Ian Melin-Jones

Glocell's Fiber value chain optimization

We have now a new presentation of what our approach is. This includes some first shots of the new optimization software that is available soon. Please see the presentation behind the link. Presentation!

We have now a new presentation of what our approach is. This includes some first shots of the new optimization software that is available soon. Please see the presentation behind the link. Presentation!

The approach includes possibility to optimize parts or the whole value chain from forest to paper and boardmaking.

Forestry

Evaluation of wood availability for planned or current useEvaluation of genotype and phenotype effects to pulp production

Raw material based quality positioning options for pulp producers

Pulp making

Evaluation of quality based on wood procurement possibilitiesPulp mill segregation of needed wood for the wanted outcome of mechanical and chemical pulps

Pulp mill process optimization for the needed quality and end user benefit outcome

Pulp sales tools

Paper and board making

Cost vs. quality optimization tool and service for paper and board gradesPulp quality selection tools for procurement purposes

On-line cost follow-up of on going production

Quality planning and trial run minimization

Presentation is included here.

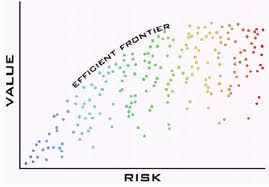

Glocell's Innovation portfolio optimization

Do you really have quantitative data on your development and innovation portfolio, or are you just making decisions based on qualitative opinions? There is a way to make innovation evaluation more accurate with Modern Portfolio Theory application.

Do you really have quantitative data on your development and innovation portfolio, or are you just making decisions based on qualitative opinions? There is a way to make innovation evaluation more accurate with Modern Portfolio Theory application.

Check out our approach presentation.

MPT has been recently criticized for its inability to understand actual market situations in investment field. As this criticism is well justified in investment banking, it has no relevance in innovation portfolio management. This is based on the nature of collecting data for the model as well as the natural predictability of future development. The approach is very suitable to companies’ innovation evaluation work when various predictions of the future need to be justified for improved decision making .

The answer to the R&D evaluation challenge is three fold. First we need to evaluate the used processes and adjust them to meet the data collection criteria. Second we need to collect all qualitative data into tools that enable variation of input. And third, we need to perform a portfolio analysis based on the data from multiple projects.

Metso supplies a recovery boiler to Grasim Industries in India

Metso will supply the Harihar Polyfibers unit of Grasim Industries Limited with a recovery boiler to replace the two existing recovery boilers at the rayon grade pulp mill located in Kumarapatnam, Karnataka state, India. Start-up of the boiler is scheduled for the Q3 of 2012. The value of the order is not disclosed. The order is included in Energy and Environmental Technology’s Q4/2010 orders received.

Metso’s delivery includes the main equipment and piping and standard equipment for the recovery boiler as well as field instruments.

The new recovery boiler will improve steam generation and help lower operating and maintenance costs over the mill’s two present bidrum recovery boilers. “We entered into a contract with Metso for a new recovery boiler as replacement for existing boilers for ensuring safe and reliable operation and enhanced environmental performance. This recovery boiler project is prestigious for Harihar plant”, says Mr. Rajendra Jain, Executive President, Harihar Polyfibers.

Metso’s Power business line established its operation in India in 2008, and since then the business operation has scaled up as a regional center to cater to the regional market. In 2009 India was the Metso Group’s 11th largest country in terms of orders received with EUR 117 million. India was also 12th largest country in terms of Metso Group’s net sales with EUR 131 million. The Metso Group has altogether about 700 employees in India.

Grasim Industries Limited, part of Aditya Birla Group, is the largest exporter of Viscose Rayon Fiber (VSF) in India, with an aggregate capacity of 333,975 tpa. The Harihar Polyfibers unit houses facility for manufacture of both VSF and rayon grade pulp, the basic raw material for VSF.

Metso supplies pulp mill equipment for Eldorado Celulose e Papel in Brazil

Metso will supply a new recovery boiler and evaporation plant for Eldorado Celulose e Papel S.A.’s new greenfield pulp mill investment in Três Lagoas, Brazil. The value of the order is not disclosed. The order will be included in Energy and Environmental Technology’s Q4/2010 orders received. The start-up of the new plant is scheduled for Q4/2012.

