Super User

Fabio Perini and MTC: prompt delivery for converting and packaging machines and lines

And on the webshop, over 80 thousand Fabio Perini spare parts immediately available

The fear generated by the coronavirus and the closures in several countries to fight the pandemic have triggered a rush to buy, or "panic buying" as the British call it. Not only food products such as pasta, milk, flour, eggs, water, but also toilet paper and tissue products are disappearing from the shelves. Many companies in the Tissue industry around the world have increased production to the maximum, however exposing machines to high risk of failure, and some of them do not have the ability to produce more. This is why Fabio Perini and MTC, Körber companies in the Tissue division, thanks to their leadership in the sector, their financial stability, and their strong worldwide presence, have decided to make available in a short time a selection of standard machines and lines for converting and packaging.

"In addition to the health emergency that we are facing globally, as a company we are committed to further develop our activities in order to respond promptly to the current production needs of the market - comments Mauro Luna, Global Sales Director Fabio Perini S.p.A. - In this historical moment the advantage of being able to deliver converting and packaging machines in a fast way is certainly an added value that we can offer our customers".

Several machines and lines are available such as, for example, for converting, the Constellation S8 and Proxima S6 or for folded products the Star M2 Napkin Folder, for packaging the A6T and CMW208 packaging machines. All can be delivered worldwide in less than 4 months. On the website northamerica.fabioperini.com/equipment you can find the available technologies with features and benefits and the possibility to contact directly the company's sales team for information and quotes.

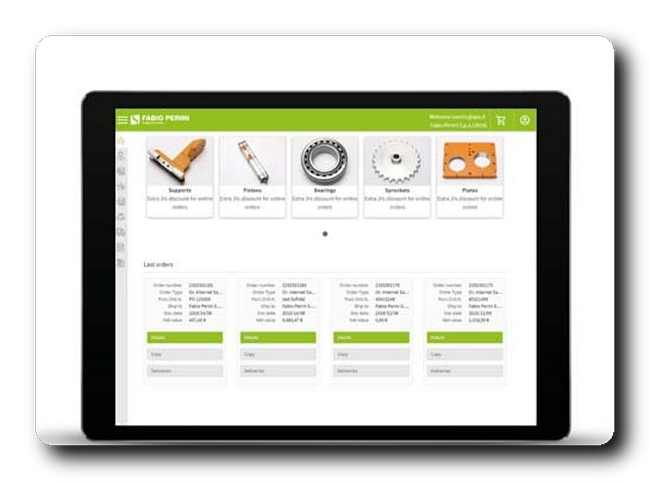

The fast procurement and delivery of spare parts is also very important because it minimizes downtime. Fabio Perini, through the Spares Online e-commerce platform, provides over 80 thousand spare parts, all available for fast delivery. On the webshop, available 24/24 from all devices, the customer can keep track of the order phases: check stock availability and delivery dates in real time, print commercial documents and track the order until it is delivered to his plant. The webshop also allows the creation of wishlists for repetitive orders and enables to receive personalized offers and promotions.

"During this period the production of equipment is pushed to its maximum with demands that far exceed normal use. - comments Gianfranco Agnusdei, Global Customer Service Director, Fabio Perini S.p.A. - Unexpected equipment failure can lead to costly downtime and delays. Investing in and storing spare parts can help maximize production time and keep operations running smoothly. It is therefore critical to have an adequate supply of OEM spare parts that can help maximize operations".

Cut the greenwash. Get the facts straight about paper and recycling.

Abraham Lincoln once said, “Don’t believe everything you read on the Internet.”

I recently drew cash at an ATM and was greeted with an on-screen message: “If everyone said no to a receipt just for one month, we would save 45 trees.” This is a classic example of greenwashing: making unsubstantiated or misleading claims about the environmental benefits of a product, service, technology or company practice.

These green claims often have no scientific basis to them – environmental myths have been published so often on the internet that they are deemed as facts.

Companies would prefer that you did not print the receipt because it saves them money.

You may have been encouraged “save the planet” by opting to receive bills or magazines electronically. Again, this is a cost-saving measure, and a practical one considering the state of our local postal system (and the associated carbon footprint); but instead companies “greenwash” it by saying you’re saving trees.

