Displaying items by tag: valmet

Valmet launches new quality management solutions for corrugators at SuperCorrExpo 2016

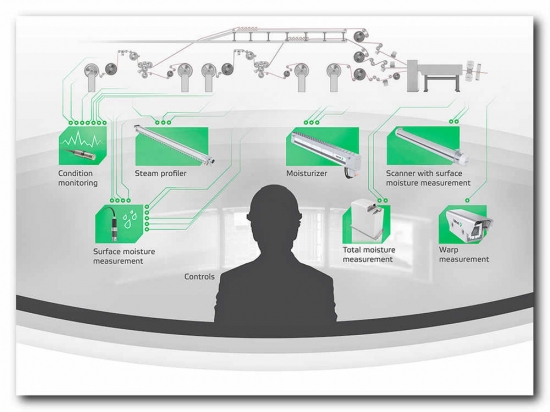

Valmet has developed a totally new concept for quality oriented process control of corrugating machines. This includes cost- and space-efficient Valmet IQ Multipoint Moisture Measurement system and a new camera based Valmet IQ Warp Measurement for the combined board flatness control.

Previously, corrugating machine process control has been based on sheet temperatures due to a lack of suitable moisture sensors built for the tight confines of corrugating machines. Valmet's experience from paper machine processes has shown that temperature measurements alone are not sufficient when controlling fiber based web processes and moisture measurements are needed to maximize productivity and decrease quality defects.

"We are now challenging the methods of traditional corrugator control with new technology, methods and concepts in an area that has previously been somewhat ignored by higher level automation. We have found out that efficient moisture control in addition to temperature control improves gluing, reduces fluting defects or washboard and eliminates warp in the final product. Our approach, which emphasizes the cost effectiveness of solutions, is being met with enthusiasm across the industry," says Mikko Talonen, Business Manager, Automation, Valmet.

Combining new innovation with experience from other processes

The Valmet IQ Multipoint Moisture Measurement sensor, a key component in the new system, has been developed to meet the need for a simple, small and cost effective moisture measurement in the tight confines of the corrugating machine. The corrugating process features up to ten drying and re-wetting cycles which, in addition to disturbances such a speed changes and raw material changes, increase variability and suboptimal process situations.

The Valmet IQ corrugator control system can utilize steam and moisture profilers and scanning sensors developed for, and utilized over many years in the paper and board industry. As well as the IQ Multipoint Moisture a new camera based warp measurement has been developed to meet user needs. Valmet's continuous development efforts, now extended to corrugating operations, promise to provide more innovation for future process and quality improvements.

Valmet IQ is quality management solution designed and built with the experience of thousands of system deliveries by Valmet over more than half a century. Designed for pulp, paper, board and tissue production, it is a customizable quality control, information and management solution that has been further developed to meet the needs of converting operations such as corrugated board and self-adhesive laminate production.

The application and its use is demonstrated at the SuperCorrExpo, the largest corrugated industry trade show in the Western hemisphere. The 4 day event is held from October 17 to October 20, 2016 at the Orange County Convention Center (OCCC) in Orlando, USA.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Online strength prediction shows promise

Models verified for OCC-furnish containerboard and TMP-based publication papers. Prediction and control of BCTMP properties has been implemented; kraft pulp models are coming.

By Mark Williamson, Journalist Engineer

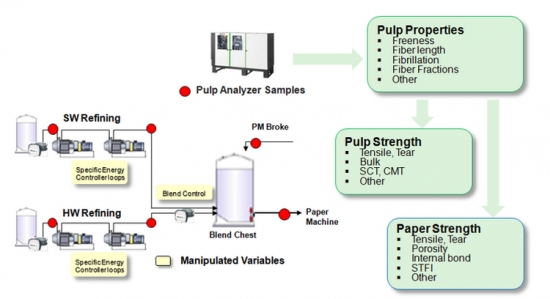

Online measurements by Valmet’s Pulp Analyzer (Valmet MAP) are the foundation for paper strength prediction

Valmet’s announcement that it had developed the capability to predict end-use paper strength properties signaled a major change in how paper quality can be controlled effectively and conclusively from an upstream location. For the first time, operators can see online how fibers are developed in the refiners and the impact of refining changes on paper sheet qualities, rather than waiting for top-of-reel physical tests. This paradigm shift is made possible by a new high definition image analysis of fiber properties added to the Valmet MAP. With this high resolution, the fine detail of fiber fibrillation created by the refiners can be seen, in addition to fiber length fractions, shives, fines, other fiber morphology measurements and freeness measurement from several sampling locations. Seeing is believing. These measurements and papermachine operating conditions are now used in a multi-variable soft sensor model which predicts final sheet properties. These predictions correlate to traditional lab tests.

