Ianadmin

Prestigious New Appointment Underpins KV Rollers’ Expansion Ambitions

Leading UK print and industrial roller manufacturers, KV Rollers, are continuing their ambitious growth plans with a prestigious new appointment.

Leading UK print and industrial roller manufacturers, KV Rollers, are continuing their ambitious growth plans with a prestigious new appointment.

Tim Hudson will join the South Wales based company as Commercial Director, having been head hunted from one of KV Rollers’ closest competitors, Böttcher.

Kevin Lower, KV Rollers Managing Director, said: “We are very pleased to welcome Tim on board. He brings with him a wealth of expertise and specialist knowledge, which will support KV Rollers during its ongoing expansion.

“KV Rollers has moved into a new and exciting phase of its life as a result of major increased investment in the company, and thanks to our continued commitment to a rolling programme of research and development. Tim’s appointment is part of that expansion. He has a sound reputation in the industry because of his aptitude for achieving marked sales growth, and we feel Tim will bring a fresh approach to the table.”

The firm, based in Cwmbran, recently made a bumper investment of £750,000 in plant and machinery at their new factory, and they are projected to increase turnover by 20 percent this year with a growing number of orders from companies across the globe over the past six months.

They have invested in, among other things, a state-of-the art milling machine, thought to be the only one of its kind being used in the UK - the Mazak VTC 820. This leviathan of a metal-milling machine has helped KV Rollers expand into supplying machine manufacturers as well as end users.

Mr Lower added: “We are now a one-stop-shop for metal components and specialist parts, having already established ourselves as field-leaders in the design, production and refurbishment of industrial rollers, and in creating bespoke rubber compounds.”

Tim, who was previously Production Director at Böttcher’s Ebbw Vale plant, said: I am excited to be joining KV Rollers at such a crucial time in their development and growth. The KV Rollers name has always been associated with excellence and innovation and I look forward to bringing my expertise to the KV Rollers talent-pool.”

KV Rollers have enjoyed a particularly successful time recently.

They were in the news at the end of 2014 for developing a ground-breaking new polymer, called Kalexite, designed to make the packaging and print industry markedly safer by cutting fire risk.

They were also fast-tracked this year as one of Tata Steel’s approved suppliers.

A.Celli Paper: Great satisfaction for the rebuild of a rewinder at United Paper Industries Co. (UPI), Kuwait.

Great results for the rebuild of a rewinder completed by A.Celli Paper at the UPI facilities in Kuwait. Initially, the project entailed replacing the old slitting unit and updating the tension control system. In a subsequent phase, the intervention was extended with the addition of a new unwinder with brake and load cell system.

This newly defined project, which got under way at the beginning of 2015 and was shipped in April, obtained great results in terms of production performance. Thanks to the close collaboration and synergies in experience created between the A.Celli team and UPI technicians, the new slitting unit was already operational in July. The customer’s open willingness to collaborate together with the expertise shown by our team made start-up fast & easy, with just a little over thirty hours (34) of stoppage of the unwinder - the very minimum amount needed for a rather critical replacement such as this one.

The customer’s satisfaction was confirmed by their words: "The advantages of the rebuild are clearly evident: thanks to the new brake system with load cells, winding quality is uniform and the roll is more compact than before; the cut is very accurate and the rewinder’s speed has increased by 20%. We are totally satisfied with the job done. A.Celli has supported and guided us through this journey, serving us impeccably. We will continue working with this company, assessing further modifications and developments on the rewinder, or in the event that other needs from our paper mills arise.”

An important confirmation and a great vote of confidence for A.Celli Paper S.p.A., who is once again acknowledged as an excellent partner capable of satisfying customers with high-level services and optimal results in terms of machine performance.

A.Celli Paper actively participates in the production growth of South-East Europe

A.Celli Paper actively participates in the production growth of South-East Europe with the supply of a new tissue machine to Metalicplas (Pehart Tec Group) in Romania.

At the beginning of January 2015, A.Celli Paper received an order confirmation by Metalicplas (part of the Pehart Tec Group) for the supply of a high-speed Tissue Machine with a production capacity of 34,000 tons per year (110 tons per day).

