Ianadmin

Fatal accident at Valmet's project site in Sweden

On Thursday, June 2, 2016 a serious workplace accident occurred in Valmet's installation activities in the pulp mill expansion project at Södra Cell's Värö mill in Sweden. An employee of Valmet's subcontractor was seriously injured in a lifting operation and later died in hospital whilst receiving treatment for injuries sustained during the accident.

"Our thoughts are with the deceased's family and colleagues. We have informed the personnel working with the project on site and are giving them the needed support. Valmet is committed to protecting the health, safety and environment (HSE) of our people, customers, partners and the communities where we operate. Everyone has the right to a safe work environment. Investigation of the accident has been started and corrective actions will be implemented to continuously improve our processes and routines to ensure safety," says Stefan Mattsson from Valmet.

"Our thoughts are with the deceased's family and colleagues. We have informed the personnel working with the project on site and are giving them the needed support. Valmet is committed to protecting the health, safety and environment (HSE) of our people, customers, partners and the communities where we operate. Everyone has the right to a safe work environment. Investigation of the accident has been started and corrective actions will be implemented to continuously improve our processes and routines to ensure safety," says Stefan Mattsson from Valmet.

Valmet has initiated an incident investigation, in co-operation with the customer and contractor. The incident is also under investigation by the police and the Swedish Work Environment Authority.

For further information, please contact:

Stefan Mattsson, Vice President, Fiber Processing Business Unit, Valmet, tel. +46 70 653 38 18

Bertel Karlstedt, President, Pulp and Energy, Valmet, tel. +358 10 676 3026

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

500,000 tonnes of dissolving pulp produced

As of mid-May, Södra has produced 500,000 tonnes of dissolving pulp at its pulp mill in Mörrum. Production started in December 2011 and has increased steadily since then.

“Demand for dissolving pulp for textile purposes is increasing globally,” said Magnus Björkman, Marketing and Sales Director at Södra Cell. “Demand is being driven by population growth and rising prosperity along with a shift toward textiles that offer a more sustainable alternative.”

“Demand for dissolving pulp for textile purposes is increasing globally,” said Magnus Björkman, Marketing and Sales Director at Södra Cell. “Demand is being driven by population growth and rising prosperity along with a shift toward textiles that offer a more sustainable alternative.”

Wood can be used in many areas and in the production of numerous products. Fibre is the main component and is thus ideal for production on an industrial scale.

“Södra made the strategic decision in 2011 to invest in an additional strong fibre product through the production of dissolving pulp,” said Annica Larsson Ahlstedt, Development Manager at Södra Cell Mörrum. “We have two production lines at Mörrum – one for dissolving pulp and one for paper pulp – which provides us with ample room to grow in the future.”

Replacing synthetic, oil-based fibre with fibre from forest raw material can significantly reduce the greenhouse gas effect. Substantial environmental gains can also be achieved by using forest-based textile fibres instead of cotton.

Sustainability and quality

Södra’s dissolving pulp is entirely traceable to certified, sustainable forestry operations. But quality is also crucial.

“Dissolving pulp from Södra maintains a high standard of quality and is a certified sustainable product,” said Magnus Björkman. “This combination is important to customers.”

Following the company’s recent decision to invest an impressive SEK 1 billion in Södra Cell Mörrum, its production of dissolving pulp is expected to increase even further as of 2018.

Facts:

Södra Cell Mörrum produces dissolving pulp for textile purposes from hardwood and paper pulp from softwood. The mill produces 145,000 tonnes of dissolving pulp for textile purposes and 280,000 tonnes of paper pulp annually, corresponding to a total of 425,000 tonnes.

In February, Södra’s Board of Directors decided to invest SEK 1 billion in the pulp mill at Mörrum. Following this new investment, the mill’s production capacity is expected to total 470,000 tonnes by 2018. 270 Exhibitors, 5000 Visitors: this is MIAC in Lucca (Italy)!

