Super User

Toscotec completes a major rebuild of Arapepco’s PM1 in Aleppo, Syria.

The Arab Company For Paper Products Ltd. (Arapepco) successfully started up its PM1 at Khan Al-Asal paper mill, near Aleppo, Syria, after a major rebuild supplied by Toscotec. The paper machine features a reel trim width of 2,850 mm, 800 mpm design speed, and produces fluting and test liner in the range of 105 to 200 gsm using 100% recycled paper. Toscotec carried out a complete rebuild of PM1 from the press section to the pope reel.

Previously, the paper machine was rebuilt by Toscotec in the forming area with the installation of a TT Headbox and modification of the Fourdrinier section, as well as a dryer section rebuild.

The latest rebuild comprises the press section, dryer section and pope reel. The former included the supply of a combi plus jumbo press and a size press. For the dryer section, Toscotec provided its energy-efficient TT SteelDryers featuring 10 bar maximum operating steam pressure, and a tail threading system with air and rope. The supply also included some approach flow system equipment, TT Unirolls, as well as a completely new pope reel and a rewinder unwind stand.

The targets of the rebuild are to increase PM1 production capacity, to extend the range of products produced and to improve paper quality.

Hasan Badinjki, Chairman of Arab Company for Paper Products Ltd., says, “This project is a miracle. We implemented it during the conflict with Toscotec’s support and it truly required all our efforts to get to today’s result. We upgraded the machine with the latest technology and it is currently performing very well. Arapepco aims to install a top layer in 2021 to meet increasing market demand especially for white top.”

Enrico Raffanti, Toscotec’s P&B Technical Manager, says, “Due to difficult country situation in Syria in the recent past, this project represented a real challenge from many points of view. We continuously supported Arapepco from our headquarters and on site, and finally we carried out a comprehensive rebuild of the existing PM1 into a state-of-the-art paper machine. Such a positive outcome is indeed a source of great satisfaction for both our work teams. I congratulate Arapepco for their strong determination to complete this project successfully.”

About Arab Company for Paper Products Ltd.

Arapepco is a privately owned company established in 1994 by the Badinjki family. It produces paper and cardboard products including fluting, test liner paper, coloured wrapping paper and carton, grey board and formica using 100% recycled fibres. The company employs 160 staff and its production base covers an area of 24,000 sq.m.

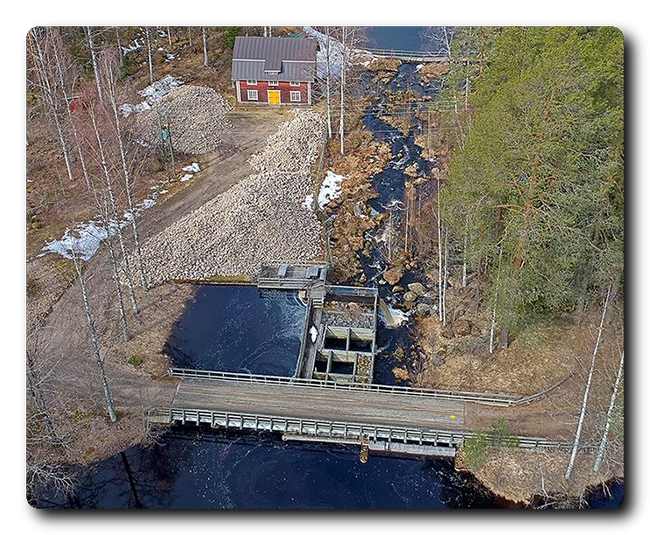

Metsä Board to restore fish migration routes

Metsä Board, the leading European producer of premium fresh fibre paperboards and part of Metsä Group, has started a rapids fishery restoration project together with WWF Finland and the local Centre for Economic Development, Transport and the Environment. Construction work at Mämmenkoski, located in Äänekoski in Central Finland, began in early May and will take a month to complete.

The aim of the restoration is to make it possible for fish to naturally migrate from Lake Kuhnamo to Lake Ala-Keitele. In addition, it is hoped that it will re-establish the possibility of natural fry production of lake trout in the rapids. The restoration project will open two existing dams to remove obstacles from the fish migration route. The riverbed will be restored into a natural migration route and spawning areas will be formed to enable natural fry production of the trout. The project has been developed in cooperation with the local fishery community.

