Ian Melin-Jones

Engraving Solutions: Tailor Made Product and 3D experiences

Tailor Made tissue products and 3D experiences: Engraving Solutions expand existing product portfolio with digital services and customized solutions for the new needs of the tissue market

Engraving Solutions, leader in the production of embossing rollers for the tissue industry and part of the Business Area Tissue of the Körber AG Group, has presented the latest products in the embossing field: innovative and highly competitive products that meet the actual needs of the market.

Premiumization and Digitization trends play an increasing role in the choice of converters. The best companies’ strength lies in offering products tailor-made according to the specific customer’s needs. Today customers want to co-create with the supplier, being part of the creative and development teams from the early stage of the project so that their requirements are fulfilled in the best way.

The challenge of Engraving Solutions is to provide customers with innovative solutions that answer and anticipate market changes and help them optimize their manufacturing performance. For this reason, thanks to its technological know-how in the production of embossing rollers, and keeping continuous exchanges and workshop with the customers, Engraving Solutions has expanded its offer with new digital and customized solutions that fit to the new market trends and simplify the development processes of new products. This assures the shortest time-to-market of a new product on the shelf.

“Ghost is designed to satisfy the current trend in the tissue market. – Giacomo Bianchi, Product Engineer of Engraving Solutions, declares – It is the new generation of embossing, obtained by combining, for the first time ever, two different micro-embossing techniques – chemical and mechanical – thereby bringing together the benefits of both. This innovative technology, unique to this market, results in a product that is more pleasing to the touch compared to the traditionally embossed one. Ghost is ideal for all high-yield products with refined embossing but is at the same time resistant, bulky and featuring excellent softness, independently from the number of plies and for every product type: toilet paper, kitchen towel and away-from-home segments”.

The name Ghost evokes the special shape of the points, similar to a ‘ghost sheet’. Actually, the profiles of the engravings have been softened, and therefore act with less cutting aggressiveness on the paper. This allows to reduce the strength loss that usually occurs during embossing when traditional rhomboid points are used.

Ex-press is a technology that allows to obtain double-colour products using embossing alone. By simply adding coloured water to the pre-embossing station, on first pass the ply is decorated with one colour, and when it is passed through the second embosser using coloured glue, the final product comes out with 2 different colours providing a stunning aesthetic effect.

The last novelty presented by Engraving Solutions is Smoothie, the embossing system specifically designed for entry-level products that is capable of making the paper smoother and softer to the touch. This helps improving products made using traditional or recycled and unstructured paper, featuring low weight and low quantities of long fiber paper, that usually are less appealing to the consumer.

With a single pass, the ply is embossed on the side portions, with or without the use of glue, and calendered on the central portion. All this is obtained using a single embossing station instead of requiring a pair of rolls or a machine dedicated to the calendering of the entire ply.

The final result is a roll that is smooth on most of its surface and aesthetically pleasing thanks to the application of (coloured or non-coloured) decorations. This represents an improvement for entry-level products that have always privileged price and convenience over aesthetics and quality.

At Tissue World Milan Engraving Solutions has also launched the new tissue configurator Touch 'N' Roll. The new configurator aims to simplify the process of new product development. Through a digital platform accessible from PC or tablet, with few simple steps, the user can create a preview of the finished product, a real-time prototype, even before making a pilot line test. This allows the customer to have an early view of the product and reduce decision-making time.

Thanks to the new configurator it is possible to create your own "tailor-made" product, choosing between three predefined types of rolls: toilet paper or kitchen paper, four types of paper each with a defined surface and colour, 36 embossing designs, eight colours. A total of 1,440 configurations are possible.

The process is very simple:

- Choose between three predefined types of rolls: toilet rolls, kitchen towels, away-from-home;

- Insert technical specifications (height, diameter, virgin or recycled paper);

- Choose between up to 36 embossing patterns in eight colours for a total of 1,440 possible configurations;

- Obtain a preview of the final product

The customer can consult at any time, remotely, the complete list of engravings made and has immediate availability and access to the technical data sheets of the rollers. Also, through the platform, the customer can communicate directly with the Engraving Solutions experts, reserve a pilot test and check the order status of new rollers or product tests. A real digital experience that allows the customer to speed up the decision-making cycle and reduce its time-to-market.

2019 edition of Paperworld China set to return between 15 – 17 November

Paperworld China, Asia’s leading trade fair dedicated to the stationery and office supplies industries, has confirmed the dates and venue for its 2019 edition as 15 – 17 November in Hall 1 of the National Exhibition and Convention Center (Shanghai). The fair will once again present fairgoers with trend setting stationery, office supplies, and hobby and craft products through its four renowned zones: ‘Tomorrow’s Office’, ‘Stationery and Hobby’, ‘Quality Suppliers’, and ‘Oriental Products’. In total, the fair is expected to welcome 500 exhibitors across 23,000 sqm of exhibition space.

