Ianadmin

Stora Enso appoints two new members to the Group Leadership Team

Stora Enso has appointed Gilles van Nieuwenhuyzen as Executive Vice President of the Packaging Solutions division and Markus Mannström as Chief Technology Officer (CTO) to head up the new Group Technology function. They will be members of the Group Leadership Team, with the appointments being effective as of 16 March 2015.

Gilles van Nieuwenhuyzen is a Dutch citizen with extensive global business leadership experience in several industries, including food ingredients, biotechnology, chemicals and polymers. Most recently, since 2010, he has been working as President of the Enablers division at DuPont Nutrition & Health (formerly Danisco), based in Denmark. Previously, he worked in senior management positions at among others the Dutch food ingredients group CSM (now Corbion), Rexam (in coated films and papers), and DSM (in chemicals and polymers). Earlier, he worked at McKinsey & Company. He holds an MSc degree in Applied Physics and an MBA from INSEAD. Gilles van Nieuwenhuyzen will be based in Stockholm.

Gilles van Nieuwenhuyzen is a Dutch citizen with extensive global business leadership experience in several industries, including food ingredients, biotechnology, chemicals and polymers. Most recently, since 2010, he has been working as President of the Enablers division at DuPont Nutrition & Health (formerly Danisco), based in Denmark. Previously, he worked in senior management positions at among others the Dutch food ingredients group CSM (now Corbion), Rexam (in coated films and papers), and DSM (in chemicals and polymers). Earlier, he worked at McKinsey & Company. He holds an MSc degree in Applied Physics and an MBA from INSEAD. Gilles van Nieuwenhuyzen will be based in Stockholm.

Markus Mannström is a Finnish citizen who has been at Stora Enso since 2001, working on several large investment and R&D projects, most recently as General Manager of Stora Enso’s Guangxi project in China. Prior to this, he held the position of SVP, Investments and Operations in Stora Enso’s Renewable Packaging division, where he also bore responsibility for R&D. From 2006 to 2009, he was responsible for Stora Enso’s investment processes, including fund allocation, project development and steering projects in progress. From 2001 to 2005, he was involved in two major paper machine investment projects.

Markus Mannström is a Finnish citizen who has been at Stora Enso since 2001, working on several large investment and R&D projects, most recently as General Manager of Stora Enso’s Guangxi project in China. Prior to this, he held the position of SVP, Investments and Operations in Stora Enso’s Renewable Packaging division, where he also bore responsibility for R&D. From 2006 to 2009, he was responsible for Stora Enso’s investment processes, including fund allocation, project development and steering projects in progress. From 2001 to 2005, he was involved in two major paper machine investment projects.

Markus Mannström will head up the new Group Technology function, which will be responsible for coordinating Stora Enso’s R&D and innovation agendas, managing the Group’s investment processes, and leading Energy Services. He has an MSc degree in Paper Technology and is based in Helsinki.

“It is a great pleasure to welcome Gilles van Nieuwenhuyzen and Markus Mannström to the Stora Enso team. Throughout his career, Gilles has demonstrated a strong track record of accelerating growth through business development and market-oriented innovation. This is the type of experience we need to transform Stora Enso into a renewable materials growth company. Markus’ solid background in technology, investments and R&D is a valuable addition to our team. I am also pleased that we are able to nominate a current Stora Enso leader to this new key position,” says Stora Enso’s CEO, Karl-Henrik Sundström.

“I would like to thank Hannu Alalauri, who has been leading the Packaging Solutions division, for his strong contribution in developing our innovative fibre-based packaging. Hannu has had a long career in our paper and packaging businesses holding several key leadership positions and has been a valued member of our team. He has decided to look for opportunities outside Stora Enso,” says Sundström.

For further information, please contact:

Ulrika Lilja, EVP Global Communications, tel. +46 1046 71668

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Our aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 27 000 people in more than 35 countries, and our sales in 2014 were EUR 10.2 billion. Stora Enso shares are listed on NASDAQ OMX Helsinki (STEAV, STERV) and Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market.

GE and Kemira Create Global Alliance to Bring Water Technology to the Pulp and Paper Industry

GE and Kemira today announced a formal distribution agreement, which combines GE's advanced water technology with Kemira’s on-site services to deliver a seamless offering to the global pulp and paper industry.

GE and Kemira today announced a formal distribution agreement, which combines GE's advanced water technology with Kemira’s on-site services to deliver a seamless offering to the global pulp and paper industry.

