Ian Melin-Jones

Liisa Nyyssönen appointed Vice President, Corporate Communications at Ahlstrom

Liisa Nyyssönen (M.Sc. Econ) has been appointed Vice President, Corporate Communications at Ahlstrom Corporation as of 1 February, 2011.

Her responsibility area includes external and internal communications as well as investor relations. She reports to Paula Aarnio, Executive Vice President, Human Resources and Sustainability.

Nyyssönen joins Ahlstrom from the Helsinki office of the international PR agency Hill and Knowlton, where she worked as Director, Corporate Communications, responsible for strategic and operative messaging and consultancy for clients across industries. Previously she has worked at Nokia Group for 14 years, where she held several global senior level positions in communications and corporate marketing.

Niina Suhonen, previous head of Ahlstrom's Communications, has left the company at the end of 2010 to pursue new challenges outside the company.

Fire at the Norske Skog Saugbrugs mill in Norway halts production

On the morning of 2 February, fire caused damage to part of the thermo-mechanical pulp plant which supplies the paper machines with fibre at Norske Skog Saugbrugs mill. Although the fire was quickly brought under control, it caused significant damage to the electrical cabling. No employee was injured as a result of the incident.

All production facilities of the mill have been stopped due to the fire. Norske Skog Saugbrugs has an annual production of 550 000 tonnes of super calandered magazine paper and employs 600 people. Property damages and business interruption are covered by insurance where Norske Skog's self retention is NOK 15 million.

- We are satisfied with the immediate and correct response to the fire from our own employees and the support from the community emergency response services. We are pleased that no one was injured in connection with the fire. We will do our utmost to re-establish normal production at Saugbrugs as soon as possible, says Norske Skog's CEO Sven Ombudstvedt.

Based on the initial reports from the mill, Norske Skog expects operations at Saugbrugs to be halted for some time. At present it is not possible to give more detailed information regarding the physical status of the operations. The fire is a force majeure event and Norske Skog has informed customers and suppliers of Saugbrugs about the situation.

Södra to convert Traryd sawmill into new hardwood sawmill

The Södra Timber Traryd sawmill is being converted from pine sawing to sawing all varieties of hardwood. At the same time the Södra Interiör business area will take over the sawmill from Södra Timber on 1 April. Until then, pine will be phased out, and at the same time a log store comprising mainly oak and birch will be built up.

"We are pleased to see that our strategy, which involves offering products made using all the hardwood varieties growing in Götaland, is starting to gain ground among consumers. We have a strong need for oak at Södra Interiör thanks to an increase in customer demand. Moreover, we are seeing an interesting and growing market for birch products both in Sweden and on the continent," said Håkan Svensson, CEO of Södra Interiör.

The target is to saw 35,000 m3 (solid volume under bark) this year. This volume is expected to grow over the next few years. The sawmill will also start sawing aspen, ash, alder and beech later this year.

"Demand for aspen and alder is already so great that we could basically sell as much of it as we can get the raw material for," continued Svensson.

"We have also started to see greater sales of ash and beech via our sales of bonded panels, for example."

The sawmill in Traryd will supplement Södra Interiör's hardwood sawmill in Djursdala, outside Vimmerby, where operations are not affected by the takeover. The objective is for the Traryd sawmill to buy in its raw materials from the west and south of Götaland and for Djursdala to get its raw materials from the east of Götaland.

Södra to close Åtvidaberg sawmill and convert Traryd sawmill to hardwood production

Södra is to shut down most of its operations at its Södra Timber Åtvidaberg sawmill. Some 39 employees will be affected by the change, and negotiations under the provisions of the Codetermination in Industry Act will commence immediately.

"The sawmill has developed well, but times are changing. The market for sawn timber products is tough, and competition for raw materials has increased," said Peter Nilsson, CEO of Södra Timber.