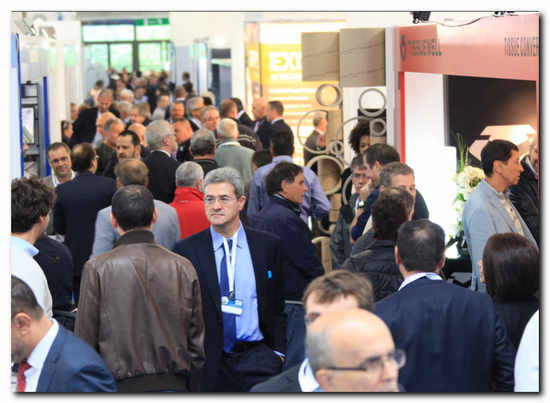

Visiting MIAC (12.13.14 October 2016) means obtaining a full overview of the technology and equipment available to the paper industry sector thanks to the constant participation of the leading companies in the sector which present the latest developments in machines, systems and avant-garde solutions to improve the management of the various stages in the paper production cycle.

MIAC has reached its 23rd edition. It is an international meeting point that allows you to compare the technologies and business proposals of 270 companies present at the Exhibition. Taking part in MIAC means being one of 5,000 Visitors from across the globe who meet in Lucca in October of each year (last year’s MIAC Exhibition registered visitors from 56 Countries).

International meeting point

Rapidly changing technological solutions require continuous education: MIAC is the answer to all this! During the 3 days of Exhibition take place 4 international Conferences, offering very interesting content and studied to provide professional information to the participants coming from all over the world.

MIAC is held in Lucca/Italy, the only officially recognized “Paper District” in Europe. But Lucca is not only synonymous with the Paper Industry! It is also one of the major tourist destinations in Italy, and is sure to charm the Visitors of MIAC with its beautiful city Walls, Towers and Squares.

MIAC is the Official Exhibition of ASSOCARTA, the association of the Paper, Board and Pulp industry manufacturing companies in Italy, and of LUCCA INDUSTRIAL ASSOCIATION

SCA: Productos Familia S.A., Colombia

Productos Familia S.A., Colombia, of which SCA (STO:SCAA) (STO:SCAB) owns 50% of the shares, has been found guilty in an anti-trust inquiry related to tissue products conducted by the Colombian competition authority. The inquiry, which targeted Familia and four other companies in the market, pertains to activities that took place up until 2013. Familia will be fined approximately SEK 170m.

As earlier communicated, SCA made a provision of approximately SEK 100m related to the Colombian competition authority’s ongoing review of Familia. The amount was reported as an item affecting comparability in the first quarter of 2016. SCA will make an additional provision of approximately SEK 70m related to the tissue category. The amount will be reported as an item affecting comparability in the second quarter of 2016.

As earlier communicated, SCA made a provision of approximately SEK 100m related to the Colombian competition authority’s ongoing review of Familia. The amount was reported as an item affecting comparability in the first quarter of 2016. SCA will make an additional provision of approximately SEK 70m related to the tissue category. The amount will be reported as an item affecting comparability in the second quarter of 2016.

The investigation in Colombia regarding the baby diapers category is still ongoing and no provision has been made for this.

SCA takes the matter very seriously. Since 2013, SCA has supported the company to revise its Code of Conduct based on a European model. As stated on page 43 of SCA’s sustainability report, Familia’s Code of Conduct now complies with all new legislation and the UN framework for business and human rights.

All questions about this matter should be addressed to Familia.

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo, Vinda and Zewa. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2015 amounted to approximately SEK 115bn (EUR 12.3bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Brenntag acquires all outstanding shares in Chinese distributor Zhong Yung

Brenntag, the global market leader in chemical distribution, has signed an agreement to acquire all outstanding shares in Zhong Yung (International) Chemical Ltd. The first tranche of 51% was already acquired in 2011 and the company has demonstrated a positive development since that time. Brenntag is now buying the remaining 49%. Zhong Yung has a significant presence across the mainland of China with modern equipped distribution facilities in Beijing, Tianjin, Shanghai and Guangzhou.

