Ianadmin

PMP Group to supply an Intelli-Jet V® hydraulic headbox and an Intelli-Nip® Shoe Press for a brand-new PM#6 to Dongguan Shunyu Paper, China

In January 2015, PMP Group – a global provider of tissue, paper and board technology, signed a contract with Dongguan Shunyu Paper, China, for the delivery of an Intelli-Jet V® hydraulic headbox and an Intelli-Nip® Shoe Press to be incorporated in a new PM#6 . PMP’s key technological units will be delivered to Dongguan mill in Guangdong Province.

In January 2015, PMP Group – a global provider of tissue, paper and board technology, signed a contract with Dongguan Shunyu Paper, China, for the delivery of an Intelli-Jet V® hydraulic headbox and an Intelli-Nip® Shoe Press to be incorporated in a new PM#6 . PMP’s key technological units will be delivered to Dongguan mill in Guangdong Province.

Dongguan Shunyu Paper Co. Ltd - high-strength corrugating medium paper producer - was founded in 2002 and at present owns 4 pulp and 6 paper-making lines (total annual capacity: 550,000 tons) in China.

A new investment based on PM#6, is focused on bringing an addition capacity of 150,000 tonnes/y of high-strength corrugating medium paper that is going to be converted in packaging boxes for various industrial use and, at the same time, widening product portfolio (through reaching excellent quality parameters of paper). PM#6 (design speed 1000 m/min, reel trim 3960 mm) is going to be built based on Optimum Cost Solutions philosophy: core technological items designed and made in Europe (by PMP Group) and the rest of PM - designed and made in China (by other suppliers). The project driving force will be based on modern technology through application of energy savings solutions following global trends and gaining excellent paper quality.

PMP Group will deliver a state-of the-art 5-channel hydraulic headbox Intelli-Jet V® (pondside:4150 mm). The new headbox will include sophisticated Consistency Profiling System as well that ensures excellent basis weight control, resulting in uniform paper web structure and better CD basis weight profile as well as machine controls. In addition Intelli-Jet V® headbox will bring excellent formation and also production flexibility (basis weight range of 90-120 g/m²). A new PM#6 press section will be equipped with a modern and compact Intelli-Nip® Shoe Press – in the second press position (design nip load 1100 kN/m, shoe press module type 1300) and will be designed to work in inverted position. Intelli- Nip® Shoe Press technology ensures reliable performance confirmed by patented solutions, top sheet dryness level resulting in significant steam consumption savings and user-friendliness of equipment. The project is another example where core technological items provided by PMP are becoming a key for success. In addition PMP will provide assembly and start-up supervision as well as optimization services. The delivery is scheduled for autumn this year, followed by erection at site and start-up at the end of 2015.

For more Info:

Wioleta Piątkowska

Marketing Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Lenord & Bauer Extreme Environment Encoders & Speed Sensors Now Widely Available in the U.S.

Sensor Products Inc., a developer and distributor of cutting edge pressure and force sensors announces a key enhancement of their product line with the addition of Lenord & Bauer industrial encoders and speed sensors. Lenord & Bauer (L&B), based in Germany, specializes in industrial automation systems that include intelligent control and drive systems, magnetic rotary and linear sensors and customized software. L&B has earned it’s quality reputation in thousands of applications worldwide that require consistent performance in ruggedconditions and harsh environments. With a strong corporate philsophy of providing tailored design. L&B focuses on highly customized solutions borne from their patented device modularity and integration with controllers. The major markets for Lenord & Bauer products include renewable energy, off road heavy vehicles, maritime, oil & gas, offshore, pulp & paper, converting, precision metalworking and woodworking industries.

Commenting on becoming a North American representative for L&B products, Sensor Products president Jeffrey Stark said, ““Lenord & Bauer is a highly respected name in the rotary encoder market with acceptance in over 20,000 installations worldwide. They exemplify the quality, reliability and commitment to customization that we seek in all our manufacturing partners.”

Complete information on all L&B products can be found at the company website www.sensorprod.com/LB.

About Sensor Products Inc.

