Ianadmin

SCA to close production plant in France

As part of SCA’s ongoing cost-savings program related to the acquisition of Georgia-Pacific’s European tissue operations, SCA will close the tissue production plant in Saint-Cyr-en-Val, France.

As part of SCA’s ongoing cost-savings program related to the acquisition of Georgia-Pacific’s European tissue operations, SCA will close the tissue production plant in Saint-Cyr-en-Val, France.

The production plant has an annual capacity of 35,000 tons. Production will be discontinued in October 2015.

The restructuring costs for the closure of the production plant are expected to amount to approximately SEK 480m, of which about SEK 380m will be recognized as an item affecting comparability in the third quarter of 2015. The remaining SEK 100m will be recognized as an item affecting comparability in 2016. Of the restructuring costs, approximately SEK 260m is expected to affect cash flow.

Total cost savings related to the acquisition of Georgia-Pacific’s European tissue operations are expected to amount to EUR 125m upon full effect in 2016. Cost savings corresponding to approximately EUR 95m on an annualized basis had been achieved in the second quarter of 2015.

The cost-savings program related to the acquisition of Georgia-Pacific’s European tissue operations is one of three efficiency programs launched by SCA in 2012. The other two programs have been concluded.

For additional information please contact:

Johan Karlsson, VP Investor Relations, 46 8 788 51 30

Karl Stoltz, Media Relations Manager, 46 8 788 51 55

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

A Recycling Landmark as Coffee Cups Become Birthday Cards

The first greetings cards to be made from recycled coffee cups are now available, courtesy of eco-friendly card company Glebe Cottage, celebrating recycling innovation at the same time as birthdays, weddings and anniversaries.

When James Cropper PLC revealed that they had solved the riddle of how to recycle many of the billions of coffee cups thrown away each year, one of the paper packaging industry’s long-standing problems, there was cause for celebration. Now, two years after that landmark announcement, British eco-friendly greetings card maker, Glebe Cottage will ensure that those coffee cups go towards making more happy memories in a new range of cards.

After life as a coffee cup, James Cropper Paper separates the high-quality pulp fibres from the plastic content and returns it to the paper supply chain. Glebe Cottage has chosen Coffee, James Cropper Paper’s leading product containing no less than 50% reclaimed fibres from this process, as the board for its new Becky Bettesworth Collection. So happy are they with the paper, the company has already started to release other collections, including the latest designs from Devon artist Kate Andrew, on the same stock.

Sue Morrish, Glebe Cottage’s Sales Director, said: “We were privileged to visit the James Cropper paper mill in February this year. When we saw this innovative new uncoated paper we knew it was a perfect fit with our environmental credentials and were thrilled when our print tests showed that it also printed beautifully.”

Opened by Her Majesty the Queen in July 2013, James Cropper’s Reclaimed Fibre Facility was the result of a £5million investment and has since seen millions of cups turned back into paper. The investment was recognised by the paper industry as a landmark development in the progression of sustainable paper production, being awarded The Luxepack In Green Award in the same year. The Coffee range, which comes in six colours, was launched in September 2014 and was the first paper to take the recycled cup content to 50%.

Chris Brown, Commercial Director of James Cropper PLC, says: “Coffee is an extremely versatile product, responding well to a wide variety of applications in packaging, print and design and fulfilling the needs of many of our customers in regards to their high standards of sustainability. Glebe Cottage have found that it stands up to commercial print requirements and we’re pleased to be a small part of putting a smile on people’s faces when they open one of these beautifully made cards.”

In 2014, James Cropper PLC became one of 14 international companies to formally join the Paper Recovery and Recycling Group (PCRRG), drawing together paper and paper cup manufacturers with high street coffee retailers, to conduct in-market trials of recycling processes and end products, with emphasis on the UK market.

James Cropper PLC maintains significant investment in new technologies not only within its paper division, incorporating converting capabilities, but also Technical Fibre Products, a specialist supplier into to the composites market for non-wovens for aerospace, automotive and construction.