Brenntag, the global market leader in chemical distribution, has signed an agreement to acquire all outstanding shares in Zhong Yung (International) Chemical Ltd. The first tranche of 51% was already acquired in 2011 and the company has demonstrated a positive development since that time. Brenntag is now buying the remaining 49%. Zhong Yung has a significant presence across the mainland of China with modern equipped distribution facilities in Beijing, Tianjin, Shanghai and Guangzhou.

Henri Nejade, Member of the Board of Management of Brenntag Group and CEO Brenntag Asia Pacific, says, “With the Zhong Yung participation, Brenntag once had its strategic market entry in the fast-growing Chinese chemical market. In the 5 years of cooperation with a local partner, we saw a successful development of the business, strengthening Brenntag’s footprint in the Asia Pacific region. Zhong Yung is an excellent base for strong future growth in China for our existing business and is an ideal platform for further acquisitions.”

Zhong Yung is a major industrial chemical distributor with excellent infrastructure in the key economic regions in China including laboratories, blending and storage capabilities. The company continuously focuses on the expansion in the fields of storage, distribution and value-added services.

Ni Jianzhong, Chairman of the Board of Directors of Zhong Yung and future Chairman of the Board of Directors of Brenntag in China: “The successful cooperation between Brenntag and Zhong Yung laid a strong foundation for the positive expansion and further growth in China. We will continue to build upon this solid platform to broaden our product portfolio further and be the preferred partner for value-added services for both customers and suppliers throughout the company’s network in China.”

About Brenntag:

Brenntag, the global market leader in chemical distribution, covers all major markets with its extensive product and service portfolio. Headquartered in Mülheim an der Ruhr, Germany, the company operates a global network with more than 530 locations in 74 countries. In 2015, the company, which has a global workforce of more than 14,000 employees, generated sales of EUR 10.3 billion (USD 11.5 billion). Brenntag connects chemical manufacturers and chemical users. The company supports its customers and suppliers with tailor-made distribution solutions for industrial and specialty chemicals. With over 10,000 products and a world-class supplier base, Brenntag offers one-stop-shop solutions to around 180,000 customers. This includes specific application technology, an extensive technical support and value-added services such as just-in-time delivery, product mixing, formulation, repackaging, inventory management and drum return handling. Long-standing experience and local excellence in the individual countries characterize the global market leader for chemical distribution.

From IMERYS to Schaefer Kalk - Technavio Uncovers Top Five Vendors in the Global Calcium Carbonate Market from 2016 to 2020

Technavio has announced the top five leading vendors in their recent global calcium carbonate market report. This research report also lists six other prominent vendors that are expected to impact the market during the forecast period.

Competitive vendor landscape

Calcium carbonate, which comprise of GCC and PCC, are the highest value-added products in the limestone value chain. The production of GCC is widespread globally. China, the US, Europe, and Japan are the largest producers of GCC. The production of PCC is restricted to a few manufacturers that have manufacturing facilities across key consuming countries. These players cater to the demanding segments such as paper, paints and coatings, plastics and adhesives and sealants.

Calcium carbonate, which comprise of GCC and PCC, are the highest value-added products in the limestone value chain. The production of GCC is widespread globally. China, the US, Europe, and Japan are the largest producers of GCC. The production of PCC is restricted to a few manufacturers that have manufacturing facilities across key consuming countries. These players cater to the demanding segments such as paper, paints and coatings, plastics and adhesives and sealants.

Globally, Omya, Imerys, Okutama Kogyo, Mineral Technologies, and Schaefer Kalk are notable PCC manufacturers. The global installed capacity of GCC and PCC is reported to be around 100 million MT. China accounts for around 50% of the total installed capacity, followed by the US at around 20%.

