Ianadmin

Restructuring and Staff Reductions Lenzing

![]() Restructuring and Staff Reductions in the Corporate Business Areas Engineering, Maintenance and Lenzing Technik as well as Repositioning of Lenzing Technik

Restructuring and Staff Reductions in the Corporate Business Areas Engineering, Maintenance and Lenzing Technik as well as Repositioning of Lenzing Technik

The Lenzing Group is resolutely and systematically counteracting the ongoing difficult market conditions in the global fiber industry on the basis of its cost optimization program as it reported on the occasion of publishing its business results for the first three quarters of 2014. The organizational optimization measures launched one year ago at all sites and in all business areas are having a positive impact. The results achieved up until now are encouraging but by far insufficient to offset the decline in viscose fiber selling prices on the international marketplace.

Lenzing continues to anticipate good volume demand for all man-made cellulose fibers. However, fiber selling prices on the global market are not expected to recover in upcoming quarters. This development is also attributable to the substantial decline in polyester fiber prices as a result of the massive oil price decrease, and the expected longer-lasting period of low or at least volatile cotton prices as a consequence of the surplus supply of Chinese cotton.

For these reasons, the Lenzing Group will not implement any major new projects at the Lenzing site or abroad in the foreseeable future which are designed to expand its viscose fiber production capacities. The investment volume of the company will be adjusted to reflect the current market situation and will be significantly reduced in the subsequent years. This should contribute to improving the supply situation on the international viscose fiber market, which the company would like to sustainably profit from in its role as one of the world’s largest producers.

Due to the successful completion of the new TENCEL® fiber plant in Lenzing and the reduced investment volume, technical planning and production capacities cannot be maintained at current levels, especially at the Lenzing site. This necessitates a reorganization of Lenzing’s internal engineering and maintenance business areas and its subsidiary Lenzing Technik GmbH. Organizational structures in these areas have to be adjusted to future requirements.

All in all, the restructuring measures will impact up to 250 jobs (including one-third temporary staff), mainly at the Lenzing site. The distribution of the job cuts among the various sites will be determined by the beginning of 2015 within the context of a project which is already under way. In this connection, Lenzing will try to avoid layoffs and strive to reach a mutually acceptable solution with the affected employees as it succeeded in doing within the context of the first cost optimization program. During initial talks on this issue held with the Lenzing Works Council, Lenzing agreed to extend the current redundancy program (social plan) and to offer the possibility for employees newly affected by the downsizing to transfer to the Lenzing Labor Foundation.

At the same time, Lenzing is working on a strategic reorientation of its subsidiary Lenzing Technik

GmbH to enable it to focus more strongly on the external market in the future.

The Lenzing Group

The Lenzing Group is a world market leader with headquarters in Austria, production sites in all major markets as well as a worldwide network of sales and marketing offices. Lenzing supplies the global textile and nonwovens industry with high-quality man-made cellulose fibers. The portfolio ranges from dissolving pulp, standard and specialty cellulose fibers to engineering services.

Lenzing quality and innovative strength set global standards for man-made cellulose fibers. With 75 years of experience in fiber production, the Lenzing Group is the only company worldwide combining the manufacturing of all three man-made cellulose fiber generations on a large industrial scale under one roof – from the classic viscose to modal and lyocell (TENCEL®) fibers. The success of the Lenzing Group results from a unique combination of consistent customer orientation together with its leadership in innovation, technology and quality.

Lenzing is committed to the principle of sustainable management and very high environmental standards.

Lenzing's core business fibers is complemented by our activities in the business field engineering.

Lenzing Technik GmbH

Lenzing Technik GmbH is a globally operating industrial partner with comprehensive expertise and specialized expert status in the fields of engineering and industrial plant design and construction.

Lenzing Technik offers engineering, production, automation and related services for various industries. The focus is on environmental technology, viscose, fiber, pulp, filtration, separation and surface technologies as well as robotics and mechatronics.

In 2013 Lenzing Technik, which has a workforce of about 600 employees and a temporary staff of 120 people, generated 40% of its total sales of approximately EUR 120 mn from external contracts.

