reported in operating profit amounts to approximately EUR 180 million of which EUR 26 million will be recorded as a positive non-recurring item in Stora Enso’s second quarter 2016 results and EUR 154 million is expected to be recorded as a positive non-recurring item in Stora Enso’s fourth quarter 2016 results. The total net gain including the closure related costs after tax will be approximately EUR 150 million.

Production is planned to be stopped during June 2016 and the transaction is expected to be completed in the fourth quarter of 2016. Operational profitability of the mill is close to break even so the transaction will not have a material impact on Stora Enso’s operational EBIT going forward.

“Suzhou Mill is a recognised high quality paper producer with an established customer base. However, the mill only has one paper machine and it will no longer be competitive after the emergence of larger-sized mills in the Chinese market. The location of the mill in the middle of a large city is not favourable for paper production,” says Kati ter Horst, EVP Stora Enso’s Paper division.

Based on annual figures for 2015, the divestment is expected to reduce Stora Enso’s annual sales by EUR 126 million and simultaneously decrease the annual woodfree coated paper production capacity by approximately 240 000 tonnes. Suzhou Mill currently employs approximately 500 people, who will receive support in finding new employment opportunities.

About the buyer

SND is the administration of the Suzhou National New & Hi-tech Industrial Development Area, established in 1992. SND is part of the Suzhou City government. Suzhou City has approximately 11 million inhabitants and borders west Shanghai. SND plans to convert the mill site from industrial use to non-industrial use.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people in more than 35 countries, and our sales in 2015 were EUR 10.0 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. storaenso.com

Verso Corporation Introduces GlazeGuard™ Family of Lightweight Oil and Grease Resistant Papers for Foodservice Packaging

Verso Corporation, a leading producer of flexible packaging, technical, and label and converting papers, has just introduced GlazeGuard™, a family of lightweight uncoated machine-glazed papers designed for demanding oil and grease resistant (OGR) foodservice applications.

The GlazeGuard™ product family is an integral part of the broader portfolio of Verso machine-glazed laminating and converting papers specifically designed for flexible packaging applications. Featuring OGR levels ranging from Kit 5 to Kit 8, GlazeGuard™ offers excellent runnability, converting performance and multiple PFOA-free chemistries, all key performance requirements for end-use applications such as sandwich and deli wraps, foodservice liners, microwave popcorn bags and laminated food pouches.

The GlazeGuard™ product family is an integral part of the broader portfolio of Verso machine-glazed laminating and converting papers specifically designed for flexible packaging applications. Featuring OGR levels ranging from Kit 5 to Kit 8, GlazeGuard™ offers excellent runnability, converting performance and multiple PFOA-free chemistries, all key performance requirements for end-use applications such as sandwich and deli wraps, foodservice liners, microwave popcorn bags and laminated food pouches.

"Foodservice packaging converters and end users seeking OGR paper options with the right combination of quality, performance and run-to-run consistency will find that Verso's GlazeGuard™ OGR papers excel in these critical areas," said Mike Weinhold, Verso Senior Vice President of Sales, Marketing and Product Development. "We will deliver these solutions with the same level of highly personalized customer service, experienced technical resources and overall attention to detail that customers have come to expect from Verso."

The GlazeGuard™ product line is produced on paper machine No. 5 at Verso's Androscoggin Mill in Jay, Maine, and offers several basis weights, ranging from 15.5 lb. to 33 lb. (3000 sq. ft.), each optimized for specific end uses. According to Jason Handel, Verso Group Vice President of Product Development and Technical Sales, "The No. 5 paper machine has a long-standing reputation for producing OGR papers with outstanding quality and consistent performance. These products, which we have branded as GlazeGuard™, will quickly be recognized as excellent, reliable solutions for demanding OGR applications."

For more information on GlazeGuard™ or other products in Verso's broad specialty papers offering, email This email address is being protected from spambots. You need JavaScript enabled to view it. or visit versoco.com/specialtypapers.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.