Ian Melin-Jones

US woody biomass prices have dropped the past three years

US woody biomass prices have dropped the past three years; west coast prices are the lowest in the country, reports the North American Wood Fiber Review

Relatively low fossil fuel prices have reduced the demand and prices of woody biomass throughout the US the past three years, reports the North American Wood Fiber Review. The Pacific Northwest currently has the lowest biomass prices, slightly lower than the South, while the Northeast continues to have among the highest costs in the country.

The full article can be found in the attached PDF file.....

M-real divests the Reflex mill’s Premium Paper business to Hahnemühle FineArt GmbH

M-real Corporation, part of Metsäliitto Group, has agreed to divest the Reflex mill’s Premium Paper business to Walzmühle AG that is owned by Hahnemühle FineArt GmbH, the Hahnemühle management and private shareholders of Hahnemühle. The divestment includes the complete Premium Paper business and related assets as well as approximately 100 of M-real’s employees.

Premium Paper products are used in high-quality graphical end-uses, such as letterhead, brochures, books, calendars and envelopes.

The divestment is expected to be closed during 1Q 2012. The divestment would decrease M-real’s annual sales by approximately EUR 20 million and it would not have a material impact on M-real’s operative result. The divestment is not expected to have a material non-recurring result or cash flow impact taking into account the bookings made in 4Q 2011.

“We are very satisfied that the well-recognised speciality paper producer Hahnemühle takes over the Reflex Premium Paper business. Our actions to build a Business Park at Reflex by finding other producers to the site have been very successful. Thanks to our Business Park concept, more than half of the originally over 400 jobs can be saved at the mill. Key issues in the success have been excellent cooperation with the union, works council, local authorities and Metsä Tissue Corporation who is already our partner at the site. Based on this experience we have a good opportunity to implement the Business Park concept successfully also at Gohrsmühle mill,” says M-real’s CEO Mikko Helander.

After the divestment of the Premium Paper business, M-real has no operations left at the Reflex mill. The discontinuation of the carbonless paper converting was agreed in late 2011. In October 2010, M-real sold the paper machine 5 and some related assets at the Reflex site to Metsä Tissue.

Hahnemühle FineArt GmbH is a German based speciality paper producer and one of the market leaders in its field in Germany (www.hahnemuehle.com).

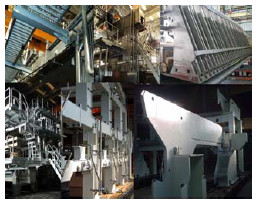

Metso-supplied fine paper production line at Zhanjiang Chenming Pulp & Paper

The Metso-supplied fine paper production line, PM 1, of Zhanjiang Chenming Pulp & Paper Co., Ltd. came successfully on stream on September 1, 2011 at the company’s greenfield pulp and paper mill in Zhanjiang City, Guangdong Province, China.

The 11.15-m-wide PM 1 has an annual dimensional production capacity of close to 600,000 tonnes of wood free uncoated printing paper within the basis weight range of 45 to 120 g/m2. The design speed is 2,000 m/min.

Geng GuangLin, Director and Deputy General Manager of Zhanjiang Chenming Pulp & Paper Co., Ltd. is satisfied with Metso and the co-operation during the project.

Metso’s delivery included a complete OptiConcept paper machine from headbox to reel, a comprehensive Metso automation system package, air and chemical systems as well as two WinDrum Pro winders.

The new paper machine comprises an OptiFlo Pro headbox, an OptiFormer shoe and blade gap former and an OptiPress two-shoe nip press. The paper machine includes a SymRun drying section with OptiDry Twin and OptiDry Horizontal impingement drying units for improved runnability and increased drying capacity. The new PM 1 also comprises an OptiSizer film sizer, an OptiSoft SlimLine double-soft nip calender, an OptiReel Plus reel and an OptiCart parent reel cart.

“The new PM 1 features a lot of new technology. Right from the start-up, the operation of the line has met the targets. In particular, the paper quality has been good,” says Mark Singler, Metso’s Paper Technology Manager.

Zhanjiang Chenming is part of Shandong Chenming Paper Holdings Limited, one of the biggest paper producers in China. In 2010, the company’s paper production capacity was over 4 million tons, turnover over EUR 2 billion and the number of employees approx. 17,000.

