Ianadmin

Catalyst Paper Re-launches Oxford C1S and the Expanded Coated Paper Line-Up

Catalyst Paper (TSX: CYT) has announced the launch of an expanded Oxford C1S line-up of products for multiple market segments, including Cut and Stack Labels, Commercial C1S & Lamination and Pressure Sensitive applications.

Catalyst Paper (TSX: CYT) has announced the launch of an expanded Oxford C1S line-up of products for multiple market segments, including Cut and Stack Labels, Commercial C1S & Lamination and Pressure Sensitive applications.

Building on its twenty-plus year reputation for high-quality results, the Oxford C1S line-up offers best in class performance in an expanded range of basis weight and brightness options with:

- Best in Class Quality and Performance

- Optimal Shades, Surfaces and Strengths

- Layflat and Stayflat properties

- The leading Innovation Management and Support team in the specialty papers industry

- Fast track line extensions, nimble response times and unique product development

- Established supply chain infrastructure

- Availability in rolls and sheets

- Multilingual sales representation

"Oxford C1S has a long history of quality and performance and we're thrilled to bring this new expanded range of products to the C1S market. We're confident these new options and our industry leading service will continue to be a very compelling combination," says Matt Hickey, Senior Director, Specialty Papers.

Catalyst papers are available as certified chain-of-custody under FSC, PEFC or SFI programs, and also available with up to 30% post-consumer waste. For product benefits and specifications, please see our website at www.catalystpaper.com/products.

About Catalyst Paper Corporation

Catalyst Paper manufactures diverse printing papers such as coated freesheet, C1S, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

SOURCE Catalyst Paper Corporation

For further information:

Matt Hickey, Senior Director, Specialty Papers, This email address is being protected from spambots. You need JavaScript enabled to view it., 312-953-5383

This information is being distributed to you by / Cette information vous est transmise par : Catalyst Paper Corporation

2nd Floor, 3600 Lysander Lane, Richmond, BC, V7B 1C3, Canada

www.catalystpaper.com

Voith launches new forming fabric for optimal performance in tissue production

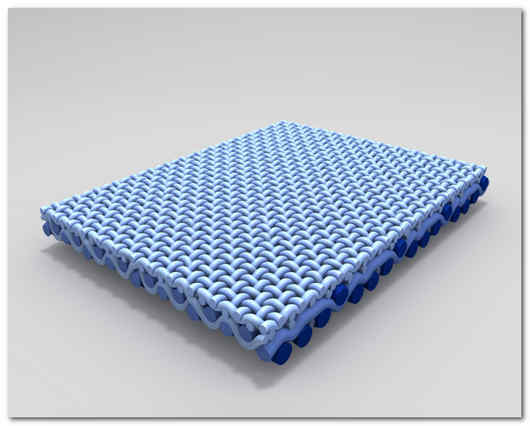

The new TissueForm ITY forming fabric that Voith has launched on the market is designed for challenging applications in tissue production. It ensures excellent stability and highest dewatering at all machine speeds.

The new forming fabric combines a very fine 2-shed paper side to obtain a smooth surface with a 4-shed wear side. The woven structure of the fabric ensures fast drainage and a high level of sheet support while maximizing dimensional stability. The entire design of TissueForm ITY is based on the patented woven structure of the I-Series and its proven 3:2 warp ratio.

The new forming fabric TissueForm ITY has already been successfully deployed in the industry many times and has demonstrated that it delivers excellent dewatering performance and fiber support also at very high speeds. Fabric wear is minimal, so that outstanding service life records are achieved.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Valmet to supply a tissue production line to Renova in Portugal

Valmet will supply an Advantage NTT tissue production line and an automation system to the European tissue brand Renova. Renova is the first tissue producer in Europe to invest in Valmet's Advantage NTT tissue technology for the production of textured and plain tissue products.

Image: Valmet Advantage NTT tissue machine

The new line, to be installed at the Torres Novas mill in Zibreira, Portugal, will allow Renova to increase its paper production capacity with 50%. The start-up is scheduled for the end of 2016.