For nearly 25 years, New Jersey based Sensor Products Inc. has been a global leader in the field of sensors. Sensor Products’ customized and off-the-shelf measurement solutions are installed within all of the Fortune 500 industrial companies as well as thousands of smaller manufacturing firms. Their technologies are used in applications as diverse as tire testing to semiconductor manufacturing and in R&D labs to space missions. Sensor Products also provides in-house and on-site stress and pressure mapping analysis. To request more information, contact Sensor Products Inc. at 1.973.884.1755, This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.sensorprod.com. emtec at the KRONA Institute in Russia

Optimization of the Production Process of Paper and Board

emtec Electronic GmbH will participate at the IV Annual International State-of-the-Art Conference 2015 at the KRONA Institute in St. Petersburg in Russia with the topic “Modern Systems for Paper and Board Quality Control”. On 18th February, Ms. Elena Beznosova will speak about “Predicting the surface behavior of paper and board during glueing and printing processes” and present some different Paper Testing Technology to optimize the production process of paper and board from the pulp to the finished product with the goal getting an efficient process and the best possible quality with the lowest possible costs.

For efficient process optimization, it is essential to look at both, the wet and dry end of paper and board production. In the wet end, it is extremely important to have detailed information about the charges of particles in the pulp suspension, which can be determined by the CAS – Charge Analyzing System. Also important is the knowledge about the surface charge of the pulp fibers, which can be measured with the FPA – Fiber Potential Analyzer. Furthermore, emtec Electronic developed a new Online measuring device FPO – Fiber Zeta Potential Analyzer Online, which measures the Zeta Potential of fibers directly during the production process and delivers immediately reliable and necessary information concerning the dosing of chemicals to the pulp.

In addition to the wet-end, it is necessary to get an idea of the quality of the base paper after the production for further steps within the conversion. This can be realized by the EST12 – Surface & Sizing Tester, which gives reliable and objective information about the surface sizing respectively hydrophoby and the surface pore structure to predict the behavior of paper and board during glueing, printing and coating processes. How this functions will be explained in detail by Ms. Elena Beznosova during her presentation on site.

Contact:

Sandra Vogt

emtec Electronic GmbH

Gorkistr. 31

04347 Leipzig

Germany

Tel: +49 (0)341 245709-35

Fax: +49 (0)341 245709-39

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

WEB: http://www.emtec-papertest.com

Damage caused by Storm Egon estimated at 3 million forest cubic metres

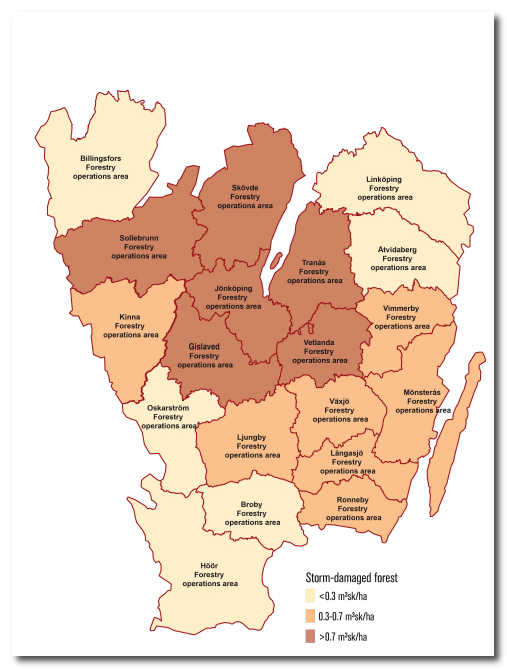

Södra estimates that damage to Södra's members' properties during Storm Egon was approximately 1.5 million forest cubic metres, corresponding to a total of about 3 million forest cubic metres in Götaland. This figure is significantly lower than anticipated given the high wind speeds registered. Södra believes that the extent of the damage may have been limited by the favourable direction of the wind, by the fact that earlier storms had already felled sensitive forest stands and that forest management practices have been better adapted to the risk of storms.

