Ianadmin

Mario Fazzi is the new Managing Director of A.Celli Paper S.p.A.

The Board of Directors of A.Celli Paper S.p.A. is pleased to announce important changes at management level: redefinition of roles and new Managing Director.

The shareholders’ meeting held on 5 August 2015 had the scope of renewing the Board of Directors and the corporate roles whose terms were expiring, and nominated Giuseppe Antonini President of A.Celli Paper S.p.A. The next day the Board met again and resolved to confer Mario Fazzi the charge of Managing Director of A.Celli Paper S.p.A.. Mauro Celli and Alessandro Celli remain at the helm of the family company, taking on the role of Vice President and Executive Director, respectively.

The shareholders’ meeting held on 5 August 2015 had the scope of renewing the Board of Directors and the corporate roles whose terms were expiring, and nominated Giuseppe Antonini President of A.Celli Paper S.p.A. The next day the Board met again and resolved to confer Mario Fazzi the charge of Managing Director of A.Celli Paper S.p.A.. Mauro Celli and Alessandro Celli remain at the helm of the family company, taking on the role of Vice President and Executive Director, respectively.

The nomination answers the strategic needs of the A.Celli Group that aim to meet increasingly important challenges in the quest for new markets and opportunities, continuing along the road to growth characterized by consistent and continuous technological and innovative development that has traditionally distinguished the company.

Thanks to his over twenty-five years of experience in the world of tissue converting and packaging, Mario Fazzi has great familiarity with international markets, in particular Asian markets, and his areas of competence span from the financial to the administrative to the commercial fields. The enthusiasm and optimism that characterize Mario make him the person A.Celli Paper S.p.A. has chosen to rely on to attain the goals it has set for itself.

Mario Fazzi’s professional career unfolded at Fabio Perini S.p.A. – leader in the manufacture of tissue converting systems – where he held various roles, undertaking a road to personal growth that brought him to the position of Managing Director of Korber Engineering Shanghai Co. Ltd.

Conyers Mill Celebrates 20 Years

More than 200 employees and guests celebrated the 20th anniversay of Pratt’s Conyers paper mill with a gala dinner in Atlanta last month.

Company COO David Dennis paid special tribute to mill GM Allen Bowlder and other 20-year veterans who were part of a weary group of pioneerng engineers, operators and maintenance crews there at start-up.

“To everyone who makes the Conyers mill the pride not only of our company but of the entire containerboard industry, I sincerely congratulate and thank you all for the dedication, hard work and long hours you’ve put in,” David said.

Since it began operations, the mill has produced approximately 6,740,000 tons of 100% recycled paper – that’s the equivalent of saving more than 113 MILLION trees – or a forest large enough to cover 115 square miles – or about 5 times the size Manhattan.

And it would literally leave a paper trail that could stretch from the Earth to the Moon and back 11 times.

In a video-taped message, company chairman Anthony Pratt, who was in Australia on business, told the audience: “I wanted to take this opportunity to thank Alan and his team for a job well done. The genesis of the mill is that we decided to put it hard up against our corrugator, thereby becoming America’s first millugator. Conyers broke the mold. It was a revolutionary mill.”

Global CEO Brian McPheely also sent a video message, saying: “I was lucky enough to be at the mill opening 20 years ago. It’s just amazing what the mill has accomplished over the last 20 years. Alan and his people have done a fantastic job.”

Along the way, they have put up some pretty impressive numbers…

- In December 2010, the mill produced an average of 1102.3 per day, the first Pratt mill to reach this mark

- In October 2013, it outdid itself by setting a new production record, averaging 1116.1 tons a day

- And most importantly, in June 2014, it reached 1 million man hours worked with no lost time injuries – a magnificent safety record that continues to this day

But it hasn’t always been easy…and the team has faced some pretty daunting challenges over the years including three fires and a tornado that knocked down a wall and damaged several pumps and piping systems. But even the worst of those events – a fire in 2010 – couldn’t keep the Conyers’ team down for long. In fact the mill was up and running again just 72 hours later.

Toscotec absorbs Milltech into tissue technology business

Toscotec has absorbed tissue machine hood and ventilation specialist Milltech into its own tissue technology operations.

Toscotec purchased Milltech in 2012 and has since operated it as a separate company, but now believes Milltech’s solutions are best offered as a brand within Toscotec’s portfolio.

All of Milltech’s employees have transferred to Toscotec, including managing director Luca Linari, who takes on the role of Sales & Product Manager for Energy and Environmental Systems for Toscotec.

