Ianadmin

Mondi gives its Nr.1 brand Color Copy a fresh new look

New packaging design with improved strength and convenience options

Mondi, the international paper and packaging Group, announces the relaunch of its market leading brand Color Copy with a new branding, improved packaging and 100% satisfaction guarantee. The focus of the campaign is to tell the story of Color Copy as the brand customers trust and have relied on for over a quarter of a century for perfect print results and consistent quality. The paper quality remains unchanged.

Color Copy enjoys very high brand awareness and a strong reputation. It is still by a large margin the most recognised brand name for colour applications in Europe (40% vs. 14% for second ranked brand), confirmed again by the latest 2016 EMGE Cut-size Survey. Mondi carried out extensive marketing research in 2016 with customers and end-users surveyed across ten countries. The aim was to better understand why end-users had stayed loyal to the brand over the years and how they saw the benefits of Color Copy for their business. “While we received some insights into what we can do better, the clear message we received from 92% of users was that they are very satisfied with the quality of the paper and we shouldn’t change anything here. So we’ve focused on the branding, packaging and convenience options where we could make Color Copy even better – on the outside - while retaining strong brand recognition,” explains Johannes Klumpp, Marketing & Sales Director, Mondi Uncoated Fine Paper.

This is the first time Color Copy has undergone any significant rebranding in its 28 years of existence. As part of the rebranding, Color Copy’s packaging has been improved threefold: in terms of design, strength and convenience. The wrappers and boxes are fully branded with a bold new look to make a bigger impact at the point of sale. The wrappers are stronger than ever with an improved base paper and now feature an easy-open tear strip for greater consumer convenience.

This is the first time Color Copy has undergone any significant rebranding in its 28 years of existence. As part of the rebranding, Color Copy’s packaging has been improved threefold: in terms of design, strength and convenience. The wrappers and boxes are fully branded with a bold new look to make a bigger impact at the point of sale. The wrappers are stronger than ever with an improved base paper and now feature an easy-open tear strip for greater consumer convenience.

What’s more, Mondi now offers a shelf-ready packaging option for paper and office supply retailers. This high-quality perforated box requires no unpacking. It comes ready for shelf display and highlights Color Copy’s eye-catching new branding to attract shoppers.

100% Satisfaction Guaranteed.

Mondi guarantees true-to-life, brilliant colour copies and perfect print results every time with Color Copy, and offers to replace the paper if not 100% satisfied with the results. Color Copy is specifically designed to meet the needs of digital colour printing. It is available in a variety of standard paper formats and reels, and in grammages ranging from 90 gsm to 400 gsm.

In July Mondi will begin the rollout of its new Color Copy branding and packaging, followed by related sub-brands in the fall. The rollout is accompanied by a comprehensive marketing campaign with the clear and reassuring slogan of “Doing a great job.” Johannes Klump explains: “For us, ‘Doing a great job.’ is more than a claim. It reflects the performance the brand has delivered consistently for over two decades. It’s also a promise. It’s you AND me together. And it’s our mission with Color Copy – to continue to do a great job for our customers every day.” The focus is on emotional messaging and compelling images that emphasise Color Copy’s guaranteed reliability. The teaser campaign, which ran from the end of April until mid-June, included magazine, billboard and online advertising, with weekly promotional prize giveaways. The marketing strategy will also include a relaunch of the Color Copy microsite (www.colorcopy.com) in a fully responsive design by the end of June, as well as an end-user social media campaign in the fall, and all new print and online marketing and sales tools.

About Color Copy

Color Copy is the leading brand for colour applications and is CO2 neutral. It is specifically designed to meet the needs of digital printing and guarantees true-to-life, brilliant colour copies and perfect print results every time. Color Copy has an elegant and smooth feel and its soft white hue gives accurate colour reproduction that emphasises your image. It also has an exceptional environmental profile, being CO2 neutral in addition to having FSC®, EU Ecolabel and ISO 9706 certifications. Color Copy is part of Mondi’s Green Range of sustainably produced products. www.colorcopy.com

We are Mondi: IN TOUCH EVERY DAY

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are located in central Europe, Russia, North America and South Africa. In 2016, Mondi had revenues of €6.7 billion and a return on capital employed of 20.3%.