Valmet’s announcement that it had developed the capability to predict end-use paper strength properties signaled a major change in how paper quality can be controlled effectively and conclusively from an upstream location. For the first time, operators can see online how fibers are developed in the refiners and the impact of refining changes on paper sheet qualities, rather than waiting for top-of-reel physical tests. This paradigm shift is made possible by a new high definition image analysis of fiber properties added to the Valmet MAP. With this high resolution, the fine detail of fiber fibrillation created by the refiners can be seen, in addition to fiber length fractions, shives, fines, other fiber morphology measurements and freeness measurement from several sampling locations. Seeing is believing. These measurements and papermachine operating conditions are now used in a multi-variable soft sensor model which predicts final sheet properties. These predictions correlate to traditional lab tests.

Of course, the same measurements can be made with offline lab instruments, and that is valuable for grade development, recipe management and incoming fiber property checking. However, for real-time process control, the immediacy of measurements from the online analyzer confirms the control moves are correct and tests are not being sacrificed.

Models confirmed

Now, the results are coming to light as customers are learning more about stock prep processes. One of the first was at a newsprint and publication paper mill using TMP as the furnish. Product Manager Ismo Joensuu reports; “The tensile strength model based on the analyzer data in their TMP has been stable and accurate over the years. Actually, we have not made any updates to the model since installation.” This is a positive confirmation that the model is repeatable and robust, which is essential for any online measurement. After using the measurement for operator adjustments, the customer plans to implement refining controls in the autumn of 2016, according to Joensuu.

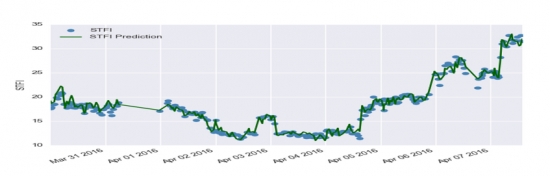

More recently, the analyzer has been used to measure OCC furnish fiber properties and freeness before a containerboard machine. Papermakers have to carefully manage the refining operation since they have to deal with a fiber source which is less desirable and less predictable than virgin kraft fibers. Figure 1 shows the correlation of the soft sensor prediction of STFI compression to laboratory tests over an eight-day period. Similar predictive models have been developed for Mullen and Concora tests.

Figure 1: Correlation of soft sensor prediction of STFI compression to laboratory results over an eight-day period. Similar predictive models have been developed for Mullen and Concora tests.

The models are based on multiple fiber measurements, freeness and board machine operating conditions. The top ranked measurements include longer fiber fractions and conditioned weight. This is not surprising since long fibers make stronger board and higher conditioned weight adds strength - at a cost of course. Other important factors include fibrillation and papermachine operating conditions, like headbox temperature, rush/drag ratio, forming table vacuums and couch vacuum. The eventual objective is to manage refining so the fibers themselves contribute the most to strength. Then, conditioned weight can be lowered - or not run too high - while still meeting the tests. Startups, grade changes and break recovery periods can be shorter with less waste.

A new window

The installation of the OCC analyzer has opened up a new window that wasn’t there before. The fiber and freeness measurements have confirmed in real-time what papermakers have always known about refining, but there have been a few surprises. For instance, the degree of fiber cutting, fiber development and fines development in top and bottom ply refiners is now well defined but sometimes different than expected. In one case, a conventional operator control action was contradicted by the predictive measurements. After analyzing the data, the predictive action was proven true. “The fiber images don’t lie,” says Kevin VanPembrook, Product Manager. “Freeness still plays a significant role but fiber analysis and freeness together tell a more complete story,” he adds.

Fiber analysis can also be used to predict refiner plate life. As VanPembrook explains, there is a tendency to over-refine to achieve freeness targets as the plates wear, and that can result in fiber cutting and loss of strength.

