Ianadmin

Laila Rogestedt appointed Senior Vice President Innovation and New Business

Laila Rogestedt has been appointed Head of Innovation and New Business at Södra. She will assume her position on 1 March, when she will also become a member of Group Senior Management reporting to the President and CEO Lars Idermark.

Laila Rogestedt has been appointed Head of Innovation and New Business at Södra. She will assume her position on 1 March, when she will also become a member of Group Senior Management reporting to the President and CEO Lars Idermark.

Laila Rogestedt has a Master of Science in Chemical Engineering from Chalmers University of Technology, with a degree in Polymer Technology, and has held various positions in the international chemicals group Borealis since 1991. She is currently responsible for the Borealis Innovation Centre in Stenungsund, and for product and technology development in polyethylene plastic. She has also held various functions in such areas as production, investment projects, HR and marketing. Prior to joining Borealis, she worked with materials development at Volvo Cars.

"I am delighted that Södra has recruited Laila Rogestedt. Innovation and New Business are strategic future areas for Södra - in our work with product and process care for the existing pulp market, but also in the development of new products from wood," said CEO Lars Idermark.

"In a rapidly changing world with major global challenges - resource supply and climate change to name but a few - it is critical that innovation is high on the agenda of successful companies. Against this background, and with Södra's key role and clear ambition, I look forward to making a contribution to this effort," commented Rogestedt.

Rogestedt succeeds Karin Emilsson who, as previously announced, will be leaving Södra. Södra Innovation and New Business is located at Värö in southern Sweden in the same area as Södra's pulp mill.

For further information, please Contact:

Lars Idermark, President and CEO

tfn: +46 (0) 470-894 35

Laila Rogestedt, incoming Senior Vice President Innovation and New Business at Södra

tfn: +46 (0) 766-378 138

Annica Gerentz, Senior Vice President Corporate Communications

tfn: +46 (0) 470-894 81

Cascades invests $13 million in Vaudreuil and Drummondville

Cascades Inc. (TSX: CAS), a leader in the recovery and manufacturing of green packaging and tissue paper products, announces the acquisition and installation of two new printing presses in its Québec plants, Norampac – Vaudreuil and Norampac – Drummondville , which specialize in manufacturing corrugated packaging products.

Cascades Inc. (TSX: CAS), a leader in the recovery and manufacturing of green packaging and tissue paper products, announces the acquisition and installation of two new printing presses in its Québec plants, Norampac – Vaudreuil and Norampac – Drummondville , which specialize in manufacturing corrugated packaging products.

Charles Malo , Vice-President and Chief Operating Officer for Packaging at Norampac stated, "This major investment in Québec is part of our efforts to modernize Norampac's and Cascades' assets. Similar investments were made at several of Norampac's corrugated converting plants in Ontario , and productivity at the plants increased significantly. We believe that the investments in Québec will have the same positive spin-offs, allowing us to respond more quickly to our customers' needs, offer packaging products of greater quality, and increase our productivity."

The Evol presses, made by Japanese company Mitsubishi, offer the latest in printing technology, including high-speed production. The investment of more than $13 million will allow the Norampac plants to increase their productivity, their versatility and the quality of their products. The new press at the Vaudreuil plant has been in operation since September 2014, and the press at the Drummondville plant was commissioned at the beginning of November.

"The new state-of-the-art equipment is part of our plan to increase our productivity and market share by focusing on strategic sectors as a means of keeping the Company on track as we move forward. Today's gesture demonstrates the trust we are placing in the employees at the Vaudreuil and Drummondville plants. Cascades will continue to grow here, as it will in the rest of North America ," added Alain Lemaire , Cascades' Executive Chairman of the Board.

Founded in 1964, Cascades produces, converts and markets packaging and tissue products that are composed mainly of recycled fibres. Cascades employs close to 12 000 women and men, who work in over a hundred production units in North America and Europe . With its management philosophy, half a century of experience in recycling, and continuous efforts in research and development as driving forces, Cascades continues to deliver the innovative products that customers have come to rely on. Cascades' shares trade on the Toronto Stock Exchange under the ticker symbol CAS .

SOURCE Cascades Inc.

Investors:

Riko Gaudreault

Director, Investor Relations, Cascades Inc.

Telephone: 514-282-2697

This email address is being protected from spambots. You need JavaScript enabled to view it.