The order was included in Valmet's second Quarter 2015 orders received. The value of the order is not disclosed.

"We are eager to see the result from the combination of Renova's proactive innovativeness and Valmet's sustainable Advantage NTT technology. Its flexibility provides endless possibilities to produce special designed textured tissue products," says Mr. Pereira da Silva, CEO of Renova

"Our Advantage NTT technology has established a strong market position in high efficiency innovative and flexible tissue production. We are excited to support Renova to bring their tissue products to the next level. We are looking forward to working with Renova and making this project a benchmark on the European tissue market," says Jan Erikson, VP Tissue Sales, Valmet.

Technical information of the delivery

The new tissue machine will have a design speed of 1 800 m/min in textured mode and 2,000 m/min in plain mode. The production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of delivery comprises a complete tissue production line including an Advantage NTT tissue machine, with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including, an AirCap hood with a WetDust system. Basic and detailed mill engineering, complete stock preparation and process ventilation are also included in the scope. Furthermore, the delivery will include a Valmet DNA Automation system.

About the customer Renova

Renova is a European brand of high quality and innovative products. Available in more than 60 countries it offers colorful designs and new functional solutions through stylish and environmental friendly tissue consumer products.

For further information, please contact:

Jan Eriksson, Vice President Sales Valmet Tissue Mills Business Unit, tel. +46 705 17 14 90

Bernhard Glifberg, Sales Manager, Valmet Tissue Mills Business Unit, tel. +46 705 17 14 27

Minerals Technologies Signs Commercial Agreement to Deploy FulFill® Technology for High-Filler Loading

Second Agreement with Global Papermaker at this North American Paper Mill

Unique High-Filler Technology Will Provide Significant Cost Savings in Reduced Fiber Consumption by Increasing PCC Filler Usage 20%

Minerals Technologies Inc. (NYSE: MTX) has announced that it has signed another commercial agreement with a prestigious global paper producer to provide Fulfill® E-325, a high-filler technology, at the paper company's mill in North America. This is the second agreement for the deployment of the FulFill® technology at this paper mill.

Minerals Technologies Inc. (NYSE: MTX) has announced that it has signed another commercial agreement with a prestigious global paper producer to provide Fulfill® E-325, a high-filler technology, at the paper company's mill in North America. This is the second agreement for the deployment of the FulFill® technology at this paper mill.

Minerals Technologies now has 22 agreements with paper mills for adoption of the Fulfill® high-filler technology portfolio that the company introduced in late 2010. The agreement with this papermaker, which wishes to remain unnamed for competitive reasons, marks MTI's eighth in North America.

These agreements confirm the commercial progress of the Fulfill® brand, a portfolio of high-filler technologies that offers papermakers a variety of efficient, flexible solutions that decreases dependency on natural fiber and reduces costs. The Fulfill® portfolio allows papermakers to increase loading levels of precipitated calcium carbonate (PCC), which replaces higher cost pulp, and increases PCC usage up to 30 percent and higher.

"The second adoption of this technology by this global papermaker at this facility illustrates its continued acceptance and reaffirms our commitment to advance our technology leadership throughout our satellite network around the world," said Joseph C. Muscari, chairman and chief executive officer.

"Adopting the FulFill® E-325 technology will allow this prestigious paper to produce quality paper at lower cost by replacing higher-cost fiber with PCC from our satellite plant at this paper mill," said W. Rand Mendez, senior vice president & managing director, Paper PCC.

PCC is a specialty pigment for filling and coating high-quality paper. By substituting Minerals Technologies' PCC for more expensive wood fiber, customers are able to produce brighter, higher quality paper at lower cost. In 1986, Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills and the concept was a major factor in revolutionizing papermaking in North America. Today, the company has 64 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

New York-based Minerals Technologies Inc. is a resource- and technology-based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral-based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, environmental, energy, polymer and consumer products industries. The company reported sales of $1.725 billion in 2014.