"Södra has to have first-class facilities in the face of competition in order to safeguard its ability to pay for timber, and the sawmill in Åtvidaberg requires significant investment at present. We do not think it is possible to continue investing in all ten of our sawmills, and this change will result in a more appropriate structure," continued Nilsson.

"Overall, we are seeing a good balance in our timber business in eastern areas thanks to our operations in Kinda and the development we are seeing in Mönsterås. We will also be increasing our sawmill production and will need more raw material at Södra Timber Värö over the year, where we are currently building a sawmill with an annual capacity of 750,000 cubic metres," added Nilsson.

However, the pressure impregnation facility in Åtvidaberg will remain in place. Södra Skog's office in Åtvidaberg will not be affected by the changeover. Södra will still need a certain level of timber on site for seasonal storage.

At the same time, the Traryd sawmill will be transferred from Södra Timber to Södra Interiör, and converted from pine production to 100 per cent hardwood. This move is due to the fact that Södra Interiör is increasing its sales of interior products made from all the hardwood varieties growing in southern Sweden. (See separate press release.)

"Handing over the sawmill in Traryd to Södra Interiör is a positive step. We have found a really excellent solution for the sawmill and the staff who work there," Nilsson concluded.

Comar to move to Infrapark® Baselland

Comar Chemicals (Pty) Ltd will establish a second production site for its organo metallic catalysts and nano-particle chemicals at Clariant’s new “Infrapark® Baselland” in Muttenz, Switzerland during the course of 2011. This plant will service European and other overseas customers of Comar Chemicals (Pty) Ltd (“Comar”).

Within Infrapark® Baselland, Comar will utilize a multi-storey modern production building that has a footprint of approximately 1200 m2. A complex specialty chemicals process plant will be established, that makes full use of existing utility infrastructure provided at the Infrapark® Baselland. Amongst the new location's activities will be Comar’s R&D efforts to develop innovative specialty chemicals. Overall, employment opportunities will be generated in due course for some 30 personnel.

Comar’s products include rare earth catalysts that are used in the synthetic rubber industry to manufacture advanced rubber types. These are used to produce car tires with the least rolling resistance, leading to lower CO2 emissions of cars.

The nano-particle chemicals are used in advanced proprietary pollution abatement systems.

The announcement, which follows the signing of a framework agreement between Comar and Clariant Produkte (Schweiz) AG on January 7, 2011, makes Comar the first company to settle at Infrapark® Baselland since its launch at the beginning of January 2011.

Infrapark® Baselland is a new industrial park aimed primarily at research and manufacturing companies from the chemicals and life science industries. Owned by Clariant, it is located on the company’s site in Muttenz in the Swiss Canton of Baselland, which lies at the border triangle of Switzerland-Germany-France. The park offers comprehensive services for successful research, development and manufacturing activities at one location.

Comar will join PanGas, Bayer and Aprentas, the training association of the Basel chemical and pharmaceutical industry, who were already operating in the area prior to its transformation into a dedicated industrial park.

The management of Comar Chemicals (Pty) Ltd comments: “Comar’s primary reasons for choosing the Infrapark® Baselland above other European sites, are Basel’s excellent chemical industry service infrastructure, the location of Basel in the centre of Europe, and the technical excellence of Swiss higher education institutions that create a general high standard of education and productivity among Swiss employees. Together these factors can contribute to Comar’s chemical technology development.”

Renaud Spitz, Country Manager of Clariant Schweiz and Manager of the Infrapark® Baselland, adds: “Clariant is very pleased to welcome Comar to Infrapark® Baselland. We would like to thank BaselArea Economic Promotion and the Volkwirtschafts and Gesundheits-Direktion of the Canton Baselland for their joint efforts and support in making this possible. We see Comar with its specialty chemicals portfolio of catalysts and nano-particle chemicals, as an excellent contributor to the development of a highly specialized chemical industry in the Basel area that is able to provide innovative products that are at the fore-front of technological developments in their respective fields”.

