Ianadmin

UPM and the Technical University of Uruguay sign agreement on new regional university in Fray Bentos

UPM and the Technological University of Uruguay (UTEC) have signed an agreement to build a new Regional Technological University (ITR) in Fray Bentos to advance technical skills and engineering expertise in rural Uruguay. The regional university will specialize in mechatronics, renewable energy, transport and logistics.

UPM and the Technological University of Uruguay (UTEC) have signed an agreement to build a new Regional Technological University (ITR) in Fray Bentos to advance technical skills and engineering expertise in rural Uruguay. The regional university will specialize in mechatronics, renewable energy, transport and logistics.

The region is home to a community of over 4,000 students who will now be able to complete university studies without having to leave their hometowns. The construction of the Fray Bentos ITR is estimated to take 14 months.

“This investment is a token of UPM’s commitment to Uruguay. It shows how our company strengthens the communities in which it operates by supporting education and the development of the local forestry sector. We are happy to announce this cooperation now that UPM is celebrating its 25th anniversary in Uruguay,” says Juha Kääriäinen , Vice President of UPM’s Uruguay Operations.

“Being able to hire highly qualified local talent is very important to us. This investment in education will create further development opportunities for generations to come, enhancing the overall competitiveness of the forest industry in Uruguay in the future,” adds Kääriäinen.

Under the agreement, UPM will fund the university, which will be based on a cooperative model between industry and the academia, maximizing mutual benefit from each other’s capabilities. Students will be able to participate in internships and hands-on training in the Uruguayan agro-industrial sector. Both parties will encourage UPM technicians and professionals to participate in Fray Bentos ITR courses. UPM and UTEC will also work on joint R&D projects.

For more information, please contact:

Juha Kääriäinen, Vice President, UPM Uruguay Operations, tel. +598 99 802 888

Matías Martinez, Communications Manager, UPM Uruguay, tel.+ 598 456 20100 int. 265

UPM in Uruguay

UPM’s operations in Uruguay include the Fray Bentos pulp mill, the forestry and wood sourcing company UPM Forestal Oriental which has two nurseries, as well as the UPM Foundation, which in cooperation with local organisations contributes to education, entrepreneurship and improving the quality of life through projects focusing on the rural areas where the company operates.

The Fray Bentos pulp mill started operations in 2007 and it is still one of the world’s most modern and efficient pulp mills. Its annual production capacity is 1.3 million tonnes of chemical eucalyptus pulp. Besides pulp, the Fray Bentos mill is a significant biomass based energy producer - its electricity production accounting for 10% of Uruguay’s total energy production. The mill’s wood raw material comes from sustainably managed local plantations.

UPM Forestal Oriental owns about 230,000 hectares of land, of which about 60% is planted with eucalyptus. The rest of the land is protected or is used for forestry-related infrastructure, cattle grazing and other non-plantation operations. All of UPM's forest plantations are certified to FSC® and PEFCTM standards. About 70% of the Fray Bentos mill’s fibre wood comes from the plantations managed by UPM Forestal Oriental and the rest is supplied by the company’s long term partners.

In Uruguay, UPM has 550 direct employees and employs indirectly around 3,400 people. The value chain of UPM’s Uruguay operations creates altogether 6,400 jobs and its contribution to Uruguay’s GDP is approximately 1.3%.

UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 20,000 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM – The Biofore Company – www.upm.com

Valmet to supply key technology to Metsä Fibre's Äänekoski bioproduct mill project

Valmet and Metsä Fibre have signed a letter of intent according to which Valmet will deliver key technology to Metsä Fibre's planned Äänekoski bioproduct mill in Finland. The letter of intent covers recovery boiler, pulp drying line, gasification plant, and lime kiln deliveries. The delivery also includes a mill wide Metso DNA automation system.

