Ian Melin-Jones

ANDRITZ launches MasterDry dryer fabric portfolio

International technology Group ANDRITZ presents its new “MasterDry™” dryer fabric portfolio based on premium-performance dryer fabric technology.

- World-class performance woven and spiral fabric technology

- For all applications including high-temperature and contamination-prone positions with improved sheet quality and long life

- Best-in-class seam technology for fast installation

- Modernized and expanded global manufacturing capabilities

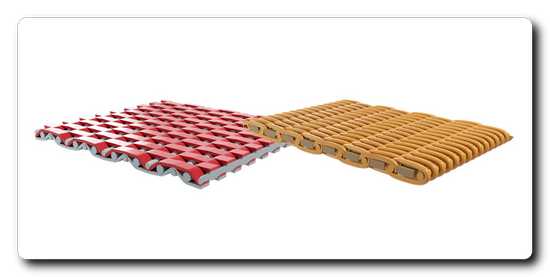

MasterDry includes best-in-class woven and spiral fabrics specifically designed for the broadest range of applications, from the fastest low-caliper, single-tier positions, for high-temperature positions, and for those positions requiring extreme contamination resistance. It includes specially engineered woven or spiral dryer fabrics to cover an entire paper machine producing paperboard/packaging and graphical papers or also pulp machines, thus providing customers with a very comprehensive suite of high-performance dryer fabric options.

MasterDry offers a complete portfolio of high-quality woven and spiral dryer fabric technology for every application in paperboard/packaging, graphical, and pulp machines. © ANDRITZ

MasterDry offers a complete portfolio of high-quality woven and spiral dryer fabric technology for every application in paperboard/packaging, graphical, and pulp machines. © ANDRITZ

“We will continue to focus on R&D to launch new innovative products and to invest in our plants to become the premier global supplier of the highest quality dryer fabric technology with shortest delivery times,“ says Bill Butterfield, Executive Vice President and Chief Technology Officer at ANDRITZ Fabrics and Rolls.

With the new MasterDry portfolio of dryer fabrics, ANDRITZ once again confirms its position as one of the global market leaders for the supply of innovative fabrics, press felts, and roll technology solutions.

For more information, please visit andritz.com/fabrics-and-rolls.

ANDRITZ GROUP

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

ANDRITZ stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, 29,600 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

Domtar to Reduce Papermaking Capacity at Two Mills

Domtar Corporation has just announced that it will permanently shut down two of its paper machines.

The closures will take place at the Ashdown, Arkansas pulp and paper mill, and the Port Huron, Michigan paper mill. These measures will reduce the Company’s annual uncoated freesheet paper capacity by approximately 204,000 short tons, and will result in a workforce reduction of approximately 100 employees. The closure of the Ashdown paper machine will be effective immediately and the closure of the Port Huron machine by mid-November.

“I wish to sincerely thank colleagues impacted by the closures and recognize their hard work and contribution to Domtar over many years. As difficult as these actions are, we believe they are necessary in light of the declining market for uncoated freesheet paper. We will be working closely with our customers to assure they continue to receive the high quality products and exceptional service they have come to expect from us,” said John D. Williams, President and Chief Executive Officer of Domtar.

“I wish to sincerely thank colleagues impacted by the closures and recognize their hard work and contribution to Domtar over many years. As difficult as these actions are, we believe they are necessary in light of the declining market for uncoated freesheet paper. We will be working closely with our customers to assure they continue to receive the high quality products and exceptional service they have come to expect from us,” said John D. Williams, President and Chief Executive Officer of Domtar.

The Ashdown mill will continue to operate one paper machine with an annual uncoated freesheet paper production capacity of 200,000 short tons and employ approximately 725 people. In addition, the mill operates one of the world’s largest fluff pulp machines, with the flexibility to produce softwood pulp depending on market conditions. As a result of the closure of the paper machine, the mill will produce an incremental 70,000 ADMT of softwood and fluff pulp, which will ramp up over the next 12 months.

The Port Huron mill will continue to produce a wide variety of technical and specialty papers for a broad range of customers, utilizing three machines with a total annual production capacity of 95,000 short tons. Following the closure, the mill will employ approximately 212 people.

“The closure of the two paper machines will enable us to right-size our paper production capacity with our customer demand. This proactive measure is necessary due to increased imports and declining paper demand,” added Williams.