Verso Paper Corp. Achieves Safety Milestone

Verso Paper Corp. has announced that it exceeded the company's safety goals for 2010 with a lost workday incidence rate (LWIR) of 0.07, which is world class performance, and a total incidence rate (TIR) of 1.36. These outstanding results place Verso at the top of the first quartile for safety performance among paper industry peers, according to the American Forest and Paper Association's most recent Benchmarking Survey.

"Verso is proud of our industry-leading safety performance and that our 2010 TIR and LWIR performance was the best in Verso's history," says David Sams, Verso's Director of Environment, Health and Safety. "More importantly, we are proud that our people are working more safely. We are moving closer to an environment where no one gets hurt at work. Verso's ultimate goal is zero injuries."

Verso's path to top quartile safety performance is the result of a carefully developed strategy that engages every employee in the spirit of ownership for safety through Advanced Safety Leadership Forums. Employees and teams at all levels in the organization are challenged to look beyond the norm to identify what's possible to achieve safety excellence. Once targeted opportunities are identified, safety leaders develop action plans to close the gaps and rally their teams to improve performance.

Verso has been recognized by the Occupational Safety and Health Administration (OSHA) for its participation in the Voluntary Protection Program (VPP). Three of Verso's four manufacturing facilities have achieved Star status in VPP, and the fourth facility continues to work on opportunities that will prepare it for VPP recognition. Less than 1% of the nation's facilities have achieved OSHA Star status.

Metso expands its maintenance cooperation with SAICA

Metso and SAICA have made an outsourcing agreement on the mill maintenance of Saica Containerboard UK Ltd’s paper mill in Partington, United Kingdom. With this multi-year agreement, which became effective as of January 11, 2011, Metso will assume full responsibility for establishment of maintenance operations, mill maintenance and management of improvement projects for the power stations, stock and paper production facilities as well as water treatment equipment at the Partington mill. The value of the agreement will not be disclosed.

of January 11, 2011, Metso will assume full responsibility for establishment of maintenance operations, mill maintenance and management of improvement projects for the power stations, stock and paper production facilities as well as water treatment equipment at the Partington mill. The value of the agreement will not be disclosed.

The containerboard production line of the Partington mill will also be supplied by Metso. The order for the production line was received from SAICA in 2010 and published on March 18, 2010. The line is scheduled to start up in the first quarter of 2012.

SAICA and Metso have a long history of maintenance cooperation. Since 2005, the companies operate a joint venture for the maintenance of the SAICA mills in Zaragoza, Spain. Since 2007, Metso also has a mill maintenance unit serving the SAICA Venizel mill in France. Based on this cooperation and Metso’s other maintenance references, SAICA and Metso have together developed a maintenance outsourcing model for SAICA’s Partington mill. The model optimizes the use of proactive, condition based, predictive, preventive and corrective maintenance and is based on Metso's streamlined reliability centered maintenance (RCM). The model ensures the highest possible equipment efficiency and cost optimization.

Saica Containerboard UK Ltd. is a subsidiary of SAICA. SAICA is a family owned Spanish company and is a world leader in the production of high performance lightweight corrugated papers from recovered paper and cardboard. The company currently employs over 8,000 people in Spain, France, Portugal, Italy, Ireland and the UK. SAICA has an annual turnover of EUR 1.9 billion.