The investment is part of the Romanian Group’s growth plan that aims at an important increase in production capacity. Following the recent entry of Abris Capital Partners (May 2015) the Group has become leader in the manufacture of tissue products in Romania and South-East Europe and the new corporate vision is set to attain important goals in these territories. The inauguration of the expansion project at the production site in Dej, as well as at the one in Petresti, is scheduled for the end of this year and will lead to a total production capacity increment of almost 100,000 tpy of tissue parent reels. Sure bases for success, in which A.Celli Paper technology will play an important part.

The new Tissue Machine, with a 2.800-mm width at the pope reel and a maximum speed of 1800 m/min, is part of a complete turnkey project that includes the “Control & Automation” system, together with all ancillary equipment. The latest-generation hood design and the 15-foot Yankee cylinder are the additional elements of technological excellence, a distinctive sign of A.Celli that makes its Turnkey offer the right choice for the many demands of the market in terms of experience and expertise - a true added value for customers. A 100% pure cellulose pulp preparation system designed to process long and short fibres, a reel handling system and a slitter/rewinder complete the supply.

In view of the start-up scheduled for the end of 2015, the first delivery left Lucca at the beginning of July bound for Metalicplas.

A.Celli Paper is set to give its technological contribution to the #1 Romanian producers towards the conquest of South-East Europe.

Metalicplas, part of Pehart Grup Companies

Pehart Grup Companies, with its three tissue converting sites and the new facilities ready to begin operation by the end of the year – thanks to the entry of Abris Capital Partners and to Romanian state grants – is the major independent producer of tissue in Romania. Pehart is present on the market with two brands, Pufina and Alint, and a strong number of retail customers for which it produces private label tissue products. Currently, the Group exports a substantial portion of its production to nearby Central and South-Eastern European countries.

Screening with BlueLine Cost-effective, efficient and gentle on fibers

Screening plays a key role in the preparation of recovered paper, as it not only removes coarse contaminants but also small and very fine impurities. Papermakers expect low fiber losses, low energy consumption and effective removal of stickies. The BlueLine product range for stock preparation has been developed to meet these requirements. The latest product from the BlueLine family is the C-bar HerculeX screen basket.

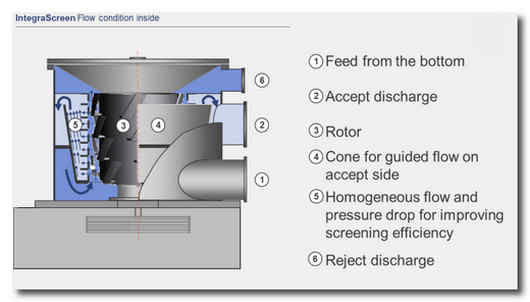

The IntegraScreen and IntegraGuard from Voith are two screening machines for stock preparation and the approach flow system. In combination with rotors and screen baskets, they are adapted to the specific requirements of paper manufacturing.

IntegraScreen: a screening machine concept turned on its head

IntegraScreen is the screening machine for various applications in the stock preparation. With its development of IntegraScreen, Voith has literally turned its screening machine concept upside down: It differs from its predecessors since the intake for the suspension is at the bottom and the outlet for the rejects is at the top. For the first time in this solution, the light contaminants are separated along with the reject via the same pipe. The advantages are obvious: there is no need for additional piping, instrumentation, pumps and valves. A cone in the machine optimizes the flow on the accept side and ensures uniform pressure conditions over the screen basket. This evens out the screen passing velocity and as a result improves the efficiency of contaminant separation.

IntegraGuard: high-quality protection in the approach flow system

IntegraGuard is the screening machine for the approach flow system, where it is particularly important to prevent pulsations, deposits and stringings because they can cause sheet breaks. This is why the IntegraGuard housing is designed to achieve a homogeneous screen passing velocity. The new head piece improves the flow profile in the machine and allows to reduce the rotor speed while maintaining the rotor’s efficiency.

C-bar HerculeX: Hybrid technology makes for a strong screen basket

The C-bar technology used in screen baskets to achieve effective screening with fine slot geometries was first launched on the market by Voith more than 25 years ago and has been constantly refined and improved ever since. The new C-bar HerculeX is regarded as the strongest screen basket on the market to date and can withstand very high loads. It is made of wear-resistant material and is suitable for various applications in pre-screening and fine screening, fractionation, broke and thick stock screening and also in the approach flow system. C-bar HerculeX has very large open screening areas and a special bar geometry. The new screen basket can be tailored to the respective screening requirements and production conditions by varying the widths, slot widths and angles of the bars.