Further information is available at: http://www.lenzing-technik.com

Valmet to strengthen its services presence in China

Valmet has made investments in its two service centers in Waigaoqiao and Guangzhou in China. The service centers are now able to offer pulp and paper customers a wider range of services, including manufacturing of pulp and paper process consumables and new press roll covers for board- and papermaking.

Valmet has made investments in its two service centers in Waigaoqiao and Guangzhou in China. The service centers are now able to offer pulp and paper customers a wider range of services, including manufacturing of pulp and paper process consumables and new press roll covers for board- and papermaking.

"Both Valmet service centers can now provide faster and more flexible support to an increasing customer base. This is in line with our target to increase our presence close to where our global customer base is operating. Valmet solutions and services help pulp-, paper- and power-makers maintain their competitiveness, meet their environmental protection goals and promote sustainable development," says Jukka Tiitinen, Business Line President, Services at Valmet.

Increasing process parts manufacturing capacity in China

Valmet has been concentrating its pulp and paper process parts manufacturing in China to Waigaoqiao service center. Operations in Waigaoqiao began in early 2000. In 2005, screen basket manufacturing started. Today, the Waigaoqiao service center also provides high-quality doctor blades and suction roll seals and related services.

New roll covering capacity in Guangzhou

The Guangzhou service center, which opened in 2008, is situated close to the pulp and paper industry in southern China. It offers dedicated roll expertise through its modern, well-equipped roll covering and maintenance workshop, advanced machinery maintenance and process development services. With this latest investment, Valmet is increasing the workshop's roll covering capacity for polyurethane roll covers.

The Guangzhou service center, which opened in 2008, is situated close to the pulp and paper industry in southern China. It offers dedicated roll expertise through its modern, well-equipped roll covering and maintenance workshop, advanced machinery maintenance and process development services. With this latest investment, Valmet is increasing the workshop's roll covering capacity for polyurethane roll covers.

The new roll covering line in Guangzhou will be fully operational at the end of November 2014, when the service center will start manufacturing PressPolar covers for board-making, PressFox and VacuFox covers for papermaking and PressHusky and VacuHusky covers for tissue-making. The new line includes roll cover technology that enables a longer cover lifetime, energy savings, and improved dewatering in customers' processes, as well as extended grinding intervals.

In addition to Waigaoqiao and Guangzhou, Valmet also operates service centers in Wuxi and Zibo in China.

For further information, please contact:

Jukka Tiitinen, Business Line President, Services, Valmet, tel. +1 404 4330937, This email address is being protected from spambots. You need JavaScript enabled to view it.

Waigaoqiao: Lars Eklund, Vice President, Performance Parts, Services, Valmet, tel. +46 70 62 68 228, This email address is being protected from spambots. You need JavaScript enabled to view it.

Guangzhou: Samppa Ahmaniemi, Director, Roll Covers, Services, Valmet, tel. +358 400 461 417, This email address is being protected from spambots. You need JavaScript enabled to view it.

Read more about:

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Two Valmet-supplied boardmaking lines successfully started up at Anhui Shanying Paper in China

Valmet has supplied two high quality containerboard machines for Anhui Shanying Paper Industry Co., Ltd in the City of Ma'anshan in Anhui Province, China. Both machines, paper machine 5 (PM 5) and paper machine 6 (PM 6), were recently successfully started up.

Record speed right after start up

The PM 5 and PM 6 start-ups were successful with good results. The new PM 6 machine set its 24 hour average machine speed record of 1,398 m/min already 12 days after the start-up.

"The Valmet board machine is very well equipped and has first-class performance. Our start-up has been very smooth. Valmet and Shanying have arranged targeted board machine training for the operators, which is also of great help for us," says Mr. Wang, Production Manager of Anhui Shanying PM6.

Lightweight containerboard with gap- and hybrid forming concepts

"Making lightweight containerboard using gap forming technology is new for Chinese containerboard makers. The most efficient European containerboard lines, making high quality lightweight end products, utilize gap forming concepts with excellent results. Now Anhui Shanying has taken this step with Valmet's technology and we are very pleased to cooperate with this forward-looking company," says Mark Singler, Director of Process Technology, Valmet.