About Domtar

Domtar is a leading provider of a wide variety of fiber-based products including communication, specialty and packaging papers, market pulp and absorbent hygiene products. With approximately 10,000 employees serving more than 50 countries around the world, Domtar is driven by a commitment to turn sustainable wood fiber into useful products that people rely on every day. Domtar’s annual sales are approximately $5.5 billion, and its common stock is traded on the New York and Toronto Stock Exchanges. Domtar’s principal executive office is in Fort Mill, South Carolina. To learn more, visit www.domtar.com.

Ametek Surface Vision strengthens leadership team with several key appointments

AMETEK Surface Vision, a world leader in surface inspection technologies, has announced sweeping appointments across its senior global team to support the business’s worldwide growth plans.

Ben Wileman has been promoted to the new role of Division Vice President and Business Manager for Surface Vision. Moving from his last role as Division Vice President — Global Sales and Marketing for Surface Vision and its sister business, AMETEK Land, Ben will now focus on growing Surface Vision’s business through the application of AMETEK’s four core growth strategies of global and market expansion, new products, operational excellence and acquisitions.

“Combined, these four strategies deliver sustained business growth while continually bringing customers improved benefits at all levels. I look forward to bringing this philosophy into Surface Vision, so the business continues to flourish within the constructive, consistent and mutually successful approach customers want,” said Wileman.

The newly-appointed senior leadership team (clockwise, from top left): Mike Hevey, Alan Tarry, Ben Wileman, Jason Zyglis

The newly-appointed senior leadership team (clockwise, from top left): Mike Hevey, Alan Tarry, Ben Wileman, Jason Zyglis

With a Bachelor of Engineering degree in Electronic Engineering from Sheffield Hallam University, Ben holds more than 14 years of experience at AMETEK in a variety of technical, sales and customer-facing roles. Additionally, he’s an AMETEK-certified Growth Kaizen Facilitator, further strengthening his drive for Surface Vision’s growth.

On the operational end of the spectrum, Alan Tarry is now Division Vice President - Operations for AMETEK Land and Surface Vision. Alan will be fully responsible for operational strategies and performance across both businesses. Formerly the Director of Operations at AMETEK Land since 2015, Alan’s continuous improvement and specialist supply chain experience will transform operational efficiencies across both companies’ manufacturing operations.

Prior to joining AMETEK, Alan held senior operational and supply chain transformational roles at ABB and has a Higher National Certificate in Electrical and Electronic Engineering from Doncaster Technical College. Like Ben, Alan is an AMETEK-certified New Product Growth Kaizen Facilitator and has facilitated several AMETEK operational and new product events.

Charged with developing strategy to remain competitive in current markets while identifying diversification opportunities, Mike Hevey has been appointed Division Vice President – Engineering and Product Management. Joining Surface Vision from SEASPAN Shipyards in Vancouver, Canada, Mike will implement an effective engineering structure to develop and support the world leading SmartView® and SmartAdvisor® surface inspection and monitoring systems, identify new product opportunities, manage the product lifecycle and introduce new products to the market.

Mike holds a Bachelor of Science degree in Electrical and Electronic Engineering from the University of Manchester Institute of Science and Technology, and a Master of Business Administration degree in Engineering and Industrial Management from the University of Loughborough.

Finally, Jason Zyglis will assume responsibility for global sales as Division Vice President of Sales and Project Management. With a deep knowledge of Surface Vision products and applications, Jason will lead the sales and project teams in addressing complex customer challenges as well as implementing a customer-first culture across the organization.

“I’m very pleased to announce these senior appointments at Surface Vision, who will maintain and develop our market-leading position into the next decade,” said Justin Smith, Division Vice President and Business Unit Manager for Surface Vision. “Their combined technical, business and customer experience will provide leadership across Surface Visions’ global sales and marketing, engineering and operational functions, effectively transforming the opportunities and benefits for our customers worldwide.”

About AMETEK Surface Vision

AMETEK Surface Vision (formerly Cognex Surface Inspection Systems Division) is a world leader in automated online surface inspection solutions with a broad product portfolio optimized for web and surface inspection and monitoring and process surveillance applications.

