Ianadmin

Kawanoe Zoki to offer GL&V Pulp and Paper’s BTF™ Headbox technology in China

GL&V Pulp and Paper is pleased to announce that Kawanoe Zoki, our long term partner in the pulp and paper market in Japan, is taking over responsibility for the BTF™ headbox technology in China.

Kawanoe Zoki has extensive experience in designing, building and marketing pulp and paper equipment in Asia, and has been a partner of GL&V for more than 20 years. Kawanoe Zoki has sold, designed, manufactured and successfully started up many BTF installations in Japan. They already have extensive experience in the Chinese pulp and paper marketplace with their tissue forming technologies.

There are now 190 BTF installations worldwide, including 44 in Asia, of which 25 are located in China. GL&V is pleased that Kawanoe Zoki will be continuing to offer customers in China the benefits of BTF Dilution Profiling headbox technology.

GL&V -GL&V Pulp and Paper Group designs and markets equipment used in various stages of pulp and paper production, from pulp preparation to sheet forming and finishing. GL&V serves the global market with spare parts, rebuilds, upgrades and optimization services for new and existing equipment. Our pulp and paper group is focused on innovation and provides technologies that generate energy and cost savings for our customers.

For further information, please contact:

GL&V - This email address is being protected from spambots. You need JavaScript enabled to view it. or visit our website www.glvpulppaper.com

Kawanoe Zoki - This email address is being protected from spambots. You need JavaScript enabled to view it. or visit our website www.kawanoe.co.jp/english/

Changes in Kemira Oyj's management

President of Kemira's Paper segment Petri Helsky, M.Sc. (Chem. Eng.), M.Sc. (Econ.), will assume a second role as the President of the Asia Pacific Region as of January 1, 2015. Petri Helsky continues to be a member of the Kemira Management Board and reports to President and CEO Jari Rosendal in these roles. He is based in Hong Kong.

President of Kemira's Paper segment Petri Helsky, M.Sc. (Chem. Eng.), M.Sc. (Econ.), will assume a second role as the President of the Asia Pacific Region as of January 1, 2015. Petri Helsky continues to be a member of the Kemira Management Board and reports to President and CEO Jari Rosendal in these roles. He is based in Hong Kong.

Joe Chan, EMBA, is appointed President, China as of January 1, 2015. In his new role, Joe Chan continues to drive profitable growth in the Chinese market. Joe will report to Petri Helsky, President of Paper Segment and APAC Region. He is based in Shanghai.

These changes in Kemira's management are made to support the announced preliminary agreement to acquire AkzoNobel's paper chemical business, which will double Kemira's Paper business in Asia Pacific. The intended transaction was announced in July 8, 2014 and is expected to be closed in the first quarter of 2015.

For more information, please contact

Kemira Oyj

Leena Lie, SVP, Communications and Corporate Responsibility

+358 10 862 1153

Tero Huovinen, VP, Investor Relations

Tel. +358 10 862 1980

Clearwater Paper Announces $100 Million Stock Repurchase

Clearwater Paper Corporation has announced that its board of directors has authorized the repurchase of up to $100 million of the company’s common stock, demonstrating the company’s strong balance sheet and positive outlook on its business. This authorization follows the successful completion of the company’s previous $100 million stock repurchase authorization, which was implemented by the board in February 2014. Clearwater Paper expects to fund the repurchase through available cash resources.

Clearwater Paper Corporation has announced that its board of directors has authorized the repurchase of up to $100 million of the company’s common stock, demonstrating the company’s strong balance sheet and positive outlook on its business. This authorization follows the successful completion of the company’s previous $100 million stock repurchase authorization, which was implemented by the board in February 2014. Clearwater Paper expects to fund the repurchase through available cash resources.

“At the same time, we are committed to maintaining a strong balance sheet and financial position. Since beginning our stock repurchase programs in 2011, we have returned $230 million to our shareholders.”

“Today’s announcement of a new stock repurchase program reflects our confidence in future cash generation capabilities and commitment to return capital to shareholders,” said Linda K. Massman, president and chief executive officer. “At the same time, we are committed to maintaining a strong balance sheet and financial position. Since beginning our stock repurchase programs in 2011, we have returned $230 million to our shareholders.”

The repurchase program authorizes the company to purchase its common stock, on occasion, through open market purchases, negotiated transactions or other means (including accelerated stock repurchases and 10b5-1 trading plans in accordance with applicable securities laws and other restrictions). The company has no obligation to repurchase stock under this program and may suspend or terminate the program at any time.

