Ianadmin

Stora Enso’s historical figures according to the new division structure

From the first quarter of 2015 onwards, Stora Enso will publish financial figures for its five divisions and its segment Other.

As announced on 18 December 2014, Stora Enso has reorganised its divisional and reporting structure. In Stora Enso, the IFRS reporting segments are formed by divisions except for the segment Other.The new structure is valid from 1 January 2015 onwards. Stora Enso will report financial figures for the divisions Consumer Board, Packaging Solutions, Biomaterials, Wood Products and Paper and the segment Other.

As announced on 18 December 2014, Stora Enso has reorganised its divisional and reporting structure. In Stora Enso, the IFRS reporting segments are formed by divisions except for the segment Other.The new structure is valid from 1 January 2015 onwards. Stora Enso will report financial figures for the divisions Consumer Board, Packaging Solutions, Biomaterials, Wood Products and Paper and the segment Other.

The former Renewable Packaging division has been split into two separate divisions: Consumer Board and Packaging Solutions. The Consumer Board division operates five board mills in Finland, Sweden and Spain. The operations of the Guangxi board mill project in China and the Bulleh Shah Packaging joint venture in Pakistan also belong to Consumer Board. Packaging Solutions operates container board mills in Finland and Poland and converting plants in ten countries in Europe and Asia, including Inpac Packaging in China and India.

The new structure in the packaging business is a further step towards strengthening Stora Enso’s focus on customers, business performance and growth. It also increases transparency in financial reporting.

| Name until 31 Dec 2014 | Name from 1 Jan 2015 |

| Renewable Packaging | - |

| - | Consumer Board Division |

| - | Packaging Solutions Division |

| Biomaterials | Biomaterials Division |

| Building and Living | Wood Products Division |

| Printing and Reading | Paper Division |

| Other | Other |

The segment Other includes the Nordic forest equity-accounted investments, Stora Enso’s shareholding in Pohjolan Voima, operations supplying wood to the Nordic mills and Group shared services and administration.

The historical figures according to the new reporting structure are presented via this link....

For further information, please contact:

Seppo Parvi, CFO, tel. +358 2046 21205

Ulla Paajanen-Sainio, SVP, Investor Relations, tel. +358 2046 21242

Ulrika Lilja, EVP, Global Communication, tel. +46 1046 71668

www.storaenso.com

www.storaenso.com/investors

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Our aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 27 000 people in more than 35 countries, and our sales in 2014 were EUR 10.2 billion. Stora Enso shares are listed on NASDAQ OMX Helsinki (STEAV, STERV) and Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market.

Mitsubishi HiTec Paper to increase prices

Due to the remarkable and steady rise in raw material costs, in particular for pulp and chemicals, the producer of coated specialty papers Mitsubishi HiTec Paper Europe GmbH announces a price increase of 7% for its product range. This price increase will be effective for deliveries from May 1st 2015 onwards.

Due to the remarkable and steady rise in raw material costs, in particular for pulp and chemicals, the producer of coated specialty papers Mitsubishi HiTec Paper Europe GmbH announces a price increase of 7% for its product range. This price increase will be effective for deliveries from May 1st 2015 onwards.

Our sales team will contact our customers to provide further information.

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's most important manufacturers of speciality paper. The roughly 700 employees at Mitsubishi HiTec Paper Europe produce high-quality thermal papers (thermoscript), digital imaging papers (jetscript), carbonless papers (giroform) and label papers (supercote) at two tradition-rich locations in Bielefeld and Flensburg.

Each factory stands out for integrated paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of speciality papers featuring a modular system for every application – and is a highly capable partner whenever customized coated paper solutions are required.

Sonoco's EcoTect(R) Uncoated Recycled Board (URB) First to be Certified to Hewlett-Packard Indigo Specifications

Sonoco (NYSE:SON), one of the largest diversified global packaging companies and a leader in innovative packaging solutions, has announced that its EcoTect® premium grade of uncoated recycled board (URB), specifically manufactured for superior printability, has become the first URB to be certified by the Rochester Institute of Technology to Hewlett-Packard (HP) Indigo print platform specifications.

Sonoco (NYSE:SON), one of the largest diversified global packaging companies and a leader in innovative packaging solutions, has announced that its EcoTect® premium grade of uncoated recycled board (URB), specifically manufactured for superior printability, has become the first URB to be certified by the Rochester Institute of Technology to Hewlett-Packard (HP) Indigo print platform specifications.