We are fully integrated across the packaging and paper value chain - from managing forests and producing pulp, paper and compound plastics, to developing effective and innovative industrial and consumer packaging solutions. With over 100 products customised into more than 100,000 solutions, we offer more than you may expect. Leading brands around the world rely on our innovative technologies and products across a variety of industries such as agriculture; automotive; building and construction; chemicals and dangerous goods; food and beverages; graphic and photographic; home and personal care; medical and pharmaceutical; office and professional printing; packaging and paper converting; pet care; retail and e-commerce; and shipping and transport.

We believe sustainable development makes good business sense. It's integral to our responsible and profitable growth, and embedded in everything we do, every day. We continue to look for ways to do more with less, promote the responsible management of ecosystems, develop and inspire our people, and enhance the value that our sustainable product solutions create.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc, under the ticker code MNDI. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is part of Mondi Group. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

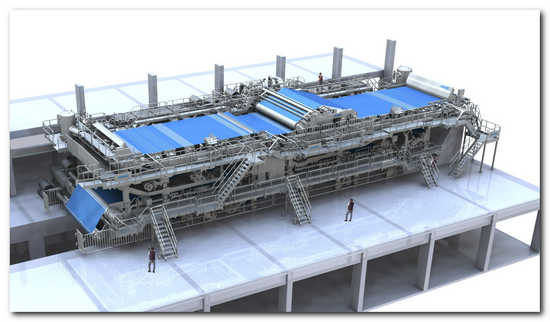

ANDRITZ to rebuild board machine for Knauf Petroboard

International technology Group ANDRITZ has received an order from AO Knauf Petroboard to rebuild the KM 2 board machine at its mill in Kommunar, Russia. The board machine – with a basis weight range from 100-320 g/m2, a working width of 4,260 mm, and a design speed of 700 m/min – has an annual capacity of 155,000 t/a for production of gypsum board made of 100% waste paper raw material. Start-up is scheduled for the fourth quarter of 2018.

The rebuild includes the supply of a new wire section with three PrimeForm SW Fourdrinier wires and new PrimeFlow SW headboxes, one of which contains a PrimeProfiler F consistency profiling system.

ANDRITZ will also supply the main components in the approach flow systems for the top, filler, and back layers at KM 2. The scope of supply comprises several ModuScreen HB-E screens, which combine lowest energy requirements with minimum pulsations at lowest fiber loss. A new ANDRITZ couch pit pulper will manage broke handling. In order to significantly improve water management of the mill, a fiber recovery system with an ANDRITZ save-all Disc Filter will be installed.

ANDRITZ will supply a new wire section with three Fourdrinier wires to Knauf Petroboard, Russia. “Photo: ANDRITZ”.

ANDRITZ will supply a new wire section with three Fourdrinier wires to Knauf Petroboard, Russia. “Photo: ANDRITZ”.

ANDRITZ AUTOMATION will deliver a complete new Multi Motor Drive for the entire machine as well as the electrification and automation equipment. The delivery will be handled on an EPC basis, where ANDRITZ takes responsibility for the installation work, including piping and cabling, as well as the required supervision works related to erection, commissioning, and training.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors as well as for animal feed and biomass pelleting. Other important business segments include automation and service business. In addition, the international Group is also active in the power generating sector (steam boiler plants, biomass boilers, recovery boilers, and gasification plants) and in environmental technology (flue gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard as well as recycling plants. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,200 employees. ANDRITZ operates more than 250 sites in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

Knauf – a family business

Knauf is one of the leading manufacturers of building materials and systems in Europe and far beyond. Knauf is operating worldwide, with production facilities and sales organizations on all five continents in more than 80 countries and at more than 220 locations. Knauf plants produce modern dry-lining systems, plasters and accessories, thermal insulation composite systems, paints, floor screed and floor systems, equipment and tools for applying these products, as well as insulation materials.