The global supply is restricted to a few companies that have operations at the regional and country level. “Being the highest value-added product, PCC is traded globally through these global suppliers. Satellite plants cater to paper mills, which is the largest end-user segment. While other segments such as paints and plastics are catered through national level manufacturers or by the global majors,” says Chandrakumar Badala Jaganathan, a lead analyst at Technavio for research on metals and minerals.

Request for sample report: http://goo.gl/udqNpQ

Top five calcium carbonate market vendors

IMERYS

IMERYS was founded in 1880 and is headquartered in Paris, France. It is a mineral-based specialty solution providing company. The company transforms materials to deliver specific functions such as coverage, conductivity, heat resistance, mechanical strength, and barrier effect for customers involved in the manufacturing process and products. It operates in 50 countries and has 250 industrial sites worldwide.

IMERYS produces a variety of ground carbonate powders that are used as drill-in fluids, lost circulation materials, and weighting agents. The company’s carbonate business comprises limestone calcium carbonates, highly soluble sized marble, and dolomite powders that are sourced from global locations.

Mineral Technologies

Minerals Technologies is a resource and technology-based company. The company offers a range of specialty minerals, synthetic mineral products, and related systems and services. The company caters to the steel, paper, foundry, energy, environmental, polymer, and consumer products industries.

In January 2014, Mineral Technologies entered into an agreement with UPM-Kymmene (UPM) to build a satellite PCC plant at UPM's paper mill in Changshu, Jiangsu province, China.

Omya

Omya was founded in 1884 and is headquartered in Oftringen, Switzerland. It is one of the leading producers of industrial minerals, including fillers and pigments derived from calcium carbonate and dolomite. It caters to the forest products, polymers, building materials, and life science markets.

Omya is the largest supplier of mined calcium carbonate globally. Calcium carbonate is valued for its versatility in its finished and finely crushed form. It is used in the paper, plastic, and paint sectors. It is added to foods to enhance the mineral content, formed into ceiling tiles to substitute asbestos, and used as an eco-friendly filler in plastics and medicines.

Okutama Kogyo

Okutama Kogyo was incorporated in 1937 and is headquartered in Tokyo, Japan. The company deals with mining, manufacturing, and marketing of limestone. It was formerly known as the Okutama Electric Railway.

The company offers limestone that is used as a raw material for ready-mixed concrete, cement, filler for asphalt concrete, and flue gas treatment. Quick lime is supplied to the steel, soil stabilization, and building materials sectors. Slaked lime is used for flue gas treatment and in the chemical industry. Crushed stone is used as a backfilling material for road construction and is also consumed as a nursery material for seeding.

Schaefer Kalk

Schaefer Kalk was founded as Johann Schaefer Kalkwerke in 1860 and is headquartered in Hahnstatten, Germany. It produces lime and quicklime products, PCC, and premixed dry factory mortar. The company owns a limestone deposit that consists of 350 million years old compact limestone, which is one of the purest limestone deposits in Europe.

The company mines limestone and processes it into a variety of products that are supplied to the construction and industrial sectors globally. The chemically pure limestone reserves in Hahnstätten has been the basis for a variety of high-quality limestone products.

Browse Related Reports:

- Global Calcium Stearate Market 2015-2019

- Calcium Carbonate Market in North America 2015-2019

- Global Silica Minerals Mining Market 2016-2020

Purchase these three reports for the price of one by becoming a Technavio subscriber. Subscribing to Technavio’s reports allows you to download any three reports per month for the price of one. Contact This email address is being protected from spambots. You need JavaScript enabled to view it. with your requirements and a link to our subscription platform.

About Technavio

Technavio is a leading global technology research and advisory company. The company develops over 2000 pieces of research every year, covering more than 500 technologies across 80 countries. Technavio has about 300 analysts globally who specialize in customized consulting and business research assignments across the latest leading edge technologies.