This development makes Toscotec one of the few tissue machinery suppliers which can offer the entire suite of technology for tissue production from one source.

“This is a natural evolution for us,” said Toscotec managing director Alessandro Mennucci. “When we acquired Milltech it created an ideal synergy because minimizing energy consumption is central to our technological vision. Milltech has proved its worth in this respect, but there is no longer any benefit from it remaining a separate company. Its manufacturing facilities are already on site here at Toscotec, and it is strategically rational to operate as one entity.”

About Toscotec S.p.A.

Toscotec is a turnkey technology supplier to the global paper industry, offering a complete suite of solutions for tissue, paper and board manufacture, as well as maintenance services for rolls and cylinders. Based in Lucca, Italy, and with subsidiaries in China and the USA, Toscotec’s tradition of innovation, energy saving and partnership with customers dates back to its foundation in 1948. From 2013-2015 Toscotec was the market leader in tissue machines sales.

Valmet to supply a tissue production line to Resolute Forest Products in the United States

Resolute Forest Products Inc. has selected Valmet's Advantage NTT tissue production technology and Valmet's automation solution for the new facility it is building in the United States to manufacture at-home, premium private label tissue paper, including bath and towel. The new machine will be installed at the company's mill in Calhoun (Tennessee), and start-up of the tissue production line is planned for early 2017.

Valmet Advantage NTT tissue machine

The order is included in Valmet's third quarter 2015 orders received. The value of the order is not disclosed.

"We are very proud to work with Resolute on this important project, and we will deliver first-class tissue technology to their state-of-the-art facility," says Soren Eriksson, Director of Sales, Tissue Mills Business Unit, Valmet.

Valmet's Advantage NTT tissue production technology is designed for maximum flexibility as well as enhanced product quality and can easily change between production of conventional tissue and textured tissue in just a few hours. It has been well received by the market, and this will be the fifth NTT machine to be delivered. The first Advantage NTT line was started up in Mexico in 2013, the second line started up in the second quarter of 2015 in Chile, a third NTT line will be started up in Abu Dhabi in 2015, followed by a fourth NTT line in the U.S. in early 2016.

Technical information

The new tissue machine will have a width of 5.2 m and a design speed of 2,000 m/min. The raw material for the new line will be virgin fiber, and the production line is optimized to save energy and fiber as well as provide flexibility and product differentiation for premium quality products.

Valmet's scope of delivery will comprise a complete tissue production line, including an Advantage NTT 200HS tissue machine. The tissue machine will be equipped with a layered OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology, including an AirCap hood and a SoftReel -B. Basic mill engineering, process equipment and process ventilation are also included in the scope.

Furthermore, the delivery includes an integrated automation solution with Valmet DNA process control system, Valmet IQ scanner with IQFibre & Moisture sensor, as well as IQProfilers and a state-of-the-art web camera system for quality and reliability control. Installation supervision, training and commissioning as well as product development support are part of the delivery.

For further information, please contact:

Soren Eriksson, Director of Sales, Valmet Tissue Mills Business Unit, North America, +1 404 242 8845

Jan Erikson, Vice President, Sales, Valmet Tissue Mills Business Unit, tel. +46 705 17 14 90

ANDRITZ to deliver logyard circular crane to Domtar’s paper mill in South Carolina, USA

International technology Group ANDRITZ has received an order from Domtar Paper Company to supply a logyard circular crane for its Marlboro mill, USA. The new crane will replace existing equipment and has a net lift capacity of 32 tons and a radial reach of 170 ft (52 m). The start-up is scheduled for early 2016.

International technology Group ANDRITZ has received an order from Domtar Paper Company to supply a logyard circular crane for its Marlboro mill, USA. The new crane will replace existing equipment and has a net lift capacity of 32 tons and a radial reach of 170 ft (52 m). The start-up is scheduled for early 2016.

ANDRITZ’s scope of supply includes the equipment, engineering, and on-site services. The crane will be able to unload log trucks in a single bite, feed the logline at the required rate, and also assist in managing log storage on site.

For further information, please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of almost 25,000 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, production equipment for biofuel (second generation), biomass torrefaction equipment, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

Xerium Celebrates 1000th Formsoft Tissue Forming Fabric

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently celebrated the shipment of its 1000th Formsoft tissue forming fabric at its Kentville, Canada plant. The globally successful and patented Formsoft technology has enabled tissue makers to produce their products with higher quality and at increased efficiency. Formsoft is one of the fastest growing products the company has ever launched into the market.