ABOUT CLEARWATER PAPER

Clearwater Paper manufactures quality consumer tissue and bleached paperboard and pulp at 13 manufacturing locations in the U.S. and Canada. The company is a premier supplier of private label tissue to major retailers and wholesale distributors. This includes grocery, drug, mass merchants and discount stores. The company also produces bleached paperboard used by quality-conscious printers and packaging converters. Clearwater Paper’s employees build shareholder value by developing strong customer partnerships through quality and service.

Wausau Paper Terminates Shareholder Purchase Rights Plan

Wausau Paper Corp. has announced that its Board of Directors has approved the redemption of the rights accompanying its outstanding common stock under its Shareholder Purchase Rights Plan originally adopted in October 1998, and amended in October 2008. The Shareholder Purchase Rights Plan was set to expire by its terms on October 31, 2018. With this action, the Shareholder Purchase Rights Plan is effectively terminated immediately.

Wausau Paper Corp. has announced that its Board of Directors has approved the redemption of the rights accompanying its outstanding common stock under its Shareholder Purchase Rights Plan originally adopted in October 1998, and amended in October 2008. The Shareholder Purchase Rights Plan was set to expire by its terms on October 31, 2018. With this action, the Shareholder Purchase Rights Plan is effectively terminated immediately.

In addition, the Board of Directors today declared a cash dividend of $0.03 per share payable on February 17, 2015, to shareholders of record at the close of business on February 2, 2015. Of the $0.03 per share declared, $0.01 represents the per purchase right redemption price under the terminated Shareholder Purchase Rights Plan.

About Wausau Paper:

Wausau Paper produces and markets a complete line of away-from-home towel and tissue products, as well as soap and dispensing systems. The Company is listed on the NYSE under the symbol WPP. To learn more about Wausau Paper visit www.wausaupaper.com

Wausau Paper Corp.

Investor and Media Contact:

Perry Grueber, 715-692-2056

Director Investor Relations

This email address is being protected from spambots. You need JavaScript enabled to view it.

Catalyst to indefinitely curtail paper machine at Powell River

Catalyst Paper (TSX: CYT) has announced the decision to indefinitely curtail the No. 9 paper machine, one of three machines at its Powell River operation. This decision is fully market-related as the company is facing a lack of orders and a declining market for the paper manufactured on paper machine No. 9, which was temporarily curtailed on October 27.

Catalyst Paper (TSX: CYT) has announced the decision to indefinitely curtail the No. 9 paper machine, one of three machines at its Powell River operation. This decision is fully market-related as the company is facing a lack of orders and a declining market for the paper manufactured on paper machine No. 9, which was temporarily curtailed on October 27.

"This is a difficult, but necessary decision that supports Catalyst's commitment to align mill operations and production with market demand," said Joe Nemeth, President and Chief Executive Officer. "We are committed to making the Powell River operation successful for the long term, and will be working with our employees, leadership and the unions on a plan to make improvements to secure our sustainability."

It is anticipated that this change will result in the loss of 50 jobs at the Power River operations and the Surrey Distribution Centre, Catalyst's product distribution hub. The company will be working with employees and the Union locals on a transition plan to mitigate the impact of this decision.

About Catalyst Paper

Catalyst manufactures diverse specialty mechanical printing papers, newsprint and pulp. Its customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With three mills in British Columbia, Catalyst has annual production capacity of 1.5 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

Valmet's second OptiConcept M boardmaking line successfully started up at Lee & Man in China

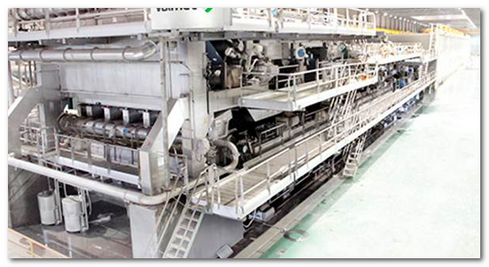

On June 18, 2014, Lee & Man Paper Manufacturing Ltd. started up their new Valmet-supplied containerboard production line, paper machine 20 (PM 20), at their Chongqing site in Sichuan Province in China. The new production line produces high-quality board grades from recycled raw material with excellent strength properties. PM 20 is the world's second start-up of Valmet's OptiConcept M -type production line. The line combines high productivity with low operating costs.

