Ianadmin

emtec Preview Tissue World Barcelona 2015

Gaining the Best Tissue Quality with Lowest Possible Costs

emtec Electronic at the Tissue World in Barcelona, Spain

Also this year emtec Electronic GmbH will attend the „Tissue World Barcelona 2015“ in Barcelona, Spain. From March 17th until March 19th, the company will be present at the exhibition at booth no. E600.

The TSA Tissue Softness Analyzer is one of the innovative testing instruments which will be presented in Barcelona during these three days of exhibition. The device is used for the objective and reliable measurement of tissue “handfeel” properties such as the real softness, smoothness / roughness and stiffness. The availability of these three parameters opens a huge amount of chances for the optimization of the tissue production and converting processes.

Additionally, emtec Electronic will present some measuring devices for the wet end area: the CAS Charge Analyzing System for determining the particle charge of filtrates and the FPA Fiber Potential Analyzer for measuring the Zeta Potential of fibers. Furthermore, emtec Electronic developed a new Online measuring device FPO – Fiber Zeta Potential Analyzer Online, which measures the Zeta Potential of fibers directly in the production process and delivers immediately reliable and necessary information concerning the dosing of chemicals to the pulp.

UPM reduced work-related accidents by 70 percent in three years

UPM has significantly reduced work-related accidents with a three year program called “Step Change in Safety 2012–2014”. UPM’s lost time accident frequency* (LTAF) has decreased by 70% from 15.2 in 2012 to 4.4 in 2014.

UPM has significantly reduced work-related accidents with a three year program called “Step Change in Safety 2012–2014”. UPM’s lost time accident frequency* (LTAF) has decreased by 70% from 15.2 in 2012 to 4.4 in 2014.

The Step Change in Safety 2012–2014 initiative engaged all UPM employees in a joint mission to improve the company’s safety culture and safety performance. The pervasive program renewed the foundations of safety work by shifting focus to preventative measures, such as proactive risk identification and management. Strong management commitment and active participation of employees and contractors have been the keys to success.

As a result, UPM’s global LTAF decreased by a total of 70% from 15.2 in the beginning of 2012 to 4.4 by the end of 2014. The total number of lost time accidents globally decreased from over 550 in 2011 to 155 in 2014.

“We have achieved excellent results and they clearly show that a new safety culture has been adopted throughout the company. All UPMers have contributed to the result and we can all be proud of the achievement,” says Jussi Pesonen, CEO of UPM.

One cornerstone for safety work are UPM safety standards, which were put in place during the Step Change in Safety initiative. The standards define the minimum requirements for safety performance and operations, and they are common to all UPM units around the world. For the next three years, the focus will be in perfecting the local implementation practices.

“The great results from our safety initiative have encouraged us to raise the bar even further. Our first goal was to get our LTAF below 5. Next we are aiming to go below 3,” Jussi Pesonen continues.

Careful induction and job specific safety training play important roles in identifying risks and consequently preventing accidents.

Employees' risk awareness is continuously improved by organising safety training, sharing information on near-miss situations and encouraging employees to report all hazardous situations and safety deficiencies.

In 2015 UPM launches a practice in which all UPM employees will be provided a regular refresher safety training to make sure that all the latest information and practices is in use.

You can read more about UPM safety induction from the UPM Viewpoint blog including UPM’s new safety induction video “STOP”.

* Number of lost time accidents per one million hours of work.

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 20,000 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM – The Biofore Company – www.upm.com Magnus Groth appointed new President and CEO of SCA

SCA’s Board of Directors has appointed Magnus Groth as new President and CEO. Magnus Groth is today President of SCA’s Business Unit Consumer Goods Europe and has previously among other things been CEO of a listed company. The appointment of Magnus Groth is effective March 1.

SCA’s Board of Directors has appointed Magnus Groth as new President and CEO. Magnus Groth is today President of SCA’s Business Unit Consumer Goods Europe and has previously among other things been CEO of a listed company. The appointment of Magnus Groth is effective March 1.

