Displaying items by tag: metso

Metso supplies a wash press to Mondi Richards Bay in South Africa

Metso will supply a new wash press to Mondi’s Richards Bay mill in South Africa. The Mondi Richards Bay mill, commissioned in 1984, produces more than 720,000 tonnes of bleached pulp per year, using mainly eucalyptus from own plantations as raw material. Start-up of the new wash press is scheduled for end of 2011. The value of the order will not be disclosed.

Metso’s delivery will include a TwinRoll Evolution wash press, basic and detail engineering and site services. The new wash press will allow Mondi to improve the existing brown stock washing process at the mill.

Mondi is an international paper and packaging company, with production operations across 31 countries and revenues of EUR 5.3 billion in 2009. The Group's key operations are located in central Europe, Russia and South Africa and employed 31,000 people on average in 2009.

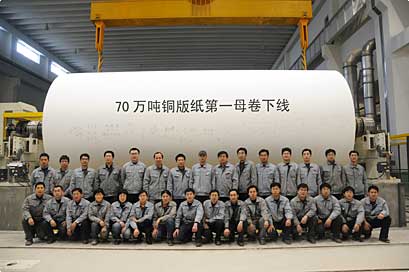

Metso-supplied fine paper line starts up at Shandong Huatai Paper in China

The Metso-supplied coated fine paper production line, PM 8, of Shandong Huatai Paper Co. Ltd came successfully on stream on Jan 18, 2011 in Dong Ying City, Shandong Province, China.

The 8.1-m-wide PM 8 has an annual dimensional production capacity of close to 700,000 tonnes of coated and uncoated fine papers within the basis weight range of 80 to 200 g/m2. The paper machine design speed is 1,800 m/min and the coater design speed is 2,000 m/min.

Metso's delivery included a complete Metso OptiConcept paper machine from headbox to reel. The paper machine line also comprises a re-reeler and an off-machine coater with coating stations, off-machine OptiLoad multinip calenders, winders, a parent reel handling system and a comprehensive Metso automation system package. The production line was started up with a Metso wet end machine clothing package.

"The PM 8 start-up was successful thanks to the state-of-the-art equipment supplied by Metso and the strong co-operation between Huatai's and Metso's project teams. Based on the good experience with Metso Huatai looks forward to producing high-quality art paper in the near future," states Wei Lijun, General Manager of Huatai PM 8 art paper line.

The first parent roll from the Metso-supplied coated fine paper production line PM 8 of Shandong Huatai Paper on January 18, 2011. Photo: courtesy of Shandong Huatai Paper.

Shandong Huatai Paper Co. Ltd. is a member of the Huatai Group. The Huatai Group has five production bases, Huatai Green Industry Park, Huatai Qinghe Green Ecology Industry Park, Rizhao Huatai Pulp & Paper Industry Park, as well as Guangdong Huatai and Anhui Huatai Industrial Parks, with an annual capacity of around 3 million tonnes.

Metso-supplied tissue making line starts up in Mexico

The Metso-supplied tissue making line of SCA in Mexico came successfully on stream on November 15, 2010, at SCA’s greenfield mill site in Ciudad Sahagún, Hidalgo State, close to Mexico City. The new PM 1 line has an annual production capacity of 60,000 tonnes of high-quality facial, toilet and towel grades.

Metso’s scope of delivery comprised a complete turn-key tissue production line. The production line is fully Metso-engineered and optimized with regard to energy savings, production efficiency and quality. The scope of supply included a tissue machine, deinking plant, effluent plant, stock preparation system, a mill-wide automation package, and also all other auxiliary equipment and systems needed for the mill. Transport, installation, training, start-up and commissioning were also included in the delivery. The combination of Metso’s wide hardware portfolio and extensive know-how and project services has created a highly competitive production unit.