Pulp mill modeling

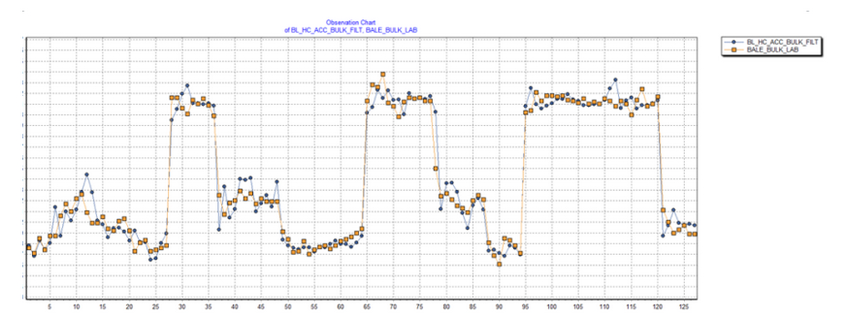

The pulp analyzer and soft-sensor modeling is also implemented in pulp mills where important fiber properties are being predicted. In a BCTMP mill bulk and tensile strength are being predicted by soft sensor models which use freeness (CSF), shives and fines measurements from the pulp analyzer plus bleach plant pH, which an advanced process control (APC) regulates to keep bulk and tensile within range. Bulk measurements from the lab and tensile tests from Valmet’s Pulp Expert automated testing lab are used to fine tune the predictive model. The APC manipulates peroxide and caustic dosage to control medium consistency brightness, high consistency brightness, residual peroxide, pH , and final pulp bulk and tensile strength.

Figure 2: Predicted bulk of different BCTMP grades (blue) compared to lab tests (brown).

Furthermore, a bleached kraft pulp mill is currently commissioning an analyzer to measure fiber properties in the machine chest of a pulp dryer. Data are being collected now to construct models of pulp strength and bulk which could be related to upstream pulping and bleaching conditions. This is something to look out for in the future, as many commodity pulp mills want to fine tune quality to customer specs.

Linking pulp to paper quality

Successful model-based controls which optimize final paper quality by managing stock prep systems are based on earlier versions of the pulp analyzer, not including the most recent high definition image analysis. These so-called pulp to paper optimization controls use inputs of automated testing labs as well as manual tests to update the models. Figure 3 shows how refining and stock blending control work with multiple inputs from the pulp analyzer. Further reports on the implementation of controls will be interesting to follow.

Note: A more thorough explanation of Valmet’s approach to strength prediction and control was presented at the Japan Tappi conference in October, 2016.

Figure 3: Model predictive control of refining and stock blending with multiple inputs from an online pulp analyzer. Valmet to supply two Advantage NTT tissue production lines to Sofidel America's new mill in USA

Sofidel America is continuing its expansion in USA and recently announced their plans for a new greenfield plant in Circleville, Ohio. Valmet will deliver two Advantage NTT tissue lines including stock preparation equipment and automation systems to the new mill. Both lines will be started up during 2018.

The order is included in Valmet's third quarter 2016 orders received. The value of the order is not disclosed.

Valmet Advantage NTT tissue machine

Valmet and Sofidel share a long history of partnership including eleven conventional tissue machine installations in various countries. Earlier this year Sofidel decided to invest in their first Advantage NTT line which will be started up at Delitissue mill in Poland in the second half of 2017.

"The Advantage NTT technology fits very well in our expansion plans for North America. We have a strong focus on the most innovative and high performance technologies and see this as an investment for the future which allow us to take the next step into the premium quality segment," says Luigi Lazzareschi, CEO of Sofidel.

"We are excited to continue our shared journey forward together with Sofidel, and are proud to support their expansion plans into new markets and segments. We are convinced that the innovative Advantage NTT lines with its flexibility, product quality and energy saving capabilities is the solution for the future," says Anders Björn, Vice President, Tissue Mills, Valmet.

Technical information about the delivery

Valmet's scope of supply comprises two complete tissue production lines including Advantage NTT tissue machines, with OptiFlo headbox and cast alloy Yankee cylinder. The machines will also be featured with the Advantage tissue technology including AirCap hoods with Air systems, WetDust systems and SoftReel B reels. Valmet has also deliveres detailed mill engineering, stock preparation equipment as well as automation packages including DCS (distributed control) and QCS (quality control) systems.