This paper innovation is revolutionary for the printing industry where customized, short runs of folding carton products and packaging – an option that was not available before now – can be created with Sonoco EcoTect on the HP Indigo 5500, 7x00, and 10000 digital press platforms.

"Printers with HP Indigo capabilities now have a certified uncoated recycled board option that is sustainable and functional as a result of this innovation," said Bill Hagen, Sonoco's senior engineer/scientist. "Sonoco is committed to innovation in all areas of the company. When the market need was discovered, our team jumped on the opportunity. It took a little more than a year for us to create it, test it and achieve HP Indigo certification through the Rochester Institute of Technology. It is revolutionary and will allow for much more intricate, higher defined, less expensive, customized printing on a 100% recycled paperboard for folding carton applications."

EcoTect products are produced in Sonoco's Trent Valley, Ontario, Canada, and Hutchinson, Kan., facilities. EcoTect for Indigo press applications is exclusively offered through GPA Specialty Substrates, McCook, Ill. For more information on EcoTect, contact Bill Sommer, account manager, EcoTect, at (920)-540-5409.

About Sonoco:

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. With annualized net sales of approximately $5 billion, the Company has 20,800 employees working in more than 330 operations in 34 countries, serving some of the world's best known brands in some 85 nations. Sonoco is a proud member of the 2014/2015 Dow Jones Sustainability World Index. For more information on the Company, visit our website at www.sonoco.com.

Södra and Statkraft launch fuel company

Södra and Statkraft have signed a cooperation agreement to start a jointly-owned company for the future production of biofuel at the former Tofte pulp mill. The company will be named Silva Green Fuel AS, and will be 49-percent owned by Södra and 51-percent owned by Statkraft. Biofuel will play an important part in the drive to achieve national and international targets for reducing climate emissions from the transportation sector.

Södra and Statkraft have signed a cooperation agreement to start a jointly-owned company for the future production of biofuel at the former Tofte pulp mill. The company will be named Silva Green Fuel AS, and will be 49-percent owned by Södra and 51-percent owned by Statkraft. Biofuel will play an important part in the drive to achieve national and international targets for reducing climate emissions from the transportation sector.

The company's first task is to find a cost-effective technology for profitable production of second generation biofuels based on forestry raw materials. A future commitment depends on whether the authorities facilitate the increased use of biofuels through tax changes and other attractive incentives.

"Statkraft views forest-based biofuel as a potential new growth area in renewable energy. I think that the collaboration with Södra constitutes a solid basis for developing a commercially-viable and profitable project," said Christian Rynning-Tønnesen, CEO of Statkraft.

"Södra is monitoring closely the technology developments and the business opportunities presented by the utilisation of forest raw materials for industrial production of climate-neutral fuels. We have also enjoyed good collaboration with Statkraft in the past and look forward to combining the two companies' expertise and experience in this project," added Södra's CEO Lars Idermark.

Statkraft has taken over all the shares in Södra Cell Tofte AS, which owns the former pulp mill site at Tofte. The site is favourably situated for a future venture into the area of biofuel: The location already has an established infrastructure to handle large volumes of wood and it is located centrally in eastern Norway, with an excellent deep-water harbour.

Statkraft is a leading company in hydropower internationally and Europe's largest generator of renewable energy. The Group produces hydropower, wind power, gas-fired power and district heating and is a global player in energy market operations. Statkraft has 3,700 employees in more than 20 countries.

Södra is a group with extensive forestry operations and a leading producer of paper pulp, sawn timber and bioenergy. The business is owned by 50,000 forest owners in southern Sweden, has 3,500 employees and sales of SEK 17 billion.

For further information, please contact:

Knut Fjerdingstad, Head of Information, Statkraft,

Tel: + 47 901 86 310.

Christen Grønvold-Hansen, President of Södra Cell Tofte AS

Tel: + 46 70 646 33 37.

Annica Gerentz, Director of Communications, Södra,

Tel: + 46 470 894 81

Steam profiler gets a new lease of life

A newsprint manufacturer has seen that retrofitting new steam profiler actuators is a cost-effective way to extend the life of the profiler, ensure reliability and reduce maintenance costs.

