Displaying items by tag: valmet

Valmet delivers new chipper to Sappi's Ngodwana pulp mill in South Africa

Valmet will deliver a new gravity feed chipper to Sappi Southern Africa (Pty) Ltd Ngodwana. The upgrade targets are to increase the chipping capacity, to maintain or improve chip quality and minimize wood losses. The chipper will be delivered and installed in May 2018 and the start-up is planned for the beginning of June 2018.

The order was included in Valmet's second quarter 2017 orders received. The value of the order will not be disclosed.

The order was included in Valmet's second quarter 2017 orders received. The value of the order will not be disclosed.

"Valmet came up with a unique solution to 'swop' out the existing chipper with a new larger chipper by not requiring any major concrete works changes allowing for a short shut-down duration to install the new chipper, thus enabling minimal operation down time," says Ryno Eksteen, Senior Regional Project Manager at Sappi.

"South Africa has been a successful market area for Valmet's wood handling business and with this delivery we continue our positive trend. The Valmet sales team concentrated on optimizing the solution for a demanding raw material and minimizing the payback time for Sappi," says Jussi Taskinen, Manager R&D, Product Portfolio & Strategy at Valmet"

Details about the order

The order consists of a Camura GS1050 chipper with auxiliaries and a screen extension, including machinery, erection, commissioning, training and start-up supervision. Mechanical installation is also carried out by Valmet.

About Sappi Ngodwana mill

The Ngodwana mill has been in operation since 1966 and entered the dissolving wood pulp market in 2013. The mill produces paper grade pulp for own and for market consumption, as well as newsprint, containerboard and dissolving wood pulp. The mill produces 330,000 tons of paper pulp for own consumption, 210,000 tons of dissolving wood pulp and 380,000 tons of paper (newsprint and kraft linerboard used for packaging) per annum. 70% of the mill's product is exported and the balance is used locally.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet reshapes its internal IT services and signs a business transfer agreement with CGI

Valmet will start a reshaping of its internal Information Technology (IT) services to improve the operations' efficiency and business focus. The set of actions to be taken include a business transfer agreement signed with CGI. Under the agreement Valmet's internal IT Service Desk, end user support and most infrastructure services, including server management, workstation management and end user computing, will be moved from Valmet and their current partners to CGI.

The transfer agreement concerns 58 current Valmet IT employees globally, who will be offered to transfer to CGI or its partner with similar terms. The transfer is targeted to become effective on October 1 and the full transfer project is to be closed by the end of March 2018.

The transfer agreement concerns 58 current Valmet IT employees globally, who will be offered to transfer to CGI or its partner with similar terms. The transfer is targeted to become effective on October 1 and the full transfer project is to be closed by the end of March 2018.

This reshaping of Valmet's IT services will allow more resources to focus on developing digital capabilities that support the future development of the company. Valmet IT's focus will be shifted from running current services to developing new competences and services. A global IT platform will be created to ensure a harmonized way of working, and additional focus will also be put on more effective IT services and supplier management.

"With these actions we will improve the performance and efficiency of our internal IT operations. Our IT resources will be able to increase focus on building the competences and ways to operate necessary for Valmet's future development. Transferring the IT infrastructure services, including service desk, after a thorough evaluation process to CGI is one of the key steps to enable this transformation," says Janne Puustinen, Vice President, Information Technology, Valmet.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work closely with our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com, www.twitter.com/valmetglobal

CGI is one of the largest IT and business process services providers in the world. Founded in 1976, it has some 70,000 professionals and hundreds of locations worldwide. CGI had a revenue of CAD 10.7 billion in 2016.

Valmet's technology in a key role at Metsä Group's newly started Äänekoski bioproduct mill

Metsä Group's bioproduct mill in Äänekoski was started up on August 15, 2017. Valmet's delivery to the mill included a recovery boiler, pulp drying line, gasification plant, lime kiln, sulfuric acid plant, and mill-wide Valmet DNA automation system.