Valmet's delivery for PM 6 included a complete 8.60-m-wide (wire) containerboard machine from headbox to winder. The delivery also included machine clothing and a wide range of process systems. This kind of an extensive overall delivery package from the same supplier enabled the design of highly energy-efficient production line.

The new PM 6 is equipped with a gap forming technology, OptiFormer Gap, which enables a new, higher production speed category for lightweight, high quality containerboard making. The production line also includes two winders. PM 6 produces fluting and testliner grades in the basis weight range of 50 -110 g/m2 and with design production speed of 1,500 m/min.

Valmet's delivery for PM 5 included a complete boardmaking line from headbox to reel with chemical systems, winder and roll handling equipment. The new PM 5 is equipped with three headboxes, multi-Fourdrinier forming section, center roll -based press section, sizing with film application as well as hard nip calender. The production line is completed with two-drum winder. The delivery also included machine clothing and a wide range of process systems.

The new 7.92-m-wide (reel) PM 5 produces recycled testliner and kraft top liner grades in the basis weight range of 90 to 175 g/m2. The design speed is 1,200 m/min.

About Anhui Shanying

Anhui Shanying Paper Industry Co., Ltd. manufactures and distributes packaging paper products in China. It offers paper and cardboard cartons. The company was established in 1957 and registration place is Maanshan, China.

For further information, please contact:

Ari J Leppänen, Senior Project Manager, Paper Mills, Valmet, Tel. +358 40 558 4946

Mark Singler, Director, Process Technology, Paper, Valmet China, Tel: +86 13911949320

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

European Paper Week – It’s all about competitiveness

European pulp and paper industry concludes successful event

The European pulp and paper industry successfully concluded its 16th European Paper Week, titled “It’s all about competitiveness”. The three-day event brought together over 350 participants from the sector, related organisations as well as the European institutions, providing a high-level discussion and networking platform.

The European pulp and paper industry successfully concluded its 16th European Paper Week, titled “It’s all about competitiveness”. The three-day event brought together over 350 participants from the sector, related organisations as well as the European institutions, providing a high-level discussion and networking platform.

Sessions not only dealt with the competitiveness of industry, but also the overall competitiveness of the EU economy. Energy costs and regulatory burden were key themes.

The focus of the Juncker Commission on jobs, growth and competitiveness is crucial for Europe. “This week showed the new European Commission launching a 300 billion euro investment package, putting a focus on better regulation and assessing the member states’ budgets. We call upon the European Commission to follow these actions with a new single project for Europe – Competitiveness,” said Gary McGann, CEPI (Confederation of European Paper Industries) chairman.

CEPI launched its PACT with EU policy makers, a call for cooperation with the Juncker Commission. It underlines the industry’s 5 billion euro investments in Europe over the next three years and the strong need for adequate policymaking to enable this.

CEPI further announced its participation in a joint project on ecodesign for paper products with the prestigious World Economic Forum.

Throughout the event, the industry reaffirmed its positioning as a strategic sector playing an active role in the bioeconomy. The sector remains focused on innovation as the way forward. Renowned economist Professor Mariana Mazzucato enticed a packed audience with her views on the government’s role in innovation, or the “entepreuneurial state”.

”Following the CEPI 2050 roadmap and Two Team project last year, we have helped build the bio-based industries Public Private Partnership and launched consortia to develop the Two Team concepts. Professor Mazzucato shows us the next step ahead – the design of EU innovation policy, post 2020,” said Marco Mensink, CEPI Director General.

For more information please contact Annie Xystouris, at This email address is being protected from spambots. You need JavaScript enabled to view it. or +32 2 627 49 24.

PACT with EU policy makers can be found at: http://www.cepi.org/node/18565

About European Paper Week

European Paper Week is one of the most important and respected events of the pulp and paper industry. It brings together key players and representatives from across the industry, related sectors and the European institutions, providing an annual platform for high-level debate on the issues that really matter to the paper industry. Its success has been reflected in its growing attendance. This year the event took place in the Thon Hotel EU in Brussels.