SCA’s Board announced today the appointment of Magnus Groth as President and CEO of SCA. Magnus Groth has worked at SCA since 2011, and his role as President of the Business Unit Consumer Goods Europe at SCA has given him deep knowledge of SCA, its customers and consumers as well as their needs. Magnus Groth also has extensive experience among other things as CEO of the listed company Studsvik. Magnus Groth has taken an active part in developing SCA into a global leading hygiene and forest products company with strong brands, fantastic employees and successful value creation for shareholders and other stakeholders.

The Board finds that Magnus Groth is the right person to continue to develop SCA in line with the strategy to focus on growth, innovation and efficiency. A key factor of success in Magnus Groth’s leadership has been to make continuous improvements for customers and consumers through innovation and cost efficiency.

”It is a great responsibility to lead SCA and I have proudly accepted. I am also humble to this task. Now we will go from today’s position as a leading global hygiene and forest products company to continuously develop SCA going forward”, says Magnus Groth, appointed President and CEO of SCA.

NB

This information is such that SCA must disclose in accordance with the Securities Markets Act and/or the Financial Instruments Trading Act. The information was submitted for publication on February 10, 2015, at 18:30 CET.

For additional information please contact:

Johan Karlsson, Vice President Investor Relations, 46 8 788 51 30

Karl Stoltz, Media Relations Manager, 46 8 788 51 55

Joséphine Edwall-Björklund, Senior Vice President Communications

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2013 amounted to approximately SEK 93bn (EUR 10.7bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Jan Johansson to leave as President and CEO of SCA

In connection to a Board meeting held on Tuesday 10th Feb 2015, it is announced that Jan Johansson will step down as President and CEO of SCA.

The last months I have spent a large part of my time on the ongoing audits related to SCA. A preliminary investigation has also started, which means that the ability to focus on the business has been further reduced. The decision that the Board and I have reached in the interest of SCA, our shareholders, employees and my family is that I step down as President and CEO, says Jan Johansson.

The last months I have spent a large part of my time on the ongoing audits related to SCA. A preliminary investigation has also started, which means that the ability to focus on the business has been further reduced. The decision that the Board and I have reached in the interest of SCA, our shareholders, employees and my family is that I step down as President and CEO, says Jan Johansson.

In line with the Board and in accordance with the employment contract, which stipulates that Jan Johansson has a notice of two years (fixed salary no bonus), Jan Johansson will be at the disposal of the Board and the appointed President and CEO.

SCA is today a leading global hygiene and forest products company with strong brands, fantastic employees, recognized sustainability work and SCA has great potential to continue to create shareholder value. As President and CEO, it has been very stimulating to lead SCA’s journey of change since 2007, Jan Johansson concludes.

SCA’s Board writes in a joint announcement:

The Board regrets, but understands and respects that Jan Johansson cannot effectively lead SCA under the current conditions. The Board would like to emphasize that there is no new information related to the ongoing audits. The Board has continued great confidence in Jan Johansson.

As President and CEO, Jan Johansson has in a very competent and value creating way led SCA during an important and successful journey of change for growth and innovation. Now we have a platform for global expansion. The Board would like to extend their warmest thanks for his valuable contributions as President and CEO.

NB

This information is such that SCA must disclose in accordance with the Securities Markets Act and/or the Financial Instruments Trading Act. The information was submitted for publication on February 10, 2015, at 18:30 CET.

For additional information please contact:

Johan Karlsson, Vice President Investor Relations, 46 8 788 51 30

Karl Stoltz, Media Relations Manager, 46 8 788 51 55

Joséphine Edwall-Björklund, Senior Vice President Communications

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2013 amounted to approximately SEK 93bn (EUR 10.7bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

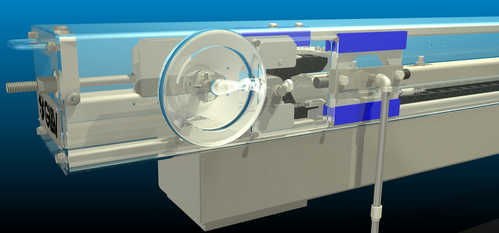

GL&V FlexTrim™ Tail Cutter Development

In 2014, GL&V initiated a development project to improve and modernize our wet end tail cutter equipment.

Features of the new design include:

- A totally enclosed and pressurized drive section that protects the motor and clutch assembly from the harsh mill environment. The drive section is also skid mounted and easily removable for off machine maintenance.

- Several control options.

- Optional travel speeds.