AO KNAUF PETROBOARD

AO KNAUF PETROBOARD is a Russian structural unit of the international KNAUF Group, which has been investing in Russia for almost 25 years. KNAUF has 15 new or fully renovated production companies in Russia, with 36 production plants manufacturing 1,400 products.

KNAUF PETROBOARD has a leading position on the markets in Russia and the CIS countries in manufacture of packaging and wall lining board used to make gypsum plasterboard. The main raw material used in the manufacture of lining board is waste paper. Implementation of this project will provide the means to cover the growing demand for lining board from companies in Russia and the CIS countries and make them less dependent on import of these products.

Computerworld Names International Paper to 2017 List of 100 Best Places to Work in IT

Computerworld have just announced that International Paper has been recognized as a 2017 Best Places to Work in IT, one of 100 top organizations that challenge their IT staffs while providing great benefits and compensation. Organizations will be included in coverage in Computerworld along with results from the 24th annual Best Places to Work in IT survey.

IP ranked 26th, on Computerworld's 2017 list for IT professionals in the large company category. The company's 1,400 IT team members deliver technology solutions for business advantage and support services to the company's 55,000 global team members, using information resources across 645 locations, speaking 13 languages and doing business in 44 currencies.

"I am proud of this team and really happy to see them recognized for helping International Paper become one of the most successful, sustainable and responsible companies in the world," said Bob Wenker, Vice President and Chief Information Officer. "Being listed as one of the Best Places to Work in IT is a great achievement, made possible by a committed group of talented team members. I am extremely proud of them."

About the Best Places to Work in IT list

The Best Places to Work in Information Technology (IT) list is an annual ranking of the top 100 work environments for technology professionals by IDG's Computerworld. The list is compiled based on a comprehensive questionnaire regarding company offerings in categories such as benefits, career development, training and retention. In addition, Computerworld conducts extensive surveys of IT workers, and their responses factor heavily in determining the rankings.

About International Paper

International Paper (NYSE: IP) is a leading global producer of renewable fiber-based packaging, pulp and paper products with manufacturing operations in North America, Latin America, Europe, North Africa, Asia and Russia. We produce packaging products that protect and promote goods, and enable world-wide commerce; pulp for diapers, tissue and other personal hygiene products that promote health and wellness; papers that facilitate education and communication; and paper bags, cups and food containers that provide convenience and portability. We are headquartered in Memphis, Tenn., and employ approximately 55,000 colleagues located in more than 24 countries. Net sales for 2016 were $21 billion. For more information about International Paper, our products and global citizenship efforts, please visit internationalpaper.com.

About Computerworld

Computerworld from IDG is the leading technology media brand helping senior IT, business decision-makers and key influencers navigate change with effective business strategy. As the voice of business technology, Computerworld enables the IT value chain with unique editorial coverage from setting strategies to deriving value. Computerworld's award-winning website (www.computerworld.com), focused conference series, strategic marketing solutions and research forms the hub of the world's largest (40+ edition) global IT media network and provides opportunities for IT vendors to engage this audience. Computerworld leads the industry with an online audience of over 7.2 million monthly page views (Omniture, January 2016 – March 2016 average) and was recognized in BtoB's 2013 Media Power 50 list; recognition Computerworld has received for more than 5 consecutive years. Computerworld is published by IDG Enterprise, a subsidiary IDG. Company information is available at www.idgenterprise.com.

SOURCE International Paper

WestRock Completes Acquisition of Five Facilities from U.S. Corrugated Holdings, Inc.

WestRock Company (NYSE:WRK) have just announced that it has completed the acquisition of certain operations of U.S. Corrugated, a large independent manufacturer of corrugated products for packaging and displays.

WestRock acquired five corrugated converting facilities in Ohio, Pennsylvania, and Louisiana from U.S. Corrugated, through which it provides a comprehensive suite of products and services to customers in a variety of end markets, including food & beverage, pharmaceuticals and consumer electronics.

WestRock acquired five corrugated converting facilities in Ohio, Pennsylvania, and Louisiana from U.S. Corrugated, through which it provides a comprehensive suite of products and services to customers in a variety of end markets, including food & beverage, pharmaceuticals and consumer electronics.