Personally, I prefer to receive bills online because it’s just more convenient (not greener) – and I’m the world’s worst filer – or the world’s best piler. But give me a printed magazine over a digi-mag with page-turning sound effects any day!

The most common form of greenwash is that little footer at the bottom of emails – “think before you print”. If you need to print it, print it. And re-use it or recycle it once it’s been dealt with. If you’re going to be referring to something regularly, print it out and file it. Every time you open a document, your computer or device consumes energy – and in South Africa, we haven’t quite got the energy mix on the greener side just yet, that's if we have any at all.

Facts about forestry and farmed trees

Statements about saving trees by not printing are blatantly untrue. Firstly, the fibre for our paper and wood products is not sourced from from indigenous forests or rainforests (we don’t have rainforests in South Africa).

Paper along with a myriad of wood-, paper- and tissue-based items are made from farmed trees, and recycled paper (which came from trees in the first place). Certain species of trees are planted in crops in South Africa specifically for the paper and wood industries, with a small percentage harvested for use each year which are then replanted within the same year. This is VERY different to deforestation which is the denuding of forested land for the likes of urban development (shopping mall, our homes, office parks) and agriculture.

Plantations are also not irrigated – they get their water from rain and groundwater and the sector even pays a “rain tax” – or streamflow reduction levy.

This make trees – and anything made from them – a renewable resource. Have you ever been asked to eat less carrots or cabbage to save the vegetable farm? No, you are supporting farmers by eating their produce.

Recycling paper does not save trees

Stating that your company has saved X number of trees because you’ve implemented a paper recycling programme is also misguided. As trees are farmed for the purpose of making paper, they do not need to be saved.

Paper recycling is important for other reasons. It diverts a useful material from landfill which paper, packaging and tissue manufacturers re-use to make stuff you use every day.

The recycling of one tonne of “paper does not save 17 pine trees” but it will save around three cubic metres of landfill space and that is something to be proud of. And it keeps the carbon in the paper fibre (absorbed from the air by the tree) locked up for longer.

One person’s waste is another’s treasure

Paper recycling – from the collection and buy-back centres to the reprocessing and manufacturing into new products – also sustains local jobs.

Recycling reclaimers and waste pickers have helped to increase the collection of hard-to-get post-consumer waste, especially office paper, which is why keeping your paper recycling separate and dry is better for them – they get more for cleaner paper.

In 2018, 71.7% of recoverable paper – 1.285 million tonnes of documents, newspaper, magazines, cardboard boxes of countless kinds, and milk and juice cartons – was diverted from landfills for re-use.

Using recycled printer paper is not necessarily greener

Recycled printing and copy paper is not made in South Africa – this is imported, carrying an additional carbon footprint. Companies should be purchasing locally made copy paper. There are two well-known South African brands, both of which are certified by the Forest Stewardship Council (FSC®) as sustainably produced.

So consider the environment before you greenwash your marketing claims.

But make a noise about using locally produced paper, your successful recycling programme and that you are supporting informal collectors or small businesses by making their paper and other recyclables available to them.

For more information, visit www.thepaperstory.co.za and www.recyclepaper.co.za

Grupo Corporativo Papelera & A.Celli Paper together for the start-up of a new tissue production line

The iDEAL® mod. 2000S Tissue Machine start-up took place on March, 20th in Mexico, perfectly in line, even in advance, compared to the challenging project scheduling and despite the very critical global conditions

The new A.Celli iDEAL® Tissue Machine machine has a 2650-mm web width, a working speed of 2000 m/min and a production capacity of about 100 tpd. It was designed to answer all the requests and demands made by Grupo Corporativo Papelera, who with this step forward made its strategic investment in the world of tissue paper production thanks to a high-performance machine.

The scope of supply represents the state of the art of A.Celli technology, in particular with the following great innovations:

- 16’ Forged Yankee, innovative and unique on the market, consisting of a single piece of steel heated to more than 1200 ° C, moulded and processed using forging and hot rolling systems, from which a cylinder of homogeneous material without welds is obtained.