The new tissue machines will have a design speed of 1,800 m/min in textured mode and 2,000 m/min in plain mode. The production lines are optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products. Each line will have an annual production capacity of 70,000 tons.

About the customer Sofidel Group and Sofidel America

The Sofidel Group, a privately held company, is one of the leading manufacturer of paper for hygienic and domestic use worldwide. Established in 1966, the Group has subsidiaries in 13 countries with more than 5,500 employees, a consolidated turnover of EUR 1,809 million in 2015 and an annual production capacity of over one million tonnes. Sofidel is a member of UN Global Compact and the international WWF Climate Savers programme. Sofidel America is a subsidiary of the Sofidel Group. It was established in 2012 through the acquisition of the Cellynne tissue company which was founded in 1988 with three production sites in the USA - Haines City (FL), Green Bay (WI) and Henderson (NV).

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

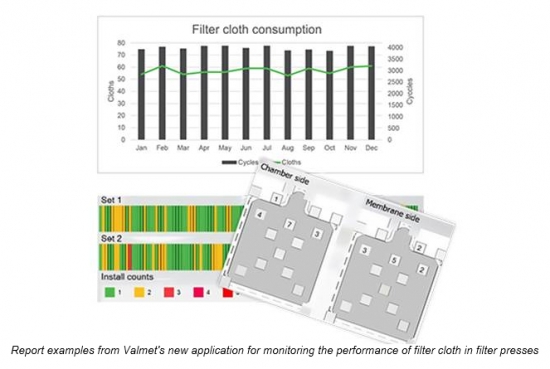

Valmet launches world's first application for monitoring filter cloth performance

Valmet launched its newest Industrial Internet application at the FILTECH exhibition in Cologne, Germany on October 11, 2016. The application is used for monitoring the performance of filter cloth in filter presses. The application has been piloted in customer filtration processes with good results, and the first customer orders have been received with implementation still in 2016.

Pending on the size of the process, a filtration process may consume thousands of filter cloths per year. By gathering information with RFID technology, the application can analyze the performance of filter cloths and filters.

"We are able to utilize the information on cloth lifetimes, the reasons for cloth removal and cloth consumption to optimize the whole filtration process. In addition, this information helps process operators to better monitor the filter itself," explains Sanna Uusitalo, Product Manager, Filtration at Valmet.

Seeing inside the filtration process contributes to savings

Valmet's application is based on special equipment and RFID tags that submit information to be used in the follow-up and analysis of the whole filtration process. An optimal process leads to remarkable savings.

"Savings can be achieved through planned maintenance and reduced filter downtime. The filter cloths and filters will be developed further as more information is gathered about their performance. The application also enables remote support from our filtration experts. By enabling us to see inside the process, the application helps us and our customers to optimize the whole filtration process," Uusitalo continues.

RFID technology has been in use for decades, but Valmet is the first to utilize it for filter cloths. Valmet has developed the application in co-operation with customers and filter manufacturers. At this stage, the application is first being used in the mining industry, but there are already plans to broaden its use to filtration processes in the pulp and paper industry.

The application and its use is demonstrated at the FILTECH exhibition in Cologne, Germany, October 11-13, 2016.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply a defibrator system to Action Group in India

Valmet will deliver a new defibrator system to Action Group, in India. The defibrator is an essential part of Action Group's new fiberboard line being built, and it will produce 28 tons per hour bd (bone dry) fiber. The start-up of the system is scheduled to be in September 2017.

The order was included in Valmet's second quarter 2016 orders received. An order with this scope of supply is usually valued in the range EUR 1.5-5 million.

"We have compared the different refiner alternatives available in the market and found that Valmet's defibrator is the most suitable choice for our line," says Mr. Vivek Jain, Director at Action Group.

"The defibrator to be delivered is specially designed for production levels up to 32 tons per hour, which is perfect in this case. The customer has two existing fiberboard production lines, and this is the first defibrator system from Valmet. The fiberboard market is growing in India, and Action Group is the second customer during 2016 that has chosen Valmet as preferred supplier," says Leif Sundberg, Sales Manager at Valmet.

Valmet's defibrator system

The delivery to Action Group includes a Valmet EVO-56 Defibrator system. The defibrator system is an essential part in a fiberboard line. Valmet's defibrators are known for their reliability and provide high-quality, homogenous fiber material. The material from Valmet's system has a minimum of shives and low fines content, which is a prerequisite for successful fiberboard production.

