Ianadmin

GRIGISKES AB starts up the new TOSCOTEC Tissue Line at Vilnius mill.

Lithuania’s GRIGISKES has successfully started up the new Toscotec-supplied 110 tons/day tissue PM 6 at Vilnius mill. The site already houses the 17,000 tpy tissue PM5 modernized with the installation of a Toscotec Steel Yankee Dryer TT SYD-4200MM in early 2011.

The new Toscotec’s line includes AHEAD-1.5S crescent former tissue machine with single-layer headbox, single press configuration and a Steel Yankee Dryer (TT SYD-15FT), machine auxiliaries (gas heated hood with three stages heat recovery system, machine dust and mist removal system, hall ventilation system were Milltech’s), stock preparation plant for virgin pulp and electrification & control system.

A two unwind stands tissue slitter rewinder TT WIND-M and an automatic roll handling system completed the supply. The machine design speed is 1900 mpm with a net web width of 2750 mm. The project has been managed by Toscotec on an EPC (Engneering, Procurement & Construction) basis.

"As announced earlier, erection of new production line was terminated in the beginning of March. All components of new machine were tested during first half of month and this week we produced the first batch of paper. We are very happy to announce that production start was smooth, and quality of first paper batch supports our optimistic belief in rightness of the investment. Having started production with new paper machine, we expect fast growth of our turnover and profit." - Gintautas Pangonis, president of GRIGISKES AB says.

New paper production line will match the needs of Company's processing lines of paper products and will allow further development of paper production and sales. ([..]RISI)

Toscotec S.p.A.

T. +39 0583 40871 – F. + 39 0583 4087 800

AkzoNobel takes impact valuation to the fourth dimension

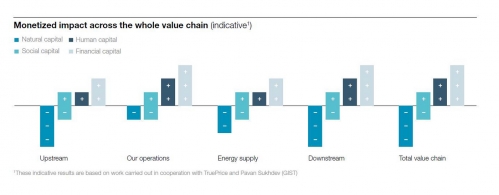

AkzoNobel is exploring new ways of increasing business value by piloting a unique four dimensional approach.

The so-called 4D method looks at the whole value chain and is designed to measure both positive and negative environmental, human, social and financial impact. Already piloted at the company's Pulp and Performance Chemicals business in Brazil, the innovative approach has been confirmed by project partner True Price as the first of its kind to be published.

Six sites in Brazil participated in the pilot, which took place during 2014. The findings - analysed in cooperation with sustainability research organization True Price and economist Pavan Sukhdev - are already being used to make relevant improvements.

AkzoNobel CEO Ton Büchner:

"We wanted to push the boundaries of our impact assessment and develop a deeper understanding of our influence across the whole value chain. By attaching an economic value to the positive and negative aspects of each dimension, we can gain valuable insights into how we can drive longer term value not only for our shareholders, but also for the environment, people and society at large. In addition, the results will inform our strategic decision-making and provide further momentum for our ongoing efforts to do more with less."

Adrian de Groot Ruiz, Executive Director at True Price:

"A 4D method such as this is the future of integrated thinking and reporting. Companies can use it internally to shape innovations and strategies that create shared value for shareholders and society."

Pavan Sukhdev, CEO of GIST Advisory:

"I am delighted with AkzoNobel's pilot study. It showcases the future of impact valuation and integrated reporting and is a first-of-its-kind integrated method in the four dimensions of capital - financial, natural, social and human."

Following the success of the pilot, the company is now looking at scaling up the project.

![]() AkzoNobel is a leading global paints and coatings company and a major producer of specialty chemicals. Calling on centuries of expertise, we supply industries and consumers worldwide with innovative products and sustainable technologies designed to meet the growing demands of our fast-changing planet. Headquartered in Amsterdam, the Netherlands, we have approximately 47,000 people in around 80 countries, while our portfolio includes well-known brands such as Dulux, Sikkens, International, Interpon and Eka. Consistently ranked as one of the leaders in the area of sustainability, we are committed to making life more liveable and our cities more human.

AkzoNobel is a leading global paints and coatings company and a major producer of specialty chemicals. Calling on centuries of expertise, we supply industries and consumers worldwide with innovative products and sustainable technologies designed to meet the growing demands of our fast-changing planet. Headquartered in Amsterdam, the Netherlands, we have approximately 47,000 people in around 80 countries, while our portfolio includes well-known brands such as Dulux, Sikkens, International, Interpon and Eka. Consistently ranked as one of the leaders in the area of sustainability, we are committed to making life more liveable and our cities more human.