By Mark Williamson, Journalist Engineer

During the latter part of 1990s the market for steam profilers was at its peak, but many of those original investments are now starting to show their age. Some actuators are failing at an accelerated rate and the cost of maintenance is getting high. Tasowheel, a profiler actuator manufacturer based in Tampere, Finland, now offers a solution for those ageing profilers to bring their performance and reliability up to a high standard. Most importantly for papermakers, a retrofit actuator solution extends the service life of older profilers and reduces the cost of maintenance. Prolonging equipment life and reducing costs is welcomed by papermakers nowadays. Moreover, the retrofit with new, improved actuators can be done at a considerably lower cost than a complete rebuild of older actuators. Tasowheel has the expertise to do this since they have been manufacturing OEM actuators for profiler suppliers for over thirtyyears. Now, they offer an independent solution for existing profilers.

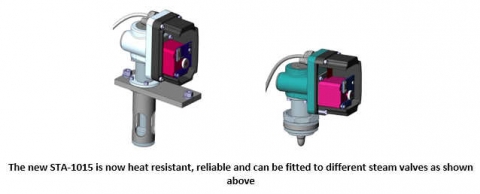

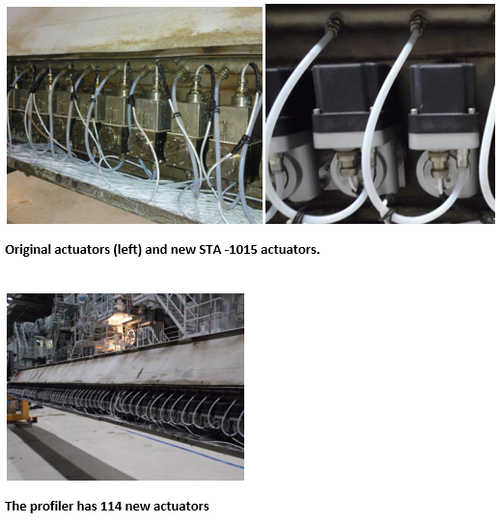

A major European newsprint manufacturer has seen the benefits of the solution. Their steambox, installed in 1999, was showing its age and many of the actuators were failing regularly in the high temperature environment. Their replacement was a maintenance burden every six months when the profiler was taken out and overhauled. Tasowheel proposed a solution in which the old and now obsolete actuators would be replaced in-situ with new bolt-on actuators that were designed to perform reliably even with high temperatures. Isolation of the control card from the heat and heat resistance of its components and motor coil cables and bearings were the key design improvements of the new STA-1015 actuator. STA-1015 can replace old model electromechanical steambox actuators types (EMA15, EMA1000 and STC900).The customer noted that the new actuators fitted perfectly with the same connections and even the same gaskets as the old ones. To evaluate the reliability, a test actuator was provided which was fitted for an extended period, ensuring that there were no control, compatibility or reliability issues. There were no problems during the test period.

Overhauls: from six months to two years

The mill placed an order for 114 new actuators. From placement of the order to the delivery mill staff were kept well informed of progress which was particularly important considering the tight delivery schedule defined by a papermachine extended shutdown opportunity. The actuators were installed in September, 2014 by three mill staff over two day shifts. No night shifts were needed.

The customer reports that the replacement cost was considerably less than alternative solutions since no original-design replacement actuator was available. Overhaul of the entire old actuator set was possible but would have required considerable downtime, manpower and lost production. The cost of the OEM service components were at least 20% more expensive than the Tasowheel solution.

With the reliablity problem solved, the mill staff hope to extend the steam profiler overhaul cycle to two years from the previous six months. This means lower maintenance costs and a longer lifetime with better reliability for the profiler.

Environmental Paper Company Index 2015 – WWF invites 80 companies

WWF, the world´s largest conservation organisation, is inviting the world’s leading pulp and paper manufacturers to participate in the Environmental Paper Company Index 2015. The biannual Index promotes transparency and continual improvement in the sector. The list of invited manufacturers from Europe, North America, South America, Asia and Africa can be viewed on www.panda.org/epci2015. Results of the evaluation will be published in October/November 2015.