Its exceptionally high stability and strength are thanks to its patented hybrid technology, a reworking of Voith’s clamping technology. An individually customizable chrome layer provides wear protection. The screen basket can be used in all Voith and third party screening machines and is suitable for all paper grades. The best screening results are achieved in combination with a Voith rotor.

MultiFoil rotor and EclipseRotor Voith offers various rotors for its screening equipment, most notably the EclipseRotor and the MultiFoil rotor. The EclipseRotor was developed specifically for screening applications with a high level of contaminants. It is suitable for energy-efficient use in stock preparation and pulp screening and can be installed in Voith screening equipment and in centrifugal pressure screens from other manufacturers. Thanks to its flat but effective foil geometry, the EclipseRotor generates strong suction and achieves a very high stock throughput with very low energy consumption for pulp consistencies up to 5%.

Voith’s MultiFoil rotor was developed for use in the stock preparation and approach flow systems. Its special foil geometry prevents stringings and undesirable pulsations. Optimum suction impulses and a uniform flow profile combined with a low rotor speed help to make the screening process gentle and energy-saving. The MultiFoil rotor can be installed in the two Voith screens, in all vertical screens and in the machines of other manufacturers for centrifugal pressure screens.

Low costs for inventory and maintenance. The screening machines, screen baskets and rotors from the BlueLine product range are easy to operate and easy to maintain. Their spare and wear parts are standardized, allowing life cycle costs to be optimized.

Voith BlueLine range for stock preparation

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

The BlueLine range includes e.g. the IntensaMaXX pulper detrashing machine, the IntensaDrum pulping drum, the InfiltraScrewpress screw press, the IntegraScreen and IntegraGuard screening machines and the InfiltraDiscfilter.

Xerium Technologies to Present at the Sidoti Emerging Growth Conference September 2, 2015

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has announced that Harold Bevis, President and CEO and Cliff Pietrafitta, Chief Financial Officer will present at the 2015 Sidoti Emerging Growth Conference on Wednesday, September 2, 2015 from 11:20 – 11:55 AM EDT at the Marriott Marquis Hotel, New York, NY.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has announced that Harold Bevis, President and CEO and Cliff Pietrafitta, Chief Financial Officer will present at the 2015 Sidoti Emerging Growth Conference on Wednesday, September 2, 2015 from 11:20 – 11:55 AM EDT at the Marriott Marquis Hotel, New York, NY.

Investors and interested parties may listen to the live webcast of this presentation by clicking here or visiting the Xerium website at www.xerium.com under the Investor Relations section at the time of the presentation.

About Xerium (NYSE:XRM)

Xerium Technologies, Inc. is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to the production of paper, paperboard, tissue, pulp, building products, nonwoven fabrics, and variety of industrial applications. Xerium products are specifically designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,100 employees.

Source: Xerium Technologies, Inc.

Xerium Technologies, Inc.

Cliff Pietrafitta, 919-526-1444

Chief Financial Officer

This email address is being protected from spambots. You need JavaScript enabled to view it.

Neenah Introduces “Let Texture Define” the ROYAL SUNDANCE Papers Identity Promotion

“Let Texture Define” includes four identity systems designed to provide ideas for making first impressions count

It is said that you have roughly three to five seconds to capture a customer’s attention. The ROYAL SUNDANCE® Papers promotion titled “Let Texture Define” shows you how to make those seconds count by enticing customers with the right paper.

“Texture can influence our decisions as it creates an emotional connection. It’s important to communicate a brand’s personality, and create a memorable first impression, through every touch point, starting with a company’s identity system,” says Neenah Sr. Brand Manager, Kathy Kemps.

Neenah’s ROYAL SUNDANCE® Identity Promotion uses all five of the collection’s finishes to showcases identities for companies in four different verticals.

“Let Texture Define”uses all five of the ROYAL SUNDANCE collection’s finishes and a combination of colorsto showcase identities for companies in four different verticals. Items in the portfolio include letterhead, envelopes, business cards, and promotional pieces such as a menu, invitation, oversized postcard, bookmark and gift card.