About True Price

True Price is a social enterprise that aims to contribute to a circular and inclusive economy that creates value for all people by providing the information needed in such an economy. True Price helps organizations - multinationals, SMEs, NGOs, governments - quantify, value and improve their economic, environmental and social impacts. True Price works directly with organizations by providing research services. In addition, True Price enables organizations to measure their impact through a multi-stakeholder platform that develops open source methods for impact measurement. Valmet to rebuild Turkish Hayat Kimya's tissue machine for improved product properties and runnability

The Turkish tissue producer Hayat Kimya has previously ordered five tissue machine lines from Valmet in the past eight years. Valmet-supplied tissue machines TM 2, 3, 4 and 5 are already producing high quality paper with high capacity and speed, while TM 6 will start-up in 2016.

The Turkish tissue producer Hayat Kimya has previously ordered five tissue machine lines from Valmet in the past eight years. Valmet-supplied tissue machines TM 2, 3, 4 and 5 are already producing high quality paper with high capacity and speed, while TM 6 will start-up in 2016.

Hayat Kimya has decided to rebuild their first tissue machine TM1 with the well performing Valmet Advantage DCT technology. This means that all production assets in their machine fleet will be equipped with Valmet's technology. The rebuild will increase energy efficiency, improve product properties as well as performance, runnability and work environment. TM1 is located at Hayat Kimya's mill in Yeniköy, near the city of Izmit in Turkey. The start-up of the rebuild machine is scheduled for November 2015.

The order is included in Valmet's first quarter, 2015 orders received. The value of the order will not be disclosed.

"We are very satisfied with the operations of our previous Valmet machines so it was a natural decision to go with Valmet also this time" says Lütfi Aydin, Director, Paper Group, Hayat Kimya.

"Through the years Hayat Kimya has achieved excellent results with the Advantage DCT technology. We are proud to continue our good relationship and convinced that also this project will be a success," says Björn Magnus, Sales Director, Tissue Mills Business Unit, EMEA, Valmet.

Technical information

The machine rebuild includes the replacement of existing press section with an Advantage ViscoNip press for improved product quality and decreased energy consumption. To further increase energy efficiency the tissue line will be equipped with a new Advantage AirCap hood as well as an upgrade and optimization of the Cogen Airsystem. The existing dust system will be upgraded to Advantage WetDust to improve the work environment and safety. A new tail threading system and sheet transfer including Advantage Run will further advance runnability and performance.

Information about Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 350,000 tonnes and a converting capacity of 200,000 tonnes per year. Through the new investment and ongoing project the total production capacity of Hayat Kimya will reach 420,000 tonnes.

For further information, please contact:

Jan Erikson, Vice President, Sales, Tissue Mills business unit, Valmet, tel. +46 70 517 14 90

Björn Magnus, Sales Director, Tissue Mills business unit, Valmet, tel. +46 703 17 79 83

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 10,500 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Endress+Hauser and Metso to restructure joint sales and service activities

Realignment relates to companies in Switzerland and Finland

The Endress+Hauser Group and Metso Automation Inc. are to restructure their sales and service activities in Switzerland and Finland with effect from 1 July 2015. Both groups of companies will demerge their mutual minority shareholdings in the respective entities and establish their own dedicated sales and service organizations to serve their customers.

The Endress+Hauser Group and Metso Automation Inc. are to restructure their sales and service activities in Switzerland and Finland with effect from 1 July 2015. Both groups of companies will demerge their mutual minority shareholdings in the respective entities and establish their own dedicated sales and service organizations to serve their customers.

Based on the strong market positions achieved over the past years in both the Swiss and Finnish marketplaces, Endress+Hauser and Metso undertake to continue to serve their customers with their own sales and service networks. Both sides have agreed to continue to cooperate closely with the aim of making the transfer of activities as easy and smooth as possible for their customers.

In Switzerland the minority shareholding of Metso Automation Inc. in Endress+Hauser Metso AG will be transferred to Endress+Hauser by 1 July 2015. The sales and service company will be renamed Endress+Hauser (Schweiz) AG and focus solely on Endress+Hauser’s offering for the process industry. Metso will continue to serve the Swiss market with its valve and pump offering.