Sustainability at Iggesund: A key factor in all decisions

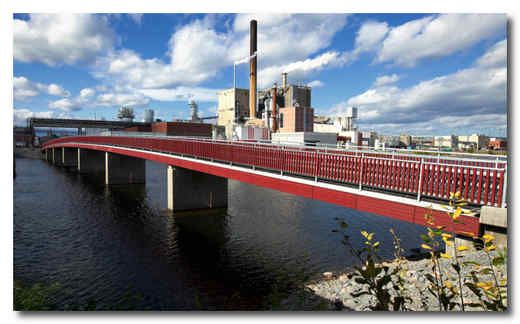

Many small steps add up to large ones. That’s a simple way to sum up Iggesund Paperboard’s environmental work. It is easy to give examples of Iggesund’s multi-million euro investments and their importance. But the company also makes many smaller investment decisions which have important environmental aspects. One of these is the wooden bridge that links the mill at Iggesund with the wastewater purification facility on the adjacent island of Skälön.

“A wooden bridge within an industrial site must of course be suitable for its purpose and good from a sustainability and durability perspective. But the fact that it is also beautiful is an added plus,” says Anna Mårtensson, Environmental Manager at Iggesund Mill, Iggesund Paperboard’s Swedish production facility. ©Iggesund

“Long-term environment work is less about making a few big decisions and more about making many small decisions which include the environmental aspects,” explains Anna Mårtensson, Environmental Manager at the company’s Swedish paperboard mill, Iggesund Mill. “In this case a wooden bridge was a better environmental choice than a concrete one.”

For over a century bridges in Sweden have primarily been built of steel and concrete. But now wooden bridges are gaining ground again. They are as durable as concrete and are also beautiful. When their environmental aspects are also considered, wooden bridges are a serious alternative.

The modern history of wooden bridges in the Nordic region really began in the 1990s. At that time Sweden, Norway and Finland agreed to develop common standards and technical solutions for wooden road bridges which would have the same performance and lifespan as bridges made of steel and concrete.

The longest wooden bridge built in Sweden to date is a 230-metre-long pedestrian and cycling bridge in the northern city of Umeå. The oldest wooden bridge in the country dates from 1737 and spans the Skellefteå River.

As architects and engineers learn more about how to use wood as a building material, more and more wooden bridges are being built.

Iggesund Paperboard has joined the trend. When Iggesund Mill expanded its wastewater purification facility on the island of Skälön outside the mill, the company decided to replace the old bridge with a stronger one. The new bridge would allow heavy trucks heading for the island to avoid making a nine-kilometre detour.

“We quickly calculated that a new bridge would pay off, both financially and environmentally,” Environmental Manager Anna Mårtensson remembers.

Wood was chosen as the material for several reasons. First, the Holmen Group, which includes Iggesund Paperboard, is a forest industry group so using wood is an obvious choice. A wooden bridge is also cheaper and faster to build.

“But above all, wood makes less of an environmental impact than steel and concrete,” Mårtensson says.

An engineering thesis from Uppsala University concludes that a lifecycle analysis of a concrete bridge, based on a lifespan of 40 years and including investment costs, construction process and maintenance, results in twice the carbon dioxide emissions as a bridge built of wood. In 1915 a long hollow pipe was built of wood in order to supply the mill with process water. That pipe still exists and still functions perfectly today – a hundred years later. So there is no doubt that wood is a durable material.

At Iggesund Paperboard, sustainability is a cornerstone of the company’s work. The environmental aspects – large and small – are considered when making every decision. The company’s environmental work is not separate from its main business because good investments always go hand in hand with a better environment.

“Many small improvements lead to major environmental gains, with lower emissions and a greater likelihood that Iggesund Paperboard will continue to lead the process industry’s sustainability league tables in the future too,” Mårtensson says.

Iggesund Mill’s environmental work to date has led to a fifty per cent reduction in the amount of sulphur and particulate emissions within only a couple of years. In addition, the mill’s major investments in water purification have resulted in a radical reduction of emissions of nutrients into the Baltic Sea outside the mill. This in turn has resulted in improved water quality and clear signs of recovery in the marine ecosystem.

Even more important, though, may be the focus which is being placed on the human factor – to get every employee to think about what he or she is doing so there is no relaxation of the joint environmental effort.

“Of course, all our work towards greater sustainability also includes the 128-metre-long, red-painted wooden bridge over to Skälön as one of many small but important steps,” Anna Mårtensson concludes. “And it’s very beautiful, too.”

Facts: The bridge to Skälön is 128 metres long and has a single one-way lane which is 4.5 metres wide and equipped with traffic lights. The bridge rests on glulam beams bolted together.