Its product portfolio includes three distinct product lines: SmartView® systems, SmartAdvisor® systems and Slit Inspection. Each product line uniquely enables customers to inspect the surfaces of materials processed in a continuous fashion across the metals, paper, plastics, nonwovens and glass industries. For more information, visit ameteksurfacevision.com

AMETEK Surface Vision is unit of AMETEK Process and Analytical Instruments, a division of AMETEK, Inc., a global manufacturer of electronic instruments and electromechanical devices.

Paper Converting Machine Company acquires STAX Technologies.

Tissue manufacturer enhances its packaging portfolio to offer the global market broader solutions.

Paper Converting Machine Company (PCMC), part of the Barry-Wehmiller Converting Solutions Platform, acquired STAX Technologies (STAX), headquartered in Čačak, Serbia. The acquisition adds reciprocating flow technology to PCMC’s tissue packaging product line offering.

STAX is a market leader in the tissue packaging equipment industry, whose core product offerings include wrappers, bundlers, casepackers and palletizers. Since its entrance into the market more than 15 years ago, STAX has built a global customer base and continues to deliver innovative and cost-effective solutions to the market.

“This marks a new era for PCMC,” said Sergio Casella, PCMC-Italy President. “By adding STAX’s expertise and capabilities, we are the only manufacturer to offer both reciprocating and continuous flow equipment as well as complete solutions from unwinders through palletizers for customers worldwide.

This acquisition will fuel STAX’s global expansion, as PCMC’s well-established footprint provides the parts and service network customers need in today’s competitive tissue market. “Our field service technicians will now deliver the same exceptional service on STAX equipment like they have on PCMC machines for the last century,” said Casella.

"This new partnership with STAX Technologies provides PCMC with an exciting opportunity to build a stronger, more sustainable global tissue packaging organization,” added Bob Chapman, Barry-Wehmiller Chairman and CEO. “We look forward to working alongside STAX’s team members whom we know will greatly benefit from Barry-Wehmiller’s unique, people-centric culture, financial strength and unwavering commitment to purpose-driven growth.”

About PCMC

Paper Converting Machine Company (PCMC) specializes in the design and manufacture of high-performance converting machinery for the tissue, nonwovens and package-printing industries worldwide. Our comprehensive product offerings include rewinding, laminating, printing, embossing, perforating and packaging equipment for tissue and towels; folding and converting machines; and a complete range of flexographic printing presses and laser anilox cleaners, serving the flexible-packaging, prime-label and carton-converting industries. For more about PCMC, which is part of Barry-Wehmiller, go to www.pcmc.com

About STAX

STAX Technologies is a renowned international company entirely focused on the continuous development of its technological innovations dedicated predominantly to the world of tissue paper packaging and to other related professional services. Since its foundation, 18th February, 2002 in Cacak, STAX Technologies has been focused on a continuous development and manufacturing of the packaging machines for the Tissue Converting Industry. Over the years, by introducing endless innovations, we have become one of the leading companies in the packaging industry. Swiftness in adapting to the quickly changing market trends and constantly supplying newly developed technological achievements is what differentiates STAX Technologies from any other manufacturer. To learn more, go to www.staxtechnologies.com

About BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper-converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $3 billion organization with nearly 12,000 team members united by a common belief: to use the power of business to build a better world. CEO Bob Chapman shares the story of the company’s transformation in his book, Everybody Matters: The Extraordinary Power of Caring for Your People Like Family. To learn more, go to www.barrywehmiller.com

Sappi Europe joins HP Indigo’s Alliance One media programme

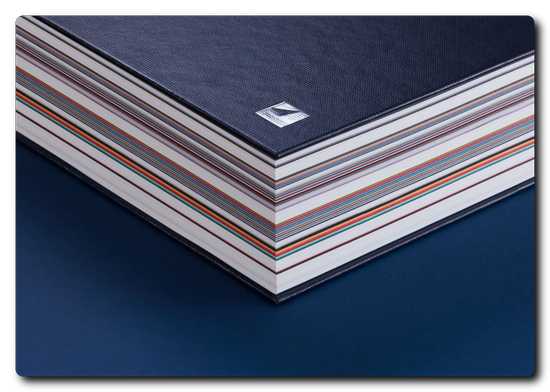

Sappi Europe is pleased to announce that it has signed a collaboration agreement with HP Indigo, as part of HP Indigo’s Alliance One programme. The alliance underlines both companies’ continued commitment to print media as the leading force in wood free coated paper and digital imaging technologies respectively. The collaboration will cover commercial, research & development and market related topics with multiple contacts being established as part of the co-development between the two companies.