For the first time, GE’s newest and most advanced boiler and utility area cooling product technologies as well as membrane cleaning chemistry and the entire chemistry water portfolio is now available to the pulp and paper industry. Also included are the remote monitoring and diagnostics products—including the InSight* Knowledge Management Solution and TrueSense*—and Novus* polymers for wastewater treatment. Pulp and paper manufacturers also will have access to experts at GE’s Service Reliability Center for 24-hour monitoring and support, all backed by both GE and Kemira on-site expertise.

“Kemira has long been recognized as a technology leader, supplying process, functional and bleaching chemistry solutions to producers of pulp, packaging and board, tissue and towel and printing and writing grades globally. This makes Kemira an ideal partner to bring GE’s water products and services to the paper industry and now positions Kemira with the broadest technical and product portfolio in the industry,” said Billy Ford, senior vice president, paper, Kemira. “After a successful 18-month pilot program with GE in the Americas, we have increased the scope of our alliance to offer a comprehensive water treatment solution to the global pulp and paper market.”

“Pulp and paper mills use vast amounts of water to create an end product while also generating considerable wastewater. GE is eager to bring our water solutions to the pulp and paper industry, and Kemira is well-positioned to bring our advanced technologies to their customers,” said Kevin Cassidy, chemical and monitoring solutions general manager—water and process technologies for GE Power & Water.

About Kemira

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2014, Kemira had annual revenue of EUR 2.1 billion and around 4,250 employees. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

About GE

GE (NYSE: GE) imagines things others don’t, builds things others can’t and delivers outcomes that make the world work better. GE brings together the physical and digital worlds in ways no other company can. In its labs and factories and on the ground with customers, GE is inventing the next industrial era to move, power, build and cure the world. www.ge.com

About GE Power & Water

GE Power & Water provides customers with a broad array of power generation, energy delivery and water process technologies to solve their challenges locally. Power & Water works in all areas of the energy industry including renewable resources such as wind and solar; biogas and alternative fuels; and coal, oil, natural gas and nuclear energy. The business also develops advanced technologies to help solve the world’s most complex challenges related to water availability and quality. Power & Water’s six business units include Distributed Power, Nuclear Energy, Power Generation Products, Power Generation Services, Renewable Energy and Water & Process Technologies. Headquartered in Schenectady, N.Y., Power & Water is GE’s largest industrial business.

Follow GE Power & Water and GE’s water business on Twitter @GE_PowerWater and @GE_Water.

* Trademark of General Electric Company; may be registered in one or more countries.

Angie Hansen

GE Power & Water

+1 215 942 3511

This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet to deliver a biomass based boiler plant to Nokianvirran Energia

Valmet will deliver a boiler plant that utilizes biomass to Nokianvirran Energia in Finland. Valmet announced the signing of a letter of intent for the delivery on November 25, 2014. Valmet's delivery will include a HYBEX boiler with a steam power of 68 megawatts (MW) that employs the fluidized bed technology, flue gas purification equipment, and the plant's electrification and automation system.

The boiler plant will be delivered for a new steam heat station to be built in Nokia. The total value of Nokianvirran Energia's investment is approximately EUR 45 million, of which the value of Valmet's delivery is slightly more than a half. The order is included in Valmet's first quarter 2015 orders received.

The boiler plant will be constructed inside an existing boiler building, in the middle of the photo, from where an old coal-fired boiler, delivered by Tampella in 1963, will be demolished.

The new boiler plant will utilize local fuels

The new heating station will produce process steam for the SCA Hygiene Products paper mill and the Nokian Renkaat factory, as well as district heat for Leppäkosken Lämpö's district heat customers. The fossil natural gas previously used for energy production will be replaced with more affordable biofuels, such as timber chips and whole tree chips. In addition, the boiler can utilize milled peat and sludge from the paper mill.

Leppäkosken Lämpö distributes the district heat produced by the power plant to its customers through its network. "This investment will especially improve the price competitiveness of district heat compared with other heating methods," says Juha Koskinen, the managing director of Leppäkosken Lämpö.

For SCA, which manufactures tissue, the investment will decrease the company's dependence on fossil natural gas. In addition the de-inking sludge derived from the tissue mill can also be used for energy production at the new power plant.

For Nokian Renkaat, the power plant will bring cost benefits, and additionally reduces the greenhouse gas emissions of the production process.