WWF, the world´s largest conservation organisation, is inviting the world’s leading pulp and paper manufacturers to participate in the Environmental Paper Company Index 2015. The biannual Index promotes transparency and continual improvement in the sector. The list of invited manufacturers from Europe, North America, South America, Asia and Africa can be viewed on www.panda.org/epci2015. Results of the evaluation will be published in October/November 2015.

The increasing number of participants in WWF´s Environmental Paper Company Index over the years is a testimony to the growing importance of transparency and the value of the Index for the industry. Participants in the 2013 Index produced 29% of the world´s newsprint, 28% of the world´s graphic paper, 14% of the world´s tissue, 6% of the world´s packaging and 14% of the world´s pulp. This means that the ecological footprint of 82 million tonnes of pulp and paper was disclosed.

WWF's Environmental Paper Company Index looks at environmental aspects of a company’s policies and targets, as well as the environmental performance of the production of newspaper grades, graphic paper, packaging, tissue, or pulp. The EPCI recognizes a company´s transparency and progress over time, without comparing the companies.

“We are expecting even higher participation in 2015” says Emmanuelle Neyroumande, Manager of WWF International’s global pulp and paper work. “While we are proactively inviting key pulp and paper producers we are open to receiving expressions of interest from other producers. The EPCI is a tool for companies that are striving for continual improvement in the environmental performance of their pulp and paper production. The Index enables them to be leaders in transparency.”

“Mondi encourages all invited companies to participate in WWF´s Environmental Paper Company Index (EPCI). We believe it is good for the industry to demonstrate increased transparency – showcasing responsible business practices and ongoing improvements. This will be Mondi’s fourth year of participating in the Index and we consider it a fair and positive exercise, providing useful management insights.” Mondi (South Africa)

"Participating in WWF’s Environmental Paper Company Index is a great opportunity to have a well-known environmental organization with high ambitions evaluate and confirm continuous improvement of sustainability performance." Stora Enso (Europe)

“We welcome WWF's Environmental Paper Company Index. The EPCI measure will aid ITC's efforts at enriching the country's environmental capital while generating significant sustainable livelihood opportunities. The EPCI tool will enable current and prospective customers to objectively view the environmental performance of the products that they buy from pulp, paper and paperboard companies" ITC (India)

"Domtar has gained significant insights from our work with WWF the past five years to create the expectation of full disclosure within the industry. As the only North American fine paper manufacturer to participate in the EPCI since its inception, we encourage our peers to follow suit. It’s impossible to verify economic, social and environmental performance without complete transparency.” Domtar (Canada)

Companies that have not been invited but would like to participate can contact the WWF International Paper Team at This email address is being protected from spambots. You need JavaScript enabled to view it.. Deadline for applications to participate is 30th of April 2015.

For further information:

Helma Brandlmaier, Senior Advisor Strategic Communications and Knowledge Management, WWF International Tel: +43676842728219 This email address is being protected from spambots. You need JavaScript enabled to view it.

Participants in the EPCI 2013 (newsprint, graphic paper, household and sanitary, packaging paper and boards, pulp)

Appleton Coated (North America), Arauco (South America), Arjowiggins Graphic (Europe), BillerudKorsnäs (Europe), Bio-PAPPEL (Central America), Cascades (North America), CMPC (South America), Domtar (North America), Fedrigoni (Europe), Fibria (South America), ITC (Asia), Klabin (South America), Lecta (Europe), Lenzing Papier (Europe), Metsä Group (Europe), Mondi (South Africa), NewPage (North America), Norske Skog (Europe), Resolute Forest Products (North America), SCA (Europe), Södra (Europe), Sofidel (Europe), Stora Enso (Europe), TNPL/Tamil Nadu (Asia), UPM (Europe). See also www.panda.org/epci2013

Participants in the EPCI 2011,

x Fine paper category: Arjowiggins Graphic, Burgo, Cascades, Domtar, Fedrigoni, Mondi, M-real, Stora Enso, Suzano, UPM

x Packaging category: Cascades, Korsnäs, Mondi, SCA Containerboard

x Tissue paper category: Arjowiggins Graphic, Metsä Tissue, Renova, SCA Tissue, Sofidel

Participants in the EPCI 2010

Fine paper category: Mondi, M-Real, Stora Enso, UPM, Domtar

The EPCI method looks at environmental aspects of a company’s policies and targets, as well as the environmental performance of the overall production of a specific product category (newsprint, graphic paper, household and sanitary, packaging paper and boards, pulp). It includes the environmental performance from own pulp and paper production, as well as performance of market pulp purchased. It has been reviewed and adapted with input of the participants in 2012.