- Extreme Automation DCS System, completely new, intuitive and user-friendly that has allowed the customer to manage the machine autonomously from the very first day, always with the prompt remote assistance of A.Celli technicians.

The A.Celli team showed great flexibility, managing to complete a highly customized project on an engineering and assembly level.

Despite the very critical global conditions and with the extraordinary support and expertise of the Grupo Corporativo Papelera’s staff, the A.Celli team did not lose concentration, being able to manage the paper to the pope and make the first reel a few hours after the ignition.

With this new Tissue Machine A.Celli Paper will offer Grupo Corporativo Papelera a leap forward in quality, aiming for important and ambitious production milestones.

The long-standing competencies, dependable reliability and technological excellence that have always distinguished the Group make A.Celli Paper the ideal supplier for every customer.

Södra selects Ledinek’s production line for new CLT facility

Last year, Södra decided to invest in an additional CLT facility at Värö and aims to become a leader in the Nordic region. Project planning and procurement is ongoing and Södra has now selected Ledinek as the supplier of a new production line – from intake to pressing.

The new facility will be established at the combined plant in Värö, adjacent to the pulp mill, the sawmill and to Södra’s first CLT facility. Ledinek also supplied the production line for the first plant.

“We selected Ledinek because it supplies a system solution that provides security for us and for our customers. Lessons learned from the existing production line have been taken into account in the procurement of the production line for the new and larger facility. The production line will feature state-of-the-art technology and a carefully planned layout to ensure an efficient process with high productivity,” said Krister Norberg, Head of Production.

A new CLT facility with a capacity of approximately 100,000 cubic metres is an important step in being competitive in an expanding market. Demand is substantial and interest in building with timber is growing considerably.

Södra offers building systems and products such as building components and fasteners, as well as new digital services to simplify and gain better control over the construction process. The focus is on driving the development of timber-based solutions in the construction and residential sectors, and thereby creating opportunities to make a climate-conscious choice in the housing market.

Valmet to supply new reeling and winding technology for Metsä Board in Finland

Valmet will supply new reel and winding technology and surrounding equipment for Metsä Board Kyro mill in Finland. In the rebuild, new reel and winder with an automatic transfer rail connection will be installed to modernize the board machine KK 1. The start-up is scheduled for the second half of 2021.

The order is included in Valmet's orders received of the second quarter 2020. The value of the order will not be disclosed. The total value of an order of this type is typically around EUR 10-20 million.

After finalizing the deal (from left): Ari Kiviranta, Mika Sainio, Jarno Lehtonen, Marko Heikkilä (all from Metsä Board), Marko Korpinen and Sami Anttilainen (both from Valmet).

After finalizing the deal (from left): Ari Kiviranta, Mika Sainio, Jarno Lehtonen, Marko Heikkilä (all from Metsä Board), Marko Korpinen and Sami Anttilainen (both from Valmet).

“Metsä Board’s Kyro mill produces high quality coated folding boxboard and the new eco-barrier paperboard. We wanted to modernize the boardmaking finishing area and eliminate bottlenecks to meet the capacity needs of today and the future. Another important factor was reducing the risk of board caliber loss. Valmet’s reeling and winding solutions have features that fit this purpose well,” says Jarno Lehtonen, Project Manager, Metsä Board.

“In addition to Valmet’s technology, there were other important factors for getting this project. Our local presence and high expertise level in project management and production support with strong training offering will secure fast startup without any disturbance in Kyro’s supply chain,” says Marko Korpinen, Product Sales Manager, Valmet.

Gulf Paper Manufacturing Kuwait boosts capacity after dryer section rebuild by Toscotec.

Established in 1978, Gulf Paper Manufacturing was the first company to start manufacturing paper in the Gulf region in 1981. Owned by two families of Kuwaiti entrepreneurs, it operates three production lines at its Mina Abdullah paper mill in Kuwait: PM1 produces packaging grades, mainly Fluting medium, Test liner and white top liner, using 100% recycled paper; PM2 manufactures tissue from 100% virgin pulp; the third is a tissue converting line.