“Within Metso we have the best professionals and very committed people to make such an extensive project as this possible. The installation at the site was finalized timely with high quality and in flawless cooperation with the SCA project team,” says Dan Finnerman, Vice President, Project Management, Tissue business line, Metso.

The civil engineering and building construction was handled by SCA. Special attention was paid to the interaction between the civil engineering and Metso’s plant design.

”Metso supplied a very complete solution for the tissue mill. The SCA project team worked closely with Metso throughout all phases of the projects. Support and cooperation from Metso was excellent. The tissue machine start-up went very smoothly,” said James Haeffele, Vice President, Tissue Technology for SCA North America and Project Director for the Sahagún greenfield tissue mill project.

Metso Corporation's Financial Statement 2010

Metso Corporation's Financial statements will be published on Thursday, February 3, 2011 at about 12:00 p.m. Finnish time/EET (10:00 a.m. GMT, 11:00 a.m. CET, 5:00 a.m. EST)

The news conferences

Metso will hold two news conferences in Helsinki on Thursday, February 3, 2011

• The press conference for media in Finnish will be arranged at 1:30 p.m. - 2:15 p.m. Finnish time

• The news conference with live webcast and conference call for investors and analysts in English will be arranged at the following local times:

• 03:00 p.m. EET (Helsinki)

• 01:00 p.m. GMT (London)

• 02:00 p.m. CET (Paris)

• 08:00 a.m. EST (New York)

Both events will take place at Metso Group Head Office, Fabianinkatu 9 A, Helsinki, Finland.

The news conference in English can also be followed through a live webcast at www.metso.com/investors or through a simultaneously arranged conference call. Due the live webcast, we are kindly asking those attending the news conference starting at 3:00 p.m. EET, to be present 5 minutes prior the start of the event.

Conference call details

Conference call participants are requested to dial in a few minutes prior to the start of the teleconference

• US: +1 334 323 6201

• other countries: +44 20 7162 0025 or +44 20 7162 0077

• please quote: : 885192

A replay will be available for 7 days until midnight on February 11, 2011 on the following phone numbers:

• US: +1 954 334 0342

• other countries: +44 20 7031 4064

• access code: 885192

After the news conference there will be an audio file (mp3) available for downloading and at the latest on Monday, February 7 also a transcript of the event at www.metso.com/Investors.

The presentation material will be available after the publishing of Metso Corporation's Financial Statements 2011 at www.metso.com/Investors.

You are most welcome to participate in these events.

Metso Corporation

Metso to rebuild tissue machine at Svenska Pappersbruket Klippan mill in Sweden

Metso has been awarded a contract to deliver a major rebuild of the PM 9 tissue machine of Svenska Pappersbruket AB’s Klippan mill in Klippan, Sweden. The start-up of the rebuilt machine is scheduled for the third quarter of 2011.

Metso’s delivery includes a major rebuild of the existing suction breast roll forming section, which will be replaced with an Advantage DCT type crescent forming section, a rebuild of the existing approach and stock preparation system and a minor rebuild of the existing press section. Furthermore, a state-of-the-art OptiFlo II TIS headbox is included in the delivery. The project is handled on an installed basis, including dismantling of the existing equipment, complete installation and start-up and training services.

The purpose of the PM 9 rebuild is to meet the growing market demand and to further increase product quality, operating speed and production capacity, as well as to reduce energy consumption. The investment amounts to EUR 2 million.

Svenska Pappersbruket AB is a leading independent producer of colored tissue paper for napkins.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

Metso concluded employee negotiations at Juankoski plant, Finland

Metso has concluded employee negotiations concerning all personnel groups at its Juankoski plant on December 16, 2010.

The negotiation proposal was given on October 20, 2010 due to economic and production reasons. In the proposal the need for personnel reduction was estimated at maximum 25 persons. In the negotiations, the number of personnel reduction was determined at 12. In addition to the lay-offs, there will be temporary lay-offs at Juankoski plant in case the production load weakens from the present situation. Possible temporary lay-offs will be executed by the end of 2011. The amount of personnel at the Juankoski plant is about 260.