- Centas Global Telecom combines the handmade feel of Laid with the crispness of Smooth to speak to the hands-on customer service this technology company delivers.

- The Flying Loon restaurant identity uses the Fiber finish to align with the natural feel of the restaurant, but uses the Felt finish on the business card as a complementing contrast with high-touch appeal.

- The Front Porch real estate company uses the tactile quality of Felt to elicit a “homey, feel-good” emotional connection with its brand.

- The Viva Home Care identity system lets the refined sophistication of Linen make a brand statement, while adding a personal touch with envelopes made with the Fiber finish.

To see how ROYAL SUNDANCE Papers can help define your message or your brand’s personality, pick up a copy of “Let Texture Define” from your local merchant.

About Neenah

For more than 100 years, Neenah Paper (NYSE: NP) has been an innovative leader in the creation and manufacturing of papers for premium writing, text, cover, digital, packaging and specialty needs. The Neenah signature portfolio includes market leading brands such as CLASSIC®, ENVIRONMENT®, and ROYAL SUNDANCE® Papers. The company also offers envelopes in thousands of unique colors, finishes and styles.

Neenah is committed to developing relevant mobile and online technologies including Neenah Cabinet™ for iPad, iPhone and Android. With multiple manufacturing facilities in Wisconsin, prime importance is also placed on recycled and alternative fiber products through the Neenah Green initiative. For more information on Neenah call (800) 558-5061. Follow Neenah on Twitter: @neenahpaper; subscribe to the Neenah Facebook page; or visit Against the Grain, Neenah’s blog for designers, printers and paper-lovers.

Contact

Neenah: Jamie Saunders, 678-518-3222, This email address is being protected from spambots. You need JavaScript enabled to view it.

Lack of domestic forest resources has forced the pulp industry in India to increasingly rely on hardwood chips from overseas

Lack of domestic forest resources has forced the pulp industry in India to increasingly rely on hardwood chips from overseas for its wood fiber needs, report the Wood Resource Quarterly

Growing consumption of pulp and paper in India has increased the demand for wood fiber for the domestic pulp industry in the country, reports the Wood Resource Quarterly. With the lack of domestic pulpwood plantations, pulp manufacturers have for the past few years increasingly been looking overseas to South Africa, Brazil, Australia and Southeast Asia for much needed hardwood chips.

India has limited domestic forest resources to supply its forest industry, and with growing domestic demand for forest products, the country’s pulp mills and sawmills have found it necessary to increase importation of wood raw-material both in the form of wood chips and logs.

Over the next five years, demand for paper is expected to increase by between 2-12% annually, depending on paper grade. Over the past decade, the domestic pulp industry has steadily increased its usage of pulpwood because of higher pulp production, less usage of bamboo and because several pulp mills switched from recycled fiber to wood fiber.

Over the next five years, demand for paper is expected to increase by between 2-12% annually, depending on paper grade. Over the past decade, the domestic pulp industry has steadily increased its usage of pulpwood because of higher pulp production, less usage of bamboo and because several pulp mills switched from recycled fiber to wood fiber.

The share of imported wood fiber for the pulp industry accounted for almost ten percent of total consumption of wood fiber in 2014, and this share is expected to increase in the coming years.

The shortage and high cost of local pulpwood in India has resulted in increased interest in sourcing wood chips from overseas despite logistical difficulties both at the ports and when transporting the chips from the ports to the pulp mills long.

Importation of chips is fairly new and Indian pulpmills did not import any wood chips until 2013 when the first shipments of hardwood chips from South Africa, Australia and Thailand arrived. The total imports reached just over 200,000 odmt in 2013, then rose to approximately 370,000 odmt in 2014, according to the Wood Resource Quarterly. South Africa has been the major supplier of chips, with shipped volumes accounting for about 70% of the total import volume in 2015.

During the first six months of 2015, India imported an estimated 180,000 m3, or about 30% more than in the same period in 2014. So far in 2015, three countries have exported wood chips to India, South Africa, Brazil and Vietnam. South Africa has been the dominant supplier to date, and is likely to continue to be the major supplier for the foreseeable future.