Its current capacity is 70,000 tons, with 70% of its packaging grades being destined for export to GCC (Gulf Cooperation Council) countries and chiefly Saudi Arabia, and the domestic market accounting for approximately 30% of its business.

Established in 1978, Gulf Paper Manufacturing was the first company to start manufacturing paper in the Gulf region in 1981. Owned by two families of Kuwaiti entrepreneurs, it operates three production lines at its Mina Abdullah paper mill in Kuwait: PM1 produces packaging grades, mainly Fluting medium, Test liner and white top liner, using 100% recycled paper; PM2 manufactures tissue from 100% virgin pulp; the third is a tissue converting line.

Its current capacity is 70,000 tons, with 70% of its packaging grades being destined for export to GCC (Gulf Cooperation Council) countries and chiefly Saudi Arabia, and the domestic market accounting for approximately 30% of its business.

In December 2019, Toscotec completed a major rebuild of its PM1 dryer section. We asked Mr. Ghaleb Al Hadhrami, Gulf Paper Manufacturing Projects & Development Manager, to talk about what they achieved with this rebuild.

Will you please tell us about yourself and your work at Gulf Paper Manufacturing?

I graduated in Paper Technology Engineering in 1981. Two years later, I joined Gulf Paper Manufacturing as a production trainee. In the following years, I held several roles at Gulf Paper until I was promoted Production Manager in 1987. During the Iraqi invasion of Kuwait in 1990, I worked as Production Engineer for Fine Group in Al Bardy Mill, Egypt and then in Nigeria for Bel Papyrus, which operated a Toscotec tissue machine. Finally, in May 1993 I went back to Gulf Paper as Production and Maintenance Manager. In 2003, the company purchased Ameer Paper Mill in Jebel Ali, Dubai. I managed this project as Project Manager first, then as Managing Director, in addition to my responsibilities at our Kuwait factory. Since 2016, I have been holding the position of Projects and Development Manager for both paper mills.

In 2019, Gulf Paper placed an order with Toscotec for a major rebuild of its PM1. What was the reason behind this investment? And why did you select Toscotec?

We had 4 main reasons to invest in this rebuild. First and foremost, we aimed to increase production. Secondly, we wanted to improve the quality of the fluting and test liner we were manufacturing. Thirdly, we wanted to reduce downtime and maintenance costs to a minimum. And finally, we wished to do a major upgrade of PM1 in order to equip it with state-of-the-art technology.

We chose Toscotec because they were the first paper machinery manufacturer to introduce steel dryers, and then steel Yankee dryers, on the market. They have installed TT SteelDryers all over the world and have successfully proven the advantages of this technology compared to cast iron cylinders. At present, they are the supplier with the most extensive experience in the design, manufacturing, operation and maintenance of steel dryers.

Why did you choose Toscotec as your supplier?

We chose Toscotec as supplier of the whole mechanical project because of their good reputation in the market, high equipment quality, their commitment, competitive prices and strict project guarantees. I am extremely satisfied with the format of the supply including the erection from the same company. I would chose it again in the future and I would recommend Toscotec to my contacts in the paper industry.

Focusing on the project, what did you achieve with this rebuild?

First, in terms of time schedule, the machine downtime was implemented precisely according to the GANTT project timetable that Toscotec provided at the beginning. In the end, PM1 was started up ahead of schedule.

Second, in terms of our targets, within two months from start-up, the production increased by 15% and we expect to achieve an increase of over 20% within the next few months after removing the stock preparation bottlenecks we currently have.

Third, the dryer section efficiency we achieved with the new TT SteelDryers and the steam & condensate removal system is higher than we predicted.

Finally, we registered a significant improvement in product quality, particularly in the moisture and basis weight profiles, as well as the final hand feel.

Are you satisfied with the new silent drive configuration?

We are very satisfied with it! PM1 is now running very silently, without noise or vibration.

What about energy efficiency: did you achieve a reduction of your energy consumption?

Yes, after the rebuild, we witnessed a significant reduction of our energy consumption figures. In particular, we cut down the electric power consumption in the drives by 35% and the diesel consumption in the steam boilers by 15%.

How would you describe the cooperation with Toscotec?