Endress+Hauser’s sales and service activities in Finland will move into a new company with the name Endress+Hauser (Finland) Oy by 1 July 2015. This company will act as Endress+Hauser’s sole representation in the country. Metso will focus on sales and service of Metso’s flow control solutions to oil & gas, pulp & paper, mining and other process industries. The minority ownership of Endress+

Hauser (International) Holding AG in the current Metso Endress+Hauser Oy will be transferred to Metso.

Based on its new strategy, communicated in 2014, Metso will continue its transformation to a more focused industrial company with three business areas — Minerals, Aggregates and Flow Control — serving customers in the mining, aggregates and oil & gas industries. Moreover, Metso will serve the pulp & paper, power and other process industries with its flow control solutions and services.

The Endress+Hauser Group

Endress+Hauser is a global leader in measurement instrumentation, services and solutions for industrial process engineering. The Group employs 12,000 personnel across the globe, generating net sales of 1.8 billion euros in 2013.

Structure

With dedicated sales centers and a strong network of partners, Endress+Hauser guarantees competent worldwide support. Our production centers in 11 countries meet customers’ needs and requirements quickly and effectively. The Group is managed and coordinated by a holding company in Reinach, Switzerland. As a successful family-owned business, Endress+Hauser is set for continued independence and self-reliance.

Products

Endress+Hauser provides sensors, instruments, systems and services for level, flow, pressure and temperature measurement as well as analytics and data acquisition. The company supports customers with automation engineering, logistics and IT services and solutions. Our products set standards in quality and technology.

Industries

We work closely with the chemical, petrochemical, food & beverage, oil & gas, water & wastewater, power & energy, life science, primaries & metal, renewable energies, pulp & paper and shipbuilding industries. Endress+Hauser supports its customers in optimizing their processes in terms of reliability, safety, economic efficiency and environmental impact.

History

Founded in 1953 by Georg H Endress and Ludwig Hauser, Endress+Hauser has been solely owned by the Endress family since 1975. The Group has developed from a specialist in level measurement to a provider of complete solutions for industrial measuring technology and automation, with constant expansion into new territories and markets.

For further information, please visit www.press.endress.com or www.endress.com

The Printing Charity appoints Dr Mark Johnson as Helps and Futures Manager

Dr Mark Johnson has joined The Printing Charity as Helps and Futures Manager to help the charity increase the number of people it supports year-on-year.

Dr Mark Johnson has joined The Printing Charity as Helps and Futures Manager to help the charity increase the number of people it supports year-on-year.

As well as managing the charity’s day-to-day Helps programme of financial support for individuals, he is responsible for developing long-term relationships with organisations and other charities to increase uptake of the charity’s services by individuals.

Johnson’s career has spanned some 20 years in the Third Sector in management and leadership roles, as well as in self-employment providing training, development and support for a number of organisations. He has also studied at the University of St Andrews, writing his Ph.D. looking at the relationship between Theology and the Arts and the power of the imagination.

Dr Johnson says: “I am looking forward to playing a part in helping those who benefit from The Printing Charity’s support and in building new working relationships. The charity has such a long, rich history and positive outlook for the future that it is clearly an exciting time to become involved.”

Stephen Gilbert, The Printing Charity’s Chief Executive, says: “We’re pleased to welcome Mark on board. His expertise will be invaluable both on a day-to-day basis managing our grants and at a strategic level taking the charity forward.”

About The Printing Charity:

Whatever a person’s job is or was for three years in an organisation that produces a printed output – printing, publishing, operating presses, driving, cleaning, advertising, warehousing, photography, journalism, graphic arts, making ink, recycling paper – The Printing Charity helps people of all ages, including dependent family members. See www.theprintingcharity.org.uk

ANDRITZ to supply complete deinking line to paper producer Nepa, India

International technology Group ANDRITZ has received an order from the Indian newsprint producer Nepa Ltd. to supply a complete deinking line. Start-up of the new line in Madhya Pradesh is scheduled for mid-2016.

Nepa is one of the leading newsprint producers in India and operates two paper machines with a total annual capacity of approximately 88,000 tons. The company produces standard and economy quality newsprint and will expand its product offerings to writing and printing paper grades after installation of the new ANDRITZ deinking system. The deinking line capacity will be 300 tons per day, processing old newsprint and old magazine grades, sorted office paper, mixed office waste, and coated book stock.