Södra has carried out an inventory on the storm damage at 267 reference properties that are well dispersed across Götaland. On the basis of this inventory, the assessment is that the storm damage corresponds to approximately 1.5 million forest cubic metres on Södra's members' properties, which corresponds to a total of about 3 million forest cubic metres in Götaland. The damage mainly comprises scattered areas of wind-felled trees and exposed areas, for example, on the edges of forests.

The map shows the extent of Storm Egon in Södra's forestry operations areas.

Storm damage has been recorded throughout Götaland with the extent varying widely among the properties, although the worst damage was caused in the Västra Götaland and Jönköping counties around the Vänern and Vättern lakes.

The extent of the damage was considerably less than that caused by Cyclone Per (2007), which felled 16 million forest cubic metres in Götaland, despite the fact that the wind speeds recorded for both storms were roughly the same. Cyclone Gudrun (2005) felled some 75 million forest cubic metres.

In the aftermath of Cyclone Gudrun, forestry began to adapt its forest management practices to reduce the risk of future storm damage.

"At Södra, we have amended our forest management instructions. Now, trees are thinned when they are at a lower height and final harvesting takes place earlier in spruce-dominated stands," says Göran Örlander, Head of Forest Management at Södra.

"In recent years, we have also had an increase in the number of storms that have felled storm-sensitive forest stands and that have made the remaining forests more resilient to storms," says Örlander.

Inventory and safety

Södra urges its members to take an inventory of the damage to their properties as soon as possible and to contact their forestry inspector.

There is a significant risk that there will be a spruce bark beetle infestation in the summer throughout the area hit by the storm. To ensure the protection of the forest and safeguard the value of the wood, it is therefore important to process the storm-felled wood as soon as possible.

Södra, which has just over 50,000 owners and members who jointly own about half of the forest land in Southern Sweden, is appealing to all forest owners to take the utmost care when processing the wood felled in the storm.

"Always put safety first! Start by taking an inventory and planning. Use mainly professional assistance and machinery when undertaking major work. Refrain from doing the work yourself if you don't have the experience or know-how, and never work alone," says Örlander.

For further information, please Contact:

Göran Örlander, Head of Forest Management

tel: +46 470 893 62

Håkan Larsson, President of the Södra Skog business area

tel: +46 470 159 81

Annica Gerentz, Director of Communications,

tel: +46 470 894 81

IBC Paper Training announces 2 trainings in water management & basics of paper

IBC Paper Training will be present again in the papermaking training spotlight with 2 workshops. While “Water Management & Effluent Treatment in Papermaking” focuses on practical solutions to improve water closure and reduce the load at the WWTP, “Basic Paper Process & Properties” wants to clarify for everyone the global overview of the papermaking process and help you acquire the right vocabulary.

1. Water Management & Effluent Treatment in Papermaking

31 March – 2nd of April, in Paris

The main guidelines and final goal of the training is to enable its participants to:

► Know the right approach to reduce the load (rejects and effluents) to the WWTP with technologies and strategy

► Know the types of crucial measurements for sustainable water closure

► Be able to manage the efficiency of additives

► Know the key for water reduction consumption – bacteria/slimes/stickies

► Be familiar with the measurement and control of aerobic water treatment installations

► Know the strategy to obtain the best WWTP performance: aerobic and anaerobic part

Follow this link to see all the details about this event!

2. Basic Paper Process & Properties

13-16 April, online, via LIVE e-Learning

There are several learning outcomes for the participants. At the successful completion of this course the participants should be able to:

► Know and be a part of a conversation about the different types of paper and their properties

► Describe chemical and mechanical pulping processes

► Describe pulp processing operations

► Identify the major grades and properties of paper

► Discuss stock preparation and the approach system

► Explain the operation of the wet end and dry end of the paper machine

► Discuss about paper sizing & coating and calendering & reeling

Concept of LIVE e-Learning

The Internet LIVE Training course is web-based. Connected to the IBC platform, the participants follow the slides of the presentation and listen to the lecturers live. They are able via the VOP audio system to interact at any time during the training. The Web program allows written interactions on a board or on the slide, chat if necessary. For a better interaction the participants can be seen via webcam if desired.