Toscotec team proved to be highly skilled and very cooperative. They were very committed throughout the entire project and were able to take fast decisions and come back with responses to our problems. We felt they had a good understanding of our needs and factored those in effectively in planning and follow-up phases.

During the erection, the onsite team was very professional and hardworking. They ensured the completion of commissioning and start-up in time and up to our quality standards. Finally, after start-up, Toscotec supported us to achieve stable operations in a very short time.

We asked Mr. Ghaleb Al Hadhrami, Gulf Paper Manufacturing Projects & Development Manager, to talk about what they achieved with this rebuild.

Will you please tell us about yourself and your work at Gulf Paper Manufacturing?

I graduated in Paper Technology Engineering in 1981. Two years later, I joined Gulf Paper Manufacturing as a production trainee. In the following years, I held several roles at Gulf Paper until I was promoted Production Manager in 1987. During the Iraqi invasion of Kuwait in 1990, I worked as Production Engineer for Fine Group in Al Bardy Mill, Egypt and then in Nigeria for Bel Papyrus, which operated a Toscotec tissue machine. Finally, in May 1993 I went back to Gulf Paper as Production and Maintenance Manager. In 2003, the company purchased Ameer Paper Mill in Jebel Ali, Dubai. I managed this project as Project Manager first, then as Managing Director, in addition to my responsibilities at our Kuwait factory. Since 2016, I have been holding the position of Projects and Development Manager for both paper mills.

In 2019, Gulf Paper placed an order with Toscotec for a major rebuild of its PM1. What was the reason behind this investment? And why did you select Toscotec?

We had 4 main reasons to invest in this rebuild. First and foremost, we aimed to increase production. Secondly, we wanted to improve the quality of the fluting and test liner we were manufacturing. Thirdly, we wanted to reduce downtime and maintenance costs to a minimum. And finally, we wished to do a major upgrade of PM1 in order to equip it with state-of-the-art technology.

We chose Toscotec because they were the first paper machinery manufacturer to introduce steel dryers, and then steel Yankee dryers, on the market. They have installed TT SteelDryers all over the world and have successfully proven the advantages of this technology compared to cast iron cylinders. At present, they are the supplier with the most extensive experience in the design, manufacturing, operation and maintenance of steel dryers.

Why did you choose Toscotec as your supplier?

We chose Toscotec as supplier of the whole mechanical project because of their good reputation in the market, high equipment quality, their commitment, competitive prices and strict project guarantees. I am extremely satisfied with the format of the supply including the erection from the same company. I would chose it again in the future and I would recommend Toscotec to my contacts in the paper industry.

Focusing on the project, what did you achieve with this rebuild?

First, in terms of time schedule, the machine downtime was implemented precisely according to the GANTT project timetable that Toscotec provided at the beginning. In the end, PM1 was started up ahead of schedule.

Second, in terms of our targets, within two months from start-up, the production increased by 15% and we expect to achieve an increase of over 20% within the next few months after removing the stock preparation bottlenecks we currently have.

Third, the dryer section efficiency we achieved with the new TT SteelDryers and the steam & condensate removal system is higher than we predicted.

Finally, we registered a significant improvement in product quality, particularly in the moisture and basis weight profiles, as well as the final hand feel.

Are you satisfied with the new silent drive configuration?

We are very satisfied with it! PM1 is now running very silently, without noise or vibration.

What about energy efficiency: did you achieve a reduction of your energy consumption?

Yes, after the rebuild, we witnessed a significant reduction of our energy consumption figures. In particular, we cut down the electric power consumption in the drives by 35% and the diesel consumption in the steam boilers by 15%.

How would you describe the cooperation with Toscotec?

Toscotec team proved to be highly skilled and very cooperative. They were very committed throughout the entire project and were able to take fast decisions and come back with responses to our problems. We felt they had a good understanding of our needs and factored those in effectively in planning and follow-up phases.

During the erection, the onsite team was very professional and hardworking. They ensured the completion of commissioning and start-up in time and up to our quality standards. Finally, after start-up, Toscotec supported us to achieve stable operations in a very short time.