ANDRITZ to supply high-speed spunlace line to Karweb Nonwovens, Turkey

International technology Group ANDRITZ has received an order from Karweb Nonwovens to supply a complete neXline spunlace line for its plant located in Gaziantep, Turkey.

The line is scheduled for installation and start-up at the beginning of 2021.

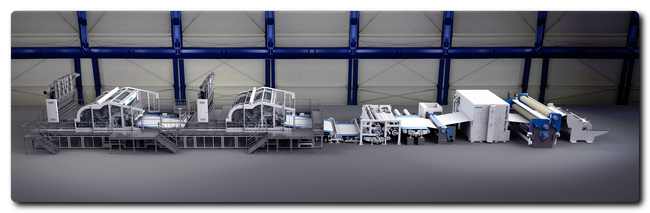

ANDRITZ neXline spunlace eXcelle line © ANDRITZ

ANDRITZ neXline spunlace eXcelle line © ANDRITZ

This new neXline spunlace eXcelle line is dedicated to the production of viscose and polyester wipes as well as biodegradable wipes. The production capacity can be up to 18,000 t/a.

ANDRITZ will provide a full line with state-of-the-art equipment – from web forming to drying. The scope of supply includes the complete opening and blending machinery, two inline high-speed TT cards, a proven JetlaceEssentiel unit (including a water filtration unit) for hydroentanglement, a neXdry through-air dryer, and a neXecodry S1 system for energy saving.

This order confirms the strong and successful relationship between ANDRITZ and Karweb Nonwovens. In 2017, ANDRITZ supplied a spunlace line to Karweb for production of roll-goods made from several types of fibers, such as polyester, viscose, Tencel, cotton and polyamide.

Karweb Nonwovens spunlace line © ANDRITZ

Karweb Nonwovens spunlace line © ANDRITZ

Karweb Nonwovens, founded in 2013, is a division of Kara Holding and the first and only Turkish manufacturer of airlaid products for health care, hygiene and special disposable materials. The company serves customers worldwide.

ANDRITZ GROUP International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 29,500 employees and more than 280 locations in over 40 countries.

PMP delivered its first steel Yankee dryer to Poland for FP Kaczory, Poland!

In November, 2018, PMP (Paper Machinery Producer) signed a contract for a modernization of a tissue machine that includes a delivery of a new Intelli-YD® steel Yankee dryer to FP Kaczory paper mill located in Poland. It is a great pleasure to announce that PM#2 with new equipment is up & running. The start-up took place in 4th quarter of 2019.

Thanks to an optimized design, PMP Yankee dryer achieves up to 15% higher drying efficiency compared to previous technologies. Intelli-YD® allows to save energy and money and ensures high durability. PMP has 18 working references of steel Yankee dryers all over the world and the project for FP Kaczory is the first reference in Poland.

PM#2 produces tissue with maximum operation speed of 1500 mpm and paper trim 3150 mm. This steel Yankee dryer diameter is 4500 mm, shell length is 3550 mm and maximum operating pressure of Intelli-YD® reaches 9,5 barg. PMP scope of supply included also spare parts, erection and start-up supervision services.

About PMP:

PMP is a global provider of tissue, paper & board technology and has been supporting the pulp and paper industry for over 165 years, executing projects on 6 continents, in 35 countries. The Company has its headquarters in Jelenia Góra, Poland and has 7 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both the paper & tissue industry. Learn more about PMP at: www.pmpgroup.com

About FP KACZORY:

Dynamically developing company that has been operating since 1992, specialized in waste paper processing and toilet paper production in production plant in Kaczory and pulp products in a second production plant in Margonin, the company offer wide range of products. FP Kaczory owns two production plants in Poland.

New L&W Autoline offers fastest, most reliable automated paper testing solution

ABB’s next-generation system provides rigorous quality control information, up to 10 times faster than manual testing, to enable the rapid reduction of off-spec production

Technology leader ABB announces its enhanced L&W Autoline automated paper testing systemscalable to fit any lab and user-friendly in operation for those new to automated testing. The fast, accurate solution optimizes quality control and minimizes operational costs for all papermaking operations.