The state-of-the-art deinking plant is designed for environmentally friendly and cost-effective operations and will enable Nepa to produce consistent paper quality with higher brightness paper grades to meet customer expectations.

ANDRITZʼs scope of supply includes the process equipment for the complete deinking line, detail engineering, erection work supervision, and start-up.

For further information, please contact:

Oliver Pokorny

Group Treasury, Corporate Communications & Investor Relations

This email address is being protected from spambots. You need JavaScript enabled to view it.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of almost 25,000 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, production equipment for biofuel (second generation), biomass torrefaction equipment, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

Bekaert Solaronics installs WebMate® systems in a paper mill manufacturing coated specialties located in Japan

Bekaert Solaronics received an order from Matsubo Corporation to install two infrared WebMate® hoods in a paper mill that manufactures coated specialties in Japan.

The objective of these two systems, installed after two new coating stations,is to correct the cross direction moisture profile before coating station and before reel for an optimal paper quality at the lower operating costs.

Two WebMate® systems are already installed after other coating stations on the machine. Both systems providing fully satisfaction in terms on quality and efficiency, the customer renewed its confidence to Bekaert Solaronics.

The new electrical non-contact infrared drying systems WebMate®are equipped with 1 row of 20 M2000 modules which guarantee perfect quality, a high drying rate as well as a long lifetime.

Furthermore, moisture profile correction is optimized thanks to the gold-coated parabolic reflector technology that ensures a focused energy radiation only where it is needed.

About Matsubo Corporation

Matsubo Corporation, established in 1949, introduces Japanese and overseas equipment, machinery, and technology for food, chemicals, pharmaceuticals, steel, non-ferrous metals, paper and electronics.

The Industrial Machinery Division provides plants and stand-alone machines necessary in all phases of production. Matsubo Corporation is also involved in the development of the electronic device industry and in equipment for powder processing.

About Bekaert Solaronics

Bekaert Solaronics supplies customized drying and heating systems based on gas and electrical infrared technology to a wide range of industries including paper and board, converting and metal processing applications. Today, more than 1000 systems have been installed worldwide, of which 60% come from repeat orders with existing customers. The company provides service and maintenance options worldwide for the upgrade optimization and improves energy efficiency of existing systems.

About Bekaert

Bekaert (www.bekaert.com) is a world market and technology leader in steel wire transformation and coatings. Bekaert (Euronext Brussels: BEKB) is a global company with headquarters in Belgium, employing more than 25000 people worldwide.

Serving customers in 120 countries, Bekaert pursues sustainable profitable growth in all its activities and generated combined sales of €4.1billion in 2013.

Domtar welcomes innovation investment by Schlumberger in CelluForce

Domtar Corporation (NYSE: UFS) (TSX: UFS) has announced an investment by Schlumberger in CelluForce, a joint venture between Domtar and FPInnovations that manufactures wood-derived nanocrystalline cellulose (NCCTM). The investment is a collaboration to explore the use of NCC to enhance the productivity of oil and gas wells. Schlumberger is the world's leading supplier of technology, integrated project management and information solutions to the oil and gas industry.

Domtar Corporation (NYSE: UFS) (TSX: UFS) has announced an investment by Schlumberger in CelluForce, a joint venture between Domtar and FPInnovations that manufactures wood-derived nanocrystalline cellulose (NCCTM). The investment is a collaboration to explore the use of NCC to enhance the productivity of oil and gas wells. Schlumberger is the world's leading supplier of technology, integrated project management and information solutions to the oil and gas industry.

NCC is manufactured using a patented process in the world's first facility of its kind, located at Domtar's pulp mill in Windsor, Quebec. NCC (also referred to as Cellulose Nanocrystals, or CNC) is the primary component that provides structural strength to trees. NCC is a renewable, biodegradable, nontoxic material.

Details of Schlumberger's investment in CelluForce remain confidential.

This investment follows a CDN$4 million grant announced by CelluForce in February 2015 from the government of Canada's sustainable development technology program (Sustainable Development Technology Canada, or SDTC) for similar research and development work.

"Innovation is one of our core values at Domtar, so we are pleased to have the opportunity to collaborate with Schlumberger, a recognized technology innovator in hydrocarbon recovery and production," said Patrick Loulou, Domtar's Senior Vice President for Corporate Development and a member of CelluForce's board of directors.

