Ian Melin-Jones

Finch Paper Appoints Dr. Peter J. Veverka to Senior Product Development Engineer

Finch Paper announces the appointment of Dr. Peter J. Veverka to its product development division as Senior Product Development Engineer.

A published scholar and author of several patent applications, Dr. Veverka comes to Finch after a 15-year tenure with International Paper, where he most recently served as Pulp Mill Technical Leader. He also previously served as Manager for Customer Satisfaction and Product Performance Manager. At IP’s Corporate Research Center, he ultimately became Program Manager/Research Scientist II, and supervised a team of scientists and technicians responsible for applied research on coated grades throughout IP.

A published scholar and author of several patent applications, Dr. Veverka comes to Finch after a 15-year tenure with International Paper, where he most recently served as Pulp Mill Technical Leader. He also previously served as Manager for Customer Satisfaction and Product Performance Manager. At IP’s Corporate Research Center, he ultimately became Program Manager/Research Scientist II, and supervised a team of scientists and technicians responsible for applied research on coated grades throughout IP.

Dr. Veverka reports to Tom Ruch, Director of Technology and Development.

Finch CEO Joseph Raccuia says, “We are very pleased that Dr. Veverka has joined our operation. His lengthy qualifications, including extensive studies and relevant research, will prove to be a welcome asset to our Product Development Team at Finch.”

“The level of commitment to product development and working to find innovative solutions for our customers was immediately apparent in talking with the management at Finch. The size and resources at Finch promotes nimbleness and speed differentiates us from our larger competitors. I am very excited to be part of this team at Finch,” Dr. Veverka says.

Dr. Veverka holds both a Ph.D. and Master’s Degree in Pulp and Paper Engineering from IPST at Georgia Tech, as well as Master’s level studies in Process Control and Production Management in the Paper and Pulp Industry from Helsinki University of Technology. His undergraduate B.S. is in Chemical Engineering, from the University of Delaware. He has authored or co-authored eight publications and two patent applications. His articles on dynamic contact line instability have helped to provide a basis understanding of film and paper coating technology.

Metso supplies a wash press to Mondi Richards Bay in South Africa

Metso will supply a new wash press to Mondi’s Richards Bay mill in South Africa. The Mondi Richards Bay mill, commissioned in 1984, produces more than 720,000 tonnes of bleached pulp per year, using mainly eucalyptus from own plantations as raw material. Start-up of the new wash press is scheduled for end of 2011. The value of the order will not be disclosed.

Metso’s delivery will include a TwinRoll Evolution wash press, basic and detail engineering and site services. The new wash press will allow Mondi to improve the existing brown stock washing process at the mill.

Mondi is an international paper and packaging company, with production operations across 31 countries and revenues of EUR 5.3 billion in 2009. The Group's key operations are located in central Europe, Russia and South Africa and employed 31,000 people on average in 2009.

Metso-supplied fine paper line starts up at Shandong Huatai Paper in China

The Metso-supplied coated fine paper production line, PM 8, of Shandong Huatai Paper Co. Ltd came successfully on stream on Jan 18, 2011 in Dong Ying City, Shandong Province, China.

The 8.1-m-wide PM 8 has an annual dimensional production capacity of close to 700,000 tonnes of coated and uncoated fine papers within the basis weight range of 80 to 200 g/m2. The paper machine design speed is 1,800 m/min and the coater design speed is 2,000 m/min.

Metso's delivery included a complete Metso OptiConcept paper machine from headbox to reel. The paper machine line also comprises a re-reeler and an off-machine coater with coating stations, off-machine OptiLoad multinip calenders, winders, a parent reel handling system and a comprehensive Metso automation system package. The production line was started up with a Metso wet end machine clothing package.

"The PM 8 start-up was successful thanks to the state-of-the-art equipment supplied by Metso and the strong co-operation between Huatai's and Metso's project teams. Based on the good experience with Metso Huatai looks forward to producing high-quality art paper in the near future," states Wei Lijun, General Manager of Huatai PM 8 art paper line.