About the customer Action Group

The Action Group is a 44 year old conglomerate with a leading presence in the footwear, steel & power, chemicals, real estate, health care and electronics industries in India. The company's headquarter is located in Udyog Nagar, New Dehli, in India. Action. Action Tesa, part of the Action Group, is one of the largest companies in fiberboard business in India and their products are mainly used for floors, door skins and furniture.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

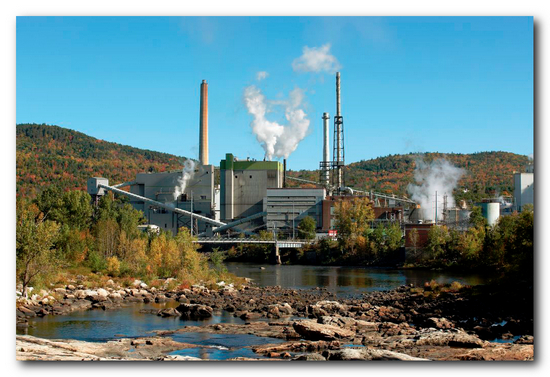

Valmet's advanced boiler control application for optimized combustion successfully commissioned at Catalyst Paper's Rumford Mill in Maine, USA

Valmet's advanced boiler control application for optimized combustion has been successfully commissioned at Catalyst Paper's Rumford Mill in Maine, USA. The new combustion management application optimizes the performance of the paper mill's fluidized bed boiler units 6 and 7.

"Valmet's experts have been able to provide us with a cost effective solution that has demonstrated concrete improvements in overall boiler control and have helped us to obtain considerable reduction in process variation," says Scott Alley, Utilities General Superintendent, Rumford Mill, Catalyst Paper.

Catalyst Paper's Rumfort Mill

The application has been integrated into the mill's existing automation system. It enables the mill to improve boiler steam output control and optimize limestone use, steam output variability and grid temperature variability. Additionally, it's now possible to operate both boiler units in fully automatic control for varying compositions of coal and biofuel. The application also provides the tools to improve operational uniformity across shifts.

"Valmet DNA FBB Combustion Manager is a powerful tool to control combustion variables simultaneously," says David Eapen, Performance Improvement Engineer, Automation, Valmet.

Valmet's delivery included a complete Valmet DNA FBB Combustion Manager application, engineering, boiler base control logic enhancements, commissioning, tuning and training. Valmet also provided a Valmet DNA Fuel Power Compensator application that compensates for disturbances caused by fuel quality and amount variations by regulating fuel feeding respectively.

"The project to implement Valmet's advanced boiler controls at the Rumford Mill was a big success. From initial control logic design, to hardware and software commissioning, to operator training, Valmet performed as promised," says Steve Day, Process Control Engineer and Project Manager, Rumford Mill, Catalyst Paper.

Technical information about Valmet's solution

Valmet DNA FBB Combustion Manageris an advanced control application for the optimized combustion of both bubbling and circulating fluidized bed boilers. The purpose of the application is to protect the combustion process against variations in production, fuel amount, fuel quality and combustion circumstances. As a result, DNA FBB Combustion Manager provides several environmental, operational and financial benefits, including a stabilized combustion process, increased boiler efficiency, a wider boiler operation range, minimized flue gas oxygen content as well as minimized NOx and CO emissions.

Valmet DNA Fuel Power Compensator is based on the estimation of fuel power input to the boiler. No additional sensors or transmitters are needed. The application calculates the fuel power online and compensates it by regulating the fuel flow accordingly. Valmet DNA Fuel Power Compensator is especially applicable for combusting multiple fuels with different fuel-specific heat values. A combustion process with changing solid fuel mixtures or a single fuel with varying dryness can also benefits from the application.

The solution is part of Valmet's Industrial Internet offering that makes the customer's processes more efficient.

Information about the customer Catalyst Paper

Catalyst Paper manufactures diverse printing papers and market pulp. Its customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has an annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

First Advantage NTT tissue production line in USA successfully started up at von Drehle Corporation's Natchez mill in USA

The von Drehle Corporation is the first tissue maker in the USA to produce tissue with Valmet's innovative Advantage NTT technology. The new line was started up at the company's mill in Natchez, Mississippi, USA.