Sappi’s flagship Magno and GalerieArt products have been certified for use on HP Indigo presses, providing unrivalled global availability of certified paper for use on the HP Indigo installed base.

Sappi’s flagship Magno and GalerieArt products have been certified for use on HP Indigo presses, providing unrivalled global availability of certified paper for use on the HP Indigo installed base.

Marco Eikelenboom VP Sales & Marketing at Sappi Europe commented:

“As market leader in coated graphical papers, our Sappi Europe Alliance One collaboration with HP Indigo is a logical component in our mission to secure the attractiveness of printed media within the media mix. Only such true relationships can safeguard the required drive for product innovation, which is exhibited in our certified media portfolio as part of the Magno, GalerieArt and EuroArt families. We’re looking forward to working together with HP Indigo & the other Alliance One media members on the sustainable success of printed media”.

Alon Bar-Shany, HP Indigo’s General Manager completed:

“Sappi and HP Indigo have worked together for years to help our joint customers grow profitably. It is very exciting to take our relationship to the next level I look forward to working together and bring the Sappi quality and capabilities to our customers.”

About Sappi

Sappi is a leading global provider of sustainable woodfibre products and solutions, in the fields of Dissolving wood pulp, Printing papers, Packaging and speciality papers, Casting and release papers, Biomaterials and Bio-energy. As a company that relies on renewable natural resources, sustainability is at our core. Sappi European mills hold chain of custody certifications under the Forest Stewardship Council® (FSC®) and/or the Programme for the Endorsement of Forest Certification™ (PEFC™) systems. Our papers are produced in mills accredited with ISO 9001, ISO 14001, ISO 50 001 and OHSAS 18001 certification. We have EMAS registration at 8 of our 10 mills in Europe.

Sappi Europe SA is a division of Sappi Limited (JSE), headquartered in Johannesburg, South Africa, with 12,500 employees and 18 production facilities on three continents in nine countries, 37 sales offices globally, and customers in over 150 countries around the world.

Learn more about Sappi at www.sappi.com.

Second phase of mbo secures further jobs and safeguards the Arjowiggins brand

The management team of Arjowiggins Creative Papers has taken ownership of the remainder of the company’s activities, protecting nearly 300 jobs in Europe and China and safeguarding the future of the iconic Arjowiggins brand.

The announcement follows the successful completion last week of a management buy-out of the companies UK operations which saved hundreds of jobs and two historic paper mills in Aberdeen and Kent.

The latest deal protects the Guarro Casas mill in Spain, which has been in operation since the end of the 17th century, the Quzhou mill in China and offices in France and Milan. This brings the total number of jobs secured to around 750.

The new company, Arjowiggins Group Ltd, will be based in Scotland and managed by an experienced leadership team under the direction of current Managing Director Jonathan Mitchell.

Arjowiggins is a name synonymous with paper manufacturing with prestigious brands such as Conqueror, Curious Collection, Rives, Pop'Set and Keaykolour. It is also the leader in the tracing paper market under the Gateway brand and also manufactures security documents and Powercoat for printed electronics.

Jonathan Mitchell, managing director, comments: “This is great news, not just for everyone at Arjowiggins but for the industry as a whole. The completion of the second phase of the MBO draws to a close an unsettling period for the business and we’re delighted to now be able to start a new chapter in the brand’s history.

“I’d like to extend my sincere thanks once again to our staff, customers, suppliers and the Scottish Government. Without their ongoing support this deal would simply not have been possible.

"Arjowiggins Creative Papers has world-leading brands and products and a talented team. There will be no major strategic change for the business. The priority now is to continue the projects we have already committed to, strengthen our activities in a sustainable manner and identify future opportunities for the sector."

About Arjowiggins Creative Papers

Arjowiggins Creative Papers is one of the world’s leading producers of fine, smart and technical papers as well as security documents. We are the makers of well-known ranges such as Conqueror, Curious Collection, Keaykolour, Pop’Set, Rives or Gateway and more recently Powercoat for printed electronics. Our papers are manufactured across 4 mills, in Europe and China.