Valmet and Metsä Fibre have signed a letter of intent according to which Valmet will deliver key technology to Metsä Fibre's planned Äänekoski bioproduct mill in Finland. The letter of intent covers recovery boiler, pulp drying line, gasification plant, and lime kiln deliveries. The delivery also includes a mill wide Metso DNA automation system.

The contract is subject to Metsä Fibre's investment decision. Metsä Fibre has announced that if the prerequisites for the investment are met, the decision on the construction of the bioproduct mill will be made during this spring, meaning that production at the new mill would begin in 2017.

The estimated value of Valmet's anticipated delivery, which includes only the core equipment supplied by Valmet, is about EUR 125-150 million.

"This technology delivery for the Metsä Fibre Äänekoski project is a good sign of Valmet's competiveness and technological innovativeness. We are delighted to be able to continue our good and long cooperation with Metsä Group and Metsä Fibre," says Pasi Laine, President and CEO of Valmet.

Important employment impact

Valmet's anticipated delivery for Metsä Fibre's planned bioproduct mill will have an important employment impact on Valmet and its subcontractors. The employment impact of Valmet's project delivery is expected to be around 250 man years, out of which half in Finland.

"In projects like Äänekoski, we can utilize our know-how in pulp and bioproduct technology. In addition to bringing work to us our delivery also employs many other suppliers in the Nordics and Europe for engineering, manufacturing and installation. This delivery would employ Valmet employees especially in Finland, in the cities of Tampere, Ulvila, Jyväskylä and Raisio," says Bertel Karlstedt, Pulp and Energy Business Line President from Valmet.

Details about Valmet's technology delivery to Metsä Fibre Äänekoski project

If materialized, the approximately EUR 1.1 billion bioproduct mill planned by Metsä Fibre would be the largest ever investment in the forest industry in Finland. The mill would have an annual pulp production capacity of 1.3 million tonnes.

Valmet's delivery would include engineering, procurement, supply and construction management of a recovery boiler, a pulp drying line, a lime kiln and a gasification plant.

The planned recovery boiler has a capacity of 7,200 TDS/d (tonnes dry solids a day). The planned pulp drying line will have a trimmed width of 8.25 meters and a capacity of 2,700 Adt/d (air dry tonnes a day). The planned lime kiln has a capacity of 1,200 t/d and will be operated by renewable fuel provided by 87 MW product gas capacity biomass gasification plant. The gasification plant dries bark and gasifies it to product gas.

Information about Metsä Fibre

Metsä Fibre is a world-leading producer of softwood pulp, whose main brand is Botnia. The company's main products are sustainably and cost-efficiently produced bleached softwood and birch pulps. Metsä Fibre has four pulp mills in Finland. Metsä Fibre's sales in 2014 totalled approximately EUR 1.3 billion, it employs some 850 people. Metsä Fibre is part of Metsä Group.

For further information, please contact:

Bertel Karlstedt, President Pulp and Energy business line, Valmet, tel. +358 40 553 3859

Kari Remes, Vice President, Recovery, Pulp and Energy business line, Valmet, tel. +358 40 709 2015

Pasi Mäkelä, Director, Pulp Mill Sales Support, Pulp and Energy business line, Valmet, tel. +358 40 505 4199

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 10,500 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

ANDRITZ to supply key production technologies for new bio-product pulp mill in Finland

International technology Group ANDRITZ has signed a letter of intent with Metsä Fibre to deliver key production technologies for a new bio-product pulp mill with an annual capacity of 1.3 million tons of pulp in Äänekoski, Finland. The order value for ANDRITZ is over 100 million euros. Start-up of the planned mill is scheduled for August 2017.

ANDRITZ’s scope of supplies includes:

- A complete wood processing plant with three debarking and chipping lines, three stacker-reclaimer chip handling systems, and bark handling. Each debarking line can process both softwood and hardwood, is designed for world record capacities (pine/spruce/birch: 470/350/270 m3 solid-over-bark per hour), and includes a de-icing conveyor, a debarking drum (5 x 48 meter), and the world’s biggest horizontally fed HHQ chipper, ensuring high capacity without compromising the chip quality.