Twitter: @EUPaperWeek #epw14

CEPI aisbl - The Confederation of European Paper Industries

The Confederation of European Paper Industries (CEPI) is a Brussels-based non-profit organisation regrouping the European pulp and paper industry and championing industry’s achievements and the benefits of its products. Through its 18 member countries (17 European Union members plus Norway) CEPI represents some 515 pulp, paper and board producing companies across Europe, ranging from small and medium sized companies to multi-nationals, and 950 paper mills. Together they represent 23% of world production.

SCA launches Solo Print, one-side coated paper

SCA has developed Solo Print, a one-side coated paper as part of its Sustainable Packaging product family. This paper gives printability in the same class as upmarket magazines, with the market’s best environmental profile.

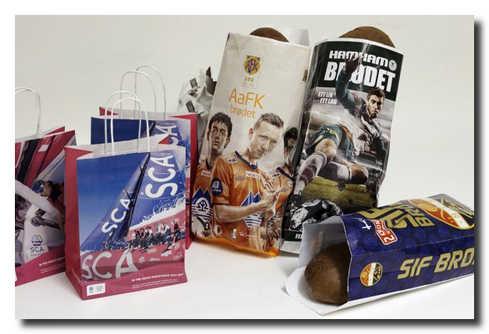

Solo Print packaging © SCA Forest Group

The new product, Solo Print, is specially developed for flexible packaging, well suited for bags, wrapping paper, flowpack and banners. Solo Print is characterised by a very high print quality and very high opacity (less transparent). Solo Print is certified for direct contact with dry and fatty food. Solo Print is also suitable for lamination base or PE/PP coating on the inside to allow for heat sealing and to provide moisture protection. Solo Print can also be used in board applications. Its high opacity and brightness provides a perfect surface for various types of board applications. Thanks to its good profiles and dimensional stability, Solo Print is also suitable as a lightweight liner in corrugated applications.

“Our new Sustainable Packaging products have been well received by converters and brand owners,” says Rolf Johannesson, Marketing Director at SCA Forest Products. “We have identified strong demand for a one-side coated paper and we have therefore decided to launch one.”

The coating is of the same high quality as the printing paper that SCA produces for magazines and advertising. The paper is based entirely on fresh fibre and is therefore highly suitable for applications within the food sector.

Solo Print complements SPLENDO, OPERIO and PURO, three product lines that have already been launched within Sustainable Packaging. They include both coated and uncoated grades and combine a resource-efficient and light packaging material with excellent printability. They also offer attractive features in terms of product safety and environmental performance, such as low carbon footprint, fresh fibre from sustainably managed forests and environmentally compatible production.

Solo Print complements SPLENDO, OPERIO and PURO, three product lines that have already been launched within Sustainable Packaging. They include both coated and uncoated grades and combine a resource-efficient and light packaging material with excellent printability. They also offer attractive features in terms of product safety and environmental performance, such as low carbon footprint, fresh fibre from sustainably managed forests and environmentally compatible production.

“We have applied our extensive knowledge of both printing on paper and packaging solutions in the development of our new products, to combine printing performance with efficient resource management and low cost. We are also proud of our world-class environmental performance,” says Rolf Johannesson, Marketing Director at SCA Forest Products.

SCA Ortviken in Sundsvall has an annual production capacity of 900,000 tonnes of coated and uncoated paper for printing and packaging and has around 700 employees.

For additional information please contact:

Rolf Johannesson, Marketing Director,

SCA Forest Products, tel. +46 (0)60 19 41 52.

Björn Lyngfelt, Information Director,

SCA Forest Products, tel. +46 (0)60 19 34 98.

New Innovation from Synthron for Tissue Paper Manufacturing

The “traditional” European Paper Making Industry has been declining and restructuring in Europe over recent years. Nonetheless there are opportunities which do appear in this industrial sector, thanks mainly to the development of new applications and product innovations. This is particularly apparent in the fields of tissue making, packaging and with specialty papers. SYNTHRON, a subsidiary of PROTEX INTERNATIONAL has a 40 year history in the paper making industry: SYNTHRON – considers that innovation is a priority – and allocates 5% of its turnover for R&D in order to develop new applications and novel chemistries for paper making and to anticipate the future requirements of this particular market.