Our products offer an extensive array of weights, colours, finishes and applications and are chosen the world over in the creation of printed communication of all kinds. They are developed and manufactured with expertise that has been passed down from generation to generation, through over 250 years of paper-making.

Our mission is to help designers, printers, advertisers and brand owners to channel the unique qualities of print and provide them with the finest and most innovative papers, wherever they may be. Through our products, our manufacturing and our service to customers, our promise is to deliver international standards for creative papers.

Arjowiggins’ creative papers are distributed worldwide.

www.arjowigginscreativepapers.com

www.powercoatpaper.com

www.arjowiggins-translucentpapers.com

California Lawmakers Reject Bill to Ban Paper Receipts

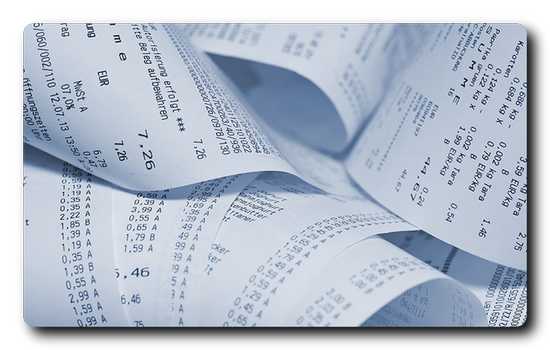

California lawmakers recently rejected a bill meant to ban paper receipts. The proposal would have required businesses to ask customers if they wanted a paper receipt before printing one, and businesses would have been forbidden to print coupons or advertisements on receipts unless requested by the customer.

Assembly Bill 161 by Assemblymember Phil Ting of San Francisco stalled in the state’s Senate Appropriations Committee as the legislature pared bills before the final two weeks of the session. Advocates of the California bill to ban paper receipts, dubbed Skip the Slip, suggested it would reduce paper waste in the state.

The bill initially would have required businesses to provide customers electronic receipts unless a paper printout was requested. After an outcry about privacy concerns related to digital receipts and what it would cost small businesses to use new payment software, that provision was dropped. The move to ban paper receipts also faced strong opposition from the California Restaurant Association and the California Retailers Association.

The bill also sought to ban the use of certain chemicals on paper receipts by promoting myths about the amount of bisphenol A (BPA) and bisphenol S (BPS) in lightweight thermal paper, the health risks associated with handling thermal paper and claims that BPA and BPS make paper receipts unrecyclable.

“The defeat of this legislation to ban paper receipts is an important victory for Domtar,” says Tom Howard, Domtar’s vice president for government relations. “California represents almost 10 percent of the receipt paper market, and other states, including Illinois and New York, have watched developments with the bill closely. California legislators took a hard look at the value receipts bring to consumers and decided consumers’ interests are paramount.”

Jessica Mause of the Keep the Receipt opposition group told the Los Angeles Times, “Public policy should be based on facts and sound science, not misinformation and unsubstantiated claims. We’re pleased that legislators recognized paper receipts are not only preferred by the majority of consumers but are also safe for consumers and employees.”

Paper Receipts Are Safe and Recyclable

Lawmakers in Illinois and Connecticut have approved measures to ban paper receipts and other documents that are printed on thermal paper that contains BPA. New York has a similar bill under consideration.

But such bills promote myths about this type of paper. Lightweight thermal receipt paper manufactured in the United States is BPA-free. We know because we make it at our Marlboro Mill and send it to Appvion in Appleton, Wisconsin, which applies the BPA-free thermal coating. At the time of this writing, Appvion is the largest North American producer of thermal point-of-sale receipt paper, and the company hasn’t used BPA since 2006.

While BPA can still be found in lightweight thermal receipt paper produced in Asia and Europe (the EU is phasing it out), the amounts are well within the acceptable levels monitored by the United States Environmental Protection Agency and the Food and Drug Administration. Paper receipts made from imported thermal paper don’t pose the significant health risk mentioned in the Skip the Slip bill to ban paper receipts. The same is true for all lightweight thermal receipt paper that contains BPS.

Similarly, claims that paper receipts can’t be recycled are overstated. Lightweight thermal receipt paper is just as recyclable as any other paper and doesn’t pose any more of a threat to the recycling stream than other materials containing phenols, such as aluminum cans and plastic bottles. In fact, as BPA levels in imported lightweight thermal receipt paper continue to fall, this will become even less of a concern.