The five facilities will operate as part of WestRock’s Corrugated Packaging segment. WestRock intends to integrate 105,000 tons of containerboard converted annually by the acquired facilities and another 50,000 tons under a long-term contract with a newly created company formed from the remaining assets of U.S. Corrugated. The transaction is expected to be accretive to earnings in year one.

About WestRock

WestRock (NYSE:WRK) partners with our customers to provide differentiated paper and packaging solutions that help them win in the marketplace. WestRock’s 45,000 team members support customers around the world from more than 300 operating and business locations spanning North America, South America, Europe and Asia. Learn more at www.westrock.com.

Source: WestRock Shared Services, LLC

Valmet and Södra Cell sign mill-wide Learning Agreement

Valmet and Södra Cell in Sweden have signed a three-year agreement for web-based training via the Valmet Online Learning portal. Valmet will provide online courses for all main mill processes to about 600 employees at all three Södra mills in Sweden; Värö, Mörrum, and Mönsterås.

Previously, Södra has purchased Valmet's online training as part of the Värö mill expansion project. Based on excellent training results and positive feedback from the trainees, Södra is now extending the agreement to all three mills over a period of three years.

Valmet Learning Services offers organization-wide training solutions tailored to the customers' needs.

Valmet Learning Services offers organization-wide training solutions tailored to the customers' needs.

"Developing the skills of our employees, both our current and newly employed, is of utmost importance. Having effective methods and tools for education is an important prerequisite. We truly believe that together with our skilled intern teachers, the Valmet Online Learning Portal will be an important part of a strong concept," says Stefan Sandberg, Mill Manager at Södra Cell Mörrum, Sweden.

Valmet Online Learning is a fully-featured Learning Management System (LMS), offering individual and group level reporting and a diversity of collaboration features, available from computers and mobile devices. It provides 24/7 access to a large online course library for operators, maintenance staff, and other personnel in the pulp, paper, energy, and other process industries. Assessments, evaluations, and certificates are integrated in the portal and can be easily customized.

"Valmet Online Learning is an efficient tool to get our customers' new employees quickly up to speed in their new roles. For experienced operators, the online courses are a time-saver when preparing for re-certification tests. We also see that our customers value the extensive reporting features which support each employee's individual competence development," says Lisa Månsson, Global Manager, Valmet Online Learning.

Information about Valmet Learning Services

Valmet Online Learning is part of the company's recently launched customer training offering - Valmet Learning Services. The renewed offering is designed to help improve the reliability and performance of the customers' processes.

"Increased mobility and digitalization create new opportunities, but also poses new challenges to businesses when it comes to developing and retaining talent. Employees expect learning to be available anywhere, at any time. Valmet Online Learning offers the features and flexibility needed to continuously build and maintain skills and expertise for individuals, teams, and organizations. Helping our customers to develop their people is a key factor in our commitment to move our customers' performance forward," says Emmeli Olén, Director, Valmet Learning Services.

Information about the Customer Södra

Södra was founded in 1938 and is the largest forest-owner association in Sweden and an international forest industry Group, with a membership of more than 50,000 forest owners. Södra's operations are based on responsible forestry and on industries where they convert the raw material into sawn timber, paper and dissolving pulp, and green energy.

Find out more about our offering at www.valmet.com/services/learningservices

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Xerium Awards Employment Inducement Award Pursuant to NYSE Rule 303A.08

Xerium Technologies, Inc. (NYSE: XRM) (“Xerium” or the “Company”), a leading global provider of industrial consumable products and services, has just announced the grant of a restricted stock unit award of up to 600,000 shares of common stock to Mr. Mark Staton under an Inducement Restricted Stock Unit Award Agreement. In addition, the Company filed with the SEC today a Form S-8 registering the shares underlying the award. The award was offered as an inducement to Mr. Staton in connection with his commencement of employment with the Company as its President and Chief Executive Officer. The award and the Inducement Restricted Stock Unit Award Agreement were approved by the Company’s Compensation Committee of the Board of Directors in reliance on the employment inducement award exception to New York Stock Exchange Listing Rule 303A.08, which requires the public announcement of such inducement awards.