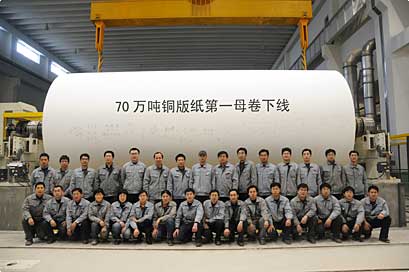

The first parent roll from the Metso-supplied coated fine paper production line PM 8 of Shandong Huatai Paper on January 18, 2011. Photo: courtesy of Shandong Huatai Paper.

Shandong Huatai Paper Co. Ltd. is a member of the Huatai Group. The Huatai Group has five production bases, Huatai Green Industry Park, Huatai Qinghe Green Ecology Industry Park, Rizhao Huatai Pulp & Paper Industry Park, as well as Guangdong Huatai and Anhui Huatai Industrial Parks, with an annual capacity of around 3 million tonnes.

Government of Canada Invests in Forest Industry Transformation at Alberta Newsprint Mill

The Government of Canada today announced an investment in new Canadian technology that will contribute to a more sustainable pulp and paper industry in Canada.

The Honourable Rob Merrifield, Minister of State (Transport), announced the $1.05-million investment at the Alberta Newsprint Company mill in Whitecourt, Alberta. The mill will receive funding under the Transformative Technologies Pilot Scale Demonstration Program to implement state-of-the-art technology that will result in substantial reductions in energy and fresh water consumption at the mill.

"The Government of Canada is investing in the evolution of our forest industry by encouraging the development and adoption of state-of-the-art Canadian technology," said Minister Merrifield. "Innovative projects such as this one are essential to expanding and diversifying market opportunities both at home and abroad and to securing high-quality jobs in forest-dependent communities."

Other funding for the project includes a contribution of more than $1 million from the Alberta Newsprint Company and an $80,000 investment by Alberta Innovates Bio Solutions.

"This technology will enable Alberta Newsprint to consume larger sawmill residual chip volumes of beetle-attacked pine and threatened green pine while simultaneously reducing our fresh water consumption from the Athabasca River," said Gary Smith, Technical Director, Alberta Newsprint Company. "The technology holds great promise for many pulp and paper producers. The technology provides for concentrating pitch-laden dark pulp fibres, enabling reductions in water usage, chemical usage and energy savings. We expect to start up the equipment in early March."

"This new technology was made possible through collaboration among industry, government and research organizations such as ours," said Stan Blade, Chief Executive Officer of Alberta Innovates Bio Solutions. "The commercialization of this technology at Alberta Newsprint may lead to new solutions for our pulp and paper industry in addressing the mountain pine beetle challenge and water sustainability."

As part of the strategic investments under the Government of Canada's Economic Action Plan, the Transformative Technologies Pilot Scale Demonstration Program is administered by FPInnovations and supports the development of new and emerging highly transformative Canadian forest products and technologies.

"As Canada's forest sector innovation hub, we believe that through multipartite projects we will be able to demonstrate the viability of new technologies with a view to creating and marketing new products and developing new markets," said Alan Potter, FPInnovations' Vice-President of Strategic Initiatives & Technology. "This innovative technology, developed by FPInnovations, positions the organization as a strong partner of the forest industry's transformation."

Today's announcement builds on the success of many initiatives that are helping to sustain and enhance Canada's forest industry and the communities that depend on it. Budget 2010: Leading the Way on Jobs and Growth established the $100-million Investments in Forest Industry Transformation program to promote the development, commercialization and implementation of advanced technologies in the forest sector — helping create a world-class industry able to compete in the clean energy economy of tomorrow.

IBS Paper Performance Group Tradition presents the first innovation of the year 2011: EPB Plus™

EPB Plus™ IBS Paper Performance Group Tradition presents the first innovation of the year 2011: EPB Plus™. The EPB Plus™ is equipped with innovative components in order to ensure a continuous and reliable vacuum control.