Valmet OptiConcept M production line at Lee & Man Paper Manufacturing's Chongqing site

Valmet's OptiConcept M production line delivery

Valmet's delivery included a complete OptiConcept M boardmaking line from headbox to reel with related air systems.

The new 6.65 meters wide (reel) PM 20 production line has a daily production capacity of approximately 1,160 tonnes of recycled testliner grades in the basis weight range of 50 to 160 g/m2. The design speed is 1,100 m/min.

OptiConcept M production line stands for economy of total investment, occupational safety and machine usability as well as reduction of environmental load. The production line optimizes the machine investment in line with the mill's capacity needs and ensures optimized productivity at minimal operational cost.

About Lee & Man Paper Manufacturing Ltd.

Lee & Man Paper Manufacturing Ltd. manufactures various linerboard and corrugating medium grades for different industrial packaging purposes and operates also in pulp making, plantation and recovered paper collection. The company was founded in 1994. At present, the company has five plants in China.

Further information, please contact:

Jussi Kairus, Senior Project Manager, Paper Mills, Valmet, tel. +358 40 551 9253

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Voith’s SensoTension LC ensures reliable operation and precise wire tensioning

With the SensoTension LC Voith has launched a new sensor on the market that measures and controls the tension of wires and press felts precisely, safely and reliably. The sensors of the new system are suitable for use in the former, press and dryer sections of paper, board and tissue machines.

The SensoTension LC’s special features include its dual-channel design and signal filtering and amplification integrated into the sensor. The dual-channel system sets the product apart from conventional sensor systems. Thanks to the redundancy provided it ensures constant wire and press felt tension and therefore also ensures the maximum possible reliability in paper manufacture. Unlike conventional systems, the signal filtering and amplification are integrated into the sensor ensuring high measuring accuracy and preventing transmission errors.

The SensoTension LC’s special features include its dual-channel design and signal filtering and amplification integrated into the sensor. The dual-channel system sets the product apart from conventional sensor systems. Thanks to the redundancy provided it ensures constant wire and press felt tension and therefore also ensures the maximum possible reliability in paper manufacture. Unlike conventional systems, the signal filtering and amplification are integrated into the sensor ensuring high measuring accuracy and preventing transmission errors.

SensoTension LC is suitable for use at temperatures of up to 120°C and is offered in a rugged stainless steel design. The new SensoTension LC measuring and control system is designed for use with the Voith tensioning systems SensoTension P for the press and SensoTension DE for the dryer section, but can also be combined with wire tensioning systems from other manufacturers.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Iggesund Investing €60 Million in increased capacity and quality

The board of the Holmen Group, which includes Iggesund Paperboard, decided on Wednesday to give the green light for investments totalling EUR 60 million in Iggesund’s mills at Iggesund, Sweden and Workington, England.

At Iggesund the investments will eliminate bottlenecks in pulp production so it can be increased from the current 370,000 tonnes to 420,000 tonnes. The target for the board mill is to increase the capacity by 10 per cent without investments.

“After we brought the new recovery boiler on line and developed our purification systems for both air and water, the mill now has unused potential, in both the pulp and board mill, which we can activate,” comments Olov Winblad von Walter, Director of Iggesund Mill. “This is exciting because we are taking yet another step towards being one of the world’s leaders in mill technology with the lowest environmental impact. This move also further reinforces our competitiveness in the form of lower variable costs.”

The investment in Workington will increase the mill’s paperboard production capacity from the current 200,000 tonnes to 220,000 tonnes. This investment will also make the mill a leader in folding box board technology thanks to a rebuild of the paperboard machine’s press section which will increase product quality. The rebuild will be completed by June 2016.

The investment in Workington will increase the mill’s paperboard production capacity from the current 200,000 tonnes to 220,000 tonnes. This investment will also make the mill a leader in folding box board technology thanks to a rebuild of the paperboard machine’s press section which will increase product quality. The rebuild will be completed by June 2016.

“We are experiencing strong demand for our improved Incada, not least because European converters regard it as the paperboard with the best runnability for applications involving mass-market consumer products,” comments Ulf Löfgren, Managing Director of Iggesund’s mill at Workington. “In that situation of course it is positive that we can increase our capacity so more people can benefit from Incada’s advantages.”