- A softwood and hardwood fiberline comprising a chip feeding system, a two-vessel continuous cooking plant, a new evaporation system for liquor extraction, and seven DD (Drum Displacer) washers for brownstock washing and bleaching. The softwood capacity of this line will be the highest in the world by far (3,900 tons per day).

- The world’s most energy-efficient black liquor evaporation plant with the highest capacity in Europe (1,650 tons/hour). The plant will have seven stages and concentrate black liquor to the very high dry solids content of 85% for efficient combustion in the recovery boiler. In addition, ANDRITZ will also deliver chloride removal systems to enhance the chemical recovery process and to produce liquid methanol, which will be used as a biofuel source.

- A recausticizing plant, which will be the largest in Europe (white liquor production of 16,000 m3/day), with two centrifuges for dregs, slaker-classifier, white liquor disc filter, and lime mud disc filter.

The new mill will be a next-generation bio-product pulp mill which can convert wood raw material into bio-materials and bio-energy in addition to high-quality pulp. It will not use any fossil-based fuels as all of the energy required will be generated from wood. The erection of the new mill is the largest investment in the Finnish forest industry ever.

For further information, please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

The ANDRITZ GROUP

The ANDRITZ GROUP is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors. The publicly listed, international technology Group is headquartered in Graz, Austria, and has a staff of around 24,500 employees. ANDRITZ operates over 250 production sites as well as service and sales companies all around the world. The ANDRITZ GROUP ranks among the global market leaders in all four of its business areas. One of the Group’s overall strategic goals is to strengthen and extend this position. At the same time, the company aims to secure the continuation of profitable growth in the long term.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, gasification plants for energy production, flue gas cleaning plants, production equipment for biofuel (second generation) and biomass pelleting, biomass torrefaction, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

Keeping the press rolling

The PM7 is one of the world’s most modern machines for the production of newsprint. It is rated to convert recycled paper and primary fibres into 360,000 tonnes of newsprint per year at an outstanding speed of 1,900 m/min.

The PM7 is one of the world’s most modern machines for the production of newsprint. It is rated to convert recycled paper and primary fibres into 360,000 tonnes of newsprint per year at an outstanding speed of 1,900 m/min.

It is a giant of a machine that operates at the Swiss firm Perlen Papier AG, around the clock, 365 days a year and a range of LOCTITE products are playing their part in ensuring its reliable service.

A short window of time, just a few hours, is allocated each month for maintenance. The inner workings of the PM7 comprise many hundreds of rollers, cylinders, pumps, drives, pipes and valves and Henkel LOCTITE is the brand on which Perlen Papier AG relies for cleaning, bonding, sealing and lubricating these vital components.

Moist cellulose is sprayed onto rollers of the PM7 as part of the paper production process and it is essential that this, as well as surplus hydraulic oil, is effectively removed so the LOCTITE anaerobic adhesives can achieve the best possible bond and seal. For this purpose the maintenance team uses LOCTITE SF 7063 to ensure there are no contaminants to impede the efficiency of the processes.

Moist cellulose is sprayed onto rollers of the PM7 as part of the paper production process and it is essential that this, as well as surplus hydraulic oil, is effectively removed so the LOCTITE anaerobic adhesives can achieve the best possible bond and seal. For this purpose the maintenance team uses LOCTITE SF 7063 to ensure there are no contaminants to impede the efficiency of the processes.

The nature of the PM7’s job means its components are subject to constant vibration. It is therefore important to ensure that threaded assemblies do not shake lose. A Henkel mainstay for this application is LOCTITE 243. This medium strength product is proven to tolerate slight contamination of industrial oil and is formulated to allow part disassembly with hand tools for servicing.