The “traditional” European Paper Making Industry has been declining and restructuring in Europe over recent years. Nonetheless there are opportunities which do appear in this industrial sector, thanks mainly to the development of new applications and product innovations. This is particularly apparent in the fields of tissue making, packaging and with specialty papers. SYNTHRON, a subsidiary of PROTEX INTERNATIONAL has a 40 year history in the paper making industry: SYNTHRON – considers that innovation is a priority – and allocates 5% of its turnover for R&D in order to develop new applications and novel chemistries for paper making and to anticipate the future requirements of this particular market.

For Robert MOOR, CEO of SYNTHRON: “we have to anticipate the future requirements of paper making which is presently in transformation. To remain focused in the chemistry of this sector, our Center of Studies and Discoveries develops products and searches to innovate constantly”.

SYNTHRON has refined and specializes its product range by launching a new auxiliary: SYNTHRO®STAB HE which is used in tissue making manufacturing process to remove bad odours. The tissue making sector produces paper for public and domestic sanitary use also products like disposable handkerchiefs, baby’s diapers, temporary medical sheeting used for examinations, domestic kitchen roll, tablecloths and towels…), this market segment is growing.

The tissue making process can involve either virgin pulp fibres of cellulose or contain some recycled cellulose fibres. One of the main problems encountered by the producers of this type of paper is the presence of bad odours, often caused by residues of hexanal (or hexanaldehyde C6H120). SYNTHRO®-STAB HE, functions by interfering with the chemical reaction which releases the smell by blocking and the deactivating the catalysts of the reaction. SYNTHRO®-STAB HE meets the requirements of the Food and Drug Administration (FDA).

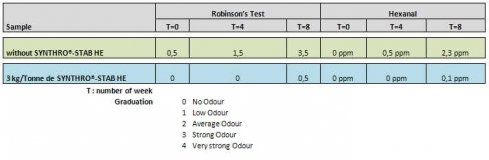

Robinson’s test proves the efficacy of SYNTHRO ®-STAB HE:

After 8 weeks, the background concentration of the treated product is 0,1 ppm versus 2,3 ppm this clearly demonstrates the effectiveness of SYNTHRO®-STAB HE as the bad odour has been eliminated from the tissue.

Generally paper tissue usage increases with rise of living standards, and for the Consumer it’s important to improve the quality of the tissue and to offer an effective solution to eradicate bad odours from the product.

The SYNTHRO®-STAB HE manufactured at industrial site of Auzouer-en-Touraine in Indre et Loire and in Saint-Avold in Moselle (France).

Stora Enso Executive Joins EcoPlanet Bamboo

EcoPlanet Bamboo Group continues its executive recruitment of world class individuals from the largest plantation forestry and fiber based manufacturing companies in the United States, Europe and Latin America with the hiring of Francisco Ferreira as Managing Director of EcoPlanet Bamboo’s Central American operations.

EcoPlanet Bamboo Group continues its executive recruitment of world class individuals from the largest plantation forestry and fiber based manufacturing companies in the United States, Europe and Latin America with the hiring of Francisco Ferreira as Managing Director of EcoPlanet Bamboo’s Central American operations.

“Mr. Ferreira is a perfect fit for our operational needs in Central America”

Mr. Ferreira brings 30 years of large scale forestry and nursery experience, most recently responsible for forestry research and a 20 million tree nursery of a 135,000 hectare plantation in Uruguay. Within those responsibilities Mr. Ferreira managed an organization with hundreds of employees, multi-million dollar annual operations budgets, and the construction of a new $17 million nursery. Mr. Ferreira joins EcoPlanet Bamboo from Montes del Plata, a joint venture company of Stora Enso and Arauco. Stora Enso, a company with Swedish and Finnish origins, has 28,000 employees and operations in 35 countries, and is included on the Dow Jones Sustainability Index (DJSI). Arauco is a leader in the production of kraft wood pulp and panels, as well as having a global network of agents that sell sustainable timber products in over 71 countries.

“Mr. Ferreira is a perfect fit for our operational needs in Central America,” says Troy Wiseman, CEO of EcoPlanet Bamboo Group. “Although Mr. Ferreira holds multiple degrees in engineering and forestry, as well as a Masters degree in soil and plant nutrition, it is his desire to be on the ground and in the field getting his hands dirty, so to speak, side by side with our team that excites me the most about his hiring. Despite over three decades of experience, his desire to teach, train and support a team from the bottom up shows great humility and represents significant value to an organization like EcoPlanet Bamboo.”