For intuitive simplicity, L&W Autoline incorporates a unique, visual touchscreen interface, requiring minimal training to master. Other features include the smoothest and most reliable feeding system on the market, that pulls the samples through the machine to minimize jamming; a unique dual test function to reduce queuing by allowing simultaneous testing; high-volume information storage, enabling identification of quality trends over time; and real-time visualization, providing direct feedback to operators on the unit and throughout the mill.

The system—which can handle everything from sample preparation to the final reel report—radically reduces dependence on manual testing, enabling resources to focus on continuous and sustainable quality improvements while reducing quality control costs.

“Our pioneering L&W Autoline automated paper testing solution plays a crucial role in mill digitalization by enabling faster, smarter decision-making and process adjustments,” said Per Sandstrom, head of lab and process testing measurements for ABB pulp and paper. “With this system, customers gain the benefits of direct access to more information in less time, in a scalable package suitable for operations of all sizes.”

The speed at which the system gathers information and highlights off-spec data facilitates rapid process tuning 24/7, 365 days of the year. Visualizations are instantly available in real time to operations and engineering personnel both locally and remotely, to ensure production targets and quality specifications are fulfilled.

Building on the legacy of almost 50 years of automatic paper testing, L&W Autoline now comes in two different sizes: L&W Autoline S has a reduced footprint for smaller mills and those new to automated testing. L&W Autoline L is a larger unit, designed for more extensive testing requirements.

Both options share the same feature set, including sequential testing coupled with the ability to capture more than 100 quality parameters by CD position, providing a high quantity and quality of information for fast corrective action.

L&W Autoline is part of the ABB Ability™ Quality Management System (QMS) solution suite, ABB’s complete offering for optimizing paper quality.

For more information about the solution go to new.abb.com/pulp-paper/abb-in-pulp-and-paper/products/lorentzen-wettre-products/automated-paper-testing

ABB is a trusted partner and leading supplier to the pulp and paper industry, offering deep expertise and a comprehensive portfolio of integrated digital solutions, automation and electrification systems, industry-focused products and comprehensive services to help our customers optimize all phases of the papermaking process. We are committed to serving packaging, paper, tissue and pulp producers to help drive availability, performance, cost and quality improvements. Active worldwide, ABB has over 1000 pulp and paper professionals who serve customers in over 50 countries. www.abb.com/pulpandpaper

ABB (ABBN: SIX Swiss Ex) is a technology leader that is driving the digital transformation of industries. With a history of innovation spanning more than 130 years, ABB has four customer-focused, globally leading businesses: Electrification, Industrial Automation, Motion, and Robotics & Discrete Automation, supported by the ABB Ability™ digital platform. ABB’s Power Grids business will be divested to Hitachi in 2020. ABB operates in more than 100 countries with about 144,000 employees. www.abb.com

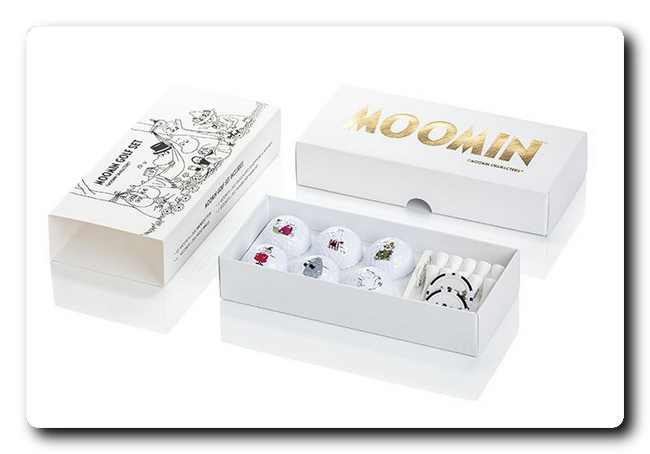

Metsä Board helps to create appealing and sustainable Moomin golf ball gift pack

An attractive gift item requires an equally impressive package. Together with its partner network Metsä Board’s packaging design team helped to create an appealing package for a luxury golf ball gift set featuring the universally loved Moomin characters - Metsä Board is a leading European producer of fresh fibre paperboards and part of Metsä Group.

Aki Kuivaniemi, Managing Director of the end client Golf Coat explained “We wanted the packaging to be both appealing and luxurious, and also as sustainable as possible. It is important that we take the environment into consideration in everything we do from the product to its packaging.”