Commercial Insulation and Protective Coating for Building Energy Efficiency

Nansulate® Energy Protect™ clear thermal insulation and mold resistance coating, insulates and reduces energy use in an easy to apply, environmentally friendly liquid coating.

Nansulate® Energy Protect™ clear thermal insulation and mold resistance coating, insulates and reduces energy use in an easy to apply, environmentally friendly liquid coating.

The product by Industrial Nanotech, Inc. is designed to increase thermal resistance of windows, walls, ceilings, and skylights of commercial buildings and facilities. It can be used over surfaces without changing their look and can also be painted over with another water-based paint. On windows, the coating allows through approximately 92% of visible light and frosts windows for security.

It is used over many types of building surfaces such as brick, drywall, finished walls, wood, stucco, concrete and more. This nanotechnology-based coating is non-toxic, low odor, and low voc, and is easily applied with standard paint sprayers, roller, or brush. Insulates surfaces while also protecting them from mold growth, moisture, and UV light. Indoor or outdoor use.

Perfect retrofit insulation for older buildings and solid wall construction. Short return on investment, with average reported energy savings of 15-30 percent.

ANDRITZ steel yankee: world records, major orders, and a new market segment.

International technology Group ANDRITZ has received important orders to supply steel yankee cylinders used in drying processes for tissue, board, and paper. The steel yankee delivers high drying rates with energy efficiency. The customers ordering steel yankees for tissue production include Doh-Ei (Japan) and LLC Pulp Invest (Russia).

Entering a new market segment

For Anhui Tobacco in China, ANDRITZ will supply a steel yankee with a diameter of 5.5 m for a new application in tobacco production. Start-up is scheduled for mid-2013. With this order and the supply of another steel yankee for Golden Leaf,China, ANDRITZ has successfully entered this new and promising market segment.

Other steel Yankees from ANDRITZ set world records:

- §With a diameter of 4.9 m and shell length exceeding 6 m, record size for the steel yankee for PM15 and PM16 atHengan Jinjiang,China.

- §With a shell length of 7.4 m, record length for a pulp and paper group in Indonesia.

The steel yankee developed by ANDRITZ is a key component in drying. It is subjected to numerous quality checks in order to meet the stringent safety requirements specific to each country (e.g. pressure vessel directives).

Buckeye Announces Closure of Americana Cotton Linter Pulp Production Line

Uncompetitive cost position necessitates closure

Potential generation of a $20 million cash benefit

Redeploy resources to higher return business opportunities

Expect $2.4 million restructuring costs and non-cash impairment charge of $49 million

Buckeye Technologies Inc. has announced the closure of its Americana, Brazil cotton linter pulp production line. The company will work closely with its customers to continue to meet their needs from its Memphis, Tennesseefacility.

Buckeye's Chairman and Chief Executive Officer John Crowe said, “This closure has become necessary due to the facility’s uncompetitive cost position for the products it makes. This is primarily driven by the high cost of its cotton linter raw material supply. It is unfortunate that this closure will result in the termination of employment for approximately 60 dedicated employees. We have owned and operated the facility since 2000, and we value and appreciate the many contributions of the organization over the past 12 years. Buckeye will continue to operate the waste water treatment facility for the shared industrial site while we continue discussions with interested parties for the sale of the facility.

We expect to incur about $2.4 million in restructuring expenses in calendar 2012 and a non-cash asset impairment charge of about $49 million in the October-December 2011 quarter. The closure is expected to generate an approximate $20 million cash benefit, primarily due to tax benefits related to the investment loss, assuming we are able to utilize all of our potential cellulosic biofuel credits by June 2016. Any additional cash benefit will be dependent on the final outcome of the facility sale process.”

Buckeye, a leading manufacturer and marketer of specialty fibers and nonwoven materials, is headquartered in Memphis, Tennessee, USA. The Company currently operates facilities in the United States, Germany, Canada, and Brazil. Its products are sold worldwide to makers of consumer and industrial goods.