Source:

Marc-André Dépin

President and Chief Executive Officer

Norampac, a division of Cascades Canada ULC

Valmet to supply new winding technology for Stora Enso in Finland

Valmet will supply Stora Enso with a new winder and auxiliaries for its BM5 board machine located in the company's Tainionkoski unit in Imatra Mills in Finland. The target of the project is to increase the winding capacity and upgrade the winding technology for improved safety and more efficient maintenance operations. The rebuilt finishing section is scheduled to start up during the last quarter of 2015.

Valmet will supply Stora Enso with a new winder and auxiliaries for its BM5 board machine located in the company's Tainionkoski unit in Imatra Mills in Finland. The target of the project is to increase the winding capacity and upgrade the winding technology for improved safety and more efficient maintenance operations. The rebuilt finishing section is scheduled to start up during the last quarter of 2015.

"This finishing area rebuild is a continuation of Valmet's and Stora Enso's cooperation and supports our strategy of offering competitive solutions to our customers that contributes both performance and sustainable operations in terms of safety", says Jari Vähäpesola, President of Paper business line, Valmet.

The order is included in Valmet's fourth quarter 2014 orders received. The value of the order will not be disclosed.

Valmet's high capacity winding technology with reliable throughput

In addition to the new OptiWin Drum two-drum winder, Valmet's delivery will include winder pulper, transfer rails, related dust control systems and core handling system. Installation supervision, commissioning, start-up and training services are also included in the finishing area rebuild delivery. The new OptiWin Drum winder combines high capacity with smooth and reliable operation and quick installation. The OptiWin Drum fully automated two-drum winder comprises parent roll transferring, core feeding, web splicing and tail end closing.

"The investment is in line with Stora Enso's transformation into a customer focused renewable materials company. Selected winder technology will enhance the quality and cost-competitiveness of our Tainionkoski unit in the global markets," says Marko Pekkola, Mill Director Imatra Mills, Stora Enso.

About Stora Enso

Stora Enso is the global rethinker of the paper, biomaterials, wood products and packaging industry. The Group has some 29 000 employees in more than 35 countries worldwide, and is a publicly traded company listed in Helsinki and Stockholm. Company's annual production capacity is 5.4 million tonnes of chemical pulp, 11.7 million tonnes of paper and board, 1.3 billion square metres of corrugated packaging and 5.6 million cubic metres of sawn wood products, including 2.9 million cubic metres of value-added products. Sales in 2013 were EUR 10.5 billion, with an operational EBIT of EUR 578 million.

Tainionkoski BM 5 board machine produces packaging board grades at the capacity of 270 000 tonnes per year.

Further information, please contact:

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills Business Unit, Valmet, tel. +358 40 744 8182

Simo Rahkonen, Senior Mill Sales Manager, EMEA, Valmet, tel. +358 40 704 8774

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

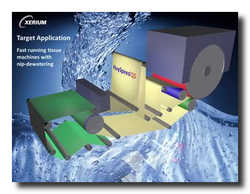

Xerium Introduces HuySpeed QS Tissue Felt Technology

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched HuySpeed QS tissue felt technology. HuySpeed QS is designed specifically to reduce the start-up cycle on new felts and to provide more efficient overall production on high speed tissue machines. The unique combination of the felt's base and surface components enable a tissue machine to achieve full speed immediately after the start-up of a new felt. In addition, HuySpeed QS technology has already proven to help reduce energy consumption along with improved tissue sheet quality. Learn more about HuySpeed QS technology at http://www.xerium.com/news/xerium-news.aspx.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched HuySpeed QS tissue felt technology. HuySpeed QS is designed specifically to reduce the start-up cycle on new felts and to provide more efficient overall production on high speed tissue machines. The unique combination of the felt's base and surface components enable a tissue machine to achieve full speed immediately after the start-up of a new felt. In addition, HuySpeed QS technology has already proven to help reduce energy consumption along with improved tissue sheet quality. Learn more about HuySpeed QS technology at http://www.xerium.com/news/xerium-news.aspx.

"We are delighted to bring our already successful QS technology to the tissue industry. This unique product concept provides enhanced felt and machine performance right from start-up," said Mr. Bill Butterfield, EVP and CTO of Xerium. "HuySpeed QS helps our customers overcome the traditional slow-speed startups for new machine clothing, and we are already seeing reports with improvements in production, efficiency, and energy savings."

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries around the world and employs approximately 3,200 employees.

Xerium Technologies, Inc.