Technical information about Valmet's delivery

Nokianvirran Energia Oy's current plant consists of two gas-fired boilers with a steam power of 57 and 110 MW. The new 68 MW plant to be constructed will be integrated with the existing power plant. As gas is replaced by biofuels, carbon dioxide emissions in the area will decrease by 60,000-80,000 tons per year.

Valmet has delivered several fluidized bed boilers of nearly the same capacity to district heating plants and industrial facilities. "Stricter emission standards and the need for using affordable bio and recycled fuels that are more demanding in terms of corrosion, present new challenges for the boiler design. The design work for Nokianvirran Energia's new boiler has mostly been completed, and the manufacturing has been started at Valmet's Lapua workshop. According to the project schedule, steam production will begin in the spring of 2016," says Jari Niemelä, Sales Director, EMEA, Valmet.

Information about Nokianvirran Energia Oy

Nokianvirran Energia Oy is a joint venture of Oy SCA Hygiene Products Ab, Nokian Renkaat Oy and Leppäkosken Sähkö Oy which is constructing a steam heat station in Nokia to be integrated with the exiting power plant. Once completed, the plant will produce process steam and district heat to its owners and improve the competitiveness of the shareholders' business operations, ensuring more stable energy prices in the long term.

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 10,500 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Appointment in Kemira's management

Mats Rönnbäck has been appointed as interim President, Paper segment and Asia Pacific region and member of Kemira's Management Board as of April 1, 2015. Mats is currently based in Hong Kong. As announced earlier this year, Petri Helsky will leave Kemira to take up the position of CEO of Metsä Tissue Corporation on April 16, 2015.

Mats Rönnbäck has been appointed as interim President, Paper segment and Asia Pacific region and member of Kemira's Management Board as of April 1, 2015. Mats is currently based in Hong Kong. As announced earlier this year, Petri Helsky will leave Kemira to take up the position of CEO of Metsä Tissue Corporation on April 16, 2015.

"The search for the new Paper segment leader is ongoing. To ensure that we continue to deliver on our growth strategy in Paper, Mats Rönnbäck will take on an interim basis the leadership of the segment and APAC region. Mats has been with Kemira since 1990 and has a vast experience in the pulp and paper business", said Jari Rosendal, Kemira's President and CEO.

For more information, please contact

Kemira Oyj

Leena Lie, SVP, Communications and Corporate Responsibility

Tel. +358 10 862 1153

Tero Huovinen, VP, Investor Relations

Tel. +358 10 862 1980

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2014, Kemira had annual revenue of EUR 2.1 billion and around 4,250 employees. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

www.kemira.com

Verso Introduces New Coated Web Product Lineup

Verso Corporation (NYSE: VRS), a leading North American producer of printing papers, specialty papers and pulp, has introduced its new coated web product lineup, unmatched by any other North American supplier. Verso offers a breadth of quality coated web brands, including No. 2, No. 3 and No. 4 grades in coated freesheet and coated groundwood, as well as supercalendered SCA+ and SCA grades. Verso's lineup includes some of the most distinguished paper brands in the industry, such as Sterling® Ultra, ArborWeb Plus®, Influence®, ArborWeb® and Liberty®, as well as two new brands, Focus™ and Balance™.

Verso Corporation (NYSE: VRS), a leading North American producer of printing papers, specialty papers and pulp, has introduced its new coated web product lineup, unmatched by any other North American supplier. Verso offers a breadth of quality coated web brands, including No. 2, No. 3 and No. 4 grades in coated freesheet and coated groundwood, as well as supercalendered SCA+ and SCA grades. Verso's lineup includes some of the most distinguished paper brands in the industry, such as Sterling® Ultra, ArborWeb Plus®, Influence®, ArborWeb® and Liberty®, as well as two new brands, Focus™ and Balance™.

Verso's two new brands, Focus™ and Balance™, will be produced to the same high standards as its other distinguished brands. Focus™, a No. 3 coated groundwood paper, is one of the best values in its category, offering cost savings without compromising performance, brightness or image reproduction. It delivers great appearance and value for quality-conscious commercial printing, catalog and magazine applications. Balance™, a No. 4 coated groundwood product, is a highly versatile and refined paper, striking the optimal combination of brightness, printability and cost. It is the perfect choice for special edition publications and is a brighter, whiter alternative to a typical No. 5 product.