Technavio analysts employ primary as well as secondary research techniques to ascertain the size and vendor landscape in a range of markets. Analysts obtain information using a combination of bottom-up and top-down approaches, besides using in-house market modeling tools and proprietary databases. They corroborate this data with the data obtained from various market participants and stakeholders across the value chain, including vendors, service providers, distributors, re-sellers, and end-users.

Södra issues green corporate bond

Södra is inviting the capital market to take part and finance investments in Södra’s green industry. It will take the form of green corporate bonds, issued by Södra, to finance energy and environmental investments in the Group’s industry.

“The capital market has shown great interest in investing in Södra, which has a strong history in sustainability leadership. Our pulp mills are virtually fossil-fuel free already and these major investments will further strengthen our environmental performance and increase the production of renewable and green energy from the mills,” said Lars Idermark, President and CEO of Södra.

“The capital market has shown great interest in investing in Södra, which has a strong history in sustainability leadership. Our pulp mills are virtually fossil-fuel free already and these major investments will further strengthen our environmental performance and increase the production of renewable and green energy from the mills,” said Lars Idermark, President and CEO of Södra.

Södra, which is owned by 50,000 forest owners in southern Sweden, is expanding its pulp production capacity and has an investment programme of some SEK 6 billion in place, in addition to regular maintenance investments. Expansion of the Värö pulp mill accounts for the largest investment, but major investments are also being made in the mill at Mörrum. The investments are two-fold – to increase production capacity, and to make the mills more energy-efficient by installing, for example, condensation turbines and evaporation plants.

The framework for Södra’s green bonds has been reviewed by the Centre for International Climate and Environmental Research Oslo (CICERO), an independent research centre linked to the University of Oslo in Norway. CICERO has given Södra its highest “Shades of Green” rating – Dark Green.

Södra’s first Green Bond, which amounts to a total value of SEK 1 billion, has a 5 year maturity and was priced with a floating rate coupon of three-month STIBOR* +1.60 per cent annually. The Green Bond was issued under Södra’s Medium Term Note (MTN) programme.

SEB acted as lead arranger of the transaction and also served as advisor for the green framework.

*Stockholm Interbank Offered Rate

For questions, please contact:

Peter Karlsson, Interim Chief Financial Officer,

Tel: +46 (0)470 – 890 28

Johan Löfmark, Director Group Treasury,

Tel: +46 (0)470 - 891 35

Global and China Dissolving Pulp Industry Report 2016-2020 - Research and Markets

Research and Markets has announced the addition of the "Global and China Dissolving Pulp Industry Report, 2016-2020" report to their offering.

Dissolving pulp refers to the pulp with cellulose content above 90%, including primarily wood pulp, bamboo pulp and cotton pulp (dissolving pulp in this report just involves wood and bamboo pulp). Viscose fibre, the main application field, accounts for 3/4 of total consumption of dissolving pulp.

Dissolving pulp refers to the pulp with cellulose content above 90%, including primarily wood pulp, bamboo pulp and cotton pulp (dissolving pulp in this report just involves wood and bamboo pulp). Viscose fibre, the main application field, accounts for 3/4 of total consumption of dissolving pulp.

Global dissolving pulp capacity totaled about 7.5 million tons in 2015, mostly distributed in the regions/countries with rich forest resources including North America, South Africa, and Brazil. The world's major dissolving pulp producers are Sappi, Aditya Birla, Lenzing, Sun Paper, Bracell, Rayonier, etc. which produce mainly dissolving wood pulp and hold a combined 57% share of the global total capacity. The dissolving pulp produced by Lenzing is completely used for in-house production of viscose fibre.

Globally, there are still a number of dissolving pulp projects under construction in 2016, such as Lenzing's ongoing dissolving capacity expansion, Aditya Birla's new 200kt dissolving pulp project in Laos, and Domtar's 516kt dissolving pulp renovation project launched in early 2015. With ever-growing dissolving pulp capacity, global dissolving pulp prices will remain low on the whole over the next couple of years.