For further information about Minerals Technologies Inc. look on the internet at http://www.mineralstech.com/

Sappi Kirkniemi Power Plant inauguration ahead of schedule

In 2013, Sappi Europe announced its intention to significantly invest (EUR 56m) in its Kirkniemi Mill in Lohja, Finland.

The decision to build a new power plant was key to supporting future operations, safeguarding the competitiveness of the mill, and backing the company’s drive for cost leadership.

Combining energy, enthusiasm and commitment, the new plant has been finished six months ahead of schedule.

In what promises to be a very exciting day in the history of the Kirkniemi Mill, inauguration proceedings for the new plant will take place on Friday 11th September in the presence of Mr Olli Rehn, Minister for Economic Affairs (Finland), Mr Pasi Laine, CEO of Valmet and Mr Berry Wiersum, CEO of Sappi Europe.

In what promises to be a very exciting day in the history of the Kirkniemi Mill, inauguration proceedings for the new plant will take place on Friday 11th September in the presence of Mr Olli Rehn, Minister for Economic Affairs (Finland), Mr Pasi Laine, CEO of Valmet and Mr Berry Wiersum, CEO of Sappi Europe.

Kirkniemi Mill’s goal is to continuously improve its energy efficiency. The new power plant will significantly reduce the mill’s cost base by decreasing energy costs and securing energy supply. The plant will flexibly use solid fuels such as bark from the mill’s debarking process, and other wood based fuels and coal. The technique will facilitate a remarkable increase of biomass fuel in the mill’s energy production. The new boiler circulates fluidized bed (CFB) and its fuel power is 96 MW. Underlining Sappi’s commitment to sustainable development, processes are based on BAT – Best Available Technology. The plant designs have taken current and future requirements into consideration to ensure the highest possible standards are met.

Commenting on the starting of the plant, Martti Savelainen, Mill Director of Sappi Kirkniemi said: “The new power plant is key to the sustainable future of Kirkniemi. We are delighted to be starting operations ahead of time and feel confident that this investment will drive the competitiveness of the mill. Kirkniemi is an effective unit committed to delivering value to the Sappi group in a sustainable way.”

Additional Information

- Construction of the new plant started in May 2014 and finished on 17 July 2015, six months ahead of the planned schedule

- Valmet is the main supplier of the new plant

- Sappi Kirkniemi mill joined the national energy savings agreement in 1997 and the national energy efficiency agreement in 2009.

- As an indication of Kirkniemi mill’s systematic work towards improving its energy efficiency, the international ISO 50001 certificate was granted in spring 2012.

About Sappi

Sappi Europe SA is the leading European producer of coated fine paper used in premium magazines, catalogues, books and high-end print advertising. Headquartered in Brussels, Belgium, Sappi Europe is recognised for innovation and quality. Its graphic paper brands include Magno™, Quatro™, Vantage™, Royal™, Galerie™ and GalerieArt™ ranges. Algro®, Leine®, Parade®, Fusion® and atelier™ are the brands for innovative solutions of speciality papers and boards. Sappi papers are produced in mills accredited with ISO 9001, ISO 14001 and OHSAS 18001 certification and EMAS registration for all our mills in the EU. Sappi European mills hold chain-of-custody certification under the Forest Stewardship Council (FSC®) and/or the Programme for the Endorsement of Forest Certification (PEFC™) schemes. Sappi Europe SA is a division of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with over 13,000 employees and manufacturing operations on three continents in seven countries, sales offices in 50 countries, and customers in over 100 countries around the world. Learn more about Sappi at www.sappi.com.

About Sappi Kirkniemi Mill

Sappi Kirkniemi mill in Lohja, Finland is part of Sappi Europe. Annually it produces 735,000 tons of high quality publication papers which are used for premium quality publications all over the world. The mill employs 550 paper industry professionals from production to product development. Over 90% of the mill’s production is exported.

The mill operates under management systems consisting of certified Environmental Management System (ISO 14001), Energy Management System (ISO 50001), Occupational Health and Safety Management System (OHSAS 18001), Quality Management System (ISO 9001) and Chain Of Custody Verification from the Programme for the Endorsement of Forest Certification® (PEFC) scheme and Forest Stewardship Council® (FSC).