For sealing of flanges – the cover of a large vacuum blower, for example – LOCTITE SI 5980 is the product of choice as it fills all surface irregularities and gaps to achieve the best possible bond. This black, alkoxy silicone that was chosen by the maintenance team for its good oil resistance.

Given the hot and damp environment, it is also essential that assemblies are protected against corrosion and fretting and why LOCTITE LB 8150 Anti-Seize is extensively used. This product contains aluminium, graphite and extreme pressure additives to provide lubrication at high temperatures and operating speeds.

Paper is an extremely sensitive and diverse product and the work of Perlen Papier AG is more of an art than a process. It is therefore particularly important that all parts of the machine are working optimally to achieve the fine-balance between productivity and performance. The efficiency of the LOCTITE maintenance products are essential to the mix and also to ensuring PM7 remains reliable over its anticipated 40 year life span.

Making Hearts Melt: Chinese Chocolate Printing Craze Wrapped-Up in ‘Cocoa’

3D printing has delivered spare parts to the International Space Station, concept cars and now delicious, personalised Valentine’s Day gifts. Few things can say ‘I love you’ like an image of your loved one perfectly printed in dark, milk and white chocolate, quite literally having the ability to make each other melt.

Chinese company, Wolfson have conquered the limitations of chocolate’s liquid tendencies to create a printer capable of producing fine images using nothing but the sweet stuff. This year they will be offering beautifully boxed, personalised portraits as gifts under the brand name ‘Euler’s Rose’.

The company, founded by graduates of the University of Cambridge, returned to the UK in search of the ideal packaging for their innovative product, deciding on James Cropper’s Cocoa papers for the in-box wrapping – a paper itself produced by recycling the cocoa shells discarded during chocolate’s production.

Developed in collaboration with international cocoa trade supplier, Barry Callebaut and launched in 2013, Cocoa is part of James Cropper’s wide range of papers developed with sustainability-conscious customers front of mind. The ‘Cocoa Shell’ colour variant of the naturally pigmented stock for the chocolate photograph’s protective wrapper contrasts with the deep red tone of the outer box made of Colorplan Scarlet from G . F Smith.

The precarious science of printing with chocolate involves bringing the three shades of confectionery to temperatures between 34c and 38c, after which point they will become too runny to form an accurate image. Such devotion to honing this craft has been applauded by James Cropper.

Chris Brown, Commercial Director, said: “It took James Cropper’s development team numerous trials to master the ability to incorporate cocoa shell powder into a paper that was ready for printing, food contact and it’s numerous other uses, but the perseverance paid off. We’re delighted that similarly tenacious and innovative entrepreneurs in China have found such a good use for the papers, and hope those who give and receive these gifts find a lifetime of happiness together.”

The luxurious gift box with gold foil print says ‘Euler’s Rose’ – a name drawn from a fable concerning two lovers, re-united over such a chocolate gift – and the great physicist, Albert Einstein’s famous quote: “Gravitation cannot be held responsible for people falling in love.”

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

Julie Tomlinson

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

T: +44 1539 818413

Innovative Solutions for Testing the Paper Quality from emtec Electronic

emtec Electronic at the IMPS 2015 in Munich

This year the IMPS – International Munich Paper Symposium will take place the 24th time and emtec Electronic GmbH will attend the event with a booth in Munich, Germany. From March 11th until 13th, emtec will present different special technical equipment – interesting for all players within the paper, board and tissue industry.

This year the IMPS – International Munich Paper Symposium will take place the 24th time and emtec Electronic GmbH will attend the event with a booth in Munich, Germany. From March 11th until 13th, emtec will present different special technical equipment – interesting for all players within the paper, board and tissue industry.

With the application of the special testing equipment it is possible to control and guide the complete process of paper, board or tissue production from the pulp to the finished product into the right direction, in order to get an efficient process and the best possible quality with the lowest possible costs.