"Verso's coated web product offering is an important component of our overall printing papers, specialty papers and pulp product portfolio," says Mike Weinhold, Verso's Senior Vice President of Sales, Marketing and Product Development. "We have the know-how to offer world-class products and the experience to offer world-class service. Our new coated web offering provides a unique combination of quality, consistency, reliability and flexibility that is very appealing to customers."

Verso demands that its mills meet strict quality standards to ensure delivery of consistent products day in and day out. All Verso facilities are located in the United States and its mills and warehouses are strategically located near large print markets. "Verso's strategic locations and large manufacturing base ensure our customers are reliably supplied," Weinhold says. "We have the flexibility to manufacture the same products on multiple machines, which means customers can get the paper they want when they need it. We are committed to going the extra mile to earn and keep our customers' loyalty."

Coated web papers are used primarily in commercial printing applications, including magazines, catalogs, books, direct mail and retail inserts.

For more information, please visit www.versoco.com.

About Verso

Verso Corporation is a leading North American producer of printing papers, specialty papers and pulp. Our printing papers are used primarily in commercial printing, media and marketing applications, including magazines, catalogs, books, direct mail, corporate collateral and retail inserts. Our specialty papers are used primarily in label and release liner, flexible packaging and technical paper applications. Headquartered in Memphis, Tennessee, with a business center in Miamisburg, Ohio, Verso operates eight mills strategically located in Kentucky, Maine, Maryland, Michigan, Minnesota and Wisconsin with a total annual production capacity of approximately 3.6 million tons.

Source: Verso Corporation

Invercote G from Iggesund

Upgraded for better digital printing

“We’re seeing almost an explosion of digitally printed folding cartons. For a company like ours which offers stiff paperboard of the highest quality this is a terrific development,” comments Fredrik Lisinski, who is responsible for developing Iggesund Paperboard’s sales to the digital print market.

Strong brands led by Coca Cola have shown that the intelligent personalisation or regionalisation of packaging and labels can drive sales. Presses designed for higher grammages as well as new finishing equipment are opening up new possibilities. At the same time, larger sheet formats are paving the way for better economies of scale for digital printing.

“In addition, new applications are appearing that were previously unimaginable,” Lisinski adds. “Fifteen – or even ten – years ago, who could have thought that a print run of five calendars featuring photos of someone’s grandchildren or three copies of a photo book could form the financial backbone of a printing firm.”

Invercote, which is Iggesund’s flagship product, has paved the way for digital printing on thicker paper materials since the technology was introduced in 1993. Today’s Invercote G is certified for a variety of digital print technologies and is recognised as the market leader by digital printers when they need a thicker or stiffer material than usual.

The rapid development of digital presses and increasingly widespread interest in using digital print on packaging led Iggesund to take the next step with Invercote.

“The upgraded Invercote G that we’re rolling out into the market this spring will give us a complete portfolio of products for digital applications,” Lisinski explains.

“Invercote Creato is the best choice for all two-sided printed materials such as covers and various types of cards, but also for packaging with equal demands on both sides of the paperboard. The upgraded Invercote G will give customers who want a clear difference between the paperboard’s two sides but who still want to be able to print on both sides using their digital presses precisely what they’re looking for.”

The secret lies in the new coating on the reverse side of the upgraded Invercote G.

Iggesund’s engineers were asked to create a reverse side with improved printing properties – in both offset and digital – but without compromising on the natural feel that has been the product’s hallmark for many years. The market’s reactions to the upgrade have far exceeded expectations.

With this new product Iggesund wants to give the entire digital print industry a tool with which to smash all the barriers that have hindered digitally printed folding cartons from achieving its full potential.

“We don’t want our customers to have to choose between good printability in digital applications and first-class packaging characteristics in terms of designability and material stiffness and strength,” Lisinski says. “With Invercote we want to give them both. Our status as the market leader proves we’re on the right path. With this upgraded product I’m convinced that the entire digital packaging print market will take another leap forward.”

Over the past year Iggesund has made major efforts to increase the availability of Invercote in the most common formats for digital presses.

“We’ve followed the market and worked with the leading press manufacturers. The result is a product portfolio that is perfectly suited to people who do digital printing on higher grammages,” Fredrik Lisinski concludes.

