Super User

The 300th Valmet Paper Lab system will be delivered to Papierfabrik Palm in Germany

Valmet will supply the 300th Valmet Paper Lab automated board and paper testing laboratory to Papierfabrik Palm's (Palm) Aalen-Neukochen mill. In total, Valmet will deliver three Valmet Paper Labs to the company’s Descartes mill in France and Wörth and Aalen-Neukochen mills in Germany. Valmet Paper Lab delivers accurate and rapid measurement results that are used either as a quality stamp for the end-product or for the board machine operation optimization.

The two Valmet Paper Lab systems were included in Valmet's orders received of the fourth quarter 2019 and one is included in the first quarter 2020. The systems will be delivered during the year 2020. The value of the order will not be disclosed. The Valmet Paper Lab systems will be equipped with a large scope of measurements for the board application quality stamp.

Valmet Paper Lab is extending the scope of Palm Aalen-Neukochen mill where Valmet will also supply a containerboard machine (PM 5) with extensive packages of mill-wide automation and services.

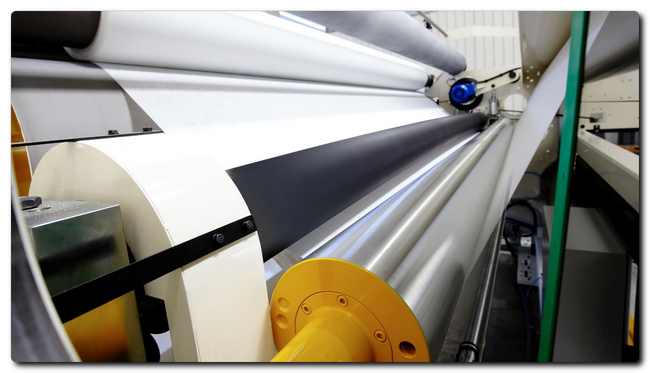

Valmet Paper Lab is an automated board and paper testing laboratory

Valmet Paper Lab is an automated board and paper testing laboratory

“Palm Group has awarded Valmet by selecting us as the supplier of their end-product quality analyzer. We have a long cooperation with Palm Group, and it is great to see that we can keep on helping them to move their performance forward, both technology and product support wise. It is a significant milestone that the 300th Valmet Paper Lab unit will be delivered to the site where Valmet also supplies the world’s largest containerboard machine,” says Bogdan Pavlovic, Business Manager, Board and Paper Analyzers, Valmet.

Technical details about the delivery

Valmet Paper Lab is a modular and scalable automated paper testing system for grades of paper and board. With the widest selection of industry-standard tests on the market, reporting can detail over 400 properties. The testing system is based on several decades of automated paper testing experience with 300 units delivered to paper and board mills around the world.

Valmet Paper Lab provides an easy-to-learn and intuitive tool for paper and board property testing which together with Valmet’s Industrial Internet remote support can take the automated laboratory’s performance to a new level.

Information about the customer Papierfabrik Palm

Palm is one of the leading companies in the European paper industry and Germany's largest family-owned business in the paper industry. The Palm Group is divided into the paper division with its 5 paper mills for the manufacture of paper and the packaging division with 28 corrugated cardboard plants. The third pillar of Palm's operations, which encompasses the purchasing of raw materials for all its papers, and corrugated boards made from 100% recycled paper are joined under the umbrella of Palm Recycling consisting of two recycling companies. The plant in Aalen-Neukochen is the origin and the head office of both the Palm Group and Papierfabrik Palm.

Read more about Valmet Paper Lab: https://www.valmet.com/paperlab

James Cropper continues to operate and vows to protect staff and customers during coronavirus pandemic

James Cropper, one of the world’s most innovative papermakers, remains operational and vows to protect its staff and customers, during the current Coronavirus pandemic.

The Kendal based, family business, is continuing to manufacture high-quality paper and highly advanced non-woven material products for a wide range of customers, including many in the packaging and medical industries.

In the light of the Coronavirus pandemic the business has adapted its operation processes in order to fulfil customer orders and field incoming enquiries, while also moving swiftly to protect its 600 employees and the wider community.

Steve Adams, Managing Director, James Cropper Paper, says: “By adhering closely to government guidelines, the Kendal mill is operating with a number of new measures in place to protect the safety of our staff and the local community.

Steve Adams, Managing Director, James Cropper Paper, says: “By adhering closely to government guidelines, the Kendal mill is operating with a number of new measures in place to protect the safety of our staff and the local community.

“Anyone who can work at home is doing so. The majority of our office staff are now working from home, including the sales and marketing, technical, finance and human resources teams. Most of those still on site are directly involved in or supporting the manufacturing and distributing of our products.

“We are limiting the number of people on site and adhering to strict social distancing throughout the mill. In the occasional cases whereby staff need to work closer than two metres apart, they are provided with highly effective FFP3 masks with respirators.”