“Our aim was to create a packaging that both protects its contents and also displays the products inside as well as possible. We also considered the unboxing experience and that it conveys the feeling of luxury,” said Ilkka Harju, Metsä Board’s Packaging Services Director EMEA and APAC.

The box material is an all-white N-flute corrugated board, produced from MetsäBoard Natural WKL Bright. It is lightweight but strong and recyclable. The package is composed of the same white kraftliner for all layers with gold foil on the lid, which gives an exclusive feel when touching the package. The Moomin characters are printed on the packaging sleeve which is made from MetsäBoard Natural FBB folding boxboard. The packaging was manufactured by Finnish Cadpack that also participated in the design process.

Essity interim Report First Quarter 2020

The Group’s net sales increased 10.0% in the first quarter of 2020 compared with the corresponding period a year ago. Organic net sales increased 7.8%, of which volume accounted for 5.9% and price/mix for 1.9%. In mature markets, organic net sales increased 10.2%. In emerging markets, which accounted for 35% of net sales, organic net sales increased 4.0%.

- Net sales increased 10.0% to SEK 33,712m (30,656)

- Organic net sales increased 7.8%

- The COVID-19 pandemic resulted in a sharp increase in sales and earnings in March 2020 as a result of stockpiling among consumers and distributors

- In emerging markets, which accounted for 35% of net sales, organic net sales increased 4.0%

- Operating profit before amortization of acquisition-related intangible assets (EBITA) increased 77% to SEK 5,316m (3,002)

- Adjusted EBITA increased 67% to SEK 5,333m (3,190)

- Adjusted EBITA margin increased 5.4 percentage points to 15.8% (10.4)

- Profit for the period increased 87% to SEK 3,610m (1,929)

- Earnings per share increased 85% to SEK 4.61 (2.49)

- Adjusted earnings per share increased 69% to SEK 4.83 (2.86)

- Cash flow from current operations increased 25% to SEK 3,044m (2,434)

The COVID-19 pandemic resulted in a sharp increase in sales in many markets for Consumer Tissue, Incontinence Products, Baby Care, Feminine Care and Professional Hygiene as a result of stockpiling among consumers and distributors. In March 2020, organic net sales for the Group increased 19.7% compared with March 2019. Organic net sales for Personal Care rose by 17.0%, for Consumer Tissue by 19.5% and for Professional Hygiene by 24.5%. Sales in future quarters will be adversely impacted by the stockpiling seen in March and sales in Professional Hygiene will also be negatively impacted by reduced travel, fewer restaurant visits and more people working from home. In the long-term, the COVID-19 pandemic may lead to increased demand for hygiene and health products due to, for example, a greater focus on hand hygiene.

The COVID-19 pandemic resulted in a sharp increase in sales in many markets for Consumer Tissue, Incontinence Products, Baby Care, Feminine Care and Professional Hygiene as a result of stockpiling among consumers and distributors. In March 2020, organic net sales for the Group increased 19.7% compared with March 2019. Organic net sales for Personal Care rose by 17.0%, for Consumer Tissue by 19.5% and for Professional Hygiene by 24.5%. Sales in future quarters will be adversely impacted by the stockpiling seen in March and sales in Professional Hygiene will also be negatively impacted by reduced travel, fewer restaurant visits and more people working from home. In the long-term, the COVID-19 pandemic may lead to increased demand for hygiene and health products due to, for example, a greater focus on hand hygiene.

During the COVID-19 pandemic, Essity has three main priorities: care for our employees, continuing to operate a successful business and contributing to society. To maintain a safe work environment for our employees, satisfy increased demand and safeguard production and logistics, we have carried out measures in all parts of the business, including new ways of working for our employees, production adaptations and securing transportation. We have increased our presence and activity in digital sales channels. We contribute to society by delivering our leading hygiene and health solutions. In Sweden, the US and Mexico, we are investing in the production of surgical masks and face masks for the healthcare sector and our employees. We support the WHO COVID-19 Solidarity Response Fund and several local initiatives.