- Adaptable to any machine width.

Our new FlexTrim™ Tail Cutter represents two of GL&V’s core values: Flexibility & adaptability.

Four of these improved units have recently been sold, installed and commissioned and have provided GL&V with positive customer feedback.

For further details, please visit our website www.glvpulppaper.com

Minerals Technologies Signs Commercial Agreement to Deploy FulFill® E-325 Technology for High Filler Loading at a Paper Mill in Europe

Unique High-Filler Technology Will Provide Significant Cost Savings in Reduced Fiber Consumption by Increasing PCC Filler Usage 20%

Minerals Technologies Inc., (NYSE: MTX) has announced that it has signed a commercial agreement to provide Fulfill® E-325, a new, high-filler technology, at a paper mill in Europe.

Minerals Technologies Inc., (NYSE: MTX) has announced that it has signed a commercial agreement to provide Fulfill® E-325, a new, high-filler technology, at a paper mill in Europe.

Minerals Technologies now has 19 agreements with paper mills that have adopted the Fulfill® E-325 technology that the company introduced in late 2010. The agreement with this papermaker is the company's fifth in Europe. The paper company wishes to remain unnamed for competitive reasons.

These agreements confirm the commercial progress of the Fulfill® brand, a portfolio of high-filler technologies that offers papermakers a variety of efficient, flexible solutions that decreases dependency on natural fiber and reduces costs. The Fulfill® E-325 series allows papermakers to increase loading levels of precipitated calcium carbonate (PCC) by three to five points, which replaces higher cost pulp, and increases PCC usage between 20 to 30 percent.

"We are pleased that this papermaker is adopting our technology that will allow them to produce quality paper at lower cost," said D.J. Monagle, senior vice president & managing director, Paper PCC. "The continued acceptance of our FulFill® E-325 of technology in Europe reaffirms the revitalization of our new product pipeline, and of our commitment to advance our technology leadership throughout our satellite network around the world."

PCC is a specialty pigment for filling and coating high-quality paper. By substituting Minerals Technologies' PCC for more expensive wood fiber, customers are able to produce brighter, higher quality paper at lower cost. In 1986, Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills and the concept was a major factor in revolutionizing papermaking in North America. Today, the company has 60 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

New York-based Minerals Technologies Inc. is a resource- and technology-based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral-based and synthetic mineral products and related systems and services. Minerals Technologies serves the paper, foundry, steel, environmental, energy, polymer and consumer products industries. The company reported sales of $1.73 billion in 2014.

Contact:

Rick B. Honey

(212) 878-1831

For further information about Minerals Technologies Inc. look on the internet at http://www.mineralstech.com/

Xerium Announces Analyst Coverage Initiated by Macquarie Capital

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, is pleased to announce that Macquarie Capital has initiated analyst coverage on Xerium.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, is pleased to announce that Macquarie Capital has initiated analyst coverage on Xerium.

"We are pleased that the investor community following Xerium is growing. The company's long term plan is to increase its share of the growing global markets in which we participate," said Harold Bevis, Xerium's President and CEO. "By selectively reinvesting in our business, we expect to generate high free cash flows that will enable the pay down of over half our debt by 2020."

Any opinions, estimates or forecasts regarding Xerium's performance made by these analysts are theirs alone and do not represent the opinions, forecasts or predictions of Xerium or its management. Xerium does not imply its endorsement of or concurrence with such information, conclusions or recommendations.

About Xerium Technologies

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 26 manufacturing facilities in 12 countries around the world and employs approximately 3,100 employees.

New Release of Pulp Paper & Logistics Magazine

Welcome to the January/February edition of Pulp, Paper & Logistics. As with each New Year the pulp and paper industry faces new challenges and changing demands from customers looking for new types and quality of product.

Welcome to the January/February edition of Pulp, Paper & Logistics. As with each New Year the pulp and paper industry faces new challenges and changing demands from customers looking for new types and quality of product.

Last year the growth in both packaging and tissue production resulted in many mills cranking up their output to keep up with demand. With these increases in output, so equipment and service suppliers also saw greater call for better systems to control processes and cut out waste.

The changes in the markets have also continued with a decline in newsprint and an increase in tissue products, especially in Asia, both of which mean investment in new mill machinery and complete lines.