To ensure further safeguarding, 42 additional hand sanitising stations, disposable gloves, alcohol wipes, disinfectant sprays and other cleaning materials have been made accessible throughout the mill, with clear guidelines about when people should use them.

The procedure for incoming deliveries has also been changed to ensure interaction between drivers and staff is minimised.

Steve added: “We are monitoring the situation closely and following advice provided by government and Public Health England. Should we need to, we have plans in place to make further changes to our operations.

“We’d like to thank our staff for their support and take this opportunity to reassure our loyal customers, who are also navigating their way through this difficult time, that we’re still operating and here to support them.”

Valmet and Orora’s Botany Mill renew the Mill Maintenance Outsourcing agreement in Australia

Valmet and Orora Limited have signed a multi-year Mill Maintenance Outsourcing (MMO) agreement to continue taking care of the site maintenance of Orora’s Botany B9 board making line in New South Wales, Australia.

In addition to the MMO agreement, Valmet and Orora have signed a Performance Agreement targeting clear and systematic production and maintenance improvements. Both agreements include Valmet Industrial Internet (VII) solutions to provide a live link between customer and Valmet experts for process optimization. The value of the agreements will not be disclosed. The renewed MMO agreement will be effective as of July 1, 2020.

“Valmet is one of our key performance development partners, supporting B9’s operation and improvement since the start up in 2012. We have worked collaboratively since then with progressive improvements and achievements in key areas such as productivity and cost reduction. This is the second renewal of our MMO and Performance Agreements and we look forward to further success in our cooperation with Valmet. Our objective is to ensure the B9 facility becomes an industry benchmark in all areas of efficiency and cost,” says Craig Nicol, General Manager Operations, Botany Mill.

“Valmet is one of our key performance development partners, supporting B9’s operation and improvement since the start up in 2012. We have worked collaboratively since then with progressive improvements and achievements in key areas such as productivity and cost reduction. This is the second renewal of our MMO and Performance Agreements and we look forward to further success in our cooperation with Valmet. Our objective is to ensure the B9 facility becomes an industry benchmark in all areas of efficiency and cost,” says Craig Nicol, General Manager Operations, Botany Mill.

“We are fully engaged and integrated into the B9 Operations team and have been working side by side to deliver progressive development since the machine’s start-up. The renewal of the MMO agreement is the best acknowledgement for the achievements over the years together with Orora. We’re delighted to be able to share the journey forward with the B9 team and to help continuously optimize the performance of our teams and our equipment and processes,” says Jaegen Peet, Director, Australia and New Zealand region, Valmet.

The long-term relationship further strengthened by Performance Agreement

Valmet has previously supplied the complete B9 containerboard line to Orora, started up in 2012. After the start-up, Valmet took full responsibility of the establishment of maintenance operations, site maintenance services including utilities and management of specific improvement projects.

The ongoing Performance Agreement was renewed for a second time in 2019 with targets and objectives focused on cost outperformance and targeted machine efficiency improvements. The results of the collaboration have been positive considering the previous annual production record was exceeded in 2019 and a new 24-hour production record was set in mid-January 2020.

The Performance Agreement includes access to the Valmet Customer Portal, that will provide an interface for both parties to easily and quickly access visualized data and VII solutions. Although Valmet’s remote services have been utilized since the machine’s start-up, the Valmet Performance Center will now offer the customer a new channel to reach Valmet’s specialists for remote support and case studies. The new agreement also includes comprehensive and expanded automation services.

About Orora Limited

Orora Limited is a public listed company, offering a range of tailored packaging and visual communication solutions. The business employs more than 6,800 people in seven counties. Orora is headquartered in Melbourne, Australia and is listed on the Australian Securities Exchange.

Located in Botany, New South Wales, Orora’s Botany Mill produces high quality recycled packaging paper, which is then primarily converted into corrugated board by Orora’s Fibre Packaging businesses.

As announced, Japanese company Nippon Paper Group has signed an agreement with Orora to acquire its paperboard fibre-based packaging business in Australia and New Zealand. The agreement involves Nippon Paper’s consolidated subsidiary Australia Paper (AP). The transaction is expected to be finalized around the end of Q1 2020.

ANDRITZ to supply complete stock preparation line to Kookil Paper, China

International technology Group ANDRITZ has received an order from Kookil Paper (Zhangjiagang) Limited Corporation to supply a complete 305 bdmt/d stock preparation line including approach flow system, broke handling and fiber recovery to the mill in Zhangjiagang, Jiangsu Province, China.

Start-up is scheduled for the first quarter of 2021.

The new line will process NBKP (Needle Bleached Kraft Pulp) and LBKP (Leaf Bleached Kraft Pulp) market pulp bales to produce specialty paper for food packaging as well as photo and special printing paper.