The recovery boiler will be the largest on the American continent, with capacity of 6.800 tons of dry solids per day (tDS/day) and steam generation of 308 kg/s. The evaporation plant will be the largest single line evaporation plant in the world, with 6 thermal stages and capacity of 1600 tons per hour.

“The definition and dimension of the equipment supplied by Metso, shows a concern not only with the return on investment, but also with the search for solutions that add high technology to sustainable industrial processes. An example is the recovery boiler supplied by Metso, it is part of the process generating clean energy, obtained from the renewable raw material, in this case, the biomass residue of eucalyptus,” says Carlos Monteiro, Industrial Director, Eldorado Celulose e Papel S.A.

Eldorado Celulose e Papel S.A. is a newly established pulp company and a newcomer in the pulp and paper industry, but already has plans to build three parallel pulp lines to produce a total of 5 million tons per year when the project is complete. The company is owned by J&F Holding and MCL Enterprises, most notably known for business in the food segment.

Invitation to the Clariant 2010 Full Year Results Press Conference

Clariant will be presenting its 2010 Full Year Results on 16 February, 201

Location:

SIX Swiss Exchange

ConventionPoint

Selnaustrasse 30

CH-8021 Zürich

Please register with Edith Schwab (This email address is being protected from spambots. You need JavaScript enabled to view it.) - by latest Wednesday February 9, 2011, if you want to attend the full year results presentation in person.

You will also have the opportunity to join the media conference via a live webcast at the following location:

http://gaia.world-television.com/clariant/20110216/mc/extern/trunc

Or by dialing in via phone line by using one of the following numbers:

+41 (0) 91 610 56 00 (Europe)

+44 (0) 203 059 58 62 (UK)

+1 866 291 41 66 (USA - Toll-Free)

Questions may be raised via the webcast or via the e-mail address: This email address is being protected from spambots. You need JavaScript enabled to view it..

In order to enable us to start on time we ask all participants to dial in 5 - 10 minutes before the conference is scheduled to start.

An audio plug-in capability will be made available during the press conference.

Please note that the press release along with other supporting material will be issued and posted on www.clariant.com at 07.00 CET on February 16.

Paperlinx reduces global corporate overheads by A$ 15m

PaperlinX today announced a further streamlining of its management and head office structure with the closure of its European head office in Amsterdam. Together with recent staff reductions at the Corporate Head Office in Melbourne, the closure of the Amsterdam office will result in ongoing cost savings of approximately A$15 million per annum and will be cost neutral in the current financial year.

The new arrangements will involve the 2 European regions reporting directly to the CEO and CFO, who will be based at the Operational Head Office in the UK. There are no plans to change PaperlinX's domicile out of Australia.

PaperlinX CEO, Toby Marchant said, "This move is consistent with our stated objective of creating a simpler and more cost efficient head office environment with fewer centres and fewer layers. The relocation of the CEO and CFO from Australia to the UK brings our senior management closer to the geographic centre of our operations, given that nearly 70% of our business is in Europe and 90% is in the Northern hemisphere."

Lower energy consumption at SCA with cleaner pulp

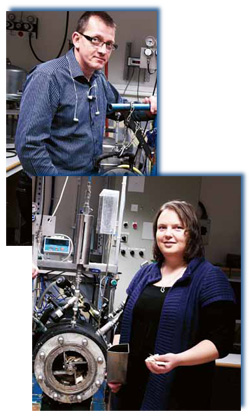

SCA R&D Centre normally supports SCA’s paper mills in their efforts to improve manufacturing processes and products. Since the growth rate in the demand for publication paper is falling all over the world, SCA R&D Centre is also working to a large extent on alternative applications for SCA’s wood raw products.

Many benefits

Not only do trees have desirable wood fibre, they also have various extractive substances such as what we usually refer to as “resin”.

These substances have no purpose in pulp and paper making; in fact they are a nuisance. But removing these extractive substances from the process would have many benefits.

“The extractive substances surround the wood fibres like soap and are one of the reasons why so much energy is required to produce pulp. If we could remove half of the extractive substances, energy needs would fall by about 15%,” says Bengt Wikman, Head of Chemical and Mechanical Pulp at SCA R&D Centre, and adds:

“Paper properties and runnability in the paper machines would also improve if we could reduce the extractive substances in the pulp.”