The award will vest on October 28, 2020 (“vesting date”) provided Mr. Staton has remained continuously employed with the Company through that date. The number of shares that will vest and be payable to Mr. Staton will depend on the number of shares earned between Mr. Staton’s hire date, April 28, 2017, and the vesting date (the “opportunity period”). Shares will be earned under the award based on whether the Company’s volume weighted 20-day average stock price (“average stock price”) achieves certain pre-established levels within various time periods during the opportunity period and during which the corresponding 20-day average daily dollar trading volume of Xerium common stock on the NYSE equals or exceeds $2,800,000 (“volume minimum”). For a more complete understanding of the various average stock prices and the time periods within which Mr. Staton can earn shares under this award, please refer to the Special Incentive Matrix on Exhibit A to his employment agreement, which is filed as Exhibit 10.1 to the Company’s Form 8-K filed with the SEC on May 1, 2017. Mr. Staton can earn the maximum number of shares subject to the award if the average stock price reaches $20.00 less than 18 months after his hire date.

The award will vest on October 28, 2020 (“vesting date”) provided Mr. Staton has remained continuously employed with the Company through that date. The number of shares that will vest and be payable to Mr. Staton will depend on the number of shares earned between Mr. Staton’s hire date, April 28, 2017, and the vesting date (the “opportunity period”). Shares will be earned under the award based on whether the Company’s volume weighted 20-day average stock price (“average stock price”) achieves certain pre-established levels within various time periods during the opportunity period and during which the corresponding 20-day average daily dollar trading volume of Xerium common stock on the NYSE equals or exceeds $2,800,000 (“volume minimum”). For a more complete understanding of the various average stock prices and the time periods within which Mr. Staton can earn shares under this award, please refer to the Special Incentive Matrix on Exhibit A to his employment agreement, which is filed as Exhibit 10.1 to the Company’s Form 8-K filed with the SEC on May 1, 2017. Mr. Staton can earn the maximum number of shares subject to the award if the average stock price reaches $20.00 less than 18 months after his hire date.

If Xerium experiences a Change in Control (as defined in the Company’s 2010 Equity Incentive Plan), the number of shares of common stock earned under this award will be determined based upon the stock price paid or implied in such Change in Control transaction. Those shares would be issued to Mr. Staton immediately prior to the consummation of the transaction. If Mr. Staton ceases to be employed with the Company prior to the vesting date, the award will be forfeited, except that if Mr. Staton’s employment is terminated without Cause or Mr. Staton terminates his employment for Good Reason (as those terms are defined in his employment agreement), he will be entitled to those shares earned through the date of termination and for a period of six-months thereafter.

The award is being made outside the Company’s 2010 Equity Incentive Plan but will generally be construed and administered consistent with that Plan.

ABOUT XERIUM TECHNOLOGIES

Xerium Technologies, Inc. (XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 28 manufacturing facilities in 13 countries around the world, Xerium has approximately 2,950 employees.

WestRock Completes Acquisition of Multi Packaging Solutions

WestRock Company (NYSE:WRK), a leading provider of differentiated paper and packaging solutions, have just announced the completion of the acquisition of Multi Packaging Solutions International Limited (NYSE:MPSX) (MPS).

WestRock refinanced MPS debt as part of the transaction.

WestRock refinanced MPS debt as part of the transaction.

“I am excited about our acquisition of MPS, which is an important step in the continuing development of WestRock,” said Steve Voorhees, chief executive officer of WestRock. “MPS is a leader in the value-added packaging sector, and the addition of MPS to WestRock strengthens our differentiated portfolio of paper and packaging solutions.”

About WestRock

WestRock (NYSE:WRK) partners with our customers to provide differentiated paper and packaging solutions that help them win in the marketplace. WestRock’s 45,000 team members support customers around the world from more than 300 operating and business locations spanning North America, South America, Europe and Asia. Learn more at www.westrock.com.

ANDRITZ successfully starts up second tissue machine with steel Yankee for Hebei Yihoucheng, China

International technology Group ANDRITZ has successfully completed start-up of the second tissue machine supplied to Hebei Yihoucheng, China.