Using wood as a building material has two major fundamental environmental advantages: first, the wood is produced from a renewable resource and with minimal energy input, and, second, the photosynthesis process in growing trees binds carbon dioxide from the atmosphere. It is also often both easier and cheaper to build in wood than in other materials. From a lifecycle perspective, wood is therefore an advantageous choice in terms of efficient resource usage, energy consumption, carbon dioxide emissions and waste.

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Further information:

Staffan Sjöberg

Public Relations Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund Paperboard

SE-825 80 Sweden

Tel: +4665028256

Mobile: +46703064800

www.iggesund.com

Valmet supplies main equipment to the pulp mill project of Huanggang Chenming Pulp & Paper Co., Ltd. in China

Valmet will supply main equipment to Huanggang Chenming Pulp & Paper's new pulp mill located in the city of Huanggang in Hubei province, China. The pulp mill is designed for flexible production to respond to market developments. The pulp line can be run to produce softwood kraft pulp and dissolving pulp depending on the market needs. The new mill is expected to start up in 2017. Valmet's delivery includes the main equipment excluding only some specific process parts.

Valmet will supply main equipment to Huanggang Chenming Pulp & Paper's new pulp mill located in the city of Huanggang in Hubei province, China. The pulp mill is designed for flexible production to respond to market developments. The pulp line can be run to produce softwood kraft pulp and dissolving pulp depending on the market needs. The new mill is expected to start up in 2017. Valmet's delivery includes the main equipment excluding only some specific process parts.

The value of the order is about EUR 110 million. The order is included in Valmet's third quarter orders received.

"Huanggang will be our new business location, where we plan to have a three-phase investment. This pulp mill investment is the first phase. We have been cooperating with Valmet close to 20 years. Our people trust Valmet's know-how and its service spirit. We are happy to select Valmet as the main equipment supplier to this project," says Mr. Chen Hongguo, Chairman of Chenming Group.

"Huanggang pulp mill project offers both our engineering and production personnel work in the Nordics, Asia Pacific and China. This pulp mill will be the world's largest dissolving pulp producer, and the order shows the customer's trust on Valmet's know-how in pulp and dissolving pulp technology," says Bertel Karlstedt, President of Valmet's Pulp and Energy Business Line.

Details of Valmet's delivery

Valmet's delivery presents state-of-the art technology in optimizing mill production, tailor making of dissolving grades, maximizing energy efficiency and minimizing environmental impact. The delivery includes specific equipment and services for wood handling and pulp drying areas, hardwood and softwood multi-grade fiber line (excluding cooking), high dry solids evaporation plant, high power recovery boiler with integrated crystallization system, biomass gasification, lime kiln and recausticizing.

In addition to the delivered equipment, the delivery includes process and basic engineering, detail engineering services and virtual site training simulator for selected areas as well as installation and start-up advisory services.

In parallel with the Huanggang supply contract, Chenming and Valmet agreed on the delivery of a separate non-condensable gas incinerator for the Chenming Group's Zhanjiang mill.

Information about the customer Huanggang Chenming

Huanggang Chenming Pulp and Paper is part of Shandong Chenming Paper Group Co., Ltd, which is one of the leading paper manufacturers in China. The group's activities include afforestation, pulp making, and paper manufacturing. Chenming Group is listed on both the China and Hong Kong stock exchanges. The company has more than 10 production sites around China. The group's annual paper production capacity is 6 million tons and it has about 13,000 employees.

For further information, please contact:

Bertel Karlstedt, President, Pulp and Energy, Valmet, tel. +358 10 676 3026

Yutong Feng, Vice President, Pulp and Energy, China, Valmet, tel. +86 1360 108 9397

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Sonoco Announces Price Increase for Paperboard Tubes and Cores

Sonoco (NYSE:SON) has announced that it will raise the price for all paperboard tubes and cores by 6 percent to 8 percent (6%-8%), effective with shipments in the United States and Canada beginning September 14, 2015.

Sonoco (NYSE:SON) has announced that it will raise the price for all paperboard tubes and cores by 6 percent to 8 percent (6%-8%), effective with shipments in the United States and Canada beginning September 14, 2015.

“The price increase is necessary due to the recent increase in the price of our primary raw material, uncoated recycled paperboard (URB),” said Adam Wood, vice president, Global Tubes and Cores. “This URB price increase, combined with continued rising operating and other raw material costs, have put pressures on Sonoco which we cannot absorb.”