About WWF

WWF is one of the world’s largest and most respected independent conservation organizations, with over 5 million supporters and a global network active in over 100 countries. WWF's mission is to stop the degradation of the earth's natural environment and to build a future in which humans live in harmony with nature, by conserving the world's biological diversity, ensuring that the use of renewable natural resources is sustainable, and promoting the reduction of pollution and wasteful consumption.

WWF´s Forests for Life Programme has a long standing track record working with companies towards continual improvement within the forest and paper sectors and to increase supply chain transparency. The Environmental Paper Company Index is one of WWF´s Forests for Life Programme´s efforts to motivate continual improvement in the forest products sector. For more information, visit www.panda.org/forests

Eurovast starts up the new tissue machine supplied by Toscotec at Cartiera della Basilica, Lucca.

The Italian producer Eurovast successfully started up a new Toscotec tissue machine at Cartiera della Basilica, Bagni di Lucca (LU).

The new machine is a MODULO-PLUS crescent former with double press configuration and steel Yankee dryer TT SYD-3200MM with a maximum speed of more than 1500 mpm; this is the ideal solution to meet the demand for high quality products and the need for energy savings and emission reductions.

The desire to care for the environment and to install an eco-sustainable and innovative system were determining factors for Eurovast to choose manufacturing excellence in a rapidly expanding sector.

Engineering services, assembly supervision, commissioning and start-up were all part of Toscotec’s scope. Thanks to the close cooperation between the two teams, the date of start-up was in line with the project’s time schedule and the operating and quality target were quickly achieved.

With this new line in operation, Eurovast becomes a leading producer in the international tissue market, focusing on the improvement of the end result both in its product range and in the development of new solutions based on the specific needs of its customers.

There is a widespread presence of the two main brands, Fiori di Carta® e Rotolotto®, in mass market retailers , discount retailers and Italian and European distribution channels.

Miltenberg PM 7 impresses with efficient tissue production

The PM 7 process line commissioned mid-November 2014 at the Miltenberg headquarters of Fripa Papierfabrik Albert Friedrich KG has achieved the production speed of 2,100 m/min, making it one of the most efficient tissue machines currently operating worldwide.

The NipcoFlex T shoe press and EvoDry Y yankee cylinder enable high speeds at lower energy consumption. An increased dry content, which reduces the thermal energy requirement by up to 20%, is achieved downstream of the press section. The PM 7 produces super soft toilet tissue and kitchen paper in superlative qualities.

“The success of our project is due to exemplary collaboration based on a spirit of partnership," explains Fripa’s Managing Director Andreas Noack and adds: “The PM 7’s innovative technology allows us to safeguard and further enhance our high quality standards.”

The roots of Fripa Papierfabrik Albert Friedrich KG, a renowned manufacturer of high-quality tissue papers for the international market, go as far back as 1911. At its production site in Miltenberg, Fripa operates a total of three paper machines and several converting plants.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Valmet Tissue Technology Award granted to modification of hard wood pulp for tissue production

The winner of Valmet Tissue Technology Award was announced at the Tissue World Conference, Barcelona, Spain, on March 17, 2015. The award and the USD 25,000 prize amount was granted to Abdus Salam, Graduate Student from North Carolina State University, USA.

The purpose of the Valmet Tissue Technology Award is to promote university students' or scientists' work to develop environmentally sound products applicable to the tissue making processes. The award is granted every second year and the winner is selected by a panel of jurors representing universities, scientific organizations and Valmet.

Valmet Tissue Technology Award ceremonies at the Tissue World Conference in Barcelona

The focus area for the award this year was environmental efficiency. Mr. Salam is awarded for his work on modified hardwood pulp for tissue production. The objective of Mr. Salam's work has been to develop a method to provide unique tissue characteristics using only natural materials. By modifying hardwood pulp, it can be cross-linked with a biodegradable product to greatly improve absorbency properties. The modified fibers are elastic, very soft, highly porous and durable, and also have microbial properties.