*** Pay just 1 fee and you can be several persons behind the connection, following the training. ***

Access this link to see all the details about this event!

Click here to ask for the detailed brochures

You can register starting with today to reserve your seat to the trainings.

Iggesund’s challenge to designers: Improve the packaging in your local shops!

Iggesund Paperboard is working via the American crowdsourcing company Crowdspring to challenge the world’s designers to improve existing consumer packaging.

“Every day we all see examples of packaging that could be improved by a better choice of materials or a better design,” explains Staffan Sjöberg, who is in charge of the project at Iggesund Paperboard. “Now we’re giving designers all over the world the chance to contribute their ideas on how to replace packaging made of glass, plastic or metal with solutions that use paperboard.”

Iggesund is challenging designers to make everyday consumer packaging more sustainable by replacing plastic, glass and metal with paperboard. As one example, a decade ago almost all sandwich packaging was made of plastic – now paperboard packaging is increasingly common for sustainability reasons.

He stresses that Iggesund is not looking for inexpensive ideas which can be put into commercial use. Instead, the aim is to get a picture of how global designers as a collective group believe they can steer packaging development in a more sustainable direction.

“We will not claim any commercial rights to the ideas that come in,” Sjöberg says. “We’re just interested in getting a snapshot of how designers believe they can improve the packaging they see in the shops they visit on a daily basis. We want to publish the ideas and maybe reproduce some of them in physical form but we are not interested in exploiting them commercially.”

For Crowdspring the collaboration with Iggesund Paperboard is an unusual project. Normally the online marketplace’s services are used when someone wants either a number of inexpensive design proposals or a wide range of ideas.

“This is an unusual reason for initiating a project with us,” comments Mike Samson, who is coordinating the project with Iggesund. “But we believe its combination of sustainability and innovative thinking will attract many of the thousands of designers listed in our database.”

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable industrial companies according to the UN Global Compact Index. Iggesund’s annual turnover is close to SEK 5bn (EUR 525m) and its flagship product Invercote is sold in over 100 countries.

The company has two product families, Invercote and Incada, which are both among the quality leaders in their segment. Since 2010 Iggesund has invested SEK 3.3bn (EUR 346m) to increase the energy efficiency and reduce the fossil carbon emissions from its paperboard mills. The investments have made both mills almost self-sufficient in electricity.

Iggesund and the Holmen Group report their fossil carbon emissions to the international Carbon Disclosure Project and are on the project’s A List, which singles out almost 200 companies world wide for their work against climate change. The two companies’ environmental data are integrated into their annual reports, which are produced in accordance with the Global Reporting Initiative’s highest level of sustainability accounting.

International Paper APPM Receives Prestigious IPMA Environment Award 2013-2014

![]() International Paper APPM Limited (IP-APPM), a group company of International Paper in India,announced that it received coveted IPMA Environment Award for the year 2013-2014. This award is constituted by Indian Paper Manufacturers Association (IPMA) – an industry body representing the resurgent and organized face of pulp and paper sector in India.

International Paper APPM Limited (IP-APPM), a group company of International Paper in India,announced that it received coveted IPMA Environment Award for the year 2013-2014. This award is constituted by Indian Paper Manufacturers Association (IPMA) – an industry body representing the resurgent and organized face of pulp and paper sector in India.

This award which is presented once in 2 years have evoked considerable interest and encouraged healthy competition within the industry. This has helped IPMA take forward its cause of enhancing competitiveness through environment conservation. This year the award is presented to IP-APPM’S Rajahmundry mill for maintaining high standard of environment management. The eminent jury which found IP –APPM stand out amongst other nominations included Dr. R M Mathur, Former Director - CPPRI, Mr. V Raghuraman, Former Adviser – Energy, CII and Mr. Arun G Bijur, Managing Director, SPB Projects & Consultancy Ltd.

Upon receiving the award Mr. Rampraveen Swaminathan, President, International Paper - India and Chairman and Managing Director – IP-APPM said, “It an honor for us to receive the environment award for our efforts to sustain the environment. It endorses the strong environmental and ethical practices that International Paper follows across its global operations. The testimony to this is the fact that out of the 6 times, this is the 3rd time that IP-APPM has received this award from IPMA.”