Sonoco is the largest producer of paper-based tubes and cores in North America, which are used to serve the paper, textiles, plastic films, tape and specialty industries. For more information about Sonoco's complete line of paperboard tubes and cores or to learn more about current pricing, please visit the Company's website or contact the Company at +800-377-2692.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging and packaging supply chain services. With annualized net sales of approximately $5.0 billion, the Company has 21,000 employees working in more than 300 facilities in 34 countries, serving many of the world’s best known brands in some 85 nations. Sonoco is a proud member of the 2014/2015 Dow Jones Sustainability World Index. For more information on the Company, visit our website at www.sonoco.com.

Waste paper baling – not just for the big boys

There was a time when only larger organisations could house in-house waste handling systems. But technological innovation, plus an ever-growing acknowledgment for the environmental and financial benefits of paper recycling, means organisations of all sizes are working smarter when it comes to this valuable material. Jonathan Oldfield, managing director of Riverside Waste Machinery investigates.

“The introduction of European legislation in January 2015 – which began to call for the separate collection of paper, plastics, metals and glass where technically, environmentally and economically practicable (TEEP) – had the potential to encourage continued sustainability progress in the UK. It was well timed too, given the rumours of ‘green fatigue’ which circulated in the media last year.

However, the fact that nobody has defined TEEP in England means it is up to waste management companies and their business customers to interpret the requirements. With so much ambiguity surrounding the movement, I don’t believe this legislation is having the impact it could. Scotland may experience greater success given separate collections have been made mandatory, but at the moment we must just wait and see.

The machinery arena deserves some credit for its commitment to driving progress though. Ongoing technological innovations, and the range of procurement options now available in the marketplace, mean paper waste handling equipment is more accessible to organisations, regardless of their size. Gone are the days when only large businesses with spacious warehouses can invest in plant and machinery to smarten up their approach to paper recycling.

Small vertical paper baling machines with a footprint of only 1040 x 720mm, for example, can slot into even the tightest of commercial environments. And typically available to purchase from £2,500, or rent from as little as £23 per week, this doesn’t represent a significant financial commitment. So, local independent retailers handling paper and board packaging waste, for instance, can invest in such technology with relative ease, as can hotels who’d like the kit to fit in their service lifts. Printing companies, catering firms, serviced offices, local authorities and hospitals are just some of the other organisations making the switch to procure their own machinery, rather than relying solely on the recycling proficiency of their chosen waste contractor.

The benefits of smarter in-house paper recycling processes are multifaceted. On a simplistic level, baling ‘waste’ paper can improve on-site cleanliness, which is particularly important when space is limited. But even in larger premises, it’s better to be tidy, so that waste paper and board doesn’t blow around a windy yard, for instance.

It can have time saving benefits too. In some organisations, loose waste paper and board is handled three or four times before it is collected. Surely that employee time would be better spent doing something more business related?

And then there’s the commercial advantage of baling waste paper, which shouldn’t be reserved purely for large companies. Why pay to dispose of paper, when it could instead be collected for free? In some instances, recycling contractors will even pay for paper or board which generates an additional revenue stream.

Much depends on the geographical vicinity of a recycling partner, and the size of the bale. Mill size bales could attract a rate of £50/tonne, for example (subject to segregation and commodity values), whilst for smaller bales, there may be no rebate but at least the waste collection fees are wiped out.

And of course there’s the argument that those responsible for producing the ‘waste’ in the first place, have a duty of care to ensure it goes on to be processed in the most environmentally responsible and resourceful manner possible.

It’s scary that a significant number of businesses – and households – still throw clean paper in with all of their other general waste. In these scenarios, the risk of the fibres within this valuable resource being damaged, to the extent that they cannot be salvaged, is simply too great. At the very least, waste paper and card should be disposed of in a DMR (dry mixed recycling) skip, so that a waste company can run it through a Materials Recycling Facility (MRF) and pick it. But why not streamline the ensuing processes in the supply chain and adopt a best practice approach before the paper even leaves the waste producer’s site?

People predicted that, with the continued evolution of IT, the business environment would become increasingly paperless. In some instances we are seeing evidence that this is the case, with a growing level of news being consumed online or via social media, for example, rather than traditional newspapers. But elsewhere, paper and board is still a very real part of business life. Offices may store less paper, for example, but they still use it in comparative volumes, just in different ways. From labels and confidential documents, through to product packaging and transit sacks, a lot of paper is here to stay, for the time being at least.

It is therefore important that we don’t lose sight of the need to work smarter when it comes to paper recycling. The ‘green fatigue’ phrase is something nobody can afford to see in the media again.