All the equipment delivered by Valmet represent the latest technology and are highly energy-efficient. The gasification technology and recovery boiler will maximize the use of bioenergy and make the pulp mill totally fossil fuel-free. The recovery boiler, pulp drying line and lime kiln are the largest in Europe.

The construction of the mill was started in April 2015. The project proceeded as planned and was started up exactly on schedule. Safety was one of the special focus areas in the project. Valmet also emphasized safety onsite with special HSE experts and in contractor cooperation. As a result, Valmet's safety performance onsite was on a very good level for a project of this magnitude.

"This project has been important for us both from the technology and employment perspective. Majority of the technology provided by Valmet was engineered and manufactured in Tampere, Jyväskylä, Ulvila and Raisio. It is our pleasure to rise to the challenge, when a customer like Metsä Group is taking the industry forward with investments of this magnitude. Success in a project like this is made possible by close cooperation between the two parties. Our cooperation has been open and constructive, and we have worked together to find the right solutions," says Bertel Karlstedt, Pulp and Energy Business Line President from Valmet.

"We have a long experience of co-operating with Valmet in our pulp mills in Finland. Throughout the project Valmet has been a good and innovative partner when building the world-class bioproduct mill in Äänekoski," says Timo Merikallio, Project Director, Metsä Group.

Largest investment of the forest industry in Finland

The new bioproduct mill in Äänekoski is the largest investment of the forest industry in Finland. Metsä Group's total investment amounted to approximately EUR 1.2 billion. The mill will achieve its nominal capacity approximately a year after start-up. The mill will produce 1.3 million tonnes of pulp per year, along with other bioproducts such as tall oil and turpentine. New bioproducts that already complement the product concept include product gas from bark, sulphuric acid from the mill's odorous gases, and biogas and biofuel pellets from sludge.

Äänekoski bioproduct mill. Photo Metsä Group

Äänekoski bioproduct mill. Photo Metsä Group

Details about Valmet's technology delivery to Äänekoski bioproduct mill

Physically the largest of the Valmet delivered equipment is the recovery boiler. The boiler is designed for a capacity of 7,200 tds/d (tonnes dry solids a day). The Äänekoski recovery boiler has multiple high-power features, including patented heat recovery from flue gas to combustion air, enabling the mill to produce 260 MW of electricity and sell 1.4 times more electricity to the grid than it needs for its own operation.

The produced pulp is dried in the pulp drying line, where the pulp web is formed, pressed and dried before being cut into bales.

Individual 250 kg bales are wrapped and consolidated into 2,000 kg units for transportation.

Valmet DNA automation system is the process control and information system for the whole bioproduct mill, and has machine and drive controls for the drying machine. It is also possible to expand the system with additional control and Industrial Internet systems.

At the biomass gasification plant bark is dried using a patented double-layer drying process with material recirculation. Dried bark is gasified to make product gas, which is then used as the fuel in the lime kiln.

Active lime is regenerated in the lime kiln using biofuels. A stationary product cooler is setting new standards for recovering process heat.

The sulfuric acid plant represents Valmet's latest innovations and has been specially developed for this kind of mill. The new technology, which produces sulfuric acid from odorous gases, will enable the bioproduct mill to be nearly self-sufficient in sulfuric acid.

Information about the customer Metsä Group

Metsä Group is a forerunner in sustainable bioeconomy utilising renewable wood from sustainably managed northern forests. Metsä Group focuses on wood supply and forest services, wood products, pulp, fresh fibre paperboards and tissue and cooking papers. Metsä Group's sales totalled EUR 4.7 billion in 2016, and it employs approximately 9,300 people. The Group operates in some 30 countries. Metsäliitto Cooperative is the parent company of Metsä Group and is owned by approximately 104,000 Finnish forest owners