All-in-one

* Vacuum transmitter

* Measuring line

* Robust FRP-housing

* Cleaning of control and actuator unit

* Cleaning of measuring line

* No need for transmitter bar

Until now an economical vacuum control system in the paper machine consisted of several components, which had to be installed and connected individually. Thus the installation was not only mechanically demanding, but also consisted of a great deal of wiring as well. In addition the operational reliability still was a very common problem. In many cases the vacuum system failed due to entered water or a clogged vacuum pick up from contaminated air flow.

These problems were recognized by the engineers of IBS PPG resulting in the development of the IBS-EPB Plus™ vacuum control valve.

The advantages of EPB Plus™ are:

* reliable vacuum control through control valve

* with integrated vacuum pick up

* minimal wiring required

* functional reliability through pneumatic cleaning system

* protective cover

SPM®HD to be installed at Smurfit Kappa Kraftliner in Sweden

SPM Instrument has been commissioned to install SPM HD on four wash presses at Smurfit Kappa Kraftliner in Piteå, Sweden. The SPM HD measuring technique, a sophisticated enhancement of the SPM method, is particularly well suited for condition monitoring of low rpm machinery like wash presses.

Smurfit Kappa Kraftliner Piteå is Europe’s largest kraftliner producer with an annual production capacity of some 700.000 tons. The kraftliner base paper, made from fresh fibre and used for production of high quality corrugated packaging, is produced on two paper machines. In the pulp and paper industry, wash presses are used for removing dissolved organic material and chemical residue from the cooking process. The wash presses at Smurfit Kappa Kraftliner Piteå run at approximately 10 rpm.

For Smurfit Kappa, the deciding factor for choosing SPM HD was a study visit at Holmen Paper in Hallstavik in conjunction with the SPM User group meeting in September, 2010. SPM HD has been in operation at Hallsta paper mill for almost two years, and the experiences of the method at Hallsta are excellent. Yet another important factor for the decision to invest in SPM HD was the detailed description of SPM HD presented during the User group meeting.

Håkan Sirkka, maintenance technician at Smurfit Kappa Kraftliner, comments:

”Earlier, we did not have a good method for detection of damaged bearings on low speed machinery. We tried vibration measurement, but to no avail. Now, with the capability to detect bearing damages with great prewarning times, enabling planned bearing replacements, we anticipate to save at least 10.000 EUR annually.”

BASF increases prices for resins and additives in Europe

Effective immediately, BASF increases prices in Europe for resins and additives for the coatings, printing and packaging industries by 5 - 12 % as existing contracts allow. The price increase affects, but is not limited to, the following product ranges: Laromer®, Joncryl®, Basonat®, Luwipal®, Luhydran® and Acronal®.

The price adjustments are necessary mainly due to further significantly increased costs of key raw materials.

Pigments & Resins

The product range of BASF’s Pigments & Resins business unit includes pigments, effect pigments, pigment preparations and dyes, resins, light stabilizers, photoinitiators and additives as well as specific masterbatches in Europe. Our products are manufactured and marketed worldwide. We are one of the world’s leading suppliers in these fields. Further information on our products may be found at www.basf.com/resins.

Verso Paper Corp. Announces Preliminary Results of Tender Offer

Verso Paper Corp. (NYSE: VRS) announced today that, pursuant to the previously announced tender offer of its subsidiary Verso Paper Holdings LLC ("Verso Holdings"), Verso Holdings received tenders from the holders of $310,415,000 aggregate principal amount of the 9⅛% second priority senior secured fixed rate notes due 2014 issued by it and Verso Paper Inc. (the "Notes") prior to the early tender payment deadline on January 25, 2011, at 5:00 p.m., New York City time (the "Early Tender Date"). The tenders for the Notes received by Verso Holdings prior to the Early Tender Date represent approximately 92.1% of the outstanding Notes.