About International Paper APPM Limited

International Paper APPM Limited (IPAPPM), a group company of International Paper in India, is a leading manufacturer of pulp and paper products and caters to both domestic and foreign markets. IPAPPM produces writing, printing and copier papers at its two manufacturing units in Andhra Pradesh, which have a total paper production capacity of 240,000 metric tons per year. The company is becoming a driving force in sustainability in the paper manufacturing arena in the world economy with sales of approximately US $182 million, focused social and community programs including its own pioneering work in raw material generation through social farm forestry and a very strong strategic growth focus. International Paper owns a majority shareholding interest in IPAPPM and the remaining shares are publicly traded on the Bombay Stock Exchange and National Stock Exchange in India. For more information on IPAPPM, please visit please visit ipappm.com.

About International Paper

International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging along with uncoated papers and pulp. Headquartered in Memphis, Tenn., the company employs approximately 58,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2014 were $24 billion. For more information about International Paper, its products and stewardship efforts, visit internationalpaper.com. Stable fourth quarter ends a strong 2014 for Billerudkorsnäs

CEO Per Lindberg comments on the development during Q4 2014:

“We end the year with another stable quarter. The operating profit level of SEK 460 million is good considering the short delivery month of December and some unexpected hick-ups in the production, of course helped by the weakened SEK. During 2014 we reached all time high volumes, in line with our growth plans. We are starting to see that our efforts to reduce working capital are paying off and we have a working capital level that has decreased substantially in spite of increased net sales. Our net debt/equity ratio is down to 0.67.

“We end the year with another stable quarter. The operating profit level of SEK 460 million is good considering the short delivery month of December and some unexpected hick-ups in the production, of course helped by the weakened SEK. During 2014 we reached all time high volumes, in line with our growth plans. We are starting to see that our efforts to reduce working capital are paying off and we have a working capital level that has decreased substantially in spite of increased net sales. Our net debt/equity ratio is down to 0.67.

The overall market for our business has been stable but as expected a bit slow. We did not run full capacity for Packaging Paper due to seasonally lower demand during the fourth quarter. Containerboard market remained under pressure on the liner side due to the increased capacity on the market. The Consumer Board market was stable.

During the quarter we have announced investments in the production unit in Skärblacka that support Packaging Paper in their selective growth strategy. The investment of SEK 260 million will increase quality and volume of brown sack paper where we see good growth potentials.

Finally to sum up the year, we have delivered what we have promised. We reached our synergy targets ahead of plan. We are on track to reach our growth targets. We have developed a strong and stable platform for the future and I believe we have proven the brilliance in merging the two companies.’’

The information is such that BillerudKorsnäs AB (publ) is obligated to publish under the Swedish Securities Market Act. Submitted for publication at 07.02 CET, 3 february 2015.

For further information, please contact:

Per Lindberg, President and CEO 46 (0)8 553 335 00

Susanne Lithander, CFO, 46 (0)8 553 335 00

BillerudKorsnäs – Packaging manufacturers and brand owners are offered added value in the form of brand-strengthening, productivity-boosting and environment-enhancing packaging solutions. BillerudKorsnäs has a world-leading market position within primary fibre-based packaging paper. The company has annual sales of around SEK 20 billion and is listed on NASDAQ OMX Stockholm. www.billerudkorsnas.com Voith Paper plans to bundle European activities

The significantly reduced market volume for new machines and major rebuilds has resulted in a difficult situation at Voith Paper, especially in the projects business. With this in mind, the Management Board of Voith Paper today presented a plan for a package of measures, which is intended to adapt the company's European structure to the market conditions.

The significantly reduced market volume for new machines and major rebuilds has resulted in a difficult situation at Voith Paper, especially in the projects business. With this in mind, the Management Board of Voith Paper today presented a plan for a package of measures, which is intended to adapt the company's European structure to the market conditions.