This is Valmet's third tissue machine delivery to von Drehle. Since earlier von Drehle operates two Advantage DCT tissue lines in the Cordova mill, North Carolina in the USA. The Advantage NTT technology is designed for maximum production flexibility, energy efficiency as well as enhanced product quality.

"We are very pleased with the equipment and systems as well as the support provided by Valmet to us and our contractors, both in the past and continuing", says Joe Pankratz, Vice President of Manufacturing, von Drehle Corporation.

"We are delighted to announce our first Advantage NTT start up in USA. This is the fourth successful NTT start-up since the first machine start-up in 2013. We want to thank von Drehle for the good cooperation and team effort to make this project a success and a benchmark in the industry. This high capacity NTT installation will provide von Drehle with excellent flexibility and capability for a wide product quality range in its operations for years to come," says Soren Eriksson, Sales Director, Tissue Mills Business Unit, Valmet.

Technical information

The new tissue machine has a width of 2.6 m and a design speed of 2,000 m/min in plain mode and 1,800 m/min in textured mode. The raw material for the new line is recycled fiber and the production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of delivery comprised a complete tissue production line including an Advantage NTT 100HS tissue machine. The tissue machine is equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It also features the Advantage tissue technology including, an AirCap hood and a SoftReel L reel. Furthermore, the delivery included an automation package with process control system. Valmet was also responsible for installation supervision, training and commissioning as well as product development support.

About the customer von Drehle Corporation

The von Drehle Corporation, established in 1974, is based in Hickory North Carolina, USA and currently operates tissue mills in Cordova, Maiden, Memphis and Las Vegas. The company provides quality towel, tissue and dispenser products for the Away From Home market in North America.

For further information, please contact:

Tom Morse, Mill Sales Manager Valmet Tissue North America, +1 225 772 4991

Soren Eriksson, Account Sales Manager Valmet Tissue North America +1 404 242 8845

Jan Eriksson, Vice President Sales Valmet Tissue Mills Business Unit, tel. +46 705 17 14 90

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply an extensive board machine rebuild for Arkhangelsk in Russia

Valmet will supply an extensive board machine and automation rebuild for Arkhangelsk Pulp & Paper Mill (PPM) in Russia. The project for the board machine 2 (BM 2) is a continuation to the pre-engineering project executed by Valmet earlier this year.

The order is included in Valmet's thirdquarter of 2016 orders received. The value of the order will not be disclosed. The value of an order of this type is typically valued around EUR 50-60 million. The rebuild is a part of Arkhangelsk's investment project "Reconstruction of board department" with total value of 8.8 billion rubles (about EUR 125 million).

Arkhangelsk Pulp & Paper Mill in Novodvinsk, Russia

The delivery will include a new Valmet OptiConcept M board machine wet end, a number of improvements to the drying section, a completely new dry end and a machine control system upgrade. Target of the rebuild is to increase production by 30%. The start-up of the rebuilt machine is scheduled for the second half of 2018.

"Valmet's OptiConcept M board making linefocuses on low operating costs combined with energy-efficient and flexible production of high-quality board grades. We have a number of excellent references verifying the targeted outcome. Furthermore, our uniquely wide scope of offering differentiates us from the competitors. The project continues our good cooperation with Arkhangelsk - we have earlier delivered several pulp and paper technologies to them, latest being the pulp mill upgrade and two modern refiner lines," says Vesa Simola, EMEA Area President of Valmet.

Technical details of the delivery

Valmet's extensive board machine and automation delivery for the rebuild includes pulpers for broke collection, equipment for approach flow systems for top and back plies, two OptiFlo Fourdrinier headboxes, OptiFormer Multi forming section, OptiPress Linear press section, a start-up package of paper machine clothing, dryer section rebuild, OptiCalender Compactcalender, OptiReel reel, automatic transfer rails,OptiWin Drum two-drum compact winder and related air systems. The automation upgrade comprises Valmet IQ quality measurement system, Valmet DNA process control system and a moisturizer. The delivery will also include a semi-automatic reels spool return system and a roll conveying system.

"The customer valued the fact that there is no need for cantilevering beams with OptiConcept M and that there are only minor changes required for the foundations. Space requirement will also be smaller compared to the traditional wet end concepts. The 'plug and play' feature of OptiCalender Compact wasalso appreciated by the customer," comments Senior Sales Manager Pekka Turtinen from Valmet.