The new challenge for researchers lies in finding suitable methods for removing the extractive substances from the wood.

“We want to know whether it’s better to remove the extractive substances before the first stage of refinement, where the wood chips are converted to pulp, or whether it’s better to do it later,” says Birgitta Engberg, Project Manager for research into the extractive substances.

Birgitta is employed at Mid Sweden University, but works part time at SCA R&D Centre.

New products

If it was possible to separate the extractive substances from the wood fibres effectively, they could also be used as raw materials in soap, adhesives or impregnating agents. But there is a lot of work remaining before we can speak about specific products.

If we could remove half of the extractive substances, energy needs would fall by about 15%.

“First of all we need an efficient method for separating the extractive substances from the process water. Only then can we decide what products might apply,” says Marie Eriksson, Head of Sustainable Chemistry, and adds:

“We also have to look at the potential for removing the extractive substances. What would it cost, and what are the benefits? One alternative could be to use them as fuel – extractive substances have a very high energy value.”

There are other interesting substances in wood besides extractive substances. One of them is hemicellulose.

“Here at SCA, we do not conduct any research into converting hemicellulose to bioethanol by fermentation, which has received a great deal of focus in the US. We are more interested in using hemicellulose as a paper chemical, or for the manufacture of barriers. A recent trend all over the world is trying to find new and more efficient methods for utilising existing raw materials,” concludes Marie.

Nalco Announces Price Increases in Europe, Africa and the Middle East

Nalco, providing essential expertise for water, energy and air, is implementing a price increase for customers across the Europe, Africa and Middle East (EAME) region, effective Feb. 1 or as contracts permit. Increases will average from 5 to 15 percent, in line with those recently announced globally. They are focused on the specific situation Nalco and its customers face in the EAME region. The level of increase will depend on the country and the specific Nalco program.

"We have experienced significant raw material cost increases and some raw material availability shortages,” said David Johnson, Nalco Executive Vice President and President, EAME. “We are also affected by REACH legislation costs impacting a relevant part of the EAME product line. By increasing our prices as our costs increase, we can continue to invest in research, manufacturing process improvements and development of our field engineers to enhance the sustainable solutions we provide and the value we create for our customers."

Nalco’s sales engineers and key account managers will discuss the particular impacts of these increases with individual customers.

Invitation to Pöyry's full year 2010 result news conferences on 8 February 2011

Pöyry PLC's financial statement release will be published 8 February 2011 at 8:30 a.m. Finnish time. The full year 2010 result will be presented by CEO Heikki Malinen at the news conferences as follows:

- A conference for analysts, investors and press in Finnish will be arranged at 12 p.m. Finnish time at Restaurant Savoy, Eteläesplanadi 14, Helsinki, Finland.

- An international conference call and webcast in English will begin at 5:00 p.m. Finnish time (EET).

10:00 a.m. US EDT (New York)

3:00 p.m. GMT (London)

4:00 p.m. CET (Paris)

5:00 p.m. EET (Helsinki)

The webcast may be followed online on the company's website www.poyry.com. A replay can be viewed on the same site the following day.

To attend the conference call please dial

US: +1 877 491 0064

Other countries: +44 20 7162 0025

Conference id: 886734

Due to the live webcast, we kindly ask those attending the international conference call to dial in 5 minutes prior to the start of the event.

PÖYRY PLC

Clariant OBAs at forefront of REACH registration

As of January 2011, Clariant’s entire range of Leucophor® optical brighteners (OBAs) on general sale in Europe comprises substances which are fully-registered under REACH.

The first phase of REACH, the Registration, Evaluation, Authorization and Restriction of Chemical Substances, was completed at Clariant by 30 November 2010. Since that time, Clariant has registered the remaining active substances of its Leucophor range, well ahead of the REACH Phase Two deadline in the year 2013.

The successful registration of Leucophor active substances means Clariant’s customers can depend on the future availability of the Leucophor range. Achieving full registration of its Leucophor range puts Clariant at the forefront of REACH legislation for OBAs, with each OBA supported by an extensive registration dossier.

“Clariant regards product safety as being of the utmost importance”, comments Andrew Jackson, Head of Product Management OBAs at Clariant Paper Specialties. “Our very significant investment in ensuring the full registration of our chemistries under REACH further demonstrates our commitment to our long-term future in optical brighteners.”