With the above measures the operations at Juankoski plant will be adjusted to the present production and financial situation. In addition to personnel reductions and possible temporary lay-offs, operations will be made more efficient and cost efficiency will be improved also through other measures in order to secure competitiveness and operations also in the future. These measures include among others increasing personnel’s versatile skills and job rotation, changing shift work systems and possible outsourcing of some operations during 2011.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

For more information:

Reima Kerttula, President, Fabrics business line, tel.+358 400 648 458

Jari Stålhammar, Senior Vice President, Production, Fabrics business line, tel. +358 40 501 4239

Howe Sound picks Metso for boiler conversion

Metso and Howe Sound Pulp & Paper have announced an agreement to retrofit the existing Babcock and Wilcox biomass power boiler at Howe Sound's integrated pulp and paper mill in Port Mellon, B.C. Metso will convert the existing hydrograte stoker boiler to a Metso HYBEXTM Bubbling Fluidized Bed (BFB) boiler. This retrofit, scheduled for installation in June 2011, will increase the boiler's steaming rate on biomass, improve the overall reliability and operability of the boiler, reduce maintenance costs, and increase the mill's ability to produce power for the BC Hydro grid.

Funding for this project is part of the Green Transformation Program provided by the Canadian government.

As well, the conversion of the boiler is enabling Howe Sound to supply green power to the provincial electric grid.

"As a result of this investment in our boiler, we will become one of the largest independent producers of wood-fuelled renewable electricity in British Columbia," said Mac Palmiere, president and CEO of Howe Sound Pulp & Paper.

The order emphasizes Metso's strong capability as a full-scope supplier of bio-energy solutions.

Modification of the current boiler includes pressure parts, fuel and ash handling and installation. Complete automation of the boiler island includes the process automation system, emission monitoring and reporting, instrumentation and electrification retrofit.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and pulp and paper industries.

More than 200 Metso Power biomass-fired boilers, based on various firing techniques, have been supplied worldwide. The fluidized bed boiler was introduced in the late 1970s and since then over 120 Metso power boilers of this design have been supplied. This technology offers an economical, flexible, cost-effective and environmentally compliant solution for burning low heat value, high moisture bio-fuels, according to Metso.

Appointments in Metso Executive Team

Metso’s Board of Directors has decided on changes to Metso Executive Team. The appointments will become effective on March 1, 2011 when Matti Kähkönen starts as Metso’s President and CEO.

Andrew Benko (b. 1949) has been appointed President, Mining and Construction Technology. He is currently President, Equipment and Systems business line, Mining and Construction Technology.

Perttu Louhiluoto (b. 1964) has been appointed President, Energy and Environmental Technology. Louhiluoto is currently Senior Vice President, EMEA market area, Mining and Construction Technology.

Pasi Laine (b. 1963) has been appointed President, Paper and Fiber Technology, and Metso’s Executive Vice President and Deputy to the CEO. Laine is currently President, Energy and Environmental Technology.

Harri Nikunen (b. 1955) has been appointed Metso Group’s Chief Financial Officer. Nikunen is currently Senior Vice President, Finance, Paper and Fiber Technology.

Merja Kamppari (b. 1958), Senior Vice President, Human Resources, Metso Group, has been appointed as a member of Metso Executive Team.

Kalle Reponen (b. 1965), Senior Vice President, Strategy and M&A, will continue as a member of the Metso Executive Team.

As of March 1, 2011, all of the above mentioned individuals will report to Matti Kähkönen, who will be Chairman of the new Metso Executive Team.

Matti Kähkönen is currently Executive Vice President of Metso Corporation, Deputy to the CEO and President of Mining and Construction Technology. Earlier this year he was appointed to succeed Metso’s current President and CEO Jorma Eloranta upon his retirement on March 1, 2011.