Clearwater Paper Announces Executive Changes

Clearwater Paper Corporation has announced the retirement of Thomas A. Colgrove as president of the company's consumer products division. Mr. Colgrove will continue to serve as president of the division until the beginning of the second quarter. Patrick T. Burke, who currently serves as the company's vice president of supply chain, will assume the role of senior vice president and president of the company's consumer products division, when his successor for the supply chain function is appointed. Mr. Colgrove will also continue to serve the company until the end of 2015 to assist in the transition.

Clearwater Paper Corporation has announced the retirement of Thomas A. Colgrove as president of the company's consumer products division. Mr. Colgrove will continue to serve as president of the division until the beginning of the second quarter. Patrick T. Burke, who currently serves as the company's vice president of supply chain, will assume the role of senior vice president and president of the company's consumer products division, when his successor for the supply chain function is appointed. Mr. Colgrove will also continue to serve the company until the end of 2015 to assist in the transition.

"Pat joined Clearwater Paper in May 2014," said Linda K. Massman, president and CEO. "During this time, Pat has proven his abilities to develop and implement a successful supply chain and warehouse operations strategy, and has also established himself as a valued and respected member of Clearwater Paper's leadership team."

Prior to joining Clearwater Paper, Mr. Burke spent nearly 30 years in manufacturing, warehouse operations and supply chain management leadership positions for PepsiCo, Quaker Oats and Ralston Foods. While at PepsiCo, he managed the Western Region of Gatorade with total sales of $4 billion. Mr. Burke received his Bachelor of Science from Jacksonville State University and his MBA from Ohio University.

"Pat's extensive experience leading manufacturing and supply chain operations, and implementing continuous improvement practices for some of the country's largest consumer-products companies fits well with our company's strong focus on gaining efficiencies in every part of our operation," said Massman.

"Tom Colgrove has logged more than 40 years of industry experience, and has brought much of that knowledge and knowhow to bear, driving success at both the paperboard and tissue segments of our company for the past six years," said Massman. "All of us at Clearwater Paper thank Tom for his service and leadership, and look forward to continuing to work with him during this transition."

ABOUT CLEARWATER PAPER

Clearwater Paper manufactures quality consumer tissue, away-from-home tissue, parent roll tissue, bleached paperboard and pulp at manufacturing facilities across the nation. The company is a premier supplier of private label tissue to major retailers and wholesale distributors, including grocery, drug, mass merchants and discount stores. In addition, the company produces bleached paperboard used by quality-conscious printers and packaging converters. Clearwater Paper's employees build shareholder value by developing strong customer partnerships through quality and service.

For additional information on Clearwater Paper, please visit the company's website at www.clearwaterpaper.com

Resolute Announces Permanent Closure of Machine #9 at the Alma Paper Mill

Resolute Forest Products Inc. (NYSE: RFP) (TSX: RFP) today announced the permanent closure of paper machine #9 at its mill in Alma (Quebec), representing a reduction of 75,000 metric tons of annual specialty papers production capacity.

Resolute Forest Products Inc. (NYSE: RFP) (TSX: RFP) today announced the permanent closure of paper machine #9 at its mill in Alma (Quebec), representing a reduction of 75,000 metric tons of annual specialty papers production capacity.

Resolute's decision to reduce specialty papers production capacity is driven by market weakness, exacerbated by fiber cost issues in Quebec, as well as ongoing misinformation campaigns by Greenpeace and other environmental activist groups.

"Greenpeace's ill-founded attacks misrepresent the company's forest management practices and cast unwarranted doubt on Resolute's compliance with Quebec's Loi sur l'aménagement durable du territoire forestier and our sustainability leadership. Quebec's forest management regime is among the best in the world, and the government ensures strict compliance. The regime deserves to be respected and upheld, and we are calling upon the Quebec government to continue to defend its standards and to refute these unjustified and unfounded attacks," stated Richard Garneau, Resolute's president and chief executive officer.

"These misinformation campaigns impact Resolute and people's lives, as they further destabilize the industry, triggering socioeconomic consequences for the communities that depend on the boreal forest for their livelihood," added Garneau.

The Alma paper mill employs approximately 340 people and has an annual production capacity of 350,000 metric tons of specialty papers across three machines. Machine #9 will be permanently closed at the beginning of April, resulting in the elimination of about 85 jobs and the permanent reduction of some 75,000 metric tons of production capacity.

Resolute understands the impact this decision will have on employees, their families and the local community. The company will work with union representatives and government officials to respond to the needs of affected employees. Local management will also ensure that each employee receives support, that the relevant conditions in the collective agreements are respected, and that as many employees as possible are transferred to other company facilities.