"We are constantly searching for new innovations to make the tissue process more sustainable and environmentally efficient. Mr. Salam's innovation is well in line with our strategy and shows how biomaterials can be utilized to add new and improved properties to tissue products. This is an excellent example of how scientists and the academic world can contribute to the important work of developing sustainable solutions for the future of tissue-making," says Anders Björn, Vice President, Tissue Mills business unit, Valmet.

"I greatly appreciate the award committee's selection of my research for Valmet Tissue Technology Award of 2015. This is my first international award which has truly inspired me to develop new products and ideas for tissue and paper towel applications. I believe the research developments related to modifying hardwood pulp can significantly contribute to the personal health care sector as well as the global economy," says Abdus Salam, the winner of the Valmet Tissue Technology Award.

More information about the Valmet Tissue Technology Award including application regulations can be found at www.valmet.com/tissueaward.

For further information, please contact:

Anders Björn, Vice President, Tissue Mills business unit, Valmet, Tel. +46 705 17 13 38

Allan Grimm, Manager, Global Technology, Tissue Mills business unit, Valmet, Tel. +46 54 17 11 42

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 10,500 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Paper and paperboard market: Demand is forecast to grow by nearly a fifth by 2030

Insight study by Pöyry indicates challenges for producers of paper and paperboard

World demand for paper and paperboard is forecast to grow to 482 million tons in 2030. This equals an increase of 1.1 per cent per year. This is the result of the new global paper market study “World Paper Markets up to 2030” by Pöyry Management Consulting. The study forecasts the demand for over 80 countries and country groups, and ten product areas, including graphic, tissue and packaging papers.

World demand for paper and paperboard is forecast to grow to 482 million tons in 2030. This equals an increase of 1.1 per cent per year. This is the result of the new global paper market study “World Paper Markets up to 2030” by Pöyry Management Consulting. The study forecasts the demand for over 80 countries and country groups, and ten product areas, including graphic, tissue and packaging papers.

The demand for paper varies depending on type and region. The graphic paper market is facing huge challenges in particular, while increasing digitalisation is shrinking demand for newsprint and other printing papers, as well as uncoated and coated wood-containing and wood-free papers. According to the Pöyry study, the demand for tissue paper, containerboards and cartonboards will, however, grow up to 2030. This is driven by increasing packaging needs in emerging markets, booming eCommerce and the growing demand for convenience food and consumer goods brands. The annual consumption of packaging material and tissue/hygiene products will, thus, rise by up to 2.9 per cent.

Focusing on regional growth markets, it can be found that the demand for paper continues to grow in the emerging markets, such as China and India. This is due to the increasing population, urbanisation and the development of a new middle class. In Japan, North America and Western Europe, on the other hand, the demand will decrease by around 0.8 per cent per year up to 2030. “Since 1950 the production of paper has continually grown. But the last five to six years were extremely challenging for the global paper industry, in particular for companies in Western markets“, says Timo Suhonen from Pöyry Management Consulting.

As a result, Pöyry experts forecast a strong need for structural changes in the paper industry. “Especially in Western Europe we find an urgent need for further capacity reductions. After the markets in the emerging Asian regions have become more mature, the industry needs to take a more disciplined approach as to capacity expansions. Industry consolidation, acquisitions, mergers and alliances start making more sense there, too“, Mr. Suhonen adds. “In the past, exits from the graphic paper industry sometimes turned to entries into the packaging paper and paperboard sector through a conversion of the machines. However, this move would probably be the least painful one for multi-sector companies and always has to be decided on a case-by-case basis“.

The latest Pöyry Insight study “World Paper Markets up to 2030” addresses these and many other significant market issues that are of current strategic interest for all business participants, including pulp and paper companies, suppliers of machinery, equipment, chemicals and related inputs, investors, financiers, institutions, paper merchants and traders and logistics companies.

Additional information by:

Timo Suhonen

Pöyry Management Consulting

This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +358 103 322 600

About Pöyry:

Pöyry is an international consulting and engineering company. We serve clients globally across the energy and industrial sectors and provide local services in our core markets. We deliver management consulting and engineering services, underpinned by strong project implementation capability and expertise. Our focus sectors are power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry has an extensive local office network employing about 6,000 experts. Pöyry's net sales in 2014 were EUR 571 million and the company's shares are quoted on NASDAQ OMX Helsinki (Pöyry PLC: POY1V).