Fibria advances the financing strategy for its expansion project at the Três Lagoas Unit, with investment of R$ 7.7 billion

Fibria advances the financing strategy for its expansion project at the

Três Lagoas Unit, with investment of R$ 7.7 billion

In the fourth edition of the Investor Tour event for analysts and investors, Fibria announces the contracting of US$400 million Export Prepayment Facility Agreement and the launch of R$500 million offering of CRAs

Fibria, a Brazilian forestry company and the world's largest eucalyptus pulp producer, reveals its financing strategy for the Horizonte 2 Project, which will expand the production capacity of its Três Lagoas Unit located in the state of Mato Grosso do Sul for investment of R$ 7.7 billion (equivalent to around US$ 2.5 billion). During the fourth edition of Investor Tour, an event held today and tomorrow in southern Bahia state that brings together around 80 investors and analysts, the company announced details of its contracting of US$ 400 million Export Prepayment Facility Agreement and the launch of R$ 500 million offering of Agribusiness Receivables Certificates (CRAs).

Fibria, a Brazilian forestry company and the world's largest eucalyptus pulp producer, reveals its financing strategy for the Horizonte 2 Project, which will expand the production capacity of its Três Lagoas Unit located in the state of Mato Grosso do Sul for investment of R$ 7.7 billion (equivalent to around US$ 2.5 billion). During the fourth edition of Investor Tour, an event held today and tomorrow in southern Bahia state that brings together around 80 investors and analysts, the company announced details of its contracting of US$ 400 million Export Prepayment Facility Agreement and the launch of R$ 500 million offering of Agribusiness Receivables Certificates (CRAs).

The Horizonte 2 Project, one of Brazil's largest private investments focusing on the export market, also expects to tap other financing sources, such as export credit agencies (ECAs), the Brazilian Development Bank (BNDES) and the Midwest Development Fund (FDCO). In addition, some 40% of investment in the project should be made using the company's equity capital.

According to Guilherme Cavalcanti, Fibria's chief financial and investor relations officer, the company's strong cash generation and the financing project developed will enable the company to keep its current leverage ratio in U.S. dollar under 2.0 times, even with the R$ 7.7 billion investment.

Competitiveness and Sustainability

Fibria new operations at Três Lagoas will have one of the lowest cash costs of pulp production in the world, and will reduce the company's average cost to US$155 per ton. Today, Fibria already has one of the industry's lowest cash costs, which stood at US$ 170/t in the second quarter of this year, compared to the average cost in Brazil of US$ 214/t and in the United States of US$ 421/t, according to the consulting firm Hawkins Wright.

"The project gives us an unparalleled competiveness equation that combines wood supply, infrastructure and logistics, certifications, long-term clients and an excellent financing structure that is very difficult to replicate in the industry," says Marcelo Castelli, Fibria´s CEO.

As is the case of all of Fibria's projects, Horizonte 2 will have sustainability as a core principle. The new industrial complex will have even cleaner production processes, with all of the energy consumed generated by the actual facility using the biomass resulting from the industrial process. The project will not only generate and consume its own power, but also produce surplus power of 120 MWh, which will complement the surplus power of 70 MWh already generated by the entire company today.

The project's industrial process will also feature the efficient use of water resources, with around 80% of the water withdrawn recycled and recirculated from 3.5 to 5 times in the production process before being treated and returned to the environment.

Another major source of the competitiveness of the Horizonte 2 Project is its access to wood resources. With the new mill, the average distance from the forest to supply the current production line and the new line at the Três Lagoas Unit, which will produce more than 3 million tons of pulp annually, will be only 95 kilometers.

With commissioning slated for the fourth quarter of 2017, the new production line will have annual pulp production capacity of 1.75 million tons. With the startup of the second mill at Três Lagoas, Fibria's total annual pulp production capacity, considering all of its units, will increase from the current 5.3 million tons to over 7 million tons. The pulp produced by Fibria in Três Lagoas will be transported by rail to the Port of Santos in the state of São Paulo to be exported to markets in Europe, North America and Asia, as well as sold in the domestic market.