This year, the company, located in Leipzig, will present a measuring device for the wet end of production. There it is extremely important to have detailed information about the surface charge of the pulp fibers, which can be measured with the FPA – Fiber Potential Analyzer. Furthermore, emtec Electronic developed a new Online measuring device FPO – Fiber Zeta Potential Analyzer Online, which measures the Zeta Potential of fibers directly during the production process and delivers immediately reliable and necessary information concerning the dosing of chemicals to the pulp.

A further new development of the company is the innovative ACA – Ash Content Analyzer, which determines the total mineral filler content as well as the percentage content of the typical fillers in the paper industry within seconds without combustion of the samples, i.e. nondestructive.

Beside these new measurement equipment, the EST12 – Surface & Sizing Tester will be presented, which makes it possible to predict the behavior of paper surfaces during converting processes like glueing, coating and printing.

For the tissue industry emtec comes up with the TSA – Tissue Softness Analyzer, which determines the softness very fast and objectively.

Strong year for Södra

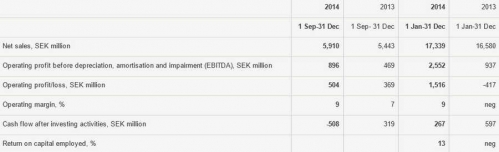

Södra reported an operating profit of SEK 1,516 million (loss: 417) for 2014. The strong results were due to positive market conditions, healthy prices for finished goods, a favourable currency situation and completed efficiency enhancements. The Board proposes to the Annual General Meeting that profits of SEK 553 million (281) be distributed to Södra’s members.

Södra reported an operating profit of SEK 1,516 million (loss: 417) for 2014. The strong results were due to positive market conditions, healthy prices for finished goods, a favourable currency situation and completed efficiency enhancements. The Board proposes to the Annual General Meeting that profits of SEK 553 million (281) be distributed to Södra’s members.

"2014 was a strong year for Södra and it feels satisfying to report operating profit that improved to SEK 1.9 billion. We are well positioned for continued investment in building an even stronger and more successful Södra," says CEO Lars Idermark.

Operating profit for the last four months of 2014 totalled SEK 504 million (369).

Operating profit for the last four months of 2014 totalled SEK 504 million (369).

Net sales for 2014 rose 5 percent to SEK 17.4 billion (16.6). Profit before tax increased to SEK 1,460 million (loss: 450). Earnings in 2013 were charged with restructuring costs of SEK 817 million for the closure of Södra Cell Tofte AS.

Return on capital employed was 13 percent (neg.) and the operating margin 9 percent. The equity ratio was 61 percent (59) at year-end, which means that Södra has achieved all of its financial objectives.

In 2014, Södra embarked on a period of heavy investment that will continue for several years to come. The decision to date is to invest approximately SEK 5 billion in the three pulp mills, including more than SEK 4 billion in the mill at Värö outside Varberg.

"Our aim is to create long-term, profitable growth for the Södra Group. We believe that the forest industry plays a key role in achieving a sustainable bioeconomy, and we have the courage to lead the way," says Lars Idermark.

The Board proposes to the Annual General Meeting that a profit of SEK 553 million (281) be distributed to members, comprising a dividend of 6 percent on contributed capital, totalling SEK 170 million, a dividend of 8 percent on wood deliveries, totalling SEK 323 million, and a bonus issue of SEK 60 million.