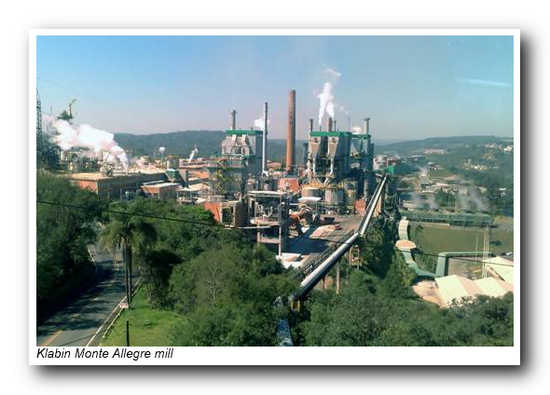

Valmet completed the annual shutdown of Klabin paper mill successfully

Valmet has completed the annual shutdown of Klabin S.A. Monte Alegre paper mill in Brazil successfully. The agreement covered the entire shutdown project from planning and execution to a safe start-up. The shutdown took place between April 24 - May 5, 2017, and included close to 500 employees from Valmet and its sub-contractors.

Valmet and Klabin have an existing agreement for full annual shutdown services. This year's project was the second of the three-year agreement.

"We have co-operated with Valmet since 2009 and the current partnership was a natural follow-up of the relationship we have been able to build over the years," says Arnaldo Jasinski, Klabin's Maintenance Manager.

Good results in safety and quality

The usual procedure for mill shutdowns is to reserve several months for planning and preparation such as spare part and tool deliveries.

"We were able to deliver everything as planned and promised. During the ten days of shutdown we made everything we could to ensure smooth operation for our customer's machines to run 24/7 for the rest of the year," says Rodolpho Quadros, Field Service Engineer from Valmet.

"We have had good results in the execution of our work in annual shutdown, both in safety and quality. Since the planning, where the focus was also to seek the optimization of resources to reduce costs, Valmet's expertise was essential to help us making decisions, says Leandro Caetano da Silva, Klabin's Maintenance Planning Coordinator.

Information about the customer

Klabin S.A. is the biggest paper producer and exporter in Brazil. It produces packaging paper and board, corrugated packaging and industrial bags in addition to selling timber in logs. Klabin has 16 industrial plants of which 15 in Brazil and one in Argentina. The company was founded in 1899.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work closely with our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet receives a repeat order of two more containerboard machines from Nine Dragons in China

Valmet will supply two more containerboard production lines with related automation systems for Nine Dragons Industries Co., Ltd., China. The new production lines will be located in Hebei (PM 41) and Shenyang (PM 42) and are similar to the previous orders of PM 39 and PM 40 announced in March 2017.

At this point, Nine Dragons also purchased steam and condensate systems for these new lines and for the previous board making lines (PM 39, PM 40, PM 41 and PM 42). All the board making lines will be designed to produce high-quality testliner grades out of 100 percent recycled raw materials. The start-ups of PM 41 and PM 42 are scheduled only a few months apart for late 2018 and early 2019. The start-ups of the two previous production lines are also scheduled a few months apart starting from the middle of 2018.

Industrial design with led lighting and video screens increase safety and usability and have a positive effect on the customer's brand

Industrial design with led lighting and video screens increase safety and usability and have a positive effect on the customer's brand

The orders are included in Valmet's second quarter of 2017 orders received. The value of the order will not be disclosed. The value of an order of this type and scale is typically valued around EUR 100-120 million.

"Paper industry market in China is very active and our customers value sustainable and innovative paper and board making technology. The high activity is well demonstrated by this Nine Dragons' decision to purchase four-in-a-row energy and resource efficient containerboard machines within a very short time. Modern industrial design played an important role in this case, too," says Jari Vähäpesola, President of Paper Business Line, Valmet.

Technical details about the delivery

Valmet's deliveries for PM 41 and PM 42 container board making lines are similar to the two previous ones. The deliveries will include steam and condensate systems, pulpers for stock preparation, a board machine from headbox to winder including a full scope automation package, chemical systems and process ventilation equipment.