Investor Tour 2015

The transparency adopted in its relations with capital market analysts and investors is of primordial importance to Fibria. The Investor Tour, an annual event now in its fourth edition, brings together the company's officers and various investors and analysts from Brazil and abroad. The 2015 edition, which lasts through tomorrow, will be held at the Veracel Unit, a joint venture with Stora Enso located in the state of Bahia.

About Fibria

A world leader in eucalyptus pulp production, Fibria is a company that strives to meet the growing global demand for forestry products in a sustainable manner. With annual pulp production capacity of 5.3 million tons, the company has industrial units in the cities of Aracruz (Espírito Santo), Jacareí (São Paulo) and Três Lagoas (Mato Grosso do Sul), and in Eunápolis (Bahia), where it operates the Veracel plant through a joint venture with Stora Enso. In May 2015, Fibria announced the expansion of its Três Lagoas unit in Mato Grosso do Sul, which will receive a new line with the capacity to produce 1.75 million tons of pulp per year. The new line, which will receive investment of R$7.7 billion (around US$2.5 billion), is slated to start operations in the fourth quarter of 2017. Fibria has 968,000 hectares of forests, with 561,000 hectares of planted forests and 342,000 hectares of environmental preservation and conservation areas. The pulp manufactured by Fibria is exported to more than 40 countries.

Mohawk Leads ‘Materials Matter’ Initiative and Launches Two New Substrate Lines at Graph Expo ‘15

Mohawk, North America’s largest privately-owned manufacturer of fine papers, envelopes and specialty substrates for commercial and digital printing, in cooperation with GASC, has organized a collaborative, featured space called ‘Materials Matter’ and will introduce two new substrate lines at Graph Expo 2015, September 13-16, 2015, at McCormick Place in Chicago.

The Materials Matter pavilion (Booth #3002) will feature multiple fine paper and substrate manufacturers to demonstrate the powerful role that paper and non-paper substrates play in every print project. The 1,200 square foot hub will feature: Graphic Design USA Magazine (GDUSA), Glatfelter, Holliston, Legion Paper, Lindenmeyr, Mohawk and Sappi North America as well as a ‘substrates lounge’ meeting space for attendees.

Mohawk spearheaded the initiative which aligns with the brand’s Maker Campaign, celebrating the role that well-crafted materials play in the print ecosystem, and supporting the brand’s leadership position in the digital print industry.

In an era of impermanence, a renewed interest in the tangible has emerged. Though the Internet and digital communications have permanently changed the graphic arts landscape, they have also revealed the lasting impact of print.

The impact of print is hard-wired in our brains and is tied to print's tactile qualities and its ability to deliver a message with an indelible impression. This underscores the importance of selecting and using the highest quality papers and substrates to achieve the finest end results.

“Better quality materials bring more senses into play. They look different, they feel different, they create an emotional response,” says Frank Romano, Professor Emeritus, Rochester Institute of Technology.

The goal of the Materials Matter pavilion is to establish a prime show floor location to improve visibility and traffic for like-minded substrate manufacturers, while raising the overall awareness of paper and substrate options at Graph Expo.

“The entire Mohawk product portfolio is designed to bring craftsmanship, tactility and quality to print. Whether Graph Expo attendees are looking for fine text and cover papers, or innovative specialty substrates for digital, offset or letterpress print projects, Mohawk has the perfect material to bring a print project to life,” says Bart Robinson, Senior Vice President, Marketing, Mohawk.

“We know when we encounter well-made things. They last longer, look more beautiful and feel good in our hands. To put it simply, materials matter,” says Chris Harrold, Vice President Business Development and Creative Director, Mohawk.

Mohawk (Booth # 3002c) will occupy a 10 x 20 foot space within the Materials Matter area, where attendees can obtain samples of high quality envelopes, innovative digital substrates, and a new line of swatchbooks, which have been redesigned to make the paper specification process clearer, easier and more intuitive for printers and designers.