Looking at our magazine’s growth and co-operation with pulp-paperworld.com, which hosts our digital edition, we again saw an increase in the number of times each issue was read. For the November-December issue the figure exceeded 15,000.

Looking forward to this year’s trade shows we can look forward to Tissue World in Barcelona, Spain (www.tissueworld.com) from 17-19 March, Zellcheming in Frankfurt, Germany (www.zellcheming.de) from 30 June to 2 July, China Paper in Shanghai from 14-16 October (www.chinapaperexpo.cn) plus MIAC 2015 in Lucca, Italy, also from 14-16 October (www.miac.info).

In the next March-April issue we will be featuring the following subject areas: chemicals, additives, coatings and pigments; mill maintenance and paper mill sheeting and cut-to-size technology. If you have new products or services in these sectors, editorial submissions are required by 13 March.

For More Info please contact:

Vince Maynard

Editor

This email address is being protected from spambots. You need JavaScript enabled to view it.

Stora Enso launches Group-wide Human Rights Assessment results together with the Danish Institute for Human Rights

Stora Enso launched the results of its Group-wide Human Rights Assessments in a report consolidated by the Danish Institute for Human Rights (DIHR). Stora Enso is among the few companies globally to publicly report on Group-wide human rights findings covering production units, wood supply operations, supply chain management and local community relations.

Stora Enso launched the results of its Group-wide Human Rights Assessments in a report consolidated by the Danish Institute for Human Rights (DIHR). Stora Enso is among the few companies globally to publicly report on Group-wide human rights findings covering production units, wood supply operations, supply chain management and local community relations.

The assessments looked at 43 human rights issue areas, covering labour rights, community impacts and controls for suppliers and business partners. Covering 93 units in 22 countries, and part of Stora Enso’s ongoing due diligence, assessments were carried out in 2014 supported by DIHR. The assessments also covered joint operations Veracel in Brazil and Montes del Plata in Uruguay, and the equity accounted investment Bulleh Shah Packaging in Pakistan.

“This was a new endeavor for us and we have our partners - especially the Danish Institute for Human Rights – to thank for guiding us” says Karl-Henrik Sundström, CEO of Stora Enso. “Going forward, we will engage with stakeholders in reviewing the results and planning actions. Launching the human rights action plans in 2015 will be a top priority for us. We see this report as a baseline, and will agree on ambitious but realistic milestones based on detailed analyses of what needs to be done to make a real change. The way we see it, transparency increases accountability.”

“The United Nations Guiding Principles on Business and Human Rights require companies to understand how they might cause or contribute to adverse impacts on human rights. Having this knowledge is a prerequisite for being a sustainable company” says Allan Lerberg Jørgensen, Director for Human Rights and Development at The Danish Institute for Human Rights. “With this report, Stora Enso demonstrates the kind of corporate leadership needed to realise that journey. Very few companies have undertaken human rights due diligence on this scale.”

The key Group-wide findings of the report are related to monitoring of employment conditions of third-party in-premise staff; promoting diversity management; improving overtime practices and entry-level wages at some units; strengthening procedures and guidance on protecting the privacy of employees; supporting and facilitating collective bargaining; improving in Occupational Health and Safety at some units; strengthening grievance mechanisms; improving procedures on environmental and social impact assessments; developing policies and procedures on security management; continuing to implement the Supplier Code of Conduct; and ensuring that all human rights impacts are considered in responsible supply chain management.

When prioritising actions, the UN Guiding Principles on Business and Human Rights advise companies to have remediation measures in place for impacts that are severe or that can become irreversible if delayed. Stora Enso will follow this approach and set action plans for prioritised impacts – severe impacts, irreversible impacts, possible legal non-compliances and gaps with Stora Enso policies – by the end of Q2 2015.

In countries where Stora Enso perceives heightened human rights impacts, it carried out human rights assessments with external third party support and site visits. In 13 units in China, Russia, Estonia, Latvia and Poland, external visits were performed by Fair Working Conditions, an independent non-profit organisation. In Guangxi, China, Stora Enso worked with DIHR. In Pakistan an external human rights consultant supported the assessment. For the trial plantation operations in Laos, Stora Enso collaborated with Business for Social Responsibility (BSR).