The PrimeLineCOMPACT tissue machine has a design speed of 1,650 m/min and a width of 2.85 m. The Yankee, manufactured entirely of steel, has a diameter of 3.65 m. It is the “twin” of its predecessor, the TM1, that was started-up successfully in 2014.

The start-up teams of Hebei Yihoucheng and ANDRITZ celebrate the first paper on reel. “Photo: ANDRITZ”

The start-up teams of Hebei Yihoucheng and ANDRITZ celebrate the first paper on reel. “Photo: ANDRITZ”

The order also included supply of the complete stock preparation plant, automation, and drives. The tissue machine and its components were manufactured at ANDRITZ production sites in Europe and China. With this turnkey delivery, ANDRITZ is once more strengthening its position as one of the leading suppliers of tissue machines and services to the Chinese paper industry.

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

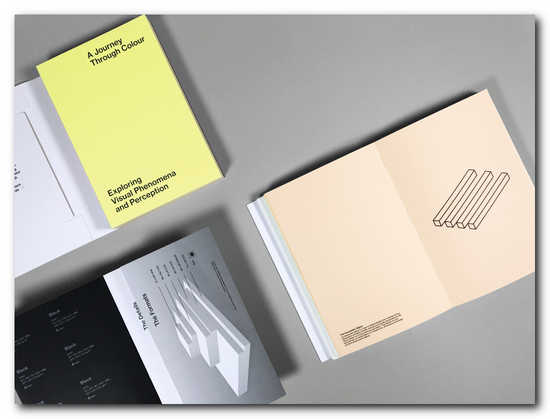

New visual book for Mondi IQ color shows expressive side of tinted papers

Mondi has published an expressive new visual book for its IQ color range of uncoated tinted papers that is itself a piece of art. Entitled ‘The Art of Seeing’, it invites people to take a journey through colour and explore visual phenomena and perception. Its 288 pages are filled with vivid colours, creative elements and optical illusions. The dynamic visual book inspires the imagination with the unlimited possibilities that IQ color offers for professional printers and the creative industries.

“The Art of Seeing” visual book – a new approach to colour

The fantastic journey into colour begins already on the front cover, which presents a visual ‘game’ in which differently coloured cards can be rearranged to trick the eye and change the pattern on the cover. ‘The Art of Seeing’ demonstrates this flexibility through a series of clever optical illusions that use a variety of printing and finishing methods.

Explore Mondi’s world of colour

Designers can easily remove colour samples from specially perforated pages to experiment with different ideas and colour combinations. Within the book are samples of all 36 standard colours - ready to be explored and used in creative projects. Johannes Klumpp, Marketing and Sales Director, Mondi Uncoated Fine Paper, says, “We designed ‘The Art of Seeing’ as a visual tool to really inspire professional printers and graphic designers to use IQ color tinted papers.

‘The Art of Seeing’ was printed in Austria by Holzhausen Druck GmbH. Hannes Fauland Jr., Customer Service at Holzhausen, had worked with IQ color papers before, and he said that after this project he will certainly work with them even more. “The project showed us how in this special case the sequence of colours bound together one after the other can put you in a good mood and generate a positive feeling,” he remarked.

IQ color – an extensive colour range

The IQ color range encompasses 36 standard colors, from soft pastels to bright neons and bold black. The new visual book shows off the superb colour uniformity and consistency of IQ color, with its smooth surface and even fibre distribution for high-quality printing. It achieves top print results whether using digital laser, hybrid or offset printing technologies. IQ color also features a high degree of light-fastness for a print product that will last for years. “IQ color delivers better print quality and more flexibility than you expect – the possibilities are endless”, added Klumpp.

Jutta Wacht, Art Director at the creative agency Say Say Say, Inc., which designed the book, was impressed by the variety of weights and formats in which IQ color is available, from A4 and A3 to folio sheets and reels. “The great number of formats and different grammages show that IQ color is perfectly suited to professional printing. Its good printability showed us that you can easily use colourful paper for a book project or a catalogue,” she said. Commenting on the impact of the unique visual book, she explained: “When you flip through the many colours, you are immediately inspired to work with tinted papers.”