Mohawk Launches Two New Product Lines at Graph Expo 2015

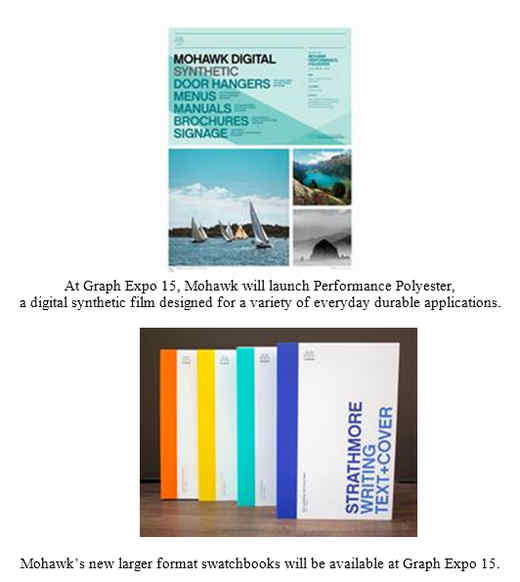

With a focus on the importance of high quality materials at Graph Expo, Mohawk plans to launch two new substrate lines: Mohawk Synthetic Performance Polyester and the Mohawk Pressure Sensitive Select Collection.

New Performance Polyester

Mohawk Synthetic Performance Polyester is a new digital synthetic film designed for a variety of everyday durable applications. The product line includes 5, 8, 10, and 14 mil caliper options, in a 93 bright white shade for printing on dry toner presses.

Mohawk Synthetic products are ideal for applications which require a high level of durability, such as menus, manuals, maps, ID cards/badges parking passes, road race bibs, outdoor tags/signage, all weather manuals, luggage tags, POP displays, table tents, and more.

Expanded Pressure Sensitive Substrates

Mohawk announces an expanded line of pressure sensitive substrates, now featuring Standard, Select and Kiss Cut Collections. With three distinct collections available for a host of end uses, Mohawk Pressure Sensitive products offer a wide range of options for digital labels and signage, including a variety of sizes, calipers, face stocks and adhesive strengths.

The new Select Collection features white polyester and vinyl labels in the three most popular adhesive strengths: permanent, removable and ultra-removable. With HP Indigo and dry toner optimized versions, this new collection is designed to run on a range of digital printing equipment including light production.

“We look forward to the opportunity to inspire and educate Graph Expo attendees about Mohawk’s category-leading materials for digital printing, including our new Performance Polyester and Pressure Sensitive Select lines,” says Mike Madura, Vice President, Digital, Mohawk.

The Most Comprehensive Package of Digital Resources in the Industry

Since 1998, Mohawk has been leading the industry with category-defining substrates for digital printing. Today, Mohawk offers a substrate solution for virtually every digital press platform on the market and is a single source for all digital print needs.

Mohawk offers the most comprehensive package of digital resources in the industry, including fine papers, specialty products, production papers, a team of dedicated and knowledgeable digital specialists, industry-leading website MohawkMakeReady.com, downloadable templates, a digital product finder, and digital equipment/substrate compatibility charts.

Printer sample kits are available, and Mohawk can provide custom orders for many substrates. For more information, visit www.mohawkconnects.com or call 1-800 the mill.

ABOUT MOHAWK

Mohawk is North America’s largest privately-owned manufacturer of fine papers and envelopes which are preferred for commercial and digital printing, photo specialties and high-end direct mail. Mohawk fine papers and envelopes include the signature brands Mohawk Superfine® and Strathmore®, as well as proprietary treatments Inxwell® and i-Tone®. With a culture of innovation, Mohawk’s business model now extends beyond paper manufacturing into new areas of growth, including digital substrates, which connect designers and printers to new markets.

As a leader in environmentally and socially responsible business practices, Mohawk was the first U.S. manufacturer of commercial printing papers to match 100% of its electricity with wind power renewable energy credits and the first U.S. premium paper mill to shift toward carbon neutral production. Mohawk’s portfolio of recycled papers is certified by Green Seal and the Forest Stewardship Council (FSC).