Download the Full Human Rights Assessments Report here: http://assets.storaenso.com/se/com/DownloadCenterDocuments/0502HRA_2015_DIHR_REPORT.pdf

For further information, please contact:

Terhi Koipijärvi, EVP Global Responsibility (acting), tel. +358 50 598 9958

Ulrika Lilja, EVP, Global Communications, tel. +46 1046 71668

www.storaenso.com

www.storaenso.com/investors

Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wood and paper. Our aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 27 000 people in more than 35 countries, and our sales in 2014 were EUR 10.2 billion. Stora Enso shares are listed on NASDAQ OMX Helsinki (STEAV, STERV) and Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market.

Newly-formed Bioeconomy Alliance calls for EU action

Creating a world-leading bioeconomy in the European Union requires bold political moves. On the occasion of its launch at the European Parliament on 4 February, the European Bioeconomy Alliance (EBA) calls for more predictable policies leading to a long-term strategy for a competitive, dynamic and sustainable bioeconomy in Europe.

Creating a world-leading bioeconomy in the European Union requires bold political moves. On the occasion of its launch at the European Parliament on 4 February, the European Bioeconomy Alliance (EBA) calls for more predictable policies leading to a long-term strategy for a competitive, dynamic and sustainable bioeconomy in Europe.

Developing the bioeconomy is only feasible if the European Union provides a holistic, coherent and harmonised framework in a range of policy fields: agriculture, forestry, marine, industrial, climate, environment, energy, research, innovation and regional development. The EU needs to act on the following four main fronts in particular, in order to help Europe become a leader in the bioeconomy:

- Implement priority recommendations from the Lead Market Initiative on bio-based products. This will not only create new markets and jobs but also stimulate economic recovery, focusing on: access to feedstock, research, development and innovation, access to markets, public procurement and communication.

- Encourage member states to implement measures to i) increase agricultural and forestry productivity and soil fertility in a sustainable way and ii) facilitate mobilisation and access to renewable feedstock at competitive prices.

- Address barriers to investment in first commercial operations, such as biorefineries in Europe. The Public Private Partnership on Bio-based Industries is a first step in the right direction and should facilitate and catalyse other European and national and regional financing sources.

- Engage with civil society, together with farmers, forest owners and industry, to encourage the debate on shaping a more competitive, sustainable bioeconomy for Europe.

EBA’s vision is to help establish a more competitive, innovative, energy-secure and sustainable Europe, separating economic growth from a reliance on imported fossil sources, resource depletion, and environmental impact. EBA fully supports both the European Commission’s work on developing an EU bioeconomy as well as on-going efforts at member state and regional level to implement local strategies. In addition, EBA entirely supports the recent establishment of the European Parliament intergroup on “climate change, biodiversity and sustainable development” and its subgroup on the bioeconomy.

Over the next decades, the bioeconomy will play an increasingly important role in boosting Europe’s economy by revitalising rural and coastal areas and disused industrialised sites while providing more growth and jobs. According to the European Commission, the European bioeconomy is worth nearly €2 trillion and provides more than 22 million jobs to EU citizens.

The bioeconomy is not a niche sector; it encompasses the sustainable production of renewable resources and their conversion into food, feed, fibres, materials, chemicals and bioenergy through efficient and/or innovative technologies, which provides widespread economic, environmental and societal benefits. Therefore, the EBA calls for the bioeconomy development to be set as a priority in the Commission’s new €315 billion investment plan as well as in national and regional measures, to help ensure Europe’s sustainable economic recovery.

For more information please contact This email address is being protected from spambots. You need JavaScript enabled to view it..

The EBA is an informal alliance of leading European organisations active in the bioeconomy. Its members are:

- BIC - Bio-based Industries Consortium

- CEFS - European Association of Sugar Producers

- CEPF - Confederation of European Forest Owners

- CEPI - Confederation of European Paper Industries

- COPA - COGECA - European Farmers and European agri-cooperatives

- ePURE - European Renewable Ethanol Producers Association

- EuropaBio - The European Association for Bioindustries

- EUBP - European Bioplastics

- FEDIOL - The EU Vegetable Oil & Proteinmeal Industry

- FTP - Forest-based Sector Technology Platform

- PFP - Primary Food Processors

- Starch Europe - European Starch Industry Association