The complete terms and conditions of the tender offer for the Notes are detailed in Verso Holdings' Offer to Purchase dated January 11, 2011, and the related Letter of Transmittal (the "Tender Offer Documents"). Verso Holdings currently expects to accept for payment, subject to conditions set forth in the Tender Offer Documents, all of the Notes validly tendered prior to the Early Tender Date on Wednesday, January 26, 2011.

Each holder who validly tendered its Notes prior to the Early Tender Date will receive, if such Notes are accepted for purchase pursuant to the tender offer, the total consideration of $1,049.38 per $1,000 principal amount of Notes tendered, which consists of $1,019.38 as the tender offer consideration and $30.00 as an early tender payment. In addition, accrued interest up to, but not including, the applicable payment date of the Notes will be paid in cash on all validly tendered and accepted Notes.

The tender offer is scheduled to expire at 11:59 p.m., New York City time, on February 8, 2011, unless extended or earlier terminated (the "Expiration Date"). Because the Early Tender Date has passed, tendered Notes may no longer be withdrawn at any time, except to the extent that Verso Holdings is required by law to provide additional withdrawal rights. Holders who validly tender their Notes after the Early Tender Date will receive only the tender offer consideration and will not be entitled to receive an early tender payment if such Notes are accepted for purchase pursuant to the tender offer.

All the conditions set forth in the Tender Offer Documents remain unchanged. If any of the conditions is not satisfied, Verso Holdings may terminate the tender offer and return tendered Notes not previously accepted. Verso Holdings has the right to waive any of the foregoing conditions with respect to the Notes. In addition, Verso Holdings has the right, in its sole discretion, to terminate the tender offer at any time, subject to applicable law.

This announcement shall not constitute an offer to purchase or a solicitation of an offer to sell any securities. The tender offer is being made only through, and subject to the terms and conditions set forth in, the Tender Offer Documents and related materials.

Credit Suisse Securities (USA) LLC and Citigroup Global Markets Inc. are acting as the Dealer Managers for the tender offer. Questions regarding the tender offer may be directed to Credit Suisse Securities (USA) LLC at (800) 820-1653 (toll-free) or at (212) 325-5912 (collect) and to Citigroup Global Markets Inc. at (800) 558-3745 (toll-free) or at (212) 723-6106 (collect).

Global Bondholder Services Corporation is acting as the Information Agent for the tender offer. Requests for the Tender Offer Documents may be directed to Global Bondholder Services Corporation at (212) 430-3774 (for brokers and banks) or (866) 470-3900 (for all others).

Neither Verso Holdings' board of directors nor any other person makes any recommendation as to whether holders of Notes should tender their Notes, and no one has been authorized to make such a recommendation. Holders of Notes must make their own decisions as to whether to tender their Notes, and if they decide to do so, the principal amount of the Notes to tender. Holders of the Notes should read carefully the Tender Offer Documents and related materials before any decision is made with respect to the tender offer.

Source: Verso Paper Corp.

Mondi showcases new digital products at the 2011 Hunkeler Innovation Days February 14-17 in Lucerne, Switzerland.

Mondi’s future-focused orientation toward the growing digital printing market continues into 2011 with new additions to its digital printing paper portfolio. This year at the Hunkeler Innovation Days, Mondi will display its latest products — DNS® indigo and Color Copy indigo — and will preview its upcoming high-speed inkjet paper, DNS® high-speed inkjet.

“We have aligned our focus with the latest markets trends and the future needs of printers,” says Johannes Klumpp, Marketing and Sales Director for Mondi Uncoated Fine Paper. “Our recent Indigo certifications for DNS® indigo and Color Copy indigo and the introduction of DNS® high-speed inkjet appeal to the professional print market and will certainly be a point of interest at this year’s Hunkeler Innovation days.”