Because of a shortage of forest resources, the Chinese dissolving pulp companies have been plagued with higher production costs and weaker competitiveness. During 2012-2015, due to sluggish demand for viscose staple fiber, dissolving pulp overcapacity, and impact of international low-cost dissolving pulp on domestic market, the dissolving pulp sector in China almost suffered losses across the industry. With the implementation of the Chinese government's anti-dumping rulings and gradual recovery of downstream viscose staple fiber industry, it is expected the country's dissolving pulp sector will bottom out during 2016-2020 with output and apparent consumption of dissolving pulp amounting to 320 kt and 3,184 kt respectively in 2020.

Key Topics Covered:

- 1 Overview of Dissolving Pulp Industry

- 2 Overview of Global Dissolving Pulp Industry

- 3 Chinese Dissolving Pulp Industry

- 4 Downstream Viscose Fiber Market

- 5 World's Major Dissolving Pulp Companies

- 6 Major Chinese Dissolving Pulp Companies

- 7 Conclusion and Prediction

Companies Mentioned

- Aditya Birla

- Bracell

- Fujian Qingshan Paper Industry Co.,Ltd.

- Jilin Chemical Fibre Co., Ltd.

- Lenzing

- Sappi

- Shandong Chenming Paper Holdings Ltd

- Shandong Huatai Paper Co., Ltd.

- Shandong Sun Paper Industry Joint Stock Co., Ltd.

- YanbianShixianDouble-deer Industrial Co., Ltd.

- Yibin Grace Group Co., Ltd.

- Yueyang Forest & Paper Co., Ltd.

For more information visit http://www.researchandmarkets.com/research/ldsfnz/global_and_china

Research and Markets

Laura Wood, Senior Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

For E.S.T Office Hours Call 1-917-300-0470

For U.S./CAN Toll Free Call 1-800-526-8630

For GMT Office Hours Call +353-1-416-8900

U.S. Fax: 646-607-1907

Fax (outside U.S.): +353-1-481-1716

Sector: Pulp and Paper

Lucart Group acquires Bokk Paper KFT

On 31st May the Lucart Group, through its holding company Lucart Spa, acquired the total capital of Bokk Paper kft, the main independent Hungarian player in the Away From Home (AFH) tissue products market.

The name of the company has already been changed to Lucart kft.

“We have had a good business relationship with Bokk Paper for over 10 years – stated Massimo Pasquini, CEO of the Lucart Group – and thanks to its geographical location, market reputation and marketing strategy, which align perfectly with our goals, Bokk Paper was the ideal acquisition for the expansion of our Company in Central- Eastern Europe”.

“We believe that with the acquisition and integration of Bokk Paper into the Lucart Group, will strengthen our presence in the Central-Eastern European A.F.H. markets, by offering the best services and products to all current and potential new customers.”

Zsolt Király, one of the former owners of Bokk Paper, declared: “We believe that the sale of our Company to the Lucart Group is the best solution to give continuity to our entrepreneurial project and to assure the future growth of the business. For this reason, my partner József Orlovits and myself will remain as Managing Directors of the company to ensure a smooth and efficient integration and take over.”

About Lucart kft (former Bokk Paper kft)

Lucart kft is a Hungarian company located in Esztergom, 50 kilometers north of Budapest, operating in the tissue paper converting products sector, in the Away From Home market. The Company employs 55 people and has a turnover of 7.5 million euros. More than one third of the turnover is in export sales to neighboring countries. Around 80% of the sales are from Bokk Paper branded products.

About the Lucart Group The Lucart Group is an Italian Group with a production capacity of 310,000 t/y of tissue, airlaid and MG paper. The Company has a turnover of over 400 million euro and more than 1,250 employees. The Group is the leader in the Italian Away From Home tissue market and is in the top 5 European players in this sector.