>> Video interview with Lars Idermark

>> Year-end report 2014

- Click Table to enlarge

For questions, please contact:

Lars Idermark, President and Chief Executive Officer

Telephone: +46 470 894 35

Carina Olson, Chief Financial Officer

Telephone: +46 470 892 62

Annica Gerentz, Senior Vice President Corporate Communications

Telephone: +46 470 894 81

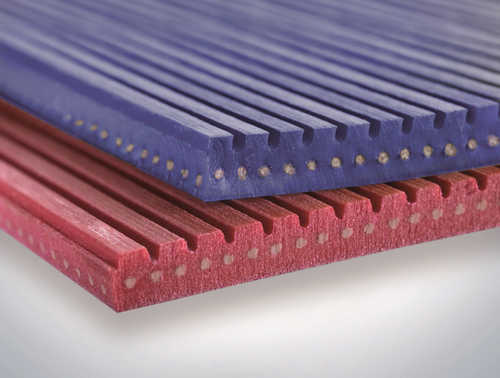

QualiFlex Crest and QualiFlex Crown press sleeves from Voith to suit all requirements

With QualiFlex Crest and QualiFlex Crown, Voith has launched a new product portfolio for press sleeve that adapts to the specific paper grades and requirements of individual paper machines. QualiFlex Crest excels with its material properties and reliable performance – with regard to service life as well as to dewatering capacity. QualiFlex Crown goes one step further and achieves maximum performance in severe conditions.

The QualiFlex product range includes press sleeves for pulp, tissue, board, packaging and graphic paper grades. For each paper grade, customers can select from both product lines according to their operating needs.

The newly developed press sleeves play an important role in optimizing the press efficiency, as the material properties of Crest and Crown have been specifically customized to suit the requirements of each application. In addition, the broad range of void volume patterns contribute to better dewatering.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Mitsubishi HiTec Paper with JETSCRIPT at the Hunkeler Innovation Days 2015

At the Hunkeler Innovationdays 2015, Mitsubishi HiTec Paper presents the extensive JETSCRIPT range of high performance coated inkjet papers for all high-speed inkjet printing applications.

Application example JETSCRIPT MH 1484 CCB: Coupon with secuity feature (coloured base paper)

In modern high-speed inkjet printing, the demands on the print quality are high, and at the same time press speed is increasing. Print quality does not only depend on the choice of the printing system, but also to a greater extent on the choice of a suitable inkjet paper, because it has to meet a variety of requirements.

Colour reproduction must be accurate, and cover a wide colour gamut. The papers must be suitable for quick drying and immediate processing. A case for a coated inkjet paper with a special ink receiving layer. A case for JETSCRIPT.

At the HID 2015 Mitsubishi is focusing on a range of new products which have been developed in recent months:

- JETSCRIPT DLS 9020 – double-sided satin coated inkjet paper with offset look and feel, suitable for pigment and dye inks

- JETSCRIPT MH 1484 CCB - a totally unique, matt coated inkjet paper which is manufactured with a coloured base paper as a security feature

- JETSCRIPT DT 8002 and DT 9002 - economy matt inkjet paper for transaction & transpromo, suitable for pigment and dye inks

Visit us at the HID 2015 (23 to 26 February 2015 Lucerne | Switzerland) at information booth 4. Learn more about the extensive JETSCRIPT range of coated inkjet papers for high-speed inkjet printing and a variety of applications including transaction & transpromo, direct mail & envelopes, publishing and security applications.

Inkjet papers for all applications from a single source - only at Mitsubishi HiTec Paper. For more information and samples contact: This email address is being protected from spambots. You need JavaScript enabled to view it.

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's most important manufacturers of speciality paper. The roughly 700 employees at Mitsubishi HiTec Paper Europe produce high-quality thermal papers (thermoscript), digital imaging papers (jetscript), carbonless papers (giroform) and label papers (supercote) at two tradition-rich locations in Bielefeld and Flensburg.

Each factory stands out for integrated paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of speciality papers featuring a modular system for every application – and is a highly capable partner whenever customised coated paper solutions are required.

Card Retailers could be contributing to forest destruction.

Two High Street retailers have recently sold greetings cards that could be contributing to forest destruction. The testing, organised by WWF-UK and carried out by a laboratory in Germany, tested 20 cards and envelopes. Three products, bought from Paperchase, the Card Factory and Clinton’s contained various amounts of Mixed Tropical Hardwood (MTH), meaning that the fibres had most likely come from natural growth tropical forests.

