Metso's unique offering of products and solutions to improve safety and productivity in the oil & gas industry is now complemented with a range of control valve innovations which will be presented at Hall 9.0. Stand B21 at ACHEMA. There will be short info sessions daily on the stand in English and German. ACHEMA 2012 will be held 18-22 June in Frankfurt, Germany.

Improved version of famous Q-Trim

Noise and vibration generated by control valves constitute a typical environmental issue in process plants and their surroundings. Further improvements to Metso's famous Q-Trim™ noise reduction technology that will be on show at ACHEMA 2012 have resulted in advanced noise and vibration control in challenging applications. These solutions help process industry customers improve personnel and plant safety while simultaneously increasing efficiency and reliability.

Third generation valve diagnostics from Metso

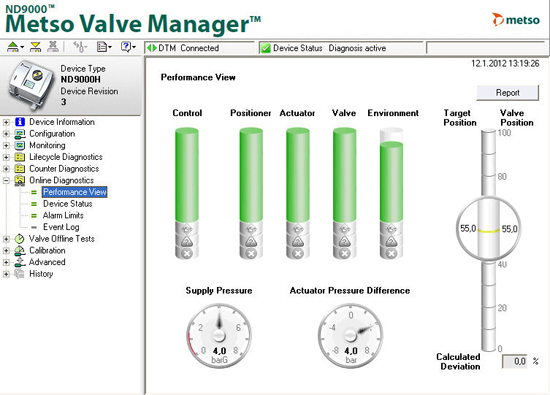

New Metso Valve Manager™ represents state-of-the art, 3rd generation valve diagnostics which is capable of processing the collected diagnostics information to visualize the condition of the valve in question with five different indices: Control performance, Valve condition, Actuator condition, Positioner condition and Environmental conditions.

With processed and visualized diagnostics information the maintenance managers and engineers and process operators are capable of making educated decisions concerning the control valve maintenance without deep valve know-how. Unexpected shutdowns can be avoided and the control valve performance can be maintained at optimum level by continuously monitoring the condition of the installed base at the plant or mill and by taking the necessary preventive actions based on the available diagnostics information. Also, with the help of the diagnostics, the available maintenance resources can be more efficiently allocated during shutdowns.

When so called preventive or schedule based maintenance strategy is followed, many valves are often needlessly maintained during shutdowns. By focusing the maintenance actions on the valves really needing maintenance, significant maintenance cost savings can be achieved through reduced spare part purchases and reduced need for maintenance resources.

Metso's new Valve Manager is available for the Neles ND9000 series intelligent valve controllers.

New features and services for intelligent emergency shutdown valves

New additions to Metso's market-leading intelligent emergency shutdown valves (iESDs) enhance the reliability and availability of emergency shutdown valves, and are designed to reduce plant safety costs efficiently and help customers maximize process plant uptime. Metso's valve sizing and selection software Nelprof® is the world's first valve selection software for safety valve optimization providing improved efficiency for safety valve selection process.

The Metso Valve HealthCare program supports the customer's preventive maintenance ensuring reliability of the critical emergency valves and helping to fulfill SIL requirements. Service is based on regular checking of valve conditions and analysing of diagnostics. The checking and reporting of recommended maintenance actions is done by Metso's certified service technicians.

The service reveals the condition of the critical valves and helps to avoid unexpected incidents affecting safety, environment or production. The service brings savings in maintenance costs by focusing on the valves needing attention or maintenance actions. Possible problems and degradation in performance are notified early to ensure time for maintenance planning.

On-going investments in global presence

Besides offering an extensive product offering, Metso is also investing in its global portfolio and presence to constantly improve services to customers in oil & gas and power. Just recently, Metso announced the acquisition of a globe valve technology and service company, Valstone Control Inc., in South Korea and established a new supply and service center in India. Currently, Metso is expanding its valve production premises in the US. Last year, Metso opened a new valve technology center in Finland, and another one in 2010 in Shanghai, China. In addition, Metso has high-class industrial valve facilities in Brazil and Germany.

Experienced in valves

Metso is the leading valve solutions and services provider. Metso's Flow Control solutions include control valves, automated on/off and emergency shut-down valves, as well as smart positioners and condition monitoring. Metso's world-leading brands include Neles, Jamesbury and Mapag.

Due to Metso's strong position in advanced valves technology, services are a major part of the offering. For example, customers like Petrobras and Arcelor Mittal have awarded Metso with large service contracts. For valve customers alone, Metso already has 32 service centers around the globe.