As in the previous orders of PM 39 and PM 40, the full scope automation packages comprise Valmet DNA process and machine controls and condition monitoring. Board final quality is managed with Valmet IQ quality control system, comprehensive range of profilers as well as web inspection and monitoring system. The deliveries include also an extensive package of modern analyzers from pulping and wet end to laboratory testing. "In addition to smoother project execution, integrated automation and process technology solutions enable faster start-up and faster optimization phase in terms of end-product quality and energy consumption," says Arto Rohola, Sales Manager, Automation Business Line, Valmet.

PM 41 and PM 42 will produce testliner grades with a basis weight range of 75-140 g/m2.

About the customer Nine Dragons

Founded in 1995, Nine Dragons Paper Group is the world's largest in recovered paper based paper manufacturing in terms of production capacity. The company and its subsidiaries produce linerboard, high performance corrugating medium and coated duplex board. The group's paper machines in China are located in a number of locations. The group produces printing and writing paper in Dongguan and Taicang and packaging paperboard and specialty paper in Leshan, Sichuan Province. The group has also acquired 100% control equity interest in Hebei Yongxin Paper Co., Ltd.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet receives its sixth tissue line order from Hayat Kimya

Valmet will supply an Advantage DCT machine including the flexible ViscoNip press and an extensive automation package to Turkish tissue producer Hayat Kimya. The company has decided to invest in a second machine at their mill in Yelabuga in Tartaristan, Russia, to meet the increasing demand for their high-quality tissue products. The new line will add 70,000 tons of tissue to Hayat Kimya's current production of facial, toilet and towel tissue.

The order is included in Valmet's second quarter 2017 orders received. The value of the order will not be disclosed.

From left: Massimiliano Corsini, Paolo Vezil (Valmet), Lütfi Aydin (Hayat), Björn Magnus, Jan Erikson (V), Yahya Kigili (H), Haluk Arican (V), Avni Kigili, Ibramih Güler, Kemal Arslan (H)

From left: Massimiliano Corsini, Paolo Vezil (Valmet), Lütfi Aydin (Hayat), Björn Magnus, Jan Erikson (V), Yahya Kigili (H), Haluk Arican (V), Avni Kigili, Ibramih Güler, Kemal Arslan (H)

This will be the seventh project where the Valmet's and Hayat's teams are working together. Previously Valmet has delivered five Advantage DCT 200TS tissue production lines to Hayat, which have started up at Hayat's mills in Turkey 2010 and 2015, Iran 2013, Russia 2014 and Egypt 2016. Furthermore, Valmet conducted an extensive rebuild of their TM1 machine in Turkey during 2015.

"We feel very comfortable with Valmet by our side and are convinced that we will be successful together. We also feel that Valmet has trust in our own technical people and our company. This is a good base for future cooperation," says Lütfi Aydin, Director, Paper Group, Hayat Kimya.

"Hayat Kimya have clearly set at new quality standard for Russian tissue products, manufactured by the Advantage DCT technology. The results from the Advantage ViscoNip press installations as such and the rebuild of Hayat's TM1 including the new AirCap Heli hood, have met all expectations regarding efficiency and quality. We are convinced that the new tissue machine TM7 will further strengthen Hayat Kimya's market leading position," says Björn Magnus, Sales Director, Tissue Mills business unit, Valmet.

Technical information

The new tissue machine TM7 will have a width of 5.6 m and a design speed of 2,200 m/min.

The raw material to be used in the tissue production will be virgin fiber and the new production line is optimized to save energy and to enhance the quality of the final product.

Valmet's scope of delivery will comprise a complete tissue production line featuring stock preparation systems and a Valmet Advantage DCT 200 TS tissue machine. The machine will be equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including ViscoNip press, an AirCap Heli hood and air system prepared for co-generation, WetDust dust system, sheet transfer system and a SoftReel L reel. The line also includes a Valmet Focus Rewinder. The stock preparation line will consist of OptiSlush pulpers, OptiFiner conical refiners and OptiScreen machine screens.