Fabio Perini solutions to guarantee operational continuity in times of Coronavirus

Augmented reality, a team of online experts, and the Tissue Performance Center for real time monitoring and technical support to the lines

The power of technology and human ingenuity allows solving problems thousands of kilometers away, without moving engineers nor tools, with the recourse to remote assistance and augmented reality. Fabio Perini has been working for a long time at solutions for remote and real time assistance to monitor information about the status of the lines, as well as for intervening in a punctual, timely manner. These solutions are proving particularly effective in circumstances like the present one.

“In these days of emergency, – Oswaldo Cruz Junior, Fabio Perini S.p.A. CEO, comments – Fabio Perini is able to offer concrete and effective support to its customers, to guarantee their operational continuity: we have in place already an outstanding infrastructure for remote connectivity and we can count on our global presence and on the know-how of all our teams around the world".

The Tissue Performance Center is a state-of-the-art technological environment where experienced technicians, with the support of the company's data scientists, continuously collect and analyze customer data to provide information on the status of their machines and suggest improvements to maximize the Overall Equipment Effectiveness (OEE) of their production lines.

A direct connection to the customers' machines makes the Tissue Performance Center's work proactive by predicting potential downtime. Thanks to the visualization of the operating parameters, the online team of experts provides an assessment of the health status of the lines and highlights any anomalies. Periodically, the customer also receives a "medical record" on the production status of the connected lines and identifies, together with Fabio Perini's converting experts, what improvements can be implemented.

"At Fabio Perini we have more than 10 people who provide assistance to over 60 customers who are sharing with us the data of 1000 machines – Gianfranco Agnusdei, Fabio Perini S.p.A. Global Customer Service Director, comments – Whenever we find anomalies, we immediately contact our customers, help them identify the causes, find appropriate solutions and thus reduce costly downtime. In the future we could also offer a predictive maintenance service: this will allow us to anticipate and thus further improve performance".

The technical support is complemented by the TeamViewer Pilot, an augmented reality technology that allows viewing machines remotely to evaluate problems and suggest appropriate solutions. Through a video streaming directly from the camera of the smartphone and tablet, in real time, Fabio Perini technicians, also through 3D markers and indications applied to the real environment, are able to observe any problem and are able to guide the customer to a complete and rapid solution of the problem, anywhere in the world.

Launch of the European alliance for a Green Recovery

Cepi, the Confederation of European paper industries and its members across Europe, strongly support the initiative of Pascal Canfin, Chair of the Environment Committee at the European Parliament, to launch a European alliance for a Green Recovery. Cepi joins 180 political decision-makers, business leaders, trade unions, NGOs, and think tanks who have come together to create the alliance.

In the face of the coronavirus crisis, the biggest challenge Europe has faced in peacetime, with devastating consequences and a shock to the economy tougher than the 2008 crisis, Ministers from 11 countries, 79 cross-party MEPs from 17 Member States, 37 CEOs, 28 business associations representing 10 different sectors, trade union confederation representing members from 90 national trade union organisations and 10 trade union federations, 7 NGOs and 6 think tanks, have committed to working together to create, support and implement solutions to prepare our economies for the world of tomorrow.

This first pan-European call for mobilisation on post-crisis green investment packages will work to build the recovery and transformation plans which enshrine the fight against climate change and biodiversity as a key pillar of the economic strategy.

This first pan-European call for mobilisation on post-crisis green investment packages will work to build the recovery and transformation plans which enshrine the fight against climate change and biodiversity as a key pillar of the economic strategy.

Sharing the belief that the economic recovery will only come with massive investments to protect and create jobs and to support all companies, regions and sectors that have suffered from the economy coming to a sudden halt, the alliance commits to contribute to the post-crisis investment decisions needed to reboot and reboost our economy.

Covid-19 will not make climate change and nature degradation go away. The fight against this crisis will not be won without a solid economic response. The alliance commits to participate in the fight and the victory of these two battles simultaneously, and by doing so, being stronger together.

About Cepi: Cepi is the European association representing the paper industry.