About EcoPlanet Bamboo - "Making Bamboo the Timber of the 21st century"

EcoPlanet Bamboo is leading the industrialization of bamboo as a viable and environmentally attractive alternative fiber for timber manufacturing industries. The conversion of degraded land into certified bamboo plantations is coupled with innovative technology development to provide bamboo based solutions for products and markets that currently contribute to the deforestation of our world’s natural forests. EcoPlanet Bamboo enables bamboo to be a viable solution across multiple sectors, including textiles, pulp and paper, renewable energy and activated carbon.

With operations currently in Central America, Southern and West Africa, expansion into Southeast Asia underway, and additional countries in Latin America under evaluation, EcoPlanet Bamboo targets areas that have suffered extreme deforestation, ensuring that bamboo plantations and bamboo based products are only ever developed on degraded land, and as a deforestation free crop. In conjunction with each plantation, R&D focuses on ensuring clean manufacturing techniques, leapfrogging current technology to create a turnkey solution.

Plantations are certified under relevant sustainability standards and climate change benefits are quantified and commercialized through the Verified Carbon Standard (VCS).

Contacts

EcoPlanet Bamboo

Kristena Blume, 847-387-3609

This email address is being protected from spambots. You need JavaScript enabled to view it.

Sappi’s most valuable brand Magno is now available on stock in Germany

The Magno range is the trusted graphic range for printers and creatives throughout the world due to its extensive availability, consistency and quality.

The Magno range is the trusted graphic range for printers and creatives throughout the world due to its extensive availability, consistency and quality.

Sappi Europe is pleased to announce that Igepa group has chosen to become a preferred stockist merchant partner for the Magno range of coated graphic papers in Germany.

Flavio Froehli, Sales Director for Sappi’s commercial print products said; “We are delighted to have our long term partner becoming our German stockist merchant for the Magno range. Igepa are the ideal partner for the German market reinforcing Magno as the strongest brand in Europe with stockist partners in all European markets. Already today Igepa has the most extensive range of Sappi products in stock, supported by a network of superb warehouse facilities. Together, Sappi and Igepa will be able to provide the best product range and service flexibility to the Germany printing market.”

Further information:

The Magno graphic paper range offers eight products including gloss, silk, matt and uncoated surfaces, basis weights range from 80gsm to 400gsm with all products having an aligned high white shade.

For further information, samples or to organize a trial please contact our local sales office

Tel: +49 (0) 511 123 33 700 email: This email address is being protected from spambots. You need JavaScript enabled to view it.

AboutSappi

Sappi Europe SA is the leading European producer of coated fine paper used in premium magazines, catalogues, books and high-end print advertising. Headquartered in Brussels, Belgium, Sappi Europe is recognised for innovation and quality. Its graphic paper brands include Magno™, Quatro™, Vantage™, Royal™, Galerie™, GalerieArt™ and Jaz™ ranges. Algro®, Fusion®, Leine® and Parade® are the brands for speciality labelling, topliner, packaging papers and boards. Sappi papers are produced in mills accredited with ISO 9001, ISO 14001 and OHSAS 18001 certification and EMAS registration for all our mills in the EU. Sappi European mills hold chain-of-custody certification under the Forest Stewardship Council (FSC®) and/or the Programme for the Endorsement of Forest Certification (PEFC™) schemes.

Sappi Europe SA is a division of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with over 13,500 employees and manufacturing operations on three continents in seven countries, sales offices in 50 countries, and customers in over 100 countries around the world.

Learn more about Sappi at www.sappi.com.

Steveco has extended the network

In two words: sell and develop...

This is how Peter Langerbeck, Country Manager, Steveco Logistics describes his new job in Swedish representative office of Steveco.

Steveco Logistics, running the Steveco forwarding business around all corners of the globe, has widened its representation network in Sweden and the Baltic countries during this autumn.

A major part of Steveco’s logistics business has to do with handling export, import and transit cargo to and from Russia as well as the CIS states. With this in mind, Sweden may sound like surprising direction for the company.