The Lucart Group is an Italian Group with a production capacity of 310,000 t/y of tissue, airlaid and MG paper. The Company has a turnover of over 400 million euro and more than 1,250 employees. The Group is the leader in the Italian Away From Home tissue market and is in the top 5 European players in this sector.

The Lucart Group is the leading producer of recycled tissue products for the A.F.H. and Consumer markets in Southern Europe.

For more information visit www.lucartgroup.com

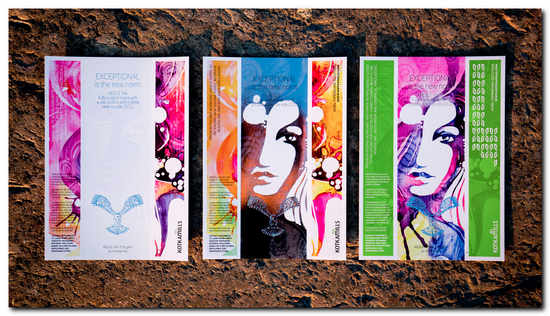

Kotkamills launches fully recyclable and repulpable consumer board products AEGLE and ISLA

Kotkamills is launching its new range of consumer board products: the folding boxboard range will be covered by the AEGLE brand and the food service range by the ISLA brand. The standard board ranges will be launched in July 2016 when Kotkamills’ new board machine starts. The option of water-based dispersion coated barriers will be added in the Autumn. The new machine will for the first time allow barrier coatings to be applied directly on the cartonboard machine as part of normal production.

“Brand owners and designers are constantly looking for new and better options for creating attractive packaging while answering to the growing consumer demand for ecological products. With AEGLE and ISLA, we offer both sustainable and cost effective solutions that do not compromise the freedom to create unique designs,” says Markku Hämäläinen, CEO of Kotkamills.

“With our next-generation barrier boards, it is possible to use the normal paper recycling process, as they are fully recyclable and repulpable. The board itself is manufactured paying special attention to utilising wood raw material effectively, as well as minimising environmental effects with the help of the latest available technology,” Hämäläinen continues.

Kotkamills’ folding boxboard AEGLE is suitable for various packaging needs from cosmetics and pharmaceuticals to dry, chilled and frozen food and general packaging. Although lightweight and bulky, the board offers high stiffness. In addition to standard fully coated glossy surfaces, Kotkamills are offering a unique silk matt coating that makes the surface of the board very even and smooth, offering excellent printability as well as enhancing the use of various special effects, such as lacquering and foiling. AEGLE folding boxboards will be available with and without recyclable barriers.

The ISLA product range is intended to be used for the production of food service packaging, such as disposable cups and plates. The fact that the dispersion coated barriers used are fully recyclable and repulpable means that after use, such paperboard cups and plates can be easily disposed of along with normal paper waste. This means that a valuable, high quality fibre source can be recovered and re-used instead of being thrown away; unlike the more normally used plastic coated barrier cups and plates.

The raw material for all Kotkamills’ board products are procured from certified Nordic forests.

Further information:

Markku Hämäläinen, CEO of Kotkamills Oy

tel. +358 40 721 0548

This email address is being protected from spambots. You need JavaScript enabled to view it.

About Kotkamills

Kotkamills is a responsible partner that delivers renewable products and performance to its customers’ processes via product innovations created from wood, a renewable raw material. Our key brands include Absorbex® and Imprex®, both innovative laminating paper products for the laminate, plywood and construction industries. Moreover, Kotkamills offers ecological, technically sound and visually attractive wood products for demanding joinery and construction. In summer 2016, Kotkamills will start-up a new cartonboard machine designed to produce folding boxboard and food service boards for consumer markets, including the capability to add barriers on-machine. All Consumer Boards material solutions will be fully recyclable and repulpable.

Kotkamills has two production sites in Finland, located in Kotka and Imatra, and a subsidiary L.P. Pacific Films for Imprex® production in Malaysia. The majority shareholder of Kotkamills is MB Funds, a Finnish private equity firm.

www.kotkamills.com