KraussMaffei Berstorff strip winding systems have long gained a strong foothold in the market. With the successful installation, set-up and start-up of several strip winding systems in Europe, the USA and Asia in 2016, the machine manufacturer has been able to continue its success story in the field of roll covering equipment.

- Cutting-edge technology for unparalleled productivity

- Strip winding systems score with premium product quality

- State-of-the-art control technology for easy control and configuration

Cutting-edge technology for unparalleled productivity

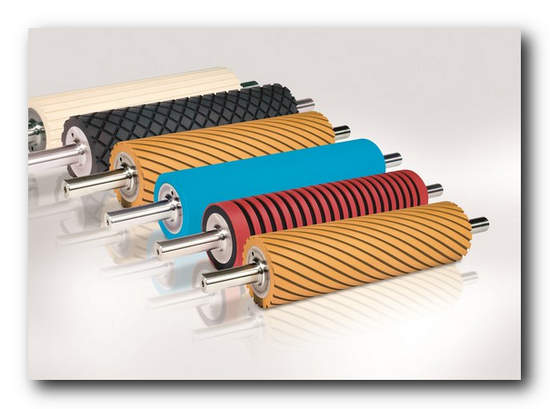

Thanks to the finely tuned interaction with state-of-the-art rubber processing extruders, KraussMaffei Berstorff strip winding systems stand out for excellent productivity, optimized advance and coating control and maximum ease of operation. All the operator has to do is to enter the application-specific compound, length, diameter and thickness, that's it – the rest is done automatically. These strip winding systems are suited for processing a wide range of different compounds – from silicone, SBR, NBR, EPDM, NR, HNBR, FKM (F)VMQ up to highly-filled special compounds. They are designed for covering rolls for the most varied industrial applications. Rolls of any face length with a core diameter between 50 and 2,800 mm can be coated with rubber layers of 0.5 to 70 mm thickness in a single working cycle.

KraussMaffei Berstorff strip winding systems stand out for excellent productivity and unparalleled ease of operation.

Strip winding systems score with premium product quality

"The rubber processing extruders used in combination with the forth strip winding system generation exhibit substantially improved feeding behavior and ensure pulsation-free extrusion even with the most challenging compounds. The dimensionally stable strip produced on these extruders is the fundamental basis for precise covering results," explains Joachim Brodmann, responsible for roll covering systems at KraussMaffei Berstorff. "Thanks to the optimized advance and covering control, the user is in a position to reduce the excess coating material required for finishing the covered rolls by up to 70%."

Apart from flat and inclined coating, KraussMaffei Berstorff has developed additional methods that allow manufacturers of rubber rolls to cover any type of roll with the most demanding rubber compounds at maximum precision and without any air inclusions. Another highlight in the KraussMaffei Berstorff machine portfolio is a wrapping system with variable tension that helps to avoid deformation in the end areas of the coated rolls.

KraussMaffei Berstorff strip winding systems are suited for a wide range of rubber compounds and designed to coat rolls, sleeves or tubes.

State-of-the-art control technology for maximum ease of operation

KraussMaffei Berstorff strip winding lines feature cutting-edge data and process control systems, which intuitively guide machine operators through all steps involved in the covering process. Easy operation, optional storage of recipe data via the central control panel and easily exchangeable final dies facilitate frequent compound changes and substantially reduce manpower requirements.

"The decisive benefits of our strip winding systems like high raw material savings, shorter set-up times and considerably reduced start-up scraps clearly convince all current users. Many of our customers have already placed orders for additional machines to revamp their production technology."

About KraussMaffei Berstorff

Around the world, the KraussMaffei Berstorff product brand stands for advanced, futureproof extrusion solutions. The company’s product spectrum ranges from single extruders with application-specific tooling, to up- and downstream components and fully automated extrusion lines. This product range, plus a customer-specific choice of service modules, guarantee that KraussMaffei Berstorff is a robust system partner for customers such as the bulk chemicals, automotive, construction, packaging and pharmaceuticals industries. KraussMaffei Berstorff, part of the KraussMaffei Group since 2007, was created through a merger of KraussMaffei and Berstorff, an engineering specialist with a long tradition. For more information: www.kraussmaffeiberstorff.com

About the KraussMaffei Group

The KraussMaffei Group is among the world’s leading suppliers of machinery and systems for producing and processing plastics and rubber. Its products and services cover the whole spectrum of injection and reaction molding and extrusion technology, giving the company a unique position in the industry. The KraussMaffei Group is innovation-powered, supplying its products, processes and services as standard or custom solutions which deliver sustained added value along the customer’s value-adding chain. The company markets it’s offering under the KraussMaffei, KraussMaffei Berstorff and Netstal brands to customers in the automotive, packaging, medical, construction, electrical, electronics and home appliance industries. Continuing a long tradition of engineering excellence, the international KraussMaffei Group currently employs around 4,000 people. With a global network of more than 30 subsidiaries and more than 10 production plants, supported by around 570 sales and service partners, the company is close to customers around the world. KraussMaffei has been headquartered in Munich since 1838. For more information: www.kraussmaffeigroup.com