Kemira appoints Tomas Biström as Director, Corporate Responsibility

Tomas Biström (Master of Science, Economics) has been appointed Director, Corporate Responsibility at Kemira starting 1 September, 2015. He has previously been responsible for Kemira's Compensation and Benefit globally, including the successful implementation of Kemira's performance management process.

Tomas Biström (Master of Science, Economics) has been appointed Director, Corporate Responsibility at Kemira starting 1 September, 2015. He has previously been responsible for Kemira's Compensation and Benefit globally, including the successful implementation of Kemira's performance management process.

"Tomas takes up this position from Riikka Timonen, who has chosen to pursue a new career path within one of Kemira's business segments. Kemira aims to excel in internal leadership development and succession planning programs, so that individuals have the opportunity to grow and develop new skills inside Kemira. Riikka has played a significant role in improving our sustainability performance, monitoring and reporting. I am confident that going forward, Tomas will bring new valuable insights into this work, which is never finished," says Tero Huovinen, SVP, Communications and Corporate Responsibility.

"Sustainable value creation is an integral part of Kemira's strategy and business: we help our customers improve their water, energy and raw material efficiency. Our stakeholders expect high sustainability performance from us, both in our own operations as well as throughout the value chain. We continue to improve our business processes to meet these growing expectations, also focusing on sustainability aspects in our new product development," says Jari Rosendal, Kemira's President and CEO.

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2014, Kemira's annual revenue was EUR 2.1 billion and we employed approximately 4,250 people. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

www.kemira.com

For more information, please contact

Kemira Oyj

Tero Huovinen, SVP, Communications and Corporate Responsibility

Tel. +358 10 862 1980

Valmet and Australian Paper sign a multi-year maintenance technical support agreement for Maryvale Mill

Valmet and Australian Paper have signed a multi-year agreement for Valmet to provide maintenance technical support at the Maryvale Mill in Victoria, Australia. The new technical support agreement (TSA) which will focus on providing onsite maintenance technical advice and expertise to the mill's maintenance organization, replaces the old maintenance agreements between Valmet and Australian Paper. The agreement came into effect on August 1, 2015.

Peter Williams, COO of Australian Paper, and Pierre de Villiers, Vice President Sales, Australia and New Zealand from Valmet.

The Maryvale Mill has three pulp lines, five papermaking machines, an elemental chlorine free bleach plant, pulp lapping machine, deinked pulp line, finishing facility and a waste paper processing plant. Valmet's TSA resources will be located within the mills power and recovery, fibre lines, paper mill and central maintenance areas.

"The new agreement builds on the partnership between Australian Paper and Valmet, providing long term technical input into Australian Paper's maintenance operation allowing for continuous improvement and development programs to be identified and implemented along with specific Pulp & Paper knowledge and knowhow," says Peter Williams, COO of Australian Paper.

"Australian Paper has developed continue to develop the Maryvale Mill to ensure its long term sustainability and profitability as a domestic producer of fine paper and packaging grades. The Technical Service Agreement provides the needed alignment to meet these objectives, reinforces the high level cooperation and commitment between our organizations and provides the platform to move our customer's performance forward," says Pierre de Villiers, Vice President Sales, Australia and New Zealand, Valmet.

Information about the customer Australian Paper

Australian Paper is Australia's largest manufacturer of fine papers for print and office applications and produces high-quality packaging papers. Australian Paper employs over 1,400 Australians and supplies more than 600,000 tonnes of product within Australia and around the world. Australian Paper is part of Nippon Paper Group that consists of approximately 180 affiliates and related companies. The Maryvale Mill is Australia's largest integrated fine paper-making and packaging papers complex, producing more than 500,000 tonnes of paper every year.

For further information, please contact:

Pierre de Villiers, Vice President, Sales, Australia and New Zealand, Valmet, tel. +61 417 055 564

Miikka Kettunen, Senior Manager, Maintenance Agreements, Asia Pacific, Services business line, Valmet, tel. +62 811 871 1571

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Georg Goldbrunner wins Huyck.Wangner's Talent Prize 2015

Awarding ceremony for best basic studies in Engineering Paper Technology at Munich University of Applied Sciences

For the sixteenth time, Xerium Technologies Inc., one of the world's leading suppliers of paper machine clothing and roll technology, awarded its 1500-euro Huyck.Wangner talent prize in conjunction with the closing ceremonies held on July 31 at the Munich University of Applied Sciences. The grant was presented together with Prof. Dr. Stephan Kleemann, head of the school's Master of Engineering in Paper Technology program. Georg Goldbrunner was the recipient of this year's traditional prize for best performance in the basic study period.