ANDRITZ ModuScreen HBE screen © ANDRITZ

ANDRITZ ModuScreen HBE screen © ANDRITZ

The market pulp bales are dissolved in ANDRITZ FibreSolve FSV pulpers, which enable highly efficient slushing at low specific energy consumption. The innovative rotor design ensures optimum impact effect of the rotor and intensive friction within the pulp itself, however without damaging the fibers. Four ANDRITZ TwinFlo double disc refiners achieve superior fiber properties with regard to fiber length and fibrillation.

The approach flow system allows fast grade changes and will be equipped with an ANDRITZ ShortFlow deaeration system, comprising four proven ModuScreen HBE headbox screens for stock and dilution water screening, a WW Deaerator for efficient air removal as well as a vacuum pump. The ShortFlow deaeration system has an extremely small footprint and makes a significant contribution towards lower energy and investment costs.

The broke handling and a DiscFilter Saveall fiber recovery system complete the scope of supply.

Established in 2003, Kookil Paper is an important South Korean paper manufacturer producing in China and specializing in the production of different types of specialty papers.

ANDRITZ to supply gasification plant and biomass handling line to Klabin’s Puma II project in Brazil

International technology group ANDRITZ has received an order from Klabin for a complete biomass gasification plant and a new biomass handling line for their Ortigueira mill in Brazil.

The scope of supply includes a 51 MW gasification plant, a belt dryer, a multi-fuel lime kiln burner and biomass handling equipment with auxiliaries. By replacing 100% of the heavy fuel oil currently burned in one of the mill’s lime kilns, the ANDRITZ gasification plant will significantly reduce the mill’s carbon footprint. The current lime kiln production will remain at 650 tons of reburnt lime per day.

Biomass gasification with product gas feeding a multi-fuel lime kiln burner (typical plant) © ANDRITZ

Biomass gasification with product gas feeding a multi-fuel lime kiln burner (typical plant) © ANDRITZ

ANDRITZ was one of the main suppliers of major process technologies and equipment areas to the Puma II project, and also supplied major technologies and equipment to Klabin’s Puma I project, which was started up successfully in 2016.

In the gasification sector, ANDRITZ offers advanced and state-of-the-art technologies, combining high efficiency with quality gas output for the replacement of fossil fuels.

Metsä Board’s Express Board service expands with three new folding boxboard grades

Metsä Board is adding three new grades into its Express Board offering. The new eco-barrier paperboard MetsäBoard Prime FBB EB, uncoated folding boxboard MetsäBoard Natural FBB and MetsäBoard Pro FBB OBAfree are now available with enhanced availability and quick lead times via the Express Board service.

“The Express Board service helps our customers respond to last-minute orders and short-term promotions which are more and more common in the unpredictable world we live in today,” says Neil Fox, VP Sales FBB EMEA, Metsä Board. “The expansion to include MetsäBoard Prime FBB EB, MetsäBoard Natural FBB and MetsäBoard Pro FBB OBAfree means that all our FBB grades are now available via our Express Board service.”

The Express Board service is designed for sheet orders with short lead times and for smaller order quantities. A wide variety of sheet sizes is available from a comprehensive cutter reel stock. The service is operated via locations in the Netherlands, Poland and Spain. Metsä Board continues to recommend direct mill orders for customers who know their product specification and volume well in advance of delivery.

PMP will deliver (2) new Intelli-Jet V® Hydraulic Headboxes to Smurfit Kappa Uberaba mill in Brazil!

In February 2020, PMP (Paper Machinery Producer) has signed a contract for delivery of (2) new Intelli-Jet V® Hydraulic Headboxes for Smurfit Kappa’s paper machine (PM5) located in the Uberaba mill in Brazil.

Thanks to long-term relationship and successful cooperation in the past, PMP has reached an agreement with Smurfit Kappa. This new project will ensure competitive advantage of Uberaba mill in fast growing Brazilian market. Moreover, this is an opportunity for PMP to enter the market and have a great reference in Brazil, first in its history.

PMP Intelli-Jet V® hydraulic headbox allows to reach outstanding performance. It ensures impressive basis weight profile, superior sheet formation and great fiber orientation. Over the years, PMP Intelli-Jet V® hydraulic headbox has become an iconic solution in the Pulp & Paper Industry. Currently, there are over 170 PMP’s headboxes working successfully on 6 continents.

The main goal of this rebuild is to significantly improve the quality of paper that is produced for the Brazilian market, enhance sheet formation and reach better control on all speed range and improve cross machine BW profile.

PMP will supply a new top layer Intelli-Jet V® Hydraulic Headbox, a new bottom layer Intelli-Jet V® Hydraulic Headbox with CP system, both equipped with attenuators, as well as engineering services. Delivery of all equipment and start-up is scheduled for the last quarter of 2020.