HP 3-star approved uncoated fine papers, DNS® indigo and Color Copy indigo are premium papers tailored to professional printers who use HP Indigo digital presses. During the production process of these papers a special primer is applied to ensure perfect adhesion of HP’s ElectroInk. The 3-star approval is the highest performance rating for HP Indigo digital presses. It indicates the best performance in terms of runnability, fixing and blanket compatibility.

Mondi launched DNS® premium in autumn 2010 as the digital printing paper that offers professional printers a single printing solution for any application. The hybrid character of the DNS® range also offers printers more versatility in terms of machine use — DNS® premiumis ideal for use on digital production machines, office laser printers, inkjet printers and copiers and is also suitable for offset printing presses.

With the advancements in inkjet technology and its resurgence into professional print rooms, Mondi has harnessed its know-how of digital printing and inkjet technology to develop a new paper targeted for high-speed inkjet printers. The surface treated paper is a welcomed alternative to the narrow selection of papers in this newly developing market.

DNS® high-speed inkjet will premiere at the Hunkeler Innovation Days. Visitors will have an opportunity to learn more about Mondi’s professional formats on display: Color Copy (a CO2 neutral product since autumn 2010), Color Copy indigo, Color Copy Xeikon reel, NAUTILUS® SuperWhite, DNS® premium, DNS® indigo, DNS® high-speed inkjet, and BIO TOP 3®.

Mondi’s complete digital printing portfolio consists of papers that are also part of Mondi’s Green Range of eco-friendly papers. All Green Range papers are FSC certified, bleached without chlorine, or 100% recycled. Please visit www.mondigroup.com/digital for more information on Mondi’s digital printing range.

8th International Paper and Coating Chemistry Symposium, Stockholm, June 10-14, 2012

FIRST CIRCULAR AND CALL FOR PAPERS

The 8th International Paper and Coating Chemistry Symposium will be arranged in Stockholm, June 10-14, 2012. Previous symposiums have been held in Stockholm 1988, 1992, 2000 and 2006, in Ottawa 1996 and in Montreal 2003 and 2009. The 2012 symposium will be organised by Innventia and KTH.

Scope of the Symposium

The 8th International Paper and Coating Chemistry Symposium will cover the latest developments in the fields of paper chemistry, coating chemistry and nanotechnology for the paper industry. The scope of the symposium will be to discuss the performance of chemical additives in papermaking and coating operations. Both fundamental and more applied contributions are welcome.

Tentative topics are listed below. There will be at least one invited overview lecture for most of the topics. Some of these may have a more futuristic character, which in a sense can add to the flavour of the symposium.

Coating chemistry

- Green coatings

- New printing techniques/inkjet

- Paper-liquid interactions

- Barriers/nanobarriers

- Interactive surfaces

- Antibacterial surfaces/Bioactive surfaces

- Colloid chemistry

Paper chemistry

- Nature of joint strength

- Green chemicals/sustainability

- The application of nanotechnology in paper applications

- Non-wood paper chemistry

- New materials in paper and board products

- Wet- and dry strength

- Fibre engineering

- Retention formation

- Sizing and hydrophobation

- Colloid chemistry

- Dewatering

- Wet-end chemistry

Oral paper and poster submissions

Prospective authors are kindly invited to submit an abstract either for an oral presentation or a poster presentation. Regarding oral presentations, authors can either chose to submit a 1 page abstract or an extended abstract (2-3 pages) for evaluation. Required length for a poster abstract is 1 page.

Please notice that abstracts will only be accepted by electronic submission. In order to submit, please use this link www.paperconferences2012.com/submissions) and follow the instructions.

Authors will be notified of acceptance of papers/posters around December 15, 2011. If the oral paper is accepted, an extended abstract is required and must be submitted before March 1, 2012.

The extended abstracts will be printed in a “Book of abstracts” and distributed at the Symposium. The length of the presentation of the contributed papers will be around 20 minutes.

Information about the The 8th International Paper and Coating Chemistry Symposium

Please visit the conferences website www.paperconferences2012.com, where more details about the programme will be made available.

For more information sign up for our newsletter or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..