Global lumber, sawlog and pulpwood market reporting is included in the 52-page quarterly publication Wood Resource Quarterly (WRQ). The report, which was established in 1988 and has subscribers in over 30 countries, tracks sawlog, pulpwood, lumber and pellet prices, trade and market developments in most key regions around the world. To subscribe to the WRQ, please go to www.woodprices.com

Contact Information

Wood Resources International LLC

Hakan Ekstrom

Seattle, USA

This email address is being protected from spambots. You need JavaScript enabled to view it.

Minerals Technologies Begins Operation of NewYield(TM) Integrated Process Technology Facility for Sun Paper Group in China

NewYield(TM) Technology Converts a Papermaking Waste Stream into a Useable Filler Pigment, Eliminating the Need to Landfill the Waste Product

Minerals Technologies Inc. (NYSE: MTX) has successfully begun operation of a new satellite plant to produce the breakthrough NewYield(TM) Integrated Process Technology for the Sun Paper Group's pulp and paper operations in Shandong Province, China.

Minerals Technologies Inc. (NYSE: MTX) has successfully begun operation of a new satellite plant to produce the breakthrough NewYield(TM) Integrated Process Technology for the Sun Paper Group's pulp and paper operations in Shandong Province, China.

"We are extremely pleased to have our new satellite plant at Sun Paper up and running and producing a useable papermaking filler that provides Sun with both cost savings and reduced environmental impact, while at the same time providing them with a filler pigment for their paper," said Joseph C. Muscari, chairman and chief executive officer. "The successful commissioning of this plant now sets the stage for MTI to roll out this new technology to other papermakers."

NewYield(TM) is an innovative technology that converts a paper and pulp mill waste stream into a functional pigment for filling paper. NewYield(TM) technology eliminates the cost of environmental disposal and remediation of certain waste streams to papermakers. The facility will produce 60,000 tons of filler pigment from Sun's waste stream.

By utilizing Minerals Technologies' NewYield(TM) Integrated Process Technology, papermakers can eliminate the costs associated with landfill disposal or energy, and in return will receive a functional paper-filling pigment. MTI and the papermaker will both benefit, as will the environment.

New York-based Minerals Technologies Inc. is a resource- and technology-based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral-based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, environmental, energy, polymer and consumer products industries. The company reported sales of $1.725 billion in 2014.

For further information about Minerals Technologies Inc. look on the internet at http://www.mineralstech.com/

Contact:

Rick B. Honey

(212) 878-1831

BillerudKorsnäs investigates opportunities for growth

The demand for sustainable packaging solutions is growing globally. BillerudKorsnäs wants to explore the opportunities to respond to the demand growth while at the same time streamline and further improve its production structure. The company is now launching two feasibility studies, one regarding investment into a new board machine at the production site in Gruvön, Sweden, and the other regarding a streamlining and development of the production structure for packaging papers.

The demand for sustainable packaging solutions is growing globally. BillerudKorsnäs wants to explore the opportunities to respond to the demand growth while at the same time streamline and further improve its production structure. The company is now launching two feasibility studies, one regarding investment into a new board machine at the production site in Gruvön, Sweden, and the other regarding a streamlining and development of the production structure for packaging papers.

BillerudKorsnäs is a leading supplier of renewable fiber based packaging materials and solutions. Within liquid packaging board and other virgin fiber cartonboard, the company is one of the world leaders. Driven by global megatrends, the demand for these types of board is increasing. BillerudKorsnäs therefore wants to investigate the possibility of installing a new board machine at the production unit in Gruvön. The investigation is a part of BillerudKorsnäs strategy for volume growth within business area Consumer Board. It is also in line with the strategies for the business areas Containerboard and Packaging Paper. The machine would become one of the most cost efficient in the world with a capacity of approximately 500 000 t/a of liquid packaging board, cartonboard, food service board and white kraftliner. In addition to growth in attractive board segments, an investment decision would also include a streamlining of the production structure within the business area Packaging Paper as the current production of kraft papers at the Gruvön production unit would be discontinued and replaced by production at other BillerudKorsnäs units. A potential investment decision can be made at the earliest during 2016.