Kemira announces a long-term extension of its bleaching chemicals supply contract with UPM-Kymmene Corporation in Uruguay

Kemira has signed a long-term agreement with UPM-Kymmene Corporation extending and expanding its current bleaching chemicals supply contract in Uruguay, pending required environmental permitting. The new agreement will include capacity to support the existing pulp mill in Fray Bentos and the new, 2.1 million ton UPM pulp mill currently under construction in Paso de los Toros.

The total Kemira investment is expected to be approximately USD 30 million into the bleaching chemicals plants, part of the chemical island at the UPM Fray Bentos site, expanding capacity for both sodium chlorate and hydrogen peroxide production. The chemical island, which became operational in 2007, was the first of its kind at the time. It has consistently demonstrated excellent operational and environmental performance which will be maintained with the additional investment into new, state-of-the-art technology.

The total Kemira investment is expected to be approximately USD 30 million into the bleaching chemicals plants, part of the chemical island at the UPM Fray Bentos site, expanding capacity for both sodium chlorate and hydrogen peroxide production. The chemical island, which became operational in 2007, was the first of its kind at the time. It has consistently demonstrated excellent operational and environmental performance which will be maintained with the additional investment into new, state-of-the-art technology.

Kim Poulsen, President, Pulp & Paper, “The extension of the contract and investment in this partnership in Uruguay demonstrates our long-term commitment in this very important market. A key element of our Kemira strategy is to grow in pulp and bleaching applications where we have deep rooted global expertise. We help our customers produce stronger, brighter and cleaner pulp”.

A.Celli Nonwovens & Sunshine Co. Ltd: start-up of a new E-WIND® STREAM winder and a RAPID slitter rewinder

Last February 28, at the Chinese plants of SUNSHINE New Material for Hygiene and Health Care Jiangyin Co. Ltd. Located in Jiangyin, two machines for Spunlace product, a winder and a rewinder installed on two different lines side by side, have been started up.

A.Celli supply, specifically tailored to the specific needs of the customer, includes:

- E-WIND® STREAM Master Roll winder of 3600 mm capable of handling reels up to 2500 mm in diameter, with basis weights ranging from 30 to 100 gsm and with a maximum operating speed of 200 m/min, specifically designed for carded products and to guarantee maximum reliability and minimal maintenance

- E-WIND® RAPID off-line slitter rewinder of 3600 mm, calibrated for reels with a maximum diameter of 1200 mm, with basis weights ranging from 30 to 100 gsm and with an operating speed of 800 m/min. Among the optionals we can find the "DSS" (defect stop system), a system able to monitor any defects on the reel, report them and give the possibility to remove them if necessary, and the “Slittomatic®”automatic slitting units positioning.

Once again, the long-standing expertise and experience of A.Celli Nonwovens and the particular attention to the customer have made possible the success of the project for the Chinese group SUNSHINE New Material for Hygiene and Health Care Jiangyin Co. Ltd.

ANDRITZ to supply new dewatering technology for RMP process to Mayr-Melnhof Karton, Austria

International technology Group ANDRITZ has received an order from Mayr-Melnhof Karton to supply a Vertical Screw Thickener (VST) dewatering system for the RMP (Refiner Mechanical Pulp) process at the mill in Frohnleiten, Austria.

Start-up is scheduled for the fourth quarter of 2020.

ANDRITZ Vertical Screw Thickener © ANDRITZ ANDRITZ will install its latest dewatering technology – the Vertical Screw Thickener (VST), an innovative screw press with a vertical design. The pulp is fed in from the top and then compressed and dewatered as it moves downwards. The self-filling and gravity-assisted dewatering principle allows higher throughput and pulp dryness because the available screen area is fully used.

ANDRITZ Vertical Screw Thickener © ANDRITZ ANDRITZ will install its latest dewatering technology – the Vertical Screw Thickener (VST), an innovative screw press with a vertical design. The pulp is fed in from the top and then compressed and dewatered as it moves downwards. The self-filling and gravity-assisted dewatering principle allows higher throughput and pulp dryness because the available screen area is fully used.

The new ANDRITZ system also comprises a dilution conveyor, MC pump including standpipe and a TurboMix agitator. Automation, instrumentation, engineering, mechanical installation, commissioning and start-up supervision are also part of the scope of supply.

At the Frohnleiten Mill, the RMP with Freeness of 350 ml is dewatered from an inlet consistency of 3.5% to 25% consistency at the discharge in one innovative unit. The pulp is then stored at a consistency of 10% in a new pulp storage tower that feeds the existing board machines.

The existing RMP system was supplied by ANDRITZ in 1996 and processes a mixture of wood chips containing spruce, larch and fir as raw material for the mill’s own board machines producing CRB (Coated Recycled Board).

Mayr-Melnhof Karton is the world’s leading producer of coated recycled cartonboard.