"The Schlumberger investment, coupled with the recent grant from SDTC, creates positive momentum in realizing the benefits of using NCC to improve the efficiency of oil and gas production," said Richard Berry, Chief Technology Officer at CelluForce.

CelluForce Inc. is the world leader in the commercial development of Cellulose Nanocrystals (CNC), also referred to as NanoCrystalline Cellulose (CelluForce NCCTM). The company is a joint venture of Domtar Inc. and FPInnovations. The company's head office is in Montreal. For more information, visit: www.celluforce.com.

About Domtar

Domtar Corporation (NYSE: UFS) (TSX: UFS) designs, manufactures, markets and distributes a wide variety of fiber-based products, including communication papers, specialty and packaging papers, and absorbent hygiene products. The foundation of our business is a network of world-class wood fiber-converting assets that produce papergrade, fluff and specialty pulp. The majority of our pulp production is consumed internally to manufacture paper and consumer products. Domtar is the largest integrated marketer and manufacturer of uncoated freesheet paper in North America with recognized brands such as Cougar®, Lynx® Opaque Ultra, Husky® Opaque Offset, First Choice®, EarthChoice® and Xerox® Paper and Specialty Media. Domtar is also a marketer and producer of a broad line of absorbent hygiene products marketed primarily under the Attends®, IncoPack® and Indasec® brand names. In 2014, Domtar had sales of $5.6 billion from some 50 countries. The Company employs approximately 9,800 people. To learn more, visit www.domtar.com.

SOURCE Domtar Corporation

Sappi guarantees the continuity of its Magno satin product availability

Sappi Europe confirms that it is no longer supplying paper sold under the Galaxi Keramik* brand. However this paper continues to be available on the market under its mill brand name MagnoTM satin through our new Magno merchant partners, Igepa in Germany, France and Switzerland as well as through Papyrus in France.

Sappi Europe confirms that it is no longer supplying paper sold under the Galaxi Keramik* brand. However this paper continues to be available on the market under its mill brand name MagnoTM satin through our new Magno merchant partners, Igepa in Germany, France and Switzerland as well as through Papyrus in France.

MagnoTM is the strongest fine paper brand in Europe with trusted products and stockist partners in all European markets. Magno satin offers the highest levels of whiteness, gloss and opacity for the best print results.

Berry Wiersum, CEO of Sappi Europe, comments: “Sappi’s recent investments in its Central European production facilities will guarantee an unrivalled cost leading, sustainable production and service performance."

Further information:

The Magno graphic paper range offers eight products including gloss, satin, matt and uncoated surfaces, basis weights range from 80gsm to 400gsm with all products having an aligned high white shade.

*Galaxi Keramik is a registered trademark of Papier Union GmbH (part of Inapa Group).

Ahlstrom announces price increases for masking tape base papers

![]() Ahlstrom, a global high performance fiber-based materials company, announces price increases on its masking tape materials produced by the Food and Medical business area. The price increases will be made to compensate for the continued high costs of raw materials in euro terms.

Ahlstrom, a global high performance fiber-based materials company, announces price increases on its masking tape materials produced by the Food and Medical business area. The price increases will be made to compensate for the continued high costs of raw materials in euro terms.

The price increases will affect all masking tape products manufactured globally and will be effective on April 1, 2015. The increase will be up to 7% depending on markets as well as the product and the agreements in place. Specific details will be discussed with each customer individually by the appropriate sales teams in the near term future.

Ahlstrom offers the widest range of masking tape base papers for a perfectly sharp finish line and optimal protection on even the most delicate surfaces. Our masking tape products are produced in France, China and Finland. Food and Medical business area's end-use applications include teabags, coffee pods and capsules, food packaging, baking papers, masking tape, surgical gowns and drapes, and sterile barrier systems.

For more information, please contact:

Liisa Nyyssönen

Vice President, Communications

Tel. +358 10 888 4757

Ahlstrom in brief

Ahlstrom is a high performance fiber-based materials company, partnering with leading businesses around the world to help them stay ahead. We aim to grow with a product offering for clean and healthy environment. Our materials are used in everyday applications such as filters, medical fabrics, life science and diagnostics, wallcoverings and food packaging. In 2014, Ahlstrom's net sales amounted to EUR 1 billion. Our 3,400 employees serve customers in 22 countries. Ahlstrom's share is quoted on the NASDAQ OMX Helsinki. More information available at www.ahlstrom.com.