Certain matters discussed in this press release may constitute forward-looking statements within the meaning of the federal securities laws that involve risks and uncertainties, including but not limited to economic, competitive, governmental, and technological factors affecting the Company’s operations, financing, markets, products, services and prices, and other factors. For further information on factors which could impact the Company and the statements contained herein, please refer to public filings with the Securities and Exchange Commission.

Source: Buckeye Technologies Inc.

PMT Pre-erection of Copy Paper Machine

PMT workshops have successfully concluded the entire pre-erection of a completely new Copy Paper Machine for the Company Advance Paper Mill 3 (doubleA) in Thailand.

PMT workshops have successfully concluded the entire pre-erection of a completely new Copy Paper Machine for the Company Advance Paper Mill 3 (doubleA) in Thailand.

The new machine sections are now being shipped to the mill site for erection.

The start-up of the new plant is scheduled for the second half of 2012.

Pöyry joins the World Business Council for Sustainable Development

Global consulting and engineering company Pöyry has become a member of the World Business Council for Sustainable Development (WBCSD). Together with other WBCSD members Pöyry contributes to solving some of our planet's biggest challenges that require high-quality consulting and design capabilities.

The WBCSD is a global association dealing exclusively with business and sustainable development. The council plays the leading advocacy role for business and provides a forum for its members to share best practices and develop innovative tools.

"I am pleased to be able to welcome this internationally respected company, with its profound consulting and engineering knowledge, to our membership. Pöyry's experts will make a valuable contribution to our comprehensive work programme not least since the areas in which they operate so closely match it," says Bjorn Stigson, President, WBCSD.

"We are honoured to have been invited to join a group of companies and individuals that are passionate about sustainable business. As stated in our vision, we aim to be recognised for our capabilities in engineering balanced sustainability. The WBCSD provides us with a valuable platform from which to collaborate and accelerate development of sustainable business," says Heikki Malinen, President and CEO of Pöyry.

PÖYRY PLC

Related info:

WBCSD is a CEO-led organisation of forward-thinking companies that galvanises the global business community to create a sustainable future for business, society and the environment. Together with its members, the council applies its respected thought leadership and effective advocacy to generate constructive solutions and take shared action. The Council plays the leading advocacy role for business. Leveraging strong relationships with stakeholders, it helps drive debate and policy change in favour of sustainable development solutions. The WBCSD provides a forum for its 200 member companies - who represent all business sectors, all continents and combined revenue of over $7 trillion - to share best practices on sustainable development issues and to develop innovative tools that change the status quo. The Council also benefits from a network of 60 national and regional business councils and partner organisations, a majority of which are based in developing countries. www.wbcsd.org

White Birch presents ultimatum to Stadacona employees

White Birch Paper Company has presented a proposal to the employees of the idled Stadacona paper mill in Quebec City, Quebec, which it calls "the final opportunity to implement the savings necessary for Stadacona to avoid permanent closure."

White Birch temporarily idled the newsprint facility on Dec. 9, 2011.

The company statement says the proposal reflects significant manufacturing cost disadvantages, as well as the ongoing deterioration of economic conditions in the newsprint industry.

Commenting on the proposal, Christopher Brant, president, White Birch Paper Company said, "While I remain acutely aware of the pain that Stadacona's idling has already imposed on our valued employees and community, I must emphasize that the situation at the mill is extremely grave. Without significant reductions in salary, pension benefits and other costs Stadacona simply cannot survive."

Brant continued, "Acceptance of this proposal is essential for the mill to resume operations and will help ensure the mill's long-term viability, while reestablishing its position as a valued employer in the Quebec community."

White Birch is a manufacturer of newsprint, directory paper and paperboard, with three mills located in Canada.

Source: pulp and paper canada

The New Burgo Polska Branch is Born

Burgo is now closer to its Polish customers: the brand newPolish branch - Burgo Polska - has just started operating in Warsaw.

The professional and experienced staff - led by Katarzyna Borowska, Managing Director - aims at providing publishers, printers and paper merchants of the Polish graphic market all the sales support needed in their daily business.

Particularly, the branch will promote the wide range of Burgo's quality graphic papers, as well as granting high levels of service.

Burgo Polska sales offices are located in ul. Pańska 98 lokal 107, Warsaw - tel. + 48 22 254 79 81