“We see no difficulty in increasing Incada’s presence in Europe,” adds Arvid Sundblad, Vice President Sales and Marketing at Iggesund. “Our market share has been limited by our capacity. The planned capacity increase combined with Incada’s recognised quality and our service gives us a excellent position.”

Over a five-year period Iggesund Paperboard has invested strongly in strengthening its competitiveness via lower energy costs, whilst simultaneously minimising its use of fossil fuels. A total of EUR 361 million has been used for this purpose in both Workington and Iggesund. The investments announced now are more focused on increasing production.

“We have reduced our environmental impact and also taken control of our energy costs,” Sundblad concludes. “We are well equipped to face tougher competition in the paperboard market but above all with regard to other types of packaging material. Our strategy is organic growth and for Workington, this is the first step in that direction. The announced investments will give us an excellent market position in terms of both product quality and capacity.”

Xerium Introduces Hyperstar XLS Roll Cover Technology for Heavy Coat Weight Applications

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Hyperstar XLS roll cover technology. Hyperstar XLS is the latest addition to the industry leading Hyperstar XL family of roll covers. Hyperstar XLS is specifically engineered to provide a softer cover option for heavier coat weight applications in film presses. In addition, due to its unique design, this cover delivers superior wear resistance compared to other similar-hardness roll covers. Hyperstar XLS also incorporates newly developed technology providing the smoothest cover finish of the XL cover family. Learn more about Hyperstar XLS technology at http://www.xerium.com/news/xerium-news.aspx.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Hyperstar XLS roll cover technology. Hyperstar XLS is the latest addition to the industry leading Hyperstar XL family of roll covers. Hyperstar XLS is specifically engineered to provide a softer cover option for heavier coat weight applications in film presses. In addition, due to its unique design, this cover delivers superior wear resistance compared to other similar-hardness roll covers. Hyperstar XLS also incorporates newly developed technology providing the smoothest cover finish of the XL cover family. Learn more about Hyperstar XLS technology at http://www.xerium.com/news/xerium-news.aspx.

"The roll technology team is proud to unveil yet another step change in roll cover performance on these demanding heavy coat weight applications. Hyperstar XLS roll cover technology was developed to address our customers' requests for a softer roll cover with increased run time between regrinds while reducing coating cost with improved film split performance," said Mr. Bill Butterfield, EVP and CTO of Xerium. "Hyperstar XLS continues Xerium's leadership in size press and film coating applications with its patented 'XL' technology. We are continually striving for innovations enabling our customers to achieve new performance levels by applying our technology."

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries around the world and employs approximately 3,200 employees.

PROGETTO TOSCOLANO 1831: HANDICRAFT PAPER KNOW-HOW AND E-BUSINESS MEET EACH OTHER

"Progetto Toscolano 1831: a paper, a story, a future", a project of the Paper Mills Valley Foundation with the support of the City of Toscolano, is one of the eight projects selected among nearly 500 applications submitted in response to the competition notice "Invisible Assets: places and masteries of craft traditions" organized by the Telecom Italia Foundation in 2013.

"Progetto Toscolano 1831: a paper, a story, a future", a project of the Paper Mills Valley Foundation with the support of the City of Toscolano, is one of the eight projects selected among nearly 500 applications submitted in response to the competition notice "Invisible Assets: places and masteries of craft traditions" organized by the Telecom Italia Foundation in 2013.

The project was presented on November 27th during a press conference in the Burgo paper mill in Toscolano Maderno (Italy) by the project manager Filippo Cantoni and it takes advantage of some prestigious partnerships: the Paper Museum of Fabriano, the Italian Calligraphy Association and the Academy of Fine Arts "Santa Giulia" of Brescia.

A real start-up making paper craft products drawing on the centuries-old papermaking tradition of Toscolano the technique and skills of master papermakers, but it speaks the up-to-date language of the net and interacts with new technologies: an e-commerce portal in 6 languages (European and Asian idioms), an App on Papermaking Museums, interactive catalogs and video-photo contest.

Three steps will take place over 18 months. In the first step they’ll collect tutorials and trainings and organize the knowledge of the paper masters; in the second step the School of papermaking will begin its courses, which aim to train young papermakers (but also bookbinders and specialists in calligraphy) and to resume the handmade paper production in the former paper mill of Maina Inferiore; the third step will be devoted to the promotion and sale of the paper products.

An ideal passing on the baton between generations because, after seven centuries, paper comes back to create jobs and business in the ancient Paper Mills Valley.

For further information: www.valledellecartiere.it