Mohawk is a fourth-generation, family-owned and operated business based in Cohoes, New York, with global sales and operations located throughout North America, Europe and Asia. For more information, please visit www.mohawkconnects.com.

European Paper Week 2015 registration is open - Paper Industry 4.0

The Confederation of European Paper Industries (CEPI) has opened the registration for European Paper Week 2015, taking place on 17-19 November in Brussels. This year’s 17th edition promises aneven wider range of topics, incorporating new features such as a session on the European pulp and paper market outlook by RISI Economists. The overriding theme is Paper Industry 4.0.

The Confederation of European Paper Industries (CEPI) has opened the registration for European Paper Week 2015, taking place on 17-19 November in Brussels. This year’s 17th edition promises aneven wider range of topics, incorporating new features such as a session on the European pulp and paper market outlook by RISI Economists. The overriding theme is Paper Industry 4.0.

CEPI is honoured to have renowned economist Jeremy Rifkin as the event’s keynote speaker, prolonging a tradition of exceptional guest speakers. Mr. Rifkin is president of the Foundation on Economic Trends and the author of 20 books about the impact of scientific and technological changes on the economy, the workforce, society, and the environment.

Industry 4.0 has monopolised the headlines of events and articles alike this year. Shedding some light on this relatively elusive concept, CEPI, in collaboration with StepChange Consulting (also the event’s platinum sponsor) and SITRA (the Finnish Innovation Fund) will publish a report covering existing Industry 4.0 examples in the pulp and paper industry. This publication is prepared on the basis of an industry-wide survey as well as one-to-one interviews with prominent industry leaders.

As is the case every year, European Paper Week will bring participants the most up-to-date, essential information from the highest levels of Brussels policymaking. Commission representatives will explain what shape Industry 4.0 is currently taking in the EU Institutions’ work, while info sessions on EU policies such as the Emissions Trading System and the Circular Economy will provide an insight to the EU’s future plans for our industry.

US ‘How Life Unfolds’ campaign programme director Mary Anne Hansan is also invited for the first time to Europe. She will talk about this industry-driven multi-million dollar campaign to help create consumer appreciation for our industry’s products. This illustrated example will put the difficult topic of the public’s perception of paper products on the table, sparking a debate on whether or not the European industry should follow the footsteps of its American counterparts.

Participants will have the privilege of seeing the industry’s most innovative products at an exciting exhibition. These will have been chosen to feature in CEPI’s new “20 most innovative products” publication, also launched at the event. Finally, this year’s European Paper Week will attest the Two Team Project’s legacy. The winning concept - Deep Eutectic Solvents - consortium will share the latest research on the project that has the potential to revolutionise the future of pulpmaking.

To register, go to www.cepi.org/epw. The early bird fee ends on 30 September. If you have any questions, please contact Annie Xystouris at This email address is being protected from spambots. You need JavaScript enabled to view it. mobile: +32(0)486 24 36 42.

European Paper Week is one of the most important and respected highlights of the pulp and paper industry calendar. It brings together key players and representatives from across industry, related sectors and the European institutions, providing an annual platform for high-level debate on the issues that really matter to the paper industry. Its success has been reflected in its growing attendance. This year the event takes place in the Thon Hotel EU in the centre of Brussels, Belgium.

Twitter: @EUPaperWeek #epw15 Website: www.cepi.org/epw

Jörgen Lindquist appointed new CFO of the Södra Group

Jörgen Lindquist, born in 1965, has been appointed the new Chief Financial Officer (CFO) of Södra, a role that also includes responsibility for Purchasing and IT. He will assume this new position on 14 September, at which point he will also become a member of Group Senior Management and report to President and CEO Lars Idermark.