From left to right:Ernst Kerschhofer, Vice President Sales & Services Xerium EMEA, this year's talent award winner Georg Goldbrunner and Professor Stephan Kleemann, Munich University of Applied Sciences, Head of the Process Engineering for Paper and Packaging program

After graduating from secondary school in 2011, the 24-year-old, who stems from Weilheim, Upper Bavaria, took a year off to backpack across Australia, before enrolling in a paper technologies apprenticeship program at UPM's Schongau paper mill in 2012. After completing his apprenticeship in 2014, he began a work-study program at the mill, one of the largest and most modern papermaking companies in Europe. In parallel, he enrolled in the Engineering Paper Technology program at the Munich University of Applied Sciences.

Receiving the Huyck Wangner Talent Prize 2015 reflects not only his outstanding performance at the top of his basic studies, but also his passion for and huge interest in paper and papermaking. Georg Goldbrunner is also a battered fan of the traditional TSV 1860 soccer club in Munich. Toughened by the performance of the Löwen (lions, as the team is known locally), which in recent years has had its ups and downs and demanded a lot of staying power from its fans, he remains optimistic about his future in spite of gloomy predictions about the future of paper, and is full of conviction as he plugs away at his aim to become a papermaker.

After all, the unanimous view regarding future career prospects for budding paper engineers expressed by graduates, professors, industry and association representatives at the closing ceremonies last July was: "Outstanding!" In fact, there was an even stronger call than usual for more new recruits, who are essential to the paper industry's future. Here is what Ernst Kerschhofer, Vice President Sales & Services Xerium EMEA, had to say as he handed over the prize: "Paper is and will remain a modern, sustainable product, and blends wonderfully with the new digital world. It is well worth the effort to keep it fit for the future by bringing new knowledge and ideas to the table." In closing, he thanked Professor Kleemann, who together with his team is creating ideal conditions for ensuring a promising future for up and coming paper engineers. The development of the Master's program, "Engineering in Paper Technology", holds special promise. It is currently a one-of-a-kind dual-study program offered in the English language in close collaboration with American universities and is recognized throughout Europe. This year for the first time, the number of participants graduating with a Master's degree (14) was even higher than those receiving a Bachelor's (12).

Asia Pulp & Paper Commits to the First-Ever Retirement of Commercial Plantations on Tropical Peatland to Cut Carbon Emissions

Asia Pulp & Paper Group (APP) has announced it is committing to retire around 7,000 hectares of commercial plantation areas to protect threatened carbon-rich peatlands, the first time that plantations on tropical peatland have been retired for conservation purposes worldwide.

Asia Pulp & Paper Group (APP) has announced it is committing to retire around 7,000 hectares of commercial plantation areas to protect threatened carbon-rich peatlands, the first time that plantations on tropical peatland have been retired for conservation purposes worldwide.

- APP partners with Deltares to develop peatland best management practice model – Greenpeace is monitoring its development

- In the largest exercise of its kind, a quarter of Indonesian peat landscapes is mapped with LiDAR technology

- APP builds on FCP commitment of a moratorium on all peatland development since 2013

Peatland development in Indonesia represents one of the single largest terrestrial sources of greenhouse gas emissions (GHG) in the world1. Retiring these plantation areas will help support the Government of Indonesia’s target of a 26 per cent reduction in emissions by 2020.

The land marked for retirement is spread across five individual acacia plantation areas in Riau and South Sumatra which have been identified as requiring immediate rehabilitation following recommendations from the applied research institute Deltares. In line with APP’s Forest Conservation Policy (FCP), a Free and Prior Informed Consent (FPIC) process will be conducted for the five areas, before any retirement proceeds.

Today’s announcement is part of APP’s commitment to establish a science-based landscape approach for best practice peatland management that can be used by the Indonesian Government and plantation companies. It builds on the conservation pledges in the company’s FCP, which placed an immediate moratorium on all natural forests and new peatland development in February 2013.