Steve Cole

Director - Global Marketing

This email address is being protected from spambots. You need JavaScript enabled to view it.

Rottneros newly developed High Yield Pulp for tissue got a head start after the launch at London Pulp Week

The newly developed High Yield Pulp by Swedish pulp producer Rottneros, Absorption Express got a very good reception at London Pulp Week the other week. This was the perfect opportunity to meet the World market with a new product when the World’s paper industry was present.

The newly developed High Yield Pulp by Swedish pulp producer Rottneros, Absorption Express got a very good reception at London Pulp Week the other week. This was the perfect opportunity to meet the World market with a new product when the World’s paper industry was present.

Tissue is a collection name for paper qualities used for paper napkins, kitchen towels and toilet paper. This area has a fast growing demand.

Absorption Express has been developed by Rottneros Bruk during last year and has been tested in full commercial scale at a number of paper mills. The product is a High Yield Pulp produced in one of Rottneros unique production lines.

The good thing about Absorption Express is that the product replaces much more expensive pulp in the production of tissue. At the same time it has twice the absorption capacity and twice the absorption speed and has an excellent bulk in relation to the pulps it replaces, says Olle Dahlin, Managing Director of the plant Rottneros Bruk.

The development of Absorption Express from idea to commercial success has been a team effort within Rottneros Bruk involving large parts of the work force. Nils Hauri, the production manager thinks the development routines at Rottneros gives a very good potential for further development and invention of new products and customer customized pulp.

The new Rottneros Group CEO, Per Lundeen, who was also present in London says that both the mills of the Rottneros Group, Rottneros Bruk and Vallviks Bruk have been very successful with their market positioning with highly specialized pulp.

For further information please contact: Olle Dahlin, Managing Director Rottneros Bruk AB +46703667300

Rottneros discloses the information provided herein pursuant to the Securities Markets Act and/or the Financial Instruments Trading Act. The Information was submitted for publication on Thursday 1:th of December 2014 at 10:00 am CET.

Rottneros is an independent producer of market pulp. The Group comprises the parent company Rottneros AB, listed on NASDAQ OMX Stockholm, and its subsidiaries Rottneros Bruk AB and Vallviks Bruk AB with operations involving the production and sale of market pulp. The Group also includes the wood procurement company Rottneros Baltic SIA in Latvia. The Group has approximately 250 employees and had a turnover of approximately SEK 1.4 billion in the 2013 financial year.

Kemira inaugurated its state-of-the-art chemical production plant in Nanjing, China

Kemira celebrated the completion of the company’s new Nanjing production base. Over 200 distinguished guests were invited to witness this historical moment, including Marja Joenusva, Consul General of the Republic of Finland, and Jari Rosendal, President and CEO at Kemira, senior officials from the Nanjing government, Kemira’s clients, media representatives and company staff.

The Nanjing plant is located in the Nanjing Chemical Park, Jiangsu Province. Kemira’s already completed and future investments into the plant will amount to approximately USD 100 million in an area of 77,000㎡. It will provide a wide range of functional and process chemicals for water-intensive industries such as the paper industry. The estimated annual capacity is 100,000 tons. The first phase operations provide nearly 100 jobs for the local community. After the ground breaking in September, 2011, the construction was completed in August 2013, and the production started in the end of 2013.

The new plant is equipped with cutting-edge facilities offering the highest quality, featuring a high degree of automation and use of sophisticated IT-systems in the production process. The plant operations are supported by Kemira’s global expert teams with strong R&D capabilities, the Asia-Pacific R&D Center in Shanghai and local laboratories. The plant conforms to the highest EHS (environment, health and safety) standards in the industry, striving to be a leader in the sustainable development of China’s chemical industry.

Kemira’s new plant is focused on the Asian market, China in particular. Production will be mainly serving the paper industry, while at the same time providing products and services to the oil & mining industry and municipal water treatment. Currently there are five production lines serving across an array of chemical products for pulp and paper manufacturing. The production capacity for sizing agent (ASA), which mainly used for improving water-resistance in middle to high end paper, will be the largest in Asia.

Besides ASA products, the new plant also produces polyacrylic ester, polyacrylamide emulsion, defoamers, and deinking agents, all of which are widely applied in key paper manufacturing processes.