Furthermore, the delivery will include an extensive Valmet automation package with Valmet DNA machine controls, process controls and Valmet IQ quality controls. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

The order also includes upgrade of Hayat Kimya's Advantage ViscoNip presses, to next generation, for TM1, 5 and 6.

Information about Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the home care, hygiene and tissue categories consumer goods industry. Hayat has continued to invest significantly, since their entrance into the tissue category 11 years ago and today The Group carries "The Largest Tissue Manufacturer of Africa, Middle East and Eastern Europe" title with 420,000 tonnes production capacity/year.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply a complete tissue production line to ICT Iberica in Spain

Valmet will supply a complete tissue production line with an extensive automation package to ICT Iberica in Spain. The new Advantage DCT 200HS tissue line will be installed at the company's mill in Burgo and will fit the company's intention to adopt state of the art technology for their highest quality tissue production. The start-up is planned for the third quarter of 2018.

The order is included in Valmet's second quarter orders received 2017. The value of the order will not be disclosed.

Valmet has previously delivered four tissue lines to ICT companies in Italy, France and Poland. The latest started up at the Kostrzyn mill in Poland in December 2015.

"The results from our most recent tissue machine installation in Poland have convinced us that the Advantage DCT with the ViscoNip press technology is the solution also for the Burgo mill. We expect to reach the same high production efficiency and target to supply ULTRA quality tissue products to the Spanish market," says Riccardo Baccelli, Executive Director, ICT.

"The flexibility of Valmet's Advantage ViscoNip press makes it possible to adjust the production to fit current and future market needs, from production of tissue with high bulk and softness to energy- and cost-efficient products with high quality, only within minutes. This will be Valmet's 43rd ViscoNip installation and we are happy to work together with the ICT team for the fifth time and make this a successful project," says Jan Erikson, VP Sales, Tissue Mills business unit, Valmet.

Information about Valmet's delivery

Valmet's Advantage DCT 200HS tissue machine

Valmet's Advantage DCT 200HS tissue machine

Valmet's scope of delivery will comprise of a complete tissue production line including a stock preparation system and an Advantage DCT 200HS tissue machine with the latest technology for highest quality consumer tissue. The production line will be optimized to save energy and enhance final product quality.

Complete engineering, training, start-up and commissioning are also included in the delivery. The delivery will also include an extensive Valmet automation package.

The new line will add 70,000 tons a year of high-quality toilet, towel, facial, and napkin grades for the European market. The raw material for the new line will be virgin fiber.

Information about ICT

ICT Group, has been in the tissue business since 1978 and is a European market leader that specializes in premium products. The Group's range of toilet rolls, kitchen towels, napkins, facial tissues and handkerchiefs is marketed both through its own brand Foxy, and through retailer's private labels. The business also includes the sales of parent reels to converters and diapers and personal hygiene products. ICT Group operates ten paper machines in four European countries: five in Italy, three in Poland, one in France and one in Spain. The global production capacity currently amounts to about 540,000 tons per annum which will increase to 610,000 tons by the end of 2018, when a new investment that will double capacity in Spain will be completed. The ICT Group, has a revenue approximatively EUR 700 million and employees just over 1,400 people. For more information: www.ictgroup.net

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply an Advantage NTT tissue production line to Sofidel S.p.A in Spain

Valmet will supply a complete tissue production line to Sofidel's Ibertissue mill in Buñuel, Navarra, in Spain. The delivery includes an Advantage NTT 200 tissue production line, stock preparation equipment and automation system. Start-up of the new line is scheduled for third quarter 2018.

The order was included in Valmet's first quarter 2017 orders received. The value of the order is not disclosed.

The up-coming new line in Spain will be Sofidel's fourth Valmet Advantage NTT tissue line in Sofidel's machine fleet. Previously the company has bought one NTT machine to their Delitissue mill in Poland and two NTT machines to their new site, Circleville in Ohio, USA. All in all, this is the 15th tissue machine supplied by Valmet to Sofidel.