We offer a wide range of renewable and recyclable wood-based fibre solutions to EU citizens: from packaging to textile, hygiene and tissue products, printing and graphic papers as well as speciality papers, but also bio-chemicals for food and pharmaceuticals, bio-composites and bioenergy.

We are a responsible industry: 92% of our raw materials are sourced in Europe and certified as sustainable, 91% of the water we use is returned in good condition to the environment. We are the world champion in recycling at the rate of 71,6%. At the forefront of the decarbonisation and industrial transformation of our economy, we embrace digitalisation and bring 20 billion value addition to the European economy and €5.5 billion investments annually.

Through its 18 national associations, Cepi gathers 500 companies operating 895 mills across Europe and directly employing more than 180,000 people.

A.Celli Rebuilding: Tissue Rewinder upgrades for KC Products Malaysia

Kimberly Clark Products Malaysia, Kluang Johor Mill: A.Celli concludes the scheduled upgrade of the TM2 Tissue Line with a new off-line shaft puller and a new set of expandable spool, in combination with the upgrade of the rewinder slitting unit

After the upgrade of the TM1 rewinder and other tissue line equipment, A.Celli Paper’s Customer Service team installed and successfully concluded the upgrades on the TM2 tissue line.

The intervention entailed updating the core handling system downstream the TM2 pope reel with the supply of the A.Celli off-line shaft puller. Since this an automated process, it allows the customer to improve and accelerate the shaft extraction from the mother roll and to improve KC Products Malaysia personnel safety. The rebuilding of the TM2 line has been completed with the upgrade of the Rewinder slitting section with a modern and efficient knives system.

A.Celli Paper worked in close contact with the customer, finding the optimal solution for a light-impact modification with a short shutdown time. The new configuration kept into consideration the convenience of the operations that had to be carried out on one hand and the needs of KC Products Malaysia on the other, in order to obtain the best results in terms of efficiency.

The customer was very appreciative of the project, acknowledging the high level of professionalism of A.Celli Paper’s Customer Service team and its ability to find functional, practical and intelligent solutions through engineering and design analyses.

A.Celli Paper is capable of offering prompt and effective consultancy in-line with any type of investment and production demand.

Contact us for a consultancy or a dedicated project.

New Engineering, Procurement and Construction Management (EPCM) services assignment for the LD Celulose S.A. pulp mill in Brazil

LD Celulose S.A. new dissolving pulp plant will produce 500,000 tons per year. The completion of the project is scheduled for 2022.

LD Celulose S.A., a joint venture between Duratex and Lenzing group, awarded Pöyry, part of AFRY, with an EPCM (Engineering, Procurement, Construction Management) assignment for the BOP (Balance of Plant) of the plant that will have the capacity to produce 500,000 tons of dissolving pulp per year and will represent an investment of US $ 1.3 billion. The services provided by Pöyry, part of AFRY, include interconnections between all process areas, turbo generators and steam distribution systems, the water cooling center and other complimentary systems.

Pöyry has been working as LD Celulose´s partner already, before the joint venture was formed, being responsible for conceptual and basic engineering development, detailed infrastructure engineering projects, external logistics studies and composing area projects, as well as supporting the project's environmental licensing process.

Pöyry has been working as LD Celulose´s partner already, before the joint venture was formed, being responsible for conceptual and basic engineering development, detailed infrastructure engineering projects, external logistics studies and composing area projects, as well as supporting the project's environmental licensing process.

Luís Künzel, CEO of LD Celulose S.A. emphasizes that the new dissolving pulp plant will bring a positive socioeconomic impact throughout the region. “Our intention is to benefit the municipalities that comprise the hub, providing opportunities in various sectors. We are committed to working with the best environmental practices, and Pöyry's expertise and ability to provide sustainable engineering solutions make it the ideal partner to lead this process, from the initial stages of the project” states Künzel.

“We are very proud to have been awarded this important assignment, which reflects the solid evolution of this trusted partnership, and leading solutions for generations to come”, says Fábio Bellotti da Fonseca, President of Pöyry in Brazil.

The LD Celulose new plant will be installed in Duratex's forest area, located in Triângulo Mineiro (MG), and all production will be destined for exportation, supplying Lenzing group's operations in Europe and Asia.