Metso’s current CFO, Olli Vaartimo, and the current President of Paper and Fiber Technology, Bertel Langenskiöld, have agreed to support the changes in Metso’s top management during the transition period. Vaartimo and Langenskiöld will step down from the Metso Executive Team as of March 1, 2011.

”Metso has now put together a new and competent Executive Team consisting of seasoned experts from different sectors who have a solid track record of success. It is a pleasure and an honor to work with them to achieve Metso’s goals. Our strategy is on a strong foundation and the prerequisites for leading the company in a successful manner are excellent,” says Metso’s incoming President and CEO Matti Kähkönen.

CVs and photos of the individuals appointed to Metso’s Executive Team are on our website at www.metso.com.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

Further information for the press:

Matti Kähkönen, Executive Vice President of Metso Corporation, and President of Mining and Construction Technology, tel. +358 20 484 2190, from 4:00-5:00 p.m.

Jorma Eloranta, President and CEO, Metso Corporation, tel. +358 20 484 3001, from 2:00-3:00 p.m.

Further information for investors:

Johanna Henttonen, Vice President, Investor Relations, Metso Corporation, tel. +358 20 484 3253

Metso to rebuild Hinton Pulp’s pulp machine in Canada

Metso will supply Hinton Pulp with a rebuild of their market pulp machine in Hinton, Alberta, Canada. The project will be delivered and installed in late 2011. The value of the order exceeds EUR 10 million. The order is included in Paper and Fiber Technology’s Q4 orders received.

Metso’s delivery will include a new top wire former, press section modifications, air borne dryer rebuild, dry end pulper rebuild, and a new high-capacity cutter layboy.

The rebuild will significantly increase the pulp machine’s capacity. Brian Grantham, General manager, Hinton Pulp, states: “The upgrade to the pulp machine will allow the mill to produce more green power, reduce its natural gas consumption, and lower its carbon footprint.”

Hinton Pulp is a division of West Fraser Timber Co. Ltd. West Fraser is an integrated wood products company producing lumber, wood chips, LVL, MDF, plywood, pulp and newsprint. The Company has operations in western Canada and the southern United States.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

For further information for the press, please contact:

Peter Jones, General Sales Manager, Pulp Drying, Fiber business line, Metso, tel. +1 770 263 1597

Jukka Tiitinen, President, North America, Paper and Fiber Technology, Metso, tel. +358 40 740 6178 or +1 404 433 0937

Metso to rebuild M-real’s board machines at Simpele and Kemiart Liners mills in Finland

Metso will rebuild two board machines for M-real in Finland to increase capacity and improve quality: the cartonboard machine at the Simpele mill and the kraftliner machine at the Kemiart Liners mill in Kemi. The start-up of the rebuilt Simpele machine is scheduled for the second quarter of 2011 and that of the rebuilt Kemiart Liners machine for the third quarter of 2011. The combined value of the orders is below EUR 20 million. The order is included in Paper and Fiber Technology’s Q4 orders received.

Metso's delivery to the Simpele mill will include a rebuild of the forming section, press section including a new shoe press and the dryer section. After the rebuild, the annual capacity of the Simpele mill will be approx. 300,000 tonnes, making the Simpele machine the biggest folding boxboard machine in Europe.

Metso’s delivery to the Kemiart Liners mill will include a coating section rebuild. Additionally, a coating drying rebuild will replace old gas infrared dryers with energy efficient high-drying-capacity air dryers. The rebuild will further improve the coated white top liner quality produced.

M-real is Europe’s leading primary fibre paperboard producer and a major paper supplier. The company’s customers include brand owners, carton printers, converters, publishers, printing houses, merchants and office suppliers. In 2009, the company’s sales totalled EUR 2.4 billion, and it has approximately 4,700 employees. M-real is part of the Metsäliitto Group.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

For further information for the press, please contact:

Mikko Tani, Vice President, Sales, Paper business line, Metso, tel. +358 40 564 2007