Source www.metsopaper.com

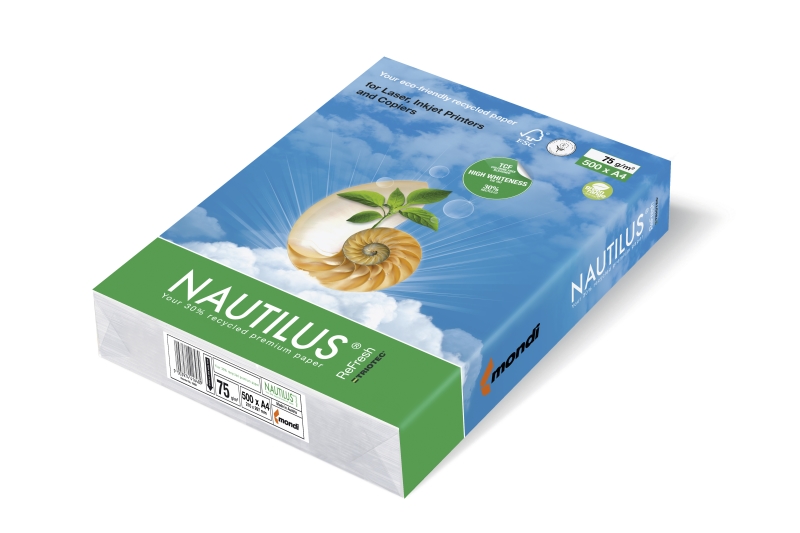

Mondi showcased 3 new papers at Paperworld 2011: NAUTILUS® ReFresh TRIOTEC, DNS® indigo and Color Copy indigo.

Visitors gained insight into upcoming developments in Mondi’s digital and environmental paper portfolios and areas for paper converting.

With Mojito and Cuba Libre scented cocktail menus and food trays made from Mondi paper, this year Mondi enticed visitors to see, feel and smell their entire paper portfolio and myriad applications at Paperworld 2011. Mondi gave visitors plenty to explore with the launch of its 30% recycled paper NAUTILUS® ReFresh TRIOTEC and a preview of Color Copy indigo and DNS indigo, new digital papers ready to hit the market later this month. The continuing development of Mondi’s green and digital printing paper portfolios is a clear priority for the global paper manufacturer.

With Mojito and Cuba Libre scented cocktail menus and food trays made from Mondi paper, this year Mondi enticed visitors to see, feel and smell their entire paper portfolio and myriad applications at Paperworld 2011. Mondi gave visitors plenty to explore with the launch of its 30% recycled paper NAUTILUS® ReFresh TRIOTEC and a preview of Color Copy indigo and DNS indigo, new digital papers ready to hit the market later this month. The continuing development of Mondi’s green and digital printing paper portfolios is a clear priority for the global paper manufacturer.

“We are acutely aware of the markets trends and are in tune with our customers’ current and future needs. We also take our commitment to the environment seriously. Our Green Range line of TCF, FSC certified or 100% recycled papers continues to expand as does our digital printing portfolio and the number of digital papers that bear the Green Range logo,” explains Johannes Klumpp, Marketing and Sales Director for Mondi Uncoated Fine Paper.

Using TRIOTEC® sandwich technology developed at the Mondi Neusiedler mill in Austria, the outer layers of NAUTILUS® ReFresh TRIOTEC consist of TCF (totally chlorine free) virgin fibre, while the inner layer is made from 30% recycled fibre. Like NAUTILUS® ReFresh TRIOTEC, DNS® indigo and Color Copy indigo are also Green Range papers that belong to Mondi´s digital portfolio. Both HP 3-star approved premium papers, DNS® indigo and Color Copy indigo appeal to professional printers who use HP Indigo digital presses. The 3-star approval is the highest performance rating for HP Indigo digital presses and indicates the best performance in terms of runnability, fixing and blanket compatibility. During the production process of these papers a special primer is applied to ensure perfect adhesion of HP’s ElectroInk.

Customers not only explored the various paper qualities Mondi offers, but also the diverse applications possible with current printing and converting technologies. Paperworld visitors were the first to peruse Mondi’s new sample book and the communication potential of selecting a paper that reflects a specific corporate identity and marketing message. The sample book compiles BIO TOP 3®, Color Copy,

Mondi’s new sample book and the communication potential of selecting a paper that reflects a specific corporate identity and marketing message. The sample book compiles BIO TOP 3®, Color Copy,

DNS® premium, IQ Color, NAUTILUS® Universal, NAUTILUS® SuperWhite, and Japanpost (with Molette watermark) for advertising and marketing material, pamphlets, menus, invitations, and complete stationery sets printed on digital and offset technologies.