“This investment is an important move for Kemira to strengthen its position in China and promote sustainable development in the paper industry,” said Jari Rosendal, President and CEO of Kemira. He further noted, “As a global chemicals company focused on serving the water intensive industries, Kemira has consistently helped clients to create more value by providing expertise, application know-how and tailored chemicals for improving our customers’ water, energy and raw material efficiency. Here in China and Asia-Pacific, we see huge business potential for us especially in serving the paper industry. We demonstrated our commitment to this industry and the region recently by announcing the acquisition of AkzoNobel’s global paper chemical business. This alone will double the size and scope of our business in the Asia-Pacific region.”

Joe Chan, President of Asia-Pacific Region at Kemira, commented: “Kemira always endeavors to provide the water-intensive industries with the best possible service and support. To further satisfy the needs of Asian and local Chinese customers, and to differentiate ourselves to gain a competitive edge, we need to constantly work on technological innovation, provide a comprehensive range of products and deliver the finest professional technical service. The completion of our new plant in Nanjing will undoubtedly raise the quality standards of our local products and service. We also hope it would develop into a leading benchmarking enterprise in China’s chemical industry, contributing to the production and operating standards in the industry.”

Arne Wallin is Leaving Holmen

![]() After 27 years with the Group, Arne Wallin, CEO of the business area Holmen Energi, has decided to leave Holmen.

After 27 years with the Group, Arne Wallin, CEO of the business area Holmen Energi, has decided to leave Holmen.

“During his time with the Group, Arne Wallin has been mill manager at Braviken Paper Mill, CEO of the business area Holmen Paper and, for the past few years, CEO of Holmen Energi. Arne has overseen several major investment projects in Braviken and most recently led Holmen’s investments in wind power. His extensive knowledge and experience have been of great importance in supporting our ability to implement our own large-scale projects. Arne has also developed and rationalised our printing paper business during challenging times,” says Henrik Sjölund, President and CEO of Holmen.

Arne Wallin will leave his post at the start of 2015. From 15 January, Staffan Jonsson will be acting CEO of Holmen Energi, alongside his regular position as head of Group Technology.

This is information that Holmen AB is obliged to disclose under the Swedish Securities Market Act and the Swedish Financial Instruments Trading Act. The information was submitted for publication on 28 November 2014 at 11.00 CET.

Holmen is a forest industry group that manufactures printing paper, paperboard and sawn timber and runs forestry and energy production operations. In 2013 Holmen’s net sales were approx. SEK 16 billion and the group has approx. 3,700 employees. Holmen’s shares are listed on Nasdaq Stockholm, Large Cap. For more information, visit www.holmen.com

Contacts

Holmen

Ingela Carlsson

Communications Director

tel. +46 702 12 97 12

Brigl & Bergmeister: Voith delivers SpeedSizer and contactless drying for Niklasdorf PM 3

Brigl & Bergmeister GmbH in Niklasdorf, Austria, contracted with Voith for the delivery of a SpeedSizer applicator unit and a contactless dryer for the Niklasdorf PM 3. The startup of the rebuild is planned for summer 2015. The contract is the first step in a multi-stage development plan, with the goal of improving the quality and speed of the production line.

Brigl & Bergmeister GmbH in Niklasdorf, Austria, contracted with Voith for the delivery of a SpeedSizer applicator unit and a contactless dryer for the Niklasdorf PM 3. The startup of the rebuild is planned for summer 2015. The contract is the first step in a multi-stage development plan, with the goal of improving the quality and speed of the production line.

Because a broad range of wet-strength label papers are produced on the PM 3, there are a variety of demands on the applicator unit. The large number of different coating colors requires a high degree of flexibility in order to achieve excellent paper characteristics. SpeedSizer allows the targeted adjustment of the technical parameters to the individual specifications.

Along with the SpeedSizer, the delivery also includes a new CB-Turn for non-contact web turning, before it is dried using a space-saving combination of infrared heaters and downstream air hood. The high-performance, contactless dryer qDry Pro is especially energy-saving, because the air hood is heated exclusively from the hot exhaust air of the infrared heater.

The signing of the contract in mid-November capped off extensive and detailed project work, where the complete process was run on Voith pilot machines, consisting of SpeedSizer applicator unit, offline coating machine, and supercalender.

Brigl & Bergmeister chose Voith as a partner for this project, because Voith has many years of experience and the corresponding major expertise for specialty paper machines. Another factor is that the SpeedSizer applicator unit is one of the proven components in the Voith portfolio.