What is also inspiring to designers and creatives is that Mondi offers the option of creating custom colours, substances and formats for IQ color. IQ color is also available in standard office formats. As a multifunctional office paper, it achieves best print results whether using laser printers or copiers or inkjet printing.

Sustainable. Every day.

For professional printers who are committed to sustainability, IQ color offers a strong environmental profile. The tinted papers are produced exclusively at the Mondi Neusiedler mill in Austria from FSC® certified virgin fibre. As part of Mondi’s Green Range of products, IQ color is fully biodegradable and recyclable and carries the EU’s Ecolabel. What’s more, the dyes are compliant with EN 71-3, the European standard for safety of toys, and the black paper (B100) is certified for food contact applications.

We are Mondi: IN TOUCH EVERY DAY

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are located in central Europe, Russia, North America and South Africa. In 2016, Mondi had revenues of €6.7 billion and a return on capital employed of 20.3%.

We are fully integrated across the packaging and paper value chain - from managing forests and producing pulp, paper and compound plastics, to developing effective and innovative industrial and consumer packaging solutions. With over 100 products customised into more than 100,000 solutions, we offer more than you may expect. Leading brands around the world rely on our innovative technologies and products across a variety of industries such as agriculture; automotive; building and construction; chemicals and dangerous goods; food and beverages; graphic and photographic; home and personal care; medical and pharmaceutical; office and professional printing; packaging and paper converting; pet care; retail and e-commerce; and shipping and transport.

We believe sustainable development makes good business sense. It's integral to our responsible and profitable growth, and embedded in everything we do, every day. We continue to look for ways to do more with less, promote the responsible management of ecosystems, develop and inspire our people, and enhance the value that our sustainable product solutions create.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc, under the ticker code MNDI. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is part of Mondi Group. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

Valmet to supply an upgrade of the washing process area for Stora Enso's Heinola fluting mill, in Finland

Valmet will supply an upgrade of the washing process area for Stora Enso's Heinola fluting mill in Finland with the TwinRoll Evolution wash press (TRPE). The upgrade will improve the Heinola's Neutral-Sulfite Semi-Chemical (NSSC) line washing, which will result in a better product quality and strengthened competitive position.

The order was included in Valmet's first quarter 2017 orders received. The value of the order will not be disclosed. The installation is scheduled to start up during spring 2018.

The order was included in Valmet's first quarter 2017 orders received. The value of the order will not be disclosed. The installation is scheduled to start up during spring 2018.

"This will be the first fifth generation Valmet TwinRoll wash press delivery to Finland. The press will give more flexibility in production and ensure an improved washing of the NSSC pulp before the board machine, and in that way, improve the quality of the final product," says Lari Lammi, Senior Process Manager at Valmet.

"We want to improve the pulp washing efficiency with moderate washing water volumes. A TwinRoll Press showed to be a compact solution when the alternative washers were more in numbers or bigger in size. We are waiting the start-up with great interest to see the TwinRoll Press operation and washing efficiency," says Timo Riuttanen, Process Development Manager at StoraEnso Heinola mill.

Information about Valmet's delivery

The scope of delivery includes the Valmet Twinroll evolution wash press (TRPE) with basic engineering, training and site services as well as spare parts. The TRPE wash press features displacement washing and pressing to 30-32% consistency at 2.5-10% feed consistency. The TRPE wash press is ideal for applications where high washing efficiency and capacity are required.

Information about the customer Stora Enso and Heinola fluting mill

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Stora Enso group has some 25,000 employees in more than 35 countries, and is publicly listed on the Helsinki and Stockholm stock exchanges. The sales in 2016 were EUR 9.8 billion, with an operational EBIT of EUR 191 million.

Heinola Fluting Mill produces semi-chemical (SC) fluting which is used as a raw material in the corrugated board industry. The SC fluting produced at Heinola mill in Finland has been developed especially for demanding circumstances and tough requirements.

There are approximately 230 employees at the Heinola Fluting Mill. The Mill is an integrated pulp and board mill, and the annual production capacity is 300 000 tons of fluting.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.