Simultaneously, BillerudKorsnäs is launching an investigation into the possibilities of further structural change and growth in selected attractive kraft paper segments. The investigation includes exploring the possibility of moving the MG paper machine in Finnish Tervasaari, unintegrated to pulp production, to Swedish Skärblacka, which is an integrated unit. The investigation also includes investment in further value adding surface treatment capacity at existing MG paper production in Skärblacka. If implemented, the investments would strengthen Skärblacka’s position as one of the world's most efficient production units for white MG papers while also opening up opportunities in attractive market segments within medical papers, food packaging and release liners. The investigation will be completed during the first half of 2016 and after a potential decision is taken about a year is required to carry out the investment in surface treatment capacity and one and a half years for a potential paper machine move.

“These two investigations clearly indicate that we have our sights set on growth. We carefully compare all different growth scenarios to each other. Right now, we consider conditions for organic, investment driven, growth in our own production structure as the most favorable. These investigations do not exclude the possibility of further acquisitions”, says Per Lindberg, President and CEO, BillerudKorsnäs.

The investigations are independent of each other. Also independent of the outcome of the investigations, BillerudKorsnäs invites to union negotiations regarding a possible closure of the BillerudKorsnäs production at Tervasaari.

For more information, please contact:

Per Lindberg, President and CEO, +46 (0)8 553 335 00

Henrik Essén, SVP Communication and Sustainability, +46 (0)8 553 335 00

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world leading provider of primary fiber based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 21 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Valmet to supply analyzers and quality control system for Stora Enso's Varkaus Mill in Finland

Valmet will supply pulp mill and board machine quality management solutions for Stora Enso's Varkaus Mill in Finland. The orders are an addition to the extensive rebuild of the Varkaus mill's PM 3 fine paper machine supplied by Valmet to produce lightweight containerboard grades announced on May 13, 2014.

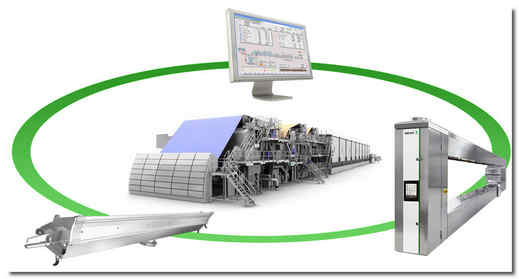

Valmet IQ Quality Control System

The order was included in Valmet's second quarter 2015 orders received. The value of the order is not disclosed. Typically, the order value of automation system deliveries ranges from below EUR 1 million to EUR 3 million.

"After the upgrades of both pulp mill and board machine quality management systems, the Varkaus mill will be able to fully exploit the rebuilt machine's performance potential," says Aki Korhonen, Director of Analyzers, Measurements and Performance Solutions from Valmet.

The Valmet delivery includes a Valmet Kappa Analyzer for the pulp mill and Valmet IQ quality control system (QCS) for the rebuilt board machine.

Technical details of the automation delivery

The Valmet delivery includes a Valmet Kappa Analyzer for the pulp mill. The analyzer will provide all the necessary measurements of fibers, shives and kappa number, for brown unbleached kraft production. Sampling capacity of the mill's Valmet Pulp Expert automatic pulp laboratory will also be expanded with 5 new samplers to accurately follow pulp property development in stock preparation.

The delivery also includes a new Valmet IQ quality control system (QCS) for the rebuilt board machine. With sensors for basis weight, moisture, caliper ash content and color; the IQ system features state-of-the-art machine and cross direction controls. Additionally four Valmet RM3 sensors will be supplied to measure wet end consistencies with the exclusive ability to monitor both total and true ash consistency from the process for active fines retention management. New modules will also be installed to the mill's existing Valmet Paper Lab and provide automated laboratory testing for key board quality parameters.

Information about the customer Stora Enso

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Customers include packaging, joinery and construction industries as well as publishers, printing houses and paper merchants. The Group has some 27 000 employees in more than 35 countries with sales in 2014 of EUR 10.2 billion.

VALMET

Corporate Communications

For further information, please contact:

Janne Tolonen, Sales Manager, Pulp & Paper, Nordics, Automation, Valmet, tel. +358 40 566 9374

Harri Kohonen, Sales Manager, Pulp & Paper, Nordics, Automation, Valmet, tel. +358 40 748 3845

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.