The Brigl & Bergmeister Group is part of the Roxcel Group, based in Vienna, and one of the leading manufacturers of label papers and flexible packaging papers.

related article - Capacity increases at Brigl & Bergmeister

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith employs more than 43,000 people, generates € 5.7 billion in sales, operates in about 50 countries around the world and is today one of the biggest family-owned companies in Europe.

World Economic Forum Project on the Circular Economy to Include EcoDesign Pilot from CEPI

Paper will show the way for other materials in ecodesign

Paper will show the way for other materials in ecodesign

The World Economic Forum’s project on the circular economy (Project MainStream) has chosen the Confederation of European Paper Industries (CEPI) to contribute to one of the project’s three pilots for advancing circular thinking.

“An excellent track record, the right mindset of wanting to continuously raise the bar and world class knowledge in recycling were the reasons for which Project MainStream chose the CEPI pilot as a contibutor”, says Johnson Yeh, Head of Circular Economy Initiatives at the World Economic Forum.

The pilot’s objective is to consolidate existing pieces of design tools into a set of user-friendly, universal ecodesign rules for all value added elements of the paper and board value chain. The pilot, running from January 2015 for 12 months, intends to create a self-enforcing mechanism of speedy adoption of new ecodesign rules, thanks to commitments by businesses.

The World Economic Forum’s Project MainStream was launched in January this year, during the World Economic Forum Annual Meeting in Davos.The project will enable annual savings of up to $10bn for the value chain, according to World Economic Forum estimations.

“Paper is a perfect place for Project MainStream to start, given paper’s currently high recycling rate and complete infrastructure for recycling. By establishing proof-of-concept with ecodesign rules for paper, the same lesson can be applied to other materials,” says Yeh.

Although originally 100% recyclable, paper is converted by many downstream industries adding auxiliary materials, such as tapes, adhesives and printing inks. These materials will later return to paper recycling mills when closing the loop, as they cannot be sorted from paper in the dry-sorting steps before they reach paper mills. “Simple ecodesign rules for paper products would give the essential guidance for designers and developers without limiting innovation and hampering the introduction of new techniques. This would be a system-level approach, identifying the root cause and preventing problems”, says Jori Ringman, Sustainability Director at CEPI.

The goal of a circular economy is to move towards a resource efficient use of materials throughout the life cycle, beyond production and consumption. In a circular economy, collected waste and by-products become new raw materials. Whereas the European paper industry has already achieved very high recycling rates of 72%, a more systemic approach supported by ecodesign will allow further improvement of the performance in the sector. “Ecodesign could reduce the overall fibre need as well as improve the safe recycling of fibres, while improving opportunities for reusing water and by-streams of the paper and paperboard process in industrial symbiosis”, says Ringman.

The proposed project is also linked to other global sustainability initiatives, notably Strategic Approach to International Chemicals Management (SAICM) by the United Nations Environment Programme (UNEP) and to Sound Material Management (SMM) policies.

For more information, please contact Jori Ringman at This email address is being protected from spambots. You need JavaScript enabled to view it., mobile: +32 478 255 070.

CEPI aisbl - The Confederation of European Paper Industries

The Confederation of European Paper Industries (CEPI) is a Brussels-based non-profit organisation regrouping the European pulp and paper industry and championing industry’s achievements and the benefits of its products. Through its 18 member countries (17 European Union members plus Norway) CEPI represents some 515 pulp, paper and board producing companies across Europe, ranging from small and medium sized companies to multi-nationals, and 940 paper mills. Together they represent 23% of world production.

SCA Conversion of shares

According to SCA’s articles of association, owners of Class A shares have the right to have such shares converted to Class B shares. Conversion reduces the total number of votes in the company. When such a conversion has occurred, the company is obligated by law to disclose any such changes in this manner.

According to SCA’s articles of association, owners of Class A shares have the right to have such shares converted to Class B shares. Conversion reduces the total number of votes in the company. When such a conversion has occurred, the company is obligated by law to disclose any such changes in this manner.

In November, at the request of shareholders 150,000 Class A shares were converted to Class B shares. The total number of votes in the company thereafter amounts to 1,479,560,454.

The total number of registered shares in the company amounts to 705,110,094 of which 86,050,040 are Class A shares and 619,060,054 are Class B shares.

NB: This information is such that SCA must disclose in accordance with the Financial Instruments Trading Act. The information was submitted for publication on November 28, 2014, at 10:00 CET.

For further information, please contact:

Karl Stoltz, Media Relations Manager, 46 8 788 51 55

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2013 amounted to approximately SEK 93bn (EUR 10.7bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.