"What we have seen from the performance of the Advantage NTT lines started up so far, we are more convinced than ever that this is the technology for the future. It will give us the flexibility we need to get a competitive advantage in the market," says Luigi Lazzareschi, CEO of Sofidel

Valmet Advantage NTT tissue machine

Valmet Advantage NTT tissue machine

"We are of course excited that Sofidel once again decided to go for the Advantage NTT technology to support their path toward future tissue making. It is a perfect match for Sofidel's ambition to produce high quality tissue products with low energy consumption supporting their goal to reduce greenhouse gas emissions," says Jan Erikson, Vice President, Sales, Tissue Mills business unit, Valmet.

Technical information of the delivery

The new tissue machine will have a design speed of 1,800 m/min in textured mode and 2,000 m/min in plain mode. The production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of supply comprises a complete tissue production line including an Advantage NTT tissue machine, with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including, an AirCap hood with Air system, WetDust system and a SoftReel B reel. Valmet will also deliver detailed mill engineering, stock preparation equipment as well as an automation package including DCS (distributed control) and QCS (quality control) systems.

About the customer Sofidel S.p.A

The Sofidel Group is one of the leading manufacturer of paper for hygienic and domestic use worldwide. Established in 1966, the Group has subsidiaries in 13 countries - Italy, Spain, the UK, France, Belgium, Germany, Sweden, Poland, Hungary, Greece, Romania, Turkey and the USA - with more than 5,500 employees, a consolidated turnover of 1,842 million Euros (2016) and a production capacity of over one million tonnes per year. Sofidel is a member of UN Global Compact and the international WWF Climate Savers programme.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet launches new Industrial Internet offering and starts partnership with Tieto

Valmet takes its Industrial Internet services to the next level by launching a new offering and opening four Performance Centers for energy, pulp, paper and board and tissue customers. At the same time, Valmet has signed a partnership agreement with Tieto, which is the first step in building a leading Industrial Internet ecosystem bringing the key players together.

"Valmet is the leading process technology, automation and services provider for pulp, paper and energy industries globally. The technologies we provide to our customers are equipped with advanced sensors and measurement devices that gather important data from machines and processes. Furthermore, Valmet's automation systems that many of our customers have provide a solid data source. Combining the data from these sources with data from customers' other mill and plant systems creates an enormous amount of data. The core benefit to our customers is that our experts know which data to analyze and how to utilize it. This know-how is built into our Industrial Internet applications and services," says Jari Almi, Director, Industrial Internet, Valmet.

"Valmet is the leading process technology, automation and services provider for pulp, paper and energy industries globally. The technologies we provide to our customers are equipped with advanced sensors and measurement devices that gather important data from machines and processes. Furthermore, Valmet's automation systems that many of our customers have provide a solid data source. Combining the data from these sources with data from customers' other mill and plant systems creates an enormous amount of data. The core benefit to our customers is that our experts know which data to analyze and how to utilize it. This know-how is built into our Industrial Internet applications and services," says Jari Almi, Director, Industrial Internet, Valmet.

Industrial Internet offering for reliability and performance

Valmet's Industrial internet applications and services are built to improve the reliability and performance of customers' processes. The Industrial Internet enabled reliability services consist of online monitoring, predictive diagnostics and data analysis to improve mill and plant efficiency, to help to plan right-timed maintenance and to prevent unplanned shutdowns. Valmet's Industrial Internet enabled performance services concentrate on integrating data from different systems together with production data to optimize mill and plant level operations. They also include both individual process and the whole machine fleet optimization services.

Four Performance Centers to provide Industrial Internet services

Valmet has established four Performance Centers that are the customer's channel to all Valmet Industrial Internet applications and services. Customers can contact the Performance Centers and get real-time support from Valmet experts and the customer's processes can also be monitored remotely. Moreover, the Performance Centers offer data discovery and big data analysis services based on agreed targets. Performance Centers have been established for pulp, energy, paper, board and tissue industry customers and the Valmet experts work in them both physically and virtually where ever they are through a remote connection.