- Long-term diminished market volume for new machines and major rebuilds

- Concentration of the paper machine business in Heidenheim and stock preparation in Ravensburg planned

- Goal is a lean, customer-focused organization

- Planned reduction of approximately 1,000 jobs worldwide

“The market volume for new systems has shrunk in half. This is going to stay that way, which means that revenues from this market will not be coming back,” says Voith Paper CEO Bertram Staudenmaier. “The consequences for our new machines and rebuilds business are significant. In this much smaller market, we are faced with strong competition and price pressure. The decline in order volume in recent years has had a very strong effect on capacity utilization, sales, and profits. Therefore, we must adapt to the changed market conditions.”

Planned is a bundling of the European paper machine business in the Heidenheim location and the stock preparation activities in Ravensburg. This will be accompanied by the termination of the paper activities in St. Pölten, Austria (reduction of approximately 150 jobs) as well as the closure of the locations in Krefeld and Neuwied (with a reduction of approximately 200 jobs and a transfer of remaining activities to Heidenheim). Also planned is an adjustment of the capacities in Ravensburg (reduction of approximately 150 jobs) with a closure of the manufacturing currently located there. In the future, the Ravensburg location will be operated exclusively as a competence center for stock preparation and roll services. Also planned is a reduction of approximately 300 jobs at the Heidenheim location, which will also affect employees in manufacturing. Overall, the package of measures plans a global reduction of around 1,000 jobs at Voith Paper.

“This step is painful for everyone involved, but necessary in order for us to become a lean organization, especially in our projects business in Europe. We must be appropriate to the market volume and oriented towards the needs of our customers,” explains Bertram Staudenmaier.

The Management Board today informed the boards and employees of the affected locations about the plans. In the next step, Voith will hold discussions with the workers' representatives about the implementation of the reduction. The current plan expects the measures to be largely implemented by December 31, 2015.

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 39,000 employees and earns 5.3 billion euros in sales. It has locations in over 50 countries in all regions of the world and is one of the large family-owned companies in Europe.

New forest terminal at the Port of Gothenburg

More sawmills throughout the Nordic region can now ship their timber via the Port of Gothenburg. A new transloading terminal for timber products has opened at the port. The terminal will be run by the family-owned company Sören Thyr AB.

Paper, pulp and timber products account for a large proportion of exports that pass through the Port of Gothenburg. Up to now, the port has lacked a dedicated terminal for transloading sawn timber products. The Port of Gothenburg has therefore invested in a completely new forest terminal that will be operated by the Gävle-based company Sören Thyr AB.

"We welcome Sören Thyr AB to Gothenburg. The company is well known in the industry. Thanks to this investment, more sawmills and paper mills throughout the world can make use of the port's worldwide service network," said Magnus Kårestedt, Port of Gothenburg Chief Executive.

"We welcome Sören Thyr AB to Gothenburg. The company is well known in the industry. Thanks to this investment, more sawmills and paper mills throughout the world can make use of the port's worldwide service network," said Magnus Kårestedt, Port of Gothenburg Chief Executive.

Linked to the rail system

The new forest terminal is proximate to the port's ro-ro and container terminals. Linked to the rail system, it can handle more than one million cubic metres of timber each year.

The terminal makes it possible for sawmills to send their timber by rail or road. On arrival in Gothenburg, the timber is loaded into the correct unit – a container or trailer for example – for onward shipment worldwide.

"We are extremely pleased that we have managed to establish operations at the largest port in the Nordic region. We know that many sawmills are interested in exporting via Gothenburg and thanks to the new terminal more mills now have the opportunity to do so," said Jörgen Thyr, CEO and son of the founder Sören Thyr.

Investment in the forest industry

The forest terminal is part of an ongoing investment to increase forest product volumes in Gothenburg. Other aspects include new rail solutions, plans for more weather-protected transloading terminals and a new collaborative venture between the Port of Gothenburg and a number of shipping companies* to market the range of shipping and peripheral services to the forest industry.

* Stena Line, DFDS Seaways, CLdN, MSC, SCI Freightman, ACL, Unifeeder and "K" Line.