As part of this approach, Deltares is working with APP to carry out the largest mapping exercise ever carried out on tropical peatland areas using LiDAR remote sensing technology. LiDAR, deployed from aircraft, allows Deltares to map around one quarter of all Indonesian peatland where APP’s suppliers are located. The area totals 4.5 million hectares, which compares to an area the size of Switzerland or the State of Pennsylvania. The resulting maps will be finalised in 2016.

The mapping will provide unprecedented insight into the hydrology and environmental conditions of a number of critically important peat landscapes. Analysis of the data will enable Deltares to provide further recommendations on how APP can minimise the impact of drainage in peat landscapes, making a significant contribution not only to reducing forest loss but also to reducing greenhouse gas emissions that lead to climate change.

Aida Greenbury, Managing Director Sustainability, APP said:

“APP’s decision to retire these areas of commercial plantation is an important milestone in the delivery of our Forest Conservation Policy and we believe it is an unprecedented commitment. The retirement of active plantations is not an easy decision for any business to take, but we believe that taking urgent steps to protect remaining areas of peatland forest, as well as reducing and avoiding climate emissions from peatlands, must be a priority. While there is still a long way to go, and we have much to learn, this announcement today represents a major breakthrough.

“However, the reality of protecting peat landscapes is that no one company like APP can do it alone. APP’s goal of supporting the conservation of forest and peat landscapes needs to be a shared objective, and one supported by meaningful actions from both the Government and other plantation companies. This should include addressing the systemic barriers to forest and peatland protection, supporting forest restoration and ensuring development opportunities for communities.”

Dr Aljosja Hooijer, programme leader at Deltares, said:

“APP has a unique opportunity to support peatland forest conservation and emission reduction. The progress announced today is a first step in a process towards the development of a new model to define best management practices in peatlands. The pioneering approach to collecting LiDAR data has allowed the technology to be deployed at an unprecedented scale economically, and will advance the science of peat and peat management not only in Indonesia, but also globally.”

1 CO2 emissions from peatland drainage in Southeast Asia contribute the equivalent of 1.3% to 3.1% of the global CO2 emissions from burning fossil fuels

About Asia Pulp & Paper

Asia Pulp & Paper Group (APP) is a trade name for a group of pulp and paper manufacturing companies in Indonesia and China. APP is responsible for delivering quality products to meet the growing global demand for tissue, packaging and paper. On any given day, our products find their way into the hands of consumers in various branded forms from all over the world.

Started in 1972 with Tjiwi Kimia producing caustic soda, now we run operations across Indonesia and China with an annual combined pulp, paper, packaging product and converting capacity of over 19 million tons per annum. Today, APP markets its products in more than 120 countries across six continents.

Over the years, we have expanded our operations significantly through the acquisition and expansion of several of our pulp and paper mills. It’s our commitment to customer satisfaction that enables us to grow our share in paper sales worldwide and broaden our presence through offices in many countries. We believe ‘tradition and modernity go hand in hand’ which means we value long term relationships as part of our Eastern traditions, while we also are eager to embrace the modern values of innovation and efficiency.

Maintaining the integrity of our supply chain is also crucial to APP’s operations as well as our commitment to our Sustainability Roadmap Vision 2020. Learn more about APP’s path to operational excellence by reading our Sustainability Reports and Forest Conservation Policy.

About Deltares

Deltares is an independent institute for applied research in the field of water, subsurface and infrastructure. Throughout the world, we work on smart solutions, innovations and applications for people, environment and society. Our main focus is on deltas, coastal regions and river basins. Managing these densely populated and vulnerable areas is complex, which is why we work closely with governments, businesses, other research institutes and universities at home and abroad. Our motto is Enabling Delta Life. As an applied research institute, the success of Deltares can be measured in the extent to which our expert knowledge can be used in and for society. For Deltares the quality of our expertise and advice is foremost. Knowledge is our core business.

Deltares has executed hundreds of advisory projects in South-East Asia, for bilateral financing agencies, international development Banks, local Governments, NGOs and private industry. In Indonesia we are a well established consultancy in the area of water and soils management, with over 40 years of local experience. In recent years, a growing component of our work has been in the area of peatland management support, with over 20 projects in the last 10 years. We publish frequently on the impacts of peatland drainage in terms of carbon emissions, land subsidence and future flooding, and on mitigation options.

Website: www.deltares.nl

APP

Paul Codd

This email address is being protected from spambots. You need JavaScript enabled to view it.

+44 (0) 207 331 5366

or

Deltares

Dr Al Hooijer

This email address is being protected from spambots. You need JavaScript enabled to view it.