In fact, Sweden is a key location for forest and other heavy industries, so many of our existing and potential customers operate there, says Tomi Rautio, Senior Vice President, Steveco Logistics.

Ultimately, it’s all about building a full-service logistics network. Poland and Germany are active routes for southbound exports, while Finland and the Baltics provide alternative options for shipments from Sweden. However, one thing is constant: the need for local expertise.

It’s important to have people on the ground who not only know the local conditions inside out, but can also handle the full range of services required by our customers, says Tomi Rautio. - Our customers are always looking for the best routes for their cargo and we are there for them.

We do not copy paste

Peter Langerbeck has his office in a computer...

Peter Langerbeck has his office in a computer...

Sweden is a significant market for logistics services. Steveco opens up new opportunities for our customers in the Baltic Sea region. Steveco’s strengths lie in strong technological expertise and experience of eastbound traffic, Peter Langerbeck says.

Steveco promotes a one stop shop principal for its customers and with almost 1000 employees and specialists in every field this runs very smoothly. Now our customers want us to arrange the same from their Swedish production units to Steveco’s main target markets, Finland, the Baltics, Russia, CIS and East Asia.

This means tailor-made services to each customer. We do not copy paste, Peter Langerbeck notes.

In addition Sweden has a local industry with eastbound markets, which are politically confused, for the time being. The last thing the sales process for this industry needs is more uncertainty, and we in Steveco can reassure the customer to trust to the long experience and professionalism of our staff. We have our own network in every market we offer our services.

Lean Flexibles Install a High Performance Universal X6 Slitting Machine

Lean Flexibles are a fast growing supplier and contract slitter of flexible packaging materials based at Hinckley, UK. Lean offer short lead time supply of a range of materials including PET, OPP, PE, CPP and multi-layer laminates. In choosing the Universal X6 slitting machine, Lean needed a wider web machine which minimised job set up times, produced consistent high quality rolls and was able to run at high speed.

The Universal X6 machine is designed for processing flexible materials. A typical specification includes digital web guiding, automatic knife setting (Computaslit), additional tension zone through slitting, closed loop rewind tension control, constant geometry contact rollers, automatic core alignment (Computacore) and a running speed of 600m/min. The machine is designed to be simple to operate with a 22inch touch screen interface. A typical changeover, including setting 20 shear knives can take less than two minutes making the machine ideal for short run work. The integrated drive and control system offers precision and repeatability with extensive diagnostics including dynamic circuit diagrams. All this performance in a machine with a small footprint.

Commenting on the investment, Darren Beardsley, Technical Director of Lean Flexibles said “To achieve our business objectives, we needed productivity, consistency,reliability and the ability to process thin extensible films through to rigid APET films.The Universal X6 has met our requirements and more. Setting shear knives used to take two people to lift the cutter shaft out and back in and the knives would take a long time to set. Now we programme the next slit pattern whilst the machine is running. Once the machine stops, the knives are set faster than we can load a new parent roll into the machine. The additional tension zone through slitting has helped us achieve consistently good quality slit edges even when running low rewind tensions. During our acceptance trials at Universal, we tailored the machine to our specific requirements, ran a range of materials and saved the settings in the recipe system. With load cell measurement of rewind tensions we know that we can return to these settings and achieve exactly the same tension profile allowing us to run at 600m/min with confidence.”

Alan Jones, MD, Universal Converting Equipment added “Lean chose to spend more than they originally planned by investing in technology that will pay back for years to come. To compete in their markets they needed to minimise downtime and maximise running speed in the knowledge that rolls will always be good quality. This is what the Universal X6 has been designed to achieve year after year. Although the X6 incorporates a lot of technology, it is based on fundamental design principles - keep the web path as short as possible, use feedback devices to ensure the machine is doing exactly as required, make the structure rigid so alignment stays perfect and ensure the machine is easy to set up and operate. Load cell tension feedback, automatic knife positioning and core alignment dramatically reduces downtime and increases the time the machine is making money.”

For further information contact Alan Jones, (Managing Director) on +44 (0) 1473 403333, This email address is being protected from spambots. You need JavaScript enabled to view it. or online at www.universalconvertingequipment.com