The Group’s adjusted gross margin for the first quarter of 2020 increased 5.6 percentage points to 32.8% compared with the corresponding period in the preceding year. The gross margin was positively impacted by higher volumes, a better mix and costs savings. Continuous cost savings amounted to SEK 260m. Lower raw materials and energy costs increased the gross margin by 4.7 percentage points. Lower raw material costs were primarily the result of lower pulp prices. Our production facilities outside of China did not experience any major production disruptions due to the COVID-19 pandemic, although distribution costs have increased. Lower prices, mainly related to Consumer Tissue in Europe and Asia, had a negative impact on the gross margin. The Group’s adjusted EBITA margin rose 5.4 percentage points to 15.8%. Investments in growth increased sales and marketing costs, also as a share of net sales. Adjusted EBITA for the first quarter of 2020 increased 67% compared with the same period in the preceding year. Adjusted return on capital employed rose 7.1 percentage points to 18.4 percent. Operating cash flow increased 108%. Earnings per share increased 85% to SEK 4.61.

Essity has a robust financial position and a solid funding situation. At March 31, 2020, net debt in relation to adjusted EBITDA was 2.09. The rapid spread of COVID-19 pandemic and related countermeasures mean the level of uncertainty in future forecasts is much greater than normal. At the Annual General Meeting, it was decided not to pay a dividend for 2019. The Board of Directors has announced that it intends to revisit the issue concerning a dividend later in the year when a better overview can be gained of the effects of the ongoing COVID-19 pandemic.

FUTURE REPORTS

In 2020, interim reports will be published on July 17 and October 22.

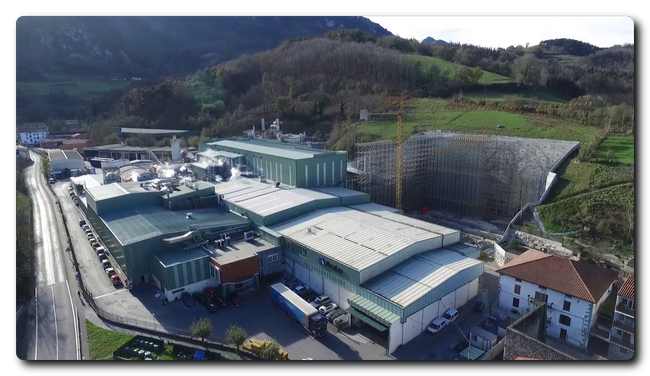

Paper machine for sustainable wet wipes by Voith and Trützschler for Papel Aralar S.A.

The Spanish paper factory Papel Aralar commissioned Voith and the nonwoven fabric expert Trützschler Nonwovens to deliver a new system for specialty paper production. The PM 5 was developed as a joint project by both companies specifically for the wiping cloth industry. Delivery is planned for September 2020.

Aralar site in Amezketa, Spain

Aralar site in Amezketa, Spain

The special sustainable feature of the wet-laid machine ordered is that the adult and baby wet wipes it produces are completely plastic-free, flushable and biodegradable, a characteristic that conventional wet wipes do not have.

HydroFormer and AquaJet for high-performance Wet-Laid Spunlacing

Voith supplies the HydroFormer, which is one of the main components of the new system. The HydroFormer technology draws on Voith’s extensive experience in the paper-making and pulp industries. In this technology, the suspension is heavily diluted to produce nonwoven materials made completely of cellulose, a renewable resource. Besides the HydroFormer, the Heidenheim-based technology company also supplies the stock preparation system, a master reel, and the wet end process for the new system constructed in accordance with the Process Line Package (PLP). A comprehensive automation and control package is also included in the delivery.

Trützschler Nonwovens completes the production process with the proven AquaJet technology for spunlacing and a multi-drum dryer. The many years of expertise and experience of the Trützschler company form the basis of the components that have been adapted to the needs of the wet-laid process.

A.Celli Nonwovens: a new complete Spunlace line for Karweb Nonwovens

A.Celli Nonwovens SpA is honored to continue the fruitful collaboration with Karweb Nonwovens thanks to the supply of a winding line dedicated to the production of Spunlace

Karweb Nonwovens, a division of the KARA Holding Co. and one of the major player active in the production of Spunlace and Airlaid, has renewed, after a first order made in 2016, the trust in A.Celli and its cutting-edge solutions in the nonwoven market.