Howard says the disruptions caused by attempts to ban paper receipts will negatively impact businesses models that are predicated on paper.

“Not all areas have sufficient internet connectivity to sustain this [type of] bill,” he says. “And not everyone carries a smartphone all the time. That would be problematic for businesses like dry cleaners and wholesale superstores where paper is an essential part of business operations.”

Skip the Myths

When it comes to legislation to ban paper receipts, skip the myths before you skip the slips.

“We are committed to not only protecting our industry’s interests but also advocating for people’s right to choose paper,” Howard says.

Debunk other paper myths by reading these articles:

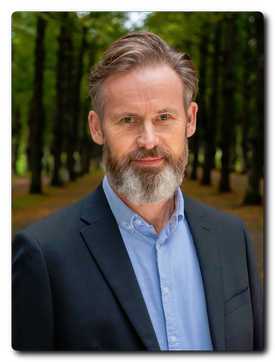

Peter Sävelin new Mill Director at Vallvik Mill

Rottneros has appointed Peter Sävelin as Mill Director at Vallvik Mill. Peter most recently comes from BillerudKorsnäs, where he held the position as Senior Technology Specialist. He will take office no later than 1 January 2020 and will be part of the Rottneros Group Management Team.

Peter Sävelin“I am very pleased that Peter will take over as Mill Director at Vallvik Mill. Vallvik has taken a number of decisive steps in recent years when it comes to both capacity growth and safety as well as leader- and employeeship. New production records and a wonderful drive in the organization are clear evidence of the success. I am convinced that Peter will continue to develop the mill to new heights thanks to his strong leadership skills and solid competence”, says Lennart Eberleh, President and CEO of Rottneros.

Peter Sävelin“I am very pleased that Peter will take over as Mill Director at Vallvik Mill. Vallvik has taken a number of decisive steps in recent years when it comes to both capacity growth and safety as well as leader- and employeeship. New production records and a wonderful drive in the organization are clear evidence of the success. I am convinced that Peter will continue to develop the mill to new heights thanks to his strong leadership skills and solid competence”, says Lennart Eberleh, President and CEO of Rottneros.

“I feel proud and happy but at the same time also humbled by the task. I am looking forward to taking the overall responsibility for Vallvik Mill and getting to know all the employees in the goal-oriented organization. It is also exciting to be part of the management team of a listed company with a clear focus on creating shareholder value combined with high sustainability ambitions”, says Peter Sävelin.

For more information please contact:

Lennart Eberleh, President and CEO, Rottneros AB, +46 (0)270 622 65, This email address is being protected from spambots. You need JavaScript enabled to view it.

Rottneros is an independent producer of market pulp. The Group comprises the parent company Rottneros AB, listed on NASDAQ Stockholm, and its subsidiaries Rottneros Bruk AB and Vallviks Bruk AB with operations involving the production and sale of market pulp. The Group also includes Rottneros Packaging AB, which manufactures fibre trays, and the wood procurement company Rottneros Baltic SIA in Latvia. The Group has about 300 employees and had a turnover of approximately SEK 2.3 billion in the 2018 financial year.

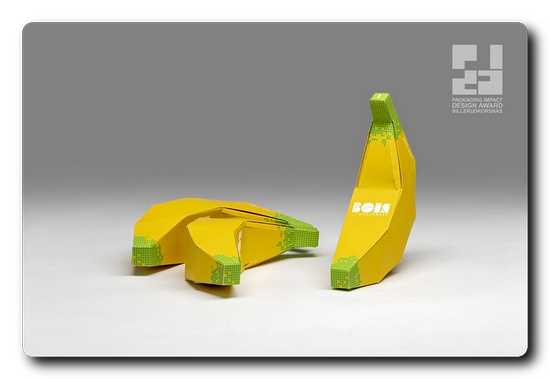

Congratulations, banana-shaped design! Winner of the Grand Finale of PIDA – Packaging Impact Design Award

For 15 years running, BillerudKorsnäs has arranged and hosted PIDA - Packaging Impact Design Award, a competition among design students in France, Germany, Sweden and the UK. For the first time in the history of the competition, an all-European winner has been selected. The Grand Finale was held at Luxe Pack Monaco, the world’s leading trade fair for luxury packaging, and the title went to “Bois Underwear” by Swedish students from design college Nackademin.