Of the three retailers, one, Paperchase, seems able to provide evidence that their product was from a sustainable source. This highlights the need for firms to carefully scrutinise their supply chains to reassure themselves and their customers that their products are not contributing to forest destruction.

More cards are bought per person in the UK than in any other country, with an average of 31 per person bought every year, and last year the UK market for greeting cards was valued at £1.29 billion. Due to legislative loopholes, it is possible to legally sell imported cards that have been made from illegally-logged or cleared forests. WWF wants the loopholes closed and firms to take proper responsibility for their supply chains. WWF believes consumers should be confident that the cards they buy are not contributing to the illegal logging or unsustainable harvest of forests in places like South East Asia.

Beatrix Richards, Head of Corporate Stewardship Timber and Seafood, WWF, said;

“These results suggest that the true cost of our Valentine’s card could be far greater than the price on the wrapping. They may be contributing to the further loss of some of the most valuable forests in the world. Companies that rely on forests for their raw materials should scrutinise their supply chains, and reassure consumers that they are buying cards made from recycled or sustainable materials.”

Over thirty UK businesses have already signed up to WWF’s Forest Campaign that will help enable a market in 100% sustainable timber and wood products by 2020, including Carillion Kingfisher, Tesco, Marks and Spencer and Travis Perkins.

Deforestation is an issue affecting some of our most important natural forests around the world, and with global demand for wood set to triple by 2050, businesses and countries need to get their act together in order to ensure a sustainable supply for the future.

The European Timber Regulation (EUTR), which came in to force in March 2013, was set up across Europe to remove illegally sourced timber from the EU markets.

Due to loopholes in the EUTR it is currently legal to import certain goods made from illegally sourced wood, such as greetings cards, musical instruments or books. These exemptions mean that some firms may be unwittingly or deliberately purchasing materials from dubious sources.

20 cards and envelopes from three outlets were tested by the Institution for Paper Science and Technology in Darmstadt, Germany.

The lab results found that one from each of the stores contained MTH (Mixed Tropical Hardwood):

Card Factory – 10% MTH (in the card itself)

Clintons – 8% MTH (in a paper component of the card)

Paperchase – 5% MTH (in the envelope)

The results shown here are products on the market in the UK that contain pulp from natural growth tropical forests – in this case, probably SE Asia. In addition all of the products contained acacia, which carries a risk of being grown in plantations that have been created on recently cleared tropical forest.

More information on WWF’s forest campaign can be found at www.wwf.org.uk/saveforests

FAO’s State of the World’s Forests 2014 report outlined key findings on just how critical forest resources are to billions of people worldwide for their livelihoods. Forest provide them with socio-economic benefits including employment, fuel,, water and shelter.

Global deforestation rates are currently estimated at around 13 million hectares per annum, which is equivalent to an area the size of a football pitch being cut down every two seconds.

The EU Timber Regulation (EUTR) came into force in March 2013. It covers a wide range of timber and wood products, as listed in its annex using EU customs code labelling. The EUTR also applies to timber products whether they were harvested in the EU or outside.

EU member states are responsible for overseeing and applying the law – which means that all 28 EU countries must take active steps, and designate appropriate resources, to do so.

For the EUTR to work in practice it will need the active participation of industry, government and civil society stakeholders, as well as even implementation across the EU.

Following the publication of WWF report on what is in or out of scope of the regulation, it is clear that the EUTR only covers 41% of all products by value. There are a wide range of products not covered by the regulation such as greetings cards, musical instruments and books.

WWF is one of the world’s largest independent conservation organisations, with more than five million supporters and a global network active in more than one hundred countries. Through our engagement with the public, businesses and government, we focus on safeguarding the natural world, creating solutions to the most serious environmental issues facing our planet, so that people and nature thrive. Find out more about our work, past and present at wwf.org.uk.