“Formsoft continues to provide our customers with excellent machine speeds and outstanding sheet softness”

“Formsoft continues to provide our customers with excellent machine speeds and outstanding sheet softness,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “Like our other innovations, Xerium has developed Formsoft technology to benefit its customers by lowering their operational cost while improving operational performance and overall efficiency. This unique tissue fabric, with patented warp and weft structure, consistently delivers top drainage performance for a stronger, yet softer, tissue product. It combines improved sheet forming and fiber retention benefits with high dimensional stability and life potential resulting in optimized tissue machine runnability.”

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,100 employees.

Kemira acquires Soto Industries, LLC of Charlotte, North Carolina, USA

Kemira has acquired certain assets of Soto Industries, LLC, a privately owned company, headquartered in Charlotte, North Carolina.

Kemira has acquired certain assets of Soto Industries, LLC, a privately owned company, headquartered in Charlotte, North Carolina.

Soto specializes in the application of scale control products, defoamers, and settling agents for the pulp and paper industry. Kemira is a leading chemicals supplier serving the global pulp and paper industry.

"The Soto Industries, LLC acquisition is another example of Kemira's dedication to the pulp and paper industry as well as Kemira's commitment to execute our global growth strategy via continued investment into our Paper segment," says Billy Ford, Senior Vice President, Paper segment, Americas.

The transaction does not have material impact on Kemira's financial figures and the parties have agreed not to disclose the transaction price.

For more information, please contact

Kemira

Billy Ford, Senior Vice President, Paper segment

Americas

Tel. +1 770 436 1542

UPM reaches one hundred years of stock exchange listing

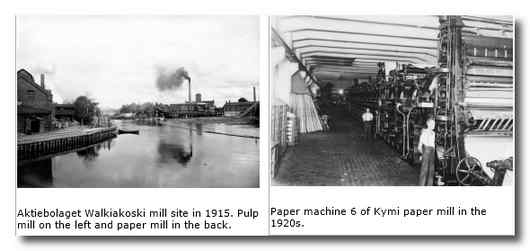

UPM’s journey at the stock market started one hundred years ago. UPM's predecessor companies Aktiebolaget Walkiakoski and Kymmene Ab were listed on the Helsinki Stock Exchange in August-September 1915. The listing is a significant example of Finnish industrialisation and economic growth as the First World War created a boom for the Finnish industry. Forest industry companies wanted to grow quickly and get additional funding for investments. Many significant Finnish forest industry companies such as Kymi, United Paper Mills, Kaukas, Kajaani, Schauman, Rosenlew, Raf. Haarla and Rauma-Repola have been merged into the UPM Group along the years.

UPM today is a global bio and forest industry company offering products made of renewable materials and low-emission energy. With good performance in the businesses, strong cash flow, and leading balance sheet in the industry, UPM can simultaneously distribute an attractive dividend, implement focused growth projects and act on strategic opportunities.

“Investors are always interested in how the company is creating value now and in the future. We create sustainable solutions and many of them replace non-renewable materials. We focus on growing and renewing our businesses and developing new products. The most recent example is renewable wood-based diesel launched in May”, says Mika Mikkola, Vice President, Investor Relations.

Interest in the company in transformation has continued. UPM's share is one of the most traded shares in the Helsinki Stock Exchange. It has a wide, 67 percent foreign ownership, while it has maintained a strong domestic private ownership. UPM has approximately 86,000 shareholders in Finland.

For additional information:

Mika Mikkola, Vice President, Investor Relations, tel. +358 40 595 3202

UPM, Media Relations

9.00-16.00 EET

tel. +358 40 588 3284

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.twitter.com/UPM_News

www.facebook.com/UPMGlobal

www.linkedin.com/company/upm-kymmene

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 20,000 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM – The Biofore Company – www.upm.com

Stora Enso’s Annual Report best in Finland in an international ranking

Stora Enso's Annual Report 2014 has been ranked the best Annual Report in Finland and in the sixth place globally in the Report Watch ranking. The ranking included 1 600 companies from 60 countries.

Stora Enso’s Annual Report was praised for its description of value creation, business transformation, and sustainability practices. Positive feedback was also given for spreading in-depth content over four books.

The Stora Enso Annual Report 2014 consists of the Progress Book, the Financial Report, the Global Responsibility Performance, and the Corporate Governance Report. The Progress Book was created in 2014 to explain Stora Enso’s strategy, how the company creates value and how its work is progressing.

The Stora Enso Annual Report 2014 consists of the Progress Book, the Financial Report, the Global Responsibility Performance, and the Corporate Governance Report. The Progress Book was created in 2014 to explain Stora Enso’s strategy, how the company creates value and how its work is progressing.