The students behind the winning design are Natasha Bosnjak, Alicia Lundgren and Christian Koch. Their design qualified for the Grand Finale by winning the Gold Award at the Swedish PIDA event. They suggested that packaging design in the future may very well be fun, playful and edgy. The winner is a retail pack for men’s underwear in the shape of a banana, which you peel to open.

“We are so happy about this prize,” says Alicia Lundgren. “It means everything. And it means a lot that we just followed our hearts, never held back, and disregarded the usual Scandinavian design conventions. We managed to make sustainability look fun, and we are very pleased with that.”

A glimpse of the future

For every year, the competition has a new theme. This year’s brief was "Bring the Future" and the students’ challenge was to develop a sustainable packaging concept for the year 2030. The jury looked at the innovativeness, sustainability, user-friendliness, concept and communication of the contesting design projects. Bois Underwear received high marks on all points, and its colourful appearance drew a lot of attention. In total, 36 design projects were nominated and four of them made it to the Grand Finale.

The Grand Finale winner was elected by a jury comprising a mix of industry professionals – designers, converters, brand owners and other specialists – all of whom have been on the jury at one of the previous PIDA-events this year.

“The brief presented to students at the PIDA 2019 was ambitious. Imagining the packaging of the future seems simple at first sight, but that is without counting the current trends that are the new technologies, the sustainable development and the aging of the population,” says Sophie Lindhe, Brand Project Coordinator, at BillerudKorsnäs.

Young talents become tomorrow’s packaging designers

The international competition PIDA is a BillerudKorsnäs initiative and is carried out in collaboration with leading universities and colleges in Sweden, the UK, France and Germany. Each year, about 200 design students participate.

“With PIDA we achieve several different purposes at the same time,” says Anders Gathu, Marketing Manager at BillerudKorsnäs. “We aim the spotlight on the importance of packaging for brands, consumer benefits and the environment. We want to shine light on the young talents who will become tomorrow’s packaging designers and bring them together with industry professionals. By offering a meeting place for ideas, innovation and inspiration, we help push industry development forward.”

Natasha Bosnjak, Alicia Lundgren and Christian Koch won the PIDA Grand Finale.

For more information about PIDA, please contact:

Sophie Lindhe, Brand Project Coordinator, BillerudKorsnäs

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

ANDRITZ to supply P-RC APMP fiberline to Dezhou Taiding, China

International technology Group ANDRITZ has received an order from Dezhou Taiding New Material Science and Technology Co., Ltd. (Dezhou Taiding) to supply a P-RC APMP (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) fiberline with a capacity of 400 t/d to the mill in Dezhou, Shandong, China.

The new system will process poplar as raw material, and the fiber produced will be used on the company’s own paper machines for P&W (printing and writing paper) and board grades. Start-up is scheduled for the third quarter of 2020.

ANDRITZ’s scope of supply includes the key components for the entire mechanical fiberline, ranging from chip washing to the reject treatment system. Engineering, training, supervision of the mechanical installation, commissioning and start-up are also part of ANDRITZ’s scope.

ANDRITZ single-disc refiner S2070 © ANDRITZ

ANDRITZ single-disc refiner S2070 © ANDRITZ

The ANDRITZ MSD 400 Impressafiner ensures a high degree of chip delamination and thus contributes to uniform bulk density and optimal removal of moisture and extractives. The excellent material maceration and partial fiber delamination results in superior preconditions for chip impregnation, enabling maximum uptake of chemicals.

Pre-bleaching of chips as well as high-consistency refining by the ANDRITZ single-disc refiner S2070 will significantly improve pulp quality and keep the amount of shives as low as possible. The S2070 operates with a narrow and stable refining gap, which is especially important when producing P&W and board grades because enhanced fiber surface and efficient fibrillation have a considerable impact on fiber bonding. The swing-door refiner design ensures fast and easy change of refiner plates to save maintenance costs.

Numerous successful references for the ANDRITZ P-RC APMP systems worldwide were decisive in Dezhou Taiding placing the order with ANDRITZ.

Dezhou Taiding New Material Science and Technology Co., Ltd. was founded in 1998 and today is a joint-stock company serving the pulp production, papermaking and thermo-electricity business. It is one of the important players in the paper industry in the Shandong region, China.

ANDRITZ GROUP

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

ANDRITZ stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, 29,600 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.