"The decision to rationalize our paper production capacity in Alma was a difficult one to make, as we are mindful of the impact it will have on the affected employees," added Richard Garneau. "Resolute remains committed to customer service and to the delivery of high-quality products, and will work closely with customers to continue to meet their needs," concluded Garneau.

About Resolute Forest Products

Resolute Forest Products is a global leader in the forest products industry with a diverse range of products, including newsprint, specialty papers, market pulp and wood products. The company owns or operates some 40 pulp and paper mills and wood products facilities in the United States, Canada and South Korea, and power generation assets in Canada. Marketing its products in close to 80 countries, Resolute has third-party certified 100% of its managed woodlands to at least one of three internationally recognized sustainable forest management standards. The shares of Resolute Forest Products trade under the stock symbol RFP on both the New York Stock Exchange and the Toronto Stock Exchange.

Resolute and other member companies of the Forest Products Association of Canada, as well as a number of environmental organizations, are partners in the Canadian Boreal Forest Agreement. The group works to identify solutions to conservation issues that meet the goal of balancing equally the three pillars of sustainability linked to human activities: environmental, social and economic.

Resolute is proud to be ranked by Corporate Knights as one of Canada's Best 50 Corporate Citizens for 2014. In addition, the company and Richard Garneau, president and chief executive officer, have been named to Canada's Clean50. And in January 2015, Resolute was awarded The New Economy magazine's global Clean Tech Award for best forestry and paper solutions.

SOURCE Resolute Forest Products Inc.

It’s Tissue – see us in Barcelona

It’s Tissue will be at Tissue World in Barcelona, March 17-19, to promote its much-anticipated event this June in Lucca, Italy’s tissue technology heartland.

It’s Tissue will be at Tissue World in Barcelona, March 17-19, to promote its much-anticipated event this June in Lucca, Italy’s tissue technology heartland.

The network behind It’s Tissue will be represented with a welcoming stand at Tissue World, to help potential visitors to register and arrange their time in Italy for the June 21-28 event. They will also have the opportunity to learn about the special programme including live demonstrations planned for this year.

Those who register for It’s Tissue in Barcelona will be entered for a prize draw offering either a ride in a Ferrari in Lucca or tickets to Expo 2015 in Milan.

It’s tissue is a unique event: A total immersion in “Made in Italy” production technology for the entire range of tissue products for health and hygiene. The hub is Lucca, with visits arranged to Reggio Emilia and Lecco.

The network comprises: A Celli, Elettric 80, Fabio Perini, Futura, Gambini, MTC, Omet, PCMC, Pulsar, Recard, TMC and Toscotec.

It’s Tissue will be on stand D90.

Q4 results reflect key decisions to position Catalyst for the future

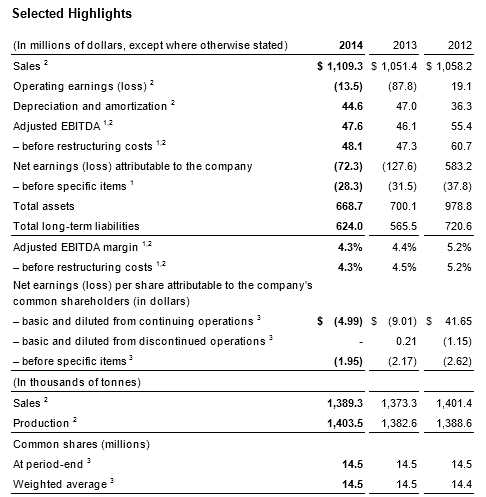

Catalyst Paper (TSX:CYT) has announced earnings before interest, taxes, depreciation and amortization (EBITDA) of $6.8 million in Q4 compared to $8.0 million in Q3.

Catalyst Paper (TSX:CYT) has announced earnings before interest, taxes, depreciation and amortization (EBITDA) of $6.8 million in Q4 compared to $8.0 million in Q3.

Catalyst reported a net loss, excluding specific items, of $10.4 million in Q4 compared to $10.8 million in Q3. Operating results were impacted by increased manufacturing expenses, including higher rates for electricity, as well as costs related to the indefinite curtailment of Paper Machine No. 9 at the Powell River mill, and the acquisition of the Biron paper mill in Wisconsin and the Rumford pulp and paper mill in Maine.