“The sample book is a good tool for customers to see and feel examples of the print results possible for a diverse assortment of papers and grammages and communications material,” says Mr. Klumpp. “It has been interesting to see visitors examining pamphlets and envelopes made from BIO TOP 3® and then minutes later see them discover that our food trays are also made out of BIO TOP 3®.”

Focus on industrial raw materials must be kept clear

The European Paper Industry welcomes the Commission’s communication on raw materials, adopted today. Concrete actions are needed to address the increasingly critical supply of raw materials to European Industries. This includes the raw materials of the European Paper Industry: The push for renewable energies calls for a biomass supply policy across Europe, taking the use of wood as raw material as a priority. The massive exports of recovered paper collected in Europe to east Asian markets is a second reason why raw material policy is needed. The Commission communication rightfully addresses both issues.

However, CEPI points out that EU has to keep a clear focus while addressing intrinsically different markets of raw materials, energy and agricultural commodities

The European pulp and paper industry’s raw material base is in Europe. Because of their renewable nature they are much sought-after. A strategy for the sustainable supply of wood and biomass is therefore needed, including concrete measures for raw materials mobilisation from European primary and secondary sources. The promotion of the resource hierarchy principle, whereby raw materials are used first to deliver added value in products, would bring consistency in EU policies

“Facilitating access to raw materials that end up in subsidy-based, unsustainable business models does not make sense” said Teresa Presas, CEPI’s Managing Director. “Instead, the priority access should be for industries that use the resources efficiently and contribute to the EU 2020 competitiveness and climate change goals.”

The European Paper Industry has already achieved a record-high recycling rate with more than 70% in 2009. It is seeking for even higher levels, but to do so, policy support is needed. Therefore CEPI applauds the proposed actions to better implement and enforce existing waste legislation, in particular waste shipment controls and separate collection by 2015.

Highlighting the importance of looking at full value chains and full life-cycles, Teresa Presas said: “The European Industry must be put in a position to use the collected secondary materials, otherwise we spend money to see them exported to countries where the environmental standards are far from being met. Certifying recycling facilities for sound environmental management is an approach CEPI is happy to support”.

