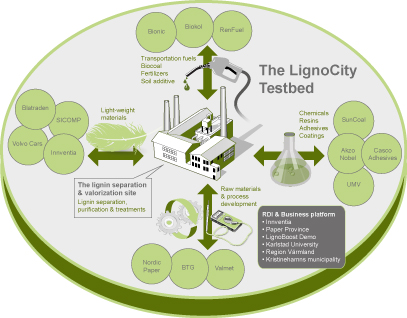

Innventia, Nordic Paper and Paper Province have started a collaboration to develop the future forest-based bioeconomy. The first step is to establish an open test bed called LignoCity. Here, companies can develop and scale up technology that refines lignin to new climate-friendly fuels, chemicals and materials.

LignoCity – a new centre for new green technologies

As the world heads towards a bio-based economy, lignin – a by-product of pulp production – is increasingly seen as a raw material with great potential. Lignin could be a green alternative for producing fuels and energy as well as chemicals and lightweight materials. Great efforts are being made to develop processes and to refine different lignin qualities for different applications.

Thanks to a broad newly established collaboration initiated by Innventia, Nordic Paper and Paper Province, several of these initiatives can now be realised. With financial support mainly from VINNOVA, Innventia’s demonstration plant in Bäckhammar will be further developed and made into an open test bed for companies who want to evaluate and validate new refining concepts in the lignin area. The plant is currently the only one in the world that can produce tailor-made lignin qualities in sufficient quantities for upscaling. The purpose of LignoCity is to create a centre where ideas are brought together and opportunities for commercial development are identified and supported. Lignin from kraft pulp production and other sources, for example from ethanol and sugar production, can be processed at the plant. The project involves 18 industrial and public players, including Karlstad University, the municipality of Kristinehamn and Casco Adhesives AB.

“With LignoCity, we are bringing together business models, technological development and infrastructure for research, development and innovation. In the long term, we also hope to be able to extract other components from the black liquor and tackle other process streams,” says Per Tomani, manager for the LignoCity project and the Lignin & Carbon Fibres focus area manager at Innventia.

“It is extremely valuable for the region’s businesses to have access to this type of open test facility, so that we can continue the development of a forest-based bioeconomy,” says Maria Hollander, CEO of Paper Province.

Kristinehamn is aiming high when it comes to innovations concerning new green fuels. Our goal is to profile ourselves as a municipality with a viable and creative business, where we carry on our technical traditions by creating future innovation. Efforts like LignoCity can help creating jobs and we are proud that the municipality contributes to this, says Carina Welin, Information manager.

Innventia established the demonstration plant in 2006 in order to demonstrate the LignoBoost process. This technology, which today is owned by Valmet and installed at pulp mills in the United States and Finland, was developed in collaboration between Innventia and Chalmers. Thanks to LignoBoost, it is possible to obtain a lignin that is so clean it can be used as a raw material for carbon fibre. Innventia runs a number of research projects in this area, and has built up an infrastructure for testing and demonstration in collaboration with the research institute Swerea SICOMP.

In addition to Innventia, Nordic Paper and Paper Province, the following organisations are involved in LignoCity: Akzo Nobel Bygglim AB, Region Värmland, Biokol Sverige AB, LignoBoost Demo AB, Blatraden AB, BTG Instruments AB, Bionic Group of Companies, Ren Fuel K2B AB, SunCoal Industries GmbH, Swerea, UMV Coating Systems AB, Valmet Power AB and Volvo Cars. More companies are welcome to join the venture.