"Our results reflect critical decisions to position the company effectively for the future," said Joe Nemeth, Catalyst President & CEO. "In Q4, we incurred one-time costs and made strategic investments that will enable us to optimize our product mix and performance, while continuing to focus on cost, productivity, efficiency and customer service."

North American paper demand was down in the fourth quarter for all segments with the exception of lightweight coated and uncoated paper. Benchmark prices remained flat for specialty grades and declined for newsprint and pulp. Despite sluggish markets, sales revenues increased modestly in Q4 compared to Q3 due to the positive impact of a weaker Canadian dollar, higher average transaction prices for pulp, and increased sales volumes for newsprint, uncoated mechanical and lightweight coated paper.

Results for the Year

Adjusted EBITDA was $47.6 million in 2014 compared to $46.1 million in 2013. Excluding specific items, our net loss was $28.3 million in 2014 compared to $31.5 million in 2013. Free cash flow was negative $17.2 million compared to negative $21.4 million in 2013.

These results understate the year-over-year improvement we achieved, as we incurred one-time costs of $3.1 million to complete the acquisition of the US assets and did not have the $4.3 million in EBITDA contribution from our interest in Powell River Energy Inc. that existed in 2013. After normalizing for these non-recurring items, adjusted EBITDA increased by $8.9 million compared to the prior year.

"Where we applied a sharp focus on operational excellence, we made substantive progress," said Joe Nemeth, Catalyst President & CEO. "As we look ahead to 2015, we expect continued improvement as we work diligently to realize the benefits of our US acquisition, revitalize our Powell River operations and consistently apply the operational excellence principles that have enabled our financial recovery."

Cost factors beyond the company's control continued to challenge the competitiveness of the business. In 2014, manufacturing costs were higher mainly due to price increases in fibre, chemicals, steam fuel and electrical power, which represents a major cost for our energy-intensive business.

A critical priority in 2014 was implementing initiatives to mitigate the increasing cost of hydroelectricity. The company took advantage of a new Power Smart Program extended to pulp producers that provides 75% of capital funding for equipment upgrades that more efficiently harness energy. Through its efforts to mitigate power usage, the company expects to realize funding potential of approximately $45 million through the Program.

Liquidity

Our total liquidity as of December 31, 2014 was $102.7 representing a $19.9 million decrease from the prior year. This decrease reflects negative free cash flow of $17.2 million generated for the year.

| 1 | Refer to section 11, Non-GAAP measures, of our Q4 2014 management's discussion and analysis. |

| 2 | Numbers exclude the Snowflake mill's results from operations which have been reclassified as discontinued operations; earnings from discontinued operations, net of tax, are shown separately from continuing operations in the consolidated statements of earnings (loss) in our annual consolidated financial statements for the year ended December 31, 2014. |

| 3 |

Earnings per share data for periods ended on and subsequent to September 30, 2012 were based on the weighted average common shares issued pursuant to our reorganization under CCAA. Earnings per share data for periods prior to September 30, 2012 were based on the weighted average common shares outstanding prior to emergence from creditor protection proceedings. These shares were cancelled on September 13, 2012. |

Outlook

A key focus for 2015 is the full integration of the Biron and Rumford mills. Our approach is to identify opportunities to optimize production, product mix and performance. We have recruited additional talent to enhance our sales capacity and capabilities, and to ensure we can continue to distinguish Catalyst as the industry's leading provider of quality products and superior services to customers worldwide.

Mitigation of increasing hydroelectricity rates remains a priority in 2015. We have launched a pilot program in concert with BC Hydro at all of our Canadian mills that financially rewards the company for shifting energy use within specific timeframes. We will explore all feasible opportunities to mitigate the impact of escalating rates, including another 6% increase planned by BC Hydro on April 1.

We anticipate that specialty printing paper markets in North America will remain challenging with the continued evolution of digital media and the displacement of printed mediums. Our strategy within this market is to focus on lightweight niches in all printing and writing grades, and to increase sales of higher-value products, including coated free sheet and coated one side grades.

Further Quarterly Results Materials

This release, along with the full annual Management Discussion &Analysis, Financial Statements and accompanying notes are available on our web site at www.catalystpaper.com/Investors. This material is also filed with SEDAR in Canada and EDGAR in the United States.

Catalyst manufactures diverse specialty mechanical printing papers, newsprint and pulp. Its customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.