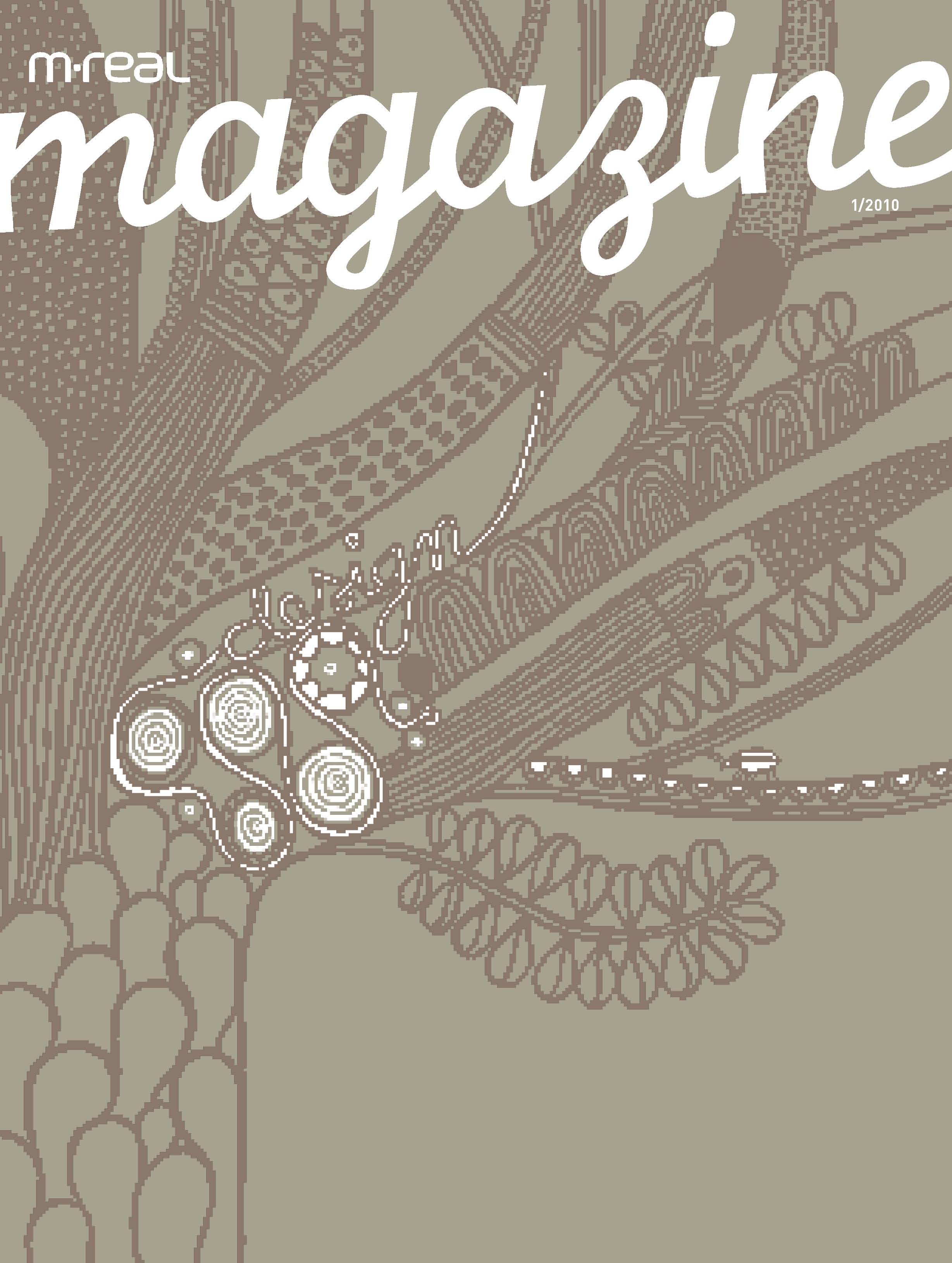

M-real Magazine wins gold in the world's largest magazine competition

M-real’s customer magazine M-real Magazine has won gold in the ‘Best Overall Design, B-to-B’ category in Folio Magazine’s Eddies and Ozzies Awards. The international Folio Awards are the magazine industry’s largest competition, celebrating the best in both editorial quality and design and visual standards. The 2010 category winners were announced in New York on 25 January 2011.

M-real’s customer magazine M-real Magazine has won gold in the ‘Best Overall Design, B-to-B’ category in Folio Magazine’s Eddies and Ozzies Awards. The international Folio Awards are the magazine industry’s largest competition, celebrating the best in both editorial quality and design and visual standards. The 2010 category winners were announced in New York on 25 January 2011.

“The team in M-real and publishing house Otavamedia Kynämies has done excellent job. M-real Magazine is a publication that stands out and is highly appreciated by our customers,” says Juha Laine, Editor-in-chief, VP Investor Relations and Communications of M-real Corporation. “The winning issue’s theme was design. A lot of thought went into making it, but even so, winning gold was a very positive surprise.”

“This issue is a great example of what can be achieved with our products, here in particular with speciality papers from M-real Zanders. The cover’s CHROMOLUX, the luxurious cast-coated paper, and the text pages’ coated paper Medley plus and transparent paper Spectral demonstrate how our papers can add impact and provide inspiration for many creative design areas,” explains Laine.

The 2010 awards drew more than 2,000 entries, which were judged by an international panel of 100 experts. Both printed magazines and web publications are represented in the competition, organised by Folio Magazine.

The gold-winning issue of M-real Magazine can be found here.