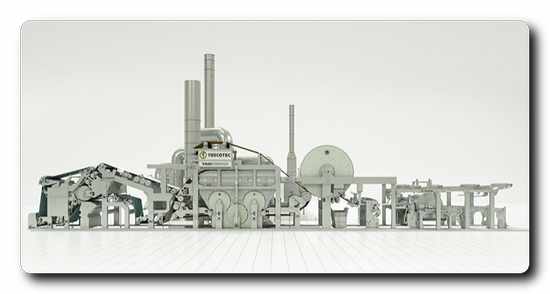

Valmet will deliver key process islands for Lenzing’s and Duratex’s joint venture named LD Celulose S.A. The new 500,000 ton/year dissolving pulp mill is located in the cities of Indianópolis and Araguari in Minas Gerais state, Brazil. Valmet’s delivery includes a fiber line, a pulp drying and baling line, an evaporation plant, a white liquor plant and a mill-wide automation system.

The order is included in Valmet's orders received of the first quarter 2020. The value of the order is not disclosed. The value of a delivery of this size and scope is typically around EUR 200-250 million.

Valmet’s delivery is part of the Lenzing and Duratex joint venture investment of approximately USD 1.3 bn in the 500,000 tonnes dissolving wood pulp mill where Lenzing holds a 51 percent and Duratex a 49 percent stake. The start-up of the new mill is planned for the first half of 2022 and will create approximately 8,000 direct jobs during the construction phase. When it is ready, LD Celulose S.A. will employ approximately 1,100 people to operate the industrial plant and the plantations that will supply it. The dissolving pulp is a key raw material for manufacturing Lenzing’s wood-based textile and speciality fibers.

“Wood-based cellulosic fibers offer an important contribution to enhance sustainability in the textile industry and this investment is in line with our growth strategy and a key milestone to structurally strengthen our cost leadership position. In planning the new production facility, particular importance was given to sustainability aspects. The plant will be among the most productive and energy-efficient mills in the world,” states Stefan Doboczky, CEO of the Lenzing Group.

“LD Celulose S.A. will bring a positive socioeconomic impact throughout the region. We are working with the best environmental practices and with leading companies in the pulp industry, such as Valmet,” emphasizes Luís Künzel, CEO of LD Celulose S.A.

“With our good references in dissolving pulp production technology and strong presence in Brazil we were able to meet the customer’s needs of high quality and energy efficiency as well as supporting high productivity and reliability with our automation solutions. We are happy to be a key partner in delivering a world class mill for Lenzing and Duratex and thus being part of turning renewable raw materials for sustainable textile fibers,” says Bertel Karlstedt, President, Pulp and Energy Business Line, Valmet.

The new 500,000 tonnes dissolving wood pulp mill is being built in Minas Gerais state, Brazil.

The new 500,000 tonnes dissolving wood pulp mill is being built in Minas Gerais state, Brazil.

Information about Valmet’s delivery

Valmet will supply key process islands with an extended scope of supply. Valmet’s technology is proven for dissolving pulp production with several references. The equipment for this project is tailored for high availability and energy efficiency resulting in low operating costs.

The fiber line features Valmet TwinRoll technology for high washing efficiency with low chemical and water consumption. The pulp drying and baling line secures flexibility and high-quality pulp with easy operation supported by Valmet Quality Control System. The evaporation plant features Valmet Tubel technology for high availability and produces clean condensate quality for 100% reuse in the mill. The white liquor plant includes recausticizing and lime kiln and is designed for high reliability and less maintenance.

The mill-wide automation system, Valmet DNA, offers unique integration with process solutions including process analyzers. In addition, the delivery includes Valmet Industrial Internet solutions for Operator Training Simulator for the whole plant as well as basic hardware for connectivity for Performance Center services.

Information about the customers Lenzing and Duratex

The Lenzing Group headquartered in Austria is an international company of wood-based cellulose fibers. These high quality fibers are used in the textile industry, in the nonwovens industry for hygiene products and are also used in work and protective wear and in industrial applications. Dissolving wood pulp is subsequently processed from the raw material wood and marketed under the brands TENCEL™ for textile applications, VEOCEL™ for nonwovens and LENZING™ for special fiber applications in other areas and other products. The annual turnover of the Lenzing Group is above EUR 2,000 million.

Duratex is the largest producer of industrialized wood panels in the southern hemisphere. The company has three business areas: Wood, Ceramic tiles and Sanitary ware, metals, electric showerheads and faucets. The Wood division covers wood products and forestry, producing eucalyptus in more than 251 thousand hectares of forests. Duratex’s head quarter is located in the city and state of São Paulo and it has seven forestry units and 16 industrial facilities in Brazil and three production facilities in Colombia.

The emtec TSATissue Softness Analyzer is a multi-functional measuring device for the objective assessment of softness, roughness and in-plane stiffness of tissue products and calculates the "Handfeel" value adapted to the respective market and product. These individually measured parameters are used for quality control, help in product and process optimization, and can also be used to develop new products. Participants at the trade show can have samples measured and evaluated directly at the booth using the TSA.

The emtec TSATissue Softness Analyzer is a multi-functional measuring device for the objective assessment of softness, roughness and in-plane stiffness of tissue products and calculates the "Handfeel" value adapted to the respective market and product. These individually measured parameters are used for quality control, help in product and process optimization, and can also be used to develop new products. Participants at the trade show can have samples measured and evaluated directly at the booth using the TSA.

Customers can collaborate with Performance Center experts, access the Industrial Internet applications, follow-up their Key Performance Indicators and see performance reports via Valmet Customer Portal.

Customers can collaborate with Performance Center experts, access the Industrial Internet applications, follow-up their Key Performance Indicators and see performance reports via Valmet Customer Portal.

Data as an Asset explained

Data as an Asset explained