Solution ecosystem with leading industry players

To provide comprehensive Industrial Internet offering to its customers, Valmet is building an Industrial Internet solution ecosystem that brings leading industry players together. The purpose of the ecosystem is to create new value-adding applications and services to pulp, paper and energy industries. This will offer superior performance for Valmet's customers, compared to each actor operating independently. The now signed partnership with Tieto is a significant step in building the ecosystem.

"This partnership with Tieto is an important step towards creating a strong Industrial Internet ecosystem and comprehensive services for our customers. Through this cooperation and the companies' complementary offerings, production process and business data can be integrated and optimized for the customers' benefit," says Jari Almi.

"We are pleased to be part of new data-driven ecosystems and to deepen our partnership with Valmet to innovate new services and solutions around supply chain and processes optimization. The collaboration starts around Enterprise Resource Planning and Manufacturing Execution Systems, and we are looking forward co-creating new opportunities around industrial internet and data to our customers," says Satu Kiiskinen, Executive Vice President, Tieto.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Tieto aims to capture the significant opportunities of the data-driven world and turn them into lifelong value for people, business and society. We aim to be customers' first choice for business renewal by combining our software and services capabilities with a strong drive for co-innovation and ecosystems. www.tieto.com

Valmet and Södra Cell sign mill-wide Learning Agreement

Valmet and Södra Cell in Sweden have signed a three-year agreement for web-based training via the Valmet Online Learning portal. Valmet will provide online courses for all main mill processes to about 600 employees at all three Södra mills in Sweden; Värö, Mörrum, and Mönsterås.

Previously, Södra has purchased Valmet's online training as part of the Värö mill expansion project. Based on excellent training results and positive feedback from the trainees, Södra is now extending the agreement to all three mills over a period of three years.

Valmet Learning Services offers organization-wide training solutions tailored to the customers' needs.

Valmet Learning Services offers organization-wide training solutions tailored to the customers' needs.

"Developing the skills of our employees, both our current and newly employed, is of utmost importance. Having effective methods and tools for education is an important prerequisite. We truly believe that together with our skilled intern teachers, the Valmet Online Learning Portal will be an important part of a strong concept," says Stefan Sandberg, Mill Manager at Södra Cell Mörrum, Sweden.

Valmet Online Learning is a fully-featured Learning Management System (LMS), offering individual and group level reporting and a diversity of collaboration features, available from computers and mobile devices. It provides 24/7 access to a large online course library for operators, maintenance staff, and other personnel in the pulp, paper, energy, and other process industries. Assessments, evaluations, and certificates are integrated in the portal and can be easily customized.

"Valmet Online Learning is an efficient tool to get our customers' new employees quickly up to speed in their new roles. For experienced operators, the online courses are a time-saver when preparing for re-certification tests. We also see that our customers value the extensive reporting features which support each employee's individual competence development," says Lisa Månsson, Global Manager, Valmet Online Learning.

Information about Valmet Learning Services

Valmet Online Learning is part of the company's recently launched customer training offering - Valmet Learning Services. The renewed offering is designed to help improve the reliability and performance of the customers' processes.

"Increased mobility and digitalization create new opportunities, but also poses new challenges to businesses when it comes to developing and retaining talent. Employees expect learning to be available anywhere, at any time. Valmet Online Learning offers the features and flexibility needed to continuously build and maintain skills and expertise for individuals, teams, and organizations. Helping our customers to develop their people is a key factor in our commitment to move our customers' performance forward," says Emmeli Olén, Director, Valmet Learning Services.

Information about the Customer Södra

Södra was founded in 1938 and is the largest forest-owner association in Sweden and an international forest industry Group, with a membership of more than 50,000 forest owners. Södra's operations are based on responsible forestry and on industries where they convert the raw material into sawn timber, paper and dissolving pulp, and green energy.

Find out more about our offering at www.valmet.com/services/learningservices

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.