Jörgen Lindquistholds a degree in business administration, having studied at Växjö University and Lund University, and has extensive experience as a CFO and Vice President. He will be joining Södra from IKEA, where he has spent the past five years working as CFO and Acting Vice President of the company’s industry division Swedspan International. Prior to this role, Lindquist was responsible for IKEA’s project to establish new furniture manufacturing facilities in the U.S. He has also served as CFO and Vice President of the Axis Group and held various senior financial positions in the chemical and packaging industries.

Jörgen Lindquistholds a degree in business administration, having studied at Växjö University and Lund University, and has extensive experience as a CFO and Vice President. He will be joining Södra from IKEA, where he has spent the past five years working as CFO and Acting Vice President of the company’s industry division Swedspan International. Prior to this role, Lindquist was responsible for IKEA’s project to establish new furniture manufacturing facilities in the U.S. He has also served as CFO and Vice President of the Axis Group and held various senior financial positions in the chemical and packaging industries.

“I look forward to starting at Södra. Södra represents many of the same values that I believe in with respect to sustainable development and corporate social responsibility, and is a well-managed forest company with an exciting journey ahead,” said Lindquist.

“I am very pleased to have recruited Jörgen to Södra. His solid background and international experience will be an asset in our continued efforts to strengthen our competitiveness, growth and long-term profitability,” commented President and CEO Lars Idermark.

Lindquist will succeed Carina Olson, who previously announced her decision to leave Södra to pursue new challenges. He will be based in Södra’s head office in Växjö.

For questions, please contact:

Lars Idermark, President and Chief Executive Officer

Telephone: +46 470 894 35

Annica Gerentz, Senior Vice President Corporate Communications

Telephone: +46 470 894 81

Paper Prime S.A. enters into tissue production with a new Toscotec Tissue Line

![]() Paper Prime S.A., company belonging to Trevipapel Group which produces Joker Gold brand hygiene professional products (AFH) in Portugal, has signed a contract with the Italian manufacturer Toscotec for the supply of a tissue line in Vila Velha de Rodão.

Paper Prime S.A., company belonging to Trevipapel Group which produces Joker Gold brand hygiene professional products (AFH) in Portugal, has signed a contract with the Italian manufacturer Toscotec for the supply of a tissue line in Vila Velha de Rodão.

The new tissue line is scheduled to come on stream in the last quarter of 2016.

Trevipapel S.A. has stepped up its expansion plan and in line with the strong partnership established with Toscotec, decided to place this order with the Italian manufacturer, based on Toscotec’s technological advantages, which delivers top product quality and considerably reduces the mill's energy costs. The investment is estimated in 35 million euros and its aim is to supply paper reels to Trevipapel converter units and export. The new paper mill will be also in line with a pulp mill which will add increased value to the investment providing eucalyptus based slush pulp.

Toscotec’s turn-key project for TM#1 includes stock preparation plant for dry virgin pulp, AHEAD-2.0S tissue machine with Steel Yankee Dryer TT SYD-16FT, machine auxiliaries including Milltech Gas fired Hood, steam & condensate and dust removal system, electrification starting from medium voltage cabinets & control system, additional plants and complete engineering and erection activity. A three unwind stand rewinder TT WIND-Hcompletes the supply.

Machine operating speed will be 2,000 mpm with a net trim width of 2750 mm and an average annual production of 38,000 tpy .

- About Trevipapel Group

Established in 1991 and headquartered in Lousã, district of Coimbra, Trevipapel Group has grown from a small private company into one of the leading manufacturer providers of hygiene professional products (AFH) in the Portugal due to its Joker Gold brand. With 2 manufacturing plants strategically located in the center of the country, where are actually converted 20,000 tpy, it serves Portugal, Spain, central Europe and started export to Africa and South America.

- About Toscotec S.p.A.

Toscotec is a turnkey technology supplier to the global paper industry, offering a complete suite of solutions for tissue, paper and board manufacture, as well as maintenance services for rolls and cylinders. Based in Lucca, Italy, and with subsidiaries in China and the USA, Toscotec’s tradition of innovation, energy saving and partnership with customers dates back to its foundation in 1948. Since 2013 Toscotec has been the market leader in tissue machines sales.