The installation and start-up of the line, which will take place in the Turkish plant of Karweb Nonwovens located in Gaziantep, are scheduled for early 2021. A.Celli's supply includes a “Stream” Master Roll winder, an off-line slitter rewinder “Rapid” with an operating speed of 800m/minute and equipped with trim suction system, a shaft handling solution with "easy core" positioning device and a finished reel handling and packaging system.

A further confirmation of the customer's trust in A.Celli Nonwovens technology, that thanks to this supply proves, as always, to be at the cutting edge of the market and able to satisfy any type of requirement with flexibility and readiness.

Södra result in line with expectations but the future is difficult to predict

Despite dramatically changed conditions in the wake of the COVID-19 pandemic, production rates at Södra’s facilities remained high and stable in the first quarter. Sales amounted to SEK 5,576 million (6,318). Operating profit for the quarter totalled SEK 227 million (1,148). At the end of the quarter, cash and cash equivalents and current investments amounted to SEK 2,627 million (1,527) and the equity ratio was 60 percent.

Peter Karlsson, Interim President and CEO“In the wake of the ongoing global spread of COVID-19, conditions changed dramatically towards the end of the first quarter. Södra has taken a number of steps to protect our employees, customers and suppliers in the first instance, but also any others that we come into contact with in order to save lives and protect health. “It is with great gratitude that I see how we are working together to slow the spread of the virus and to mitigate the negative effects of the ongoing crisis,” said Peter Karlsson, Interim President and CEO.

Peter Karlsson, Interim President and CEO“In the wake of the ongoing global spread of COVID-19, conditions changed dramatically towards the end of the first quarter. Södra has taken a number of steps to protect our employees, customers and suppliers in the first instance, but also any others that we come into contact with in order to save lives and protect health. “It is with great gratitude that I see how we are working together to slow the spread of the virus and to mitigate the negative effects of the ongoing crisis,” said Peter Karlsson, Interim President and CEO.

“The economic slowdown from 2019 was replaced by a general decline in supply and demand due to the outbreak of COVID-19, and the consequences are difficult to predict at present. Nonetheless, the first quarter result was in line with expectations. Net sales amounted to SEK 5,576 million (6,318) and operating profit totalled SEK 227 million (1,148),” said Karlsson. “Demand for Södra’s core products was favourable, although prices for paper pulp and sawn timber remained low during the quarter, albeit slightly higher at the end of the quarter compared with the beginning of the year.

“The necessary adjustment to these changed market conditions has been handled impressively by all employees in our respective operations. Without this commitment, we would not be so well-equipped to meet the future,” said Karlsson. “So, although the global economy is now slowing down, it is important that we maintain a long-term approach. Economic cycles will always cause market conditions to fluctuate, but in the long run, there is an underlying and steadily rising demand for forest-based products,” Karlsson concluded.

***********

During the first quarter, consolidated net sales amounted to SEK 5,576 million (6,318), down 12 percent year-on-year. Operating profit totalled SEK 227 million (1,148) and the decline in profitability was due to lower price levels for paper pulp and sawn timber. The result corresponds to an operating margin of 4 percent (18). Return on capital employed was 4 per cent (22). At the end of the quarter, cash and cash equivalents and current investments amounted to SEK 2,627 million (1,527) and the equity ratio was 60 percent.

Södra Skog’s operating profit for the period totalled SEK 1 million (56). The result was due to weaker margins. During the period, Södra Skog acquired 4.9 million m³sub, comprising 54 percent pulpwood and cellulose chips, 32 percent saw logs and 14 percent biofuels.

Södra Wood’s operating profit for the period totalled SEK 22 million (147) and reflects the considerably lower price formation for sawn timber. Underlying demand for sawn timber also remained favourable. Sales for the quarter amounted to SEK 1,507 million (1,498). The delivery volume from Södra Wood rose to 519 km³ SW, compared with 476 km³ SW in the year-earlier period.

Södra Cell’s operating profit for the period totalled SEK 302 million (1,112). The earnings decline was due to a weaker price level, while higher volumes and a more favourable USD exchange rate had a positive impact. Sales for the quarter amounted to SEK 2,867 million (3,501). The production volume totalled 474 ktonnes, comprising 402 ktonnes of softwood sulphate pulp, 34 ktonnes of hardwood sulphate pulp and 38 ktonnes of dissolving pulp.