All parts of the Annual Report are available in PDF format at storaenso.com/annualreport

The Progress Book (in English, Finnish and Swedish) and the Financial Report (in English) can be ordered as printed copies at www.storaenso.com/order

The Top 400 Annual Reports list by Report Watch:

http://www.reportwatch.net/annual-report-on-annual-reports-2015/top-400-annual-reports/

For further information, please contact:

Ulrika Lilja, EVP, Global Communications, tel. +46 72 221 92 28

Ulla Paajanen-Sainio, SVP, Investor Relations, tel. +358 40 763 8767

Hanne Karrinaho, Head of Financial Communications, tel. +358 40 766 9452

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Our aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 27 000 people in more than 35 countries, and our sales in 2014 were EUR 10.2 billion. Stora Enso shares are listed on NASDAQ OMX Helsinki (STEAV, STERV) and Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. storaenso.com

Rottneros: INTERIM REPORT JANUARY – JUNE 2015

- Income after net financial items amounted to SEK 75 (31) million for the second quarter of 2015 and SEK 177 (50) for the six-month period, our best six-month performance in the current structure.

- Net turnover for the second quarter totalled SEK 456 (394) million, a 16% increase compared with 2014.

- Production volumes increased by 9% compared with the second quarter of 2014.

- The PIX price in USD declined during the second quarter and amounted to an average of USD 855. Denominated in SEK, the price decrease was 5% compared with the first quarter. Compared with the second quarter of 2014, the price increase in SEK was about 19%.

- Cash flow before investments for the second quarter of 2015 was strong at SEK 116 (-3) million and SEK 278 million on a rolling 12-month basis, compared with SEK 104 million for full-year 2014. Interest-bearing net receivables as of 30 June amounted to SEK 165 (-42) million.

Comments by the president

The second quarter remained strong for the Rottneros Group. Profit after net financial items was SEK 75 million, an improvement of SEK 44 million compared with the same quarter in 2014. As in the first quarter, the improvement was mainly driven by both currencies and the pulp market moving in the right direction in relation to the corresponding quarter in 2014. Increased sales and production were also important factors. Both plants delivered good profitability and substantial improvements in earnings.

The second quarter remained strong for the Rottneros Group. Profit after net financial items was SEK 75 million, an improvement of SEK 44 million compared with the same quarter in 2014. As in the first quarter, the improvement was mainly driven by both currencies and the pulp market moving in the right direction in relation to the corresponding quarter in 2014. Increased sales and production were also important factors. Both plants delivered good profitability and substantial improvements in earnings.

The higher volumes can be explained by the higher availability in production, especially at Rottneros Mill. This clearly shows the results of our determined efforts towards higher production volumes that we have conducted over the past year. Compared with the corresponding quarter last year, production increased by 9 per cent for the Group. At Rottneros Mill, volume increased an impressive 16 per cent, driven by a sharp upswing in groundwood pulp.

In general, customer demand for our grades of pulp remains stable. However, we have experienced continued pressure on prices during the quarter, mainly driven by an increased supply on the market. Translated into SEK, prices continue to be high, thanks to the weakening of the SEK against the USD.

Absorption Express, the high yield pulp for absorbing fluids, which we launched last fall, continues to exceed our expectations with respect to demand. During the quarter, we carried out yet another successful product launch, Bulk Booster, Rottneros’ newly developed high-yield pulp for cardboard. It increases the bulk or thickness more than other available raw materials, increased bending stiffness is a quality that is crucial for many carton applications.

During the first half of the year Rottneros’ Board of Directors decided on the first investments, for a total of SEK 180 million, to kick off our long-term industrial plan, Agenda 500. The plan is to increase the capacity of the Group through successive investments to eliminate the bottlenecks in the two mills. Investments are planned in renewed production equipment as well as in a stronger organisation. The long-term goal is to expand Rottneros’ total capacity to reach a business volume of at least 460.000 tonnes of pulp per year, compared with the 345,000 tonnes produced last year. The total plan is about SEK 800 million for Agenda 500 in full, divided into about SEK 400 million in the medium term and SEK 400 million in the longer term. Compared with investment levels for increased capacity per tonne found in the international paper industry, Rottneros’ investments are highly competitive. The pace of the investments will be determined by Rottneros’ ability to allocate the increased volumes in the market.

We continue to have a good starting position for the future. The strong dollar more than compensates for the negative price trend. Our highly motivated employees are working intensively to expand our business towards higher volumes and thus more efficient production. I look forward to the coming year and the strategic steps that we will take.