The 7,000 mm wide (wire) BM2 produces fluting and kraftliner grades with a basis weight range of 90 - 200 g/m2. The design speed for the new parts is 1,000 m/min. The annual production will be about 330,000 tonnes.

Information about the customer Arkhangelsk PPM

Arkhangelsk PPM (APPM) is one of the leading pulp and paper mills in Russia and Eastern Europe focusing on pulp, board and paper production. Austrian Pulp Mill Holding GmbH is the owner of the mill. Pulp production of the mill is 850.000 tons and corrugated board production 500.000 tons.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply a rewinder to Roto-cart in Italy

The Italian tissue converting company Roto-cart Spa has selected Valmet as supplier for their new rewinder to be installed at the greenfield converting plant in Castelminio di Resana in Italy. The new site will be one of the biggest in the country.

The order was included in Valmet's second quarter 2016, orders received. The new Focus Reelite 20 ENS rewinder is planned to be in operation during the first quarter of 2017.

"Our target is to always invest in cutting-edge technology to be able to fulfill our customers' and consumers' requirements. Roto-cart has served this business for 35 years and we immediately recognized the Focus electromechanical rewinder's ability to provide outstanding paper properties preservation," says Giuliano Gelain, CEO of Roto-cart Spa.

"The Valmet Focus with offline printers has a long record of successful installations and we are excited to be part of Roto-cart's expansion plans and support their production of excellent tissue products," says Massimiliano Corsini, Vice President, Rewinder Technology, Valmet.

Valmet Focus Rewinder

Technical information

The new installation includes a Valmet Focus Reelite 20 ENS Rewinder with two unwind stands. The machine is pre-disposed for the installation of an offset printer. The offset printer can be by-passed. In by-pass mode the rewinder has a design speed of 1,800 m/minute depending on the paper characteristics and winding spool diameter. With the offset printer in operation the design speed is 900 m/min. Installation supervision services are included in the scope of supply.

Information about the customer Roto-cart

Roto-cart is an integrated tissue company with two converting units and one paper mill and thirty five years of experience. Their products are present in the Italian and European markets under their own and private label brands. Thanks to high technological avant-garde lines and the certifications of business quality FSC and ISO 9001, Roto-cart has chosen to specialize in the "premium quality" range of products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply paper machine modifications and a new winder to Laakirchen Papier in Austria

Valmet will supply paper machine modifications and a new winder toLaakirchen Papier AG in Austria. Laakirchen Papier will convert its paper machine 10 (PM 10) to produce lightweight containerboard. Currently PM 10 is producing publication paper. The start-up of the paper machine and the winder is scheduled for the autumn of 2017.

The order is included in Valmet's third quarter 2016 orders received. The value of the order will not be disclosed. The value of an order of this type is typically EUR 5-10 million.

"With this investment, the product range of Laakirchen Papier will be widened into a growing market sector. Valmet's technology and vast reference list of high speed containerboard winders convinced us," comment project manager Johann Stadlmayr and production manager Jan Reibert from Laakirchen Papier.

Valmet OptiWin Drum two-drum winder

Technical details about the delivery

Valmet's delivery includes a press section upgrade, relocation and modification of the existing reel and one OptiWin Drum two-drum winder. The winder is equipped with Dual Unwind, which is Valmet's new two-unwind system. This new feature makes it possible to change the parent roll in only one minute.

"Grade conversion projects often include a production change from two winders to one high capacity winder to increase mill's automation level. This also the case in Laakirchen PM10. A Valmet high capacity winder with two-unwind will do the demanding job," says Kenneth Åkerlund, Product Manager, Winders and Reels from Valmet.

The 7,500 mm wide (reel) PM 10 will produce containerboard products with a basis weight range of 70 g/m2 upwards. After the full extension, the annual production of PM 10 will reach 450,000 tonnes.

Information about the customer Laakirchen Papier AG

Laakirchen Papier AG is part of Heinzel Group, which is united under the Heinzel Holding umbrella. The group ranks among the largest producers of market pulp and magazine paper in Central and Eastern Europe. Laakirchen Papier produces SC paper, a high-gloss publication paper for magazines, catalogues and printed advertising material. The paper production amounts to an annual 550 000 tons, manufactured on two paper machines PM 10 and PM 11.