Thanks to high demands from the country’s growing student population, China’s stationery industry is entering into a new growth period. China has the world’s largest student population[1]. According to the National Bureau of Statistics of China, the total number of students in China exceeded 240 million in 2017. With the number of students forecasted to rise to its peak between 2020 and 2030, the coming decade can be considered the golden decade for international stationery brands to penetrate the Chinese market.

At the same time, the per capita GDP in China is also set to continue steadily increasing, from USD 4,411 per capita in 2010, it reached USD 8,523 in 2017. Based on the measurement standard of the World Bank, once a country’s GDP per capita reaches 8,000 USD and above, it is considered a high-income developing country. China’s rise in wealth, in tandem with its record numbers of school students, has the potential to lead to a drastic increase in demand for educational and stationery related products, with consumers increasing their consumption volume and demanding higher quality.

At the same time, the per capita GDP in China is also set to continue steadily increasing, from USD 4,411 per capita in 2010, it reached USD 8,523 in 2017. Based on the measurement standard of the World Bank, once a country’s GDP per capita reaches 8,000 USD and above, it is considered a high-income developing country. China’s rise in wealth, in tandem with its record numbers of school students, has the potential to lead to a drastic increase in demand for educational and stationery related products, with consumers increasing their consumption volume and demanding higher quality.

Paperworld China is an ideal gateway for industry players to step into the market and capture the growing number of business opportunities. Ms Judy Cheung, Deputy General Manager of Messe Frankfurt (HK) Ltd, is looking forward to the coming edition: “Paperworld China is the right platform for suppliers to connect with quality buyers and increase their brand exposure. As we step into the golden decade for the Chinese stationery industry, Paperworld China will continue to serve as a business and information exchange hub for the most up-to-date products and trends.”

The 2018 edition of the fair received highly positive feedback from exhibitors and visitors alike for its dedicated themed zones and product areas. In light of the positive response, the coming edition of the fair will once again be divided into the four zones of ‘Tomorrow’s Office’, ‘Stationery and Hobby’, ‘Quality Suppliers’, and ‘Oriental Products’. In addition, the Small yet Beautiful showcase, which serves as a mock retail store that includes a cafe area and an interactive art workshop, will return at the Stationery and Hobby zone. Visitors to the showcase will find adaptations of Zakka, a Japanese concept that describes a variety of consumer lifestyle goods, including products such as home office supplies and travel accessories.

The design area, which made its debut to promote originality and intellectual property protection in the industry, is set to return under the new name of ‘Design S’, providing an opportunity for original stationery brands to showcase their creatively designed products and enhance their brand image. Unique products showcased at the last edition came from well-established and emerging brands such as AIT, Card Lover, Douban, Ggem, Happihood, Honorscent, Orange Creation, Tsnow Stationery, Whitehole, and Xiaolin Creative.

Another avenue through which Paperworld China promotes original stationery designs is the ‘Best Stationery of China Awards’, which will return this year to discover inventive stationery from around the world. The award ceremony will be held on the first day of the fair.

To additionally enhance attendee experience at the fairground, various fringe events will take place during the fair to allow participants to catch up with the latest trends in the industry. Further information on fringe events and other aspects of the show will be revealed closer to the show dates.

For more information about the show, please visit www.paperworldchina.com

Other Paperworld brand shows include:

Paperworld Middle East / Playworld Middle East

18 – 20 March 2019, Dubai

Hong Kong International Stationery Fair

6 – 9 January 2020, Hong Kong

Paperworld

25 – 28 January 2020, Frankfurt am Main

Stationery & Write Show presented by Paperworld

21 – 23 February 2020, Mumbai

For more details about these fairs, please visit

www.global.paperworld.messefrankfurt.com

Paper and Board industry helps demonstrate safety of its materials in food contact applications

The paper and board manufacturing industry, as well as converting sectors including the tissue industry publish today the completely rewritten voluntary ‘Food Contact Guidelines for the Compliance of Paper and Board Materials and Articles’.

Formally called “Industry Guideline”, the revised guidelines are intended to enhance the trust of public authorities, business operators and consumers in the safety of paper and board materials for food contact applications.

This technical document, first published in 2010 and updated in 2012, outlines how to meet the highest safety standards for paper and board products used in food contact applications. The processing chain for paper and board food contact articles is diverse; it has to deal with many challenges in demonstrating the safety of materials:

This technical document, first published in 2010 and updated in 2012, outlines how to meet the highest safety standards for paper and board products used in food contact applications. The processing chain for paper and board food contact articles is diverse; it has to deal with many challenges in demonstrating the safety of materials:

"Our sectors’ key priority is to safeguard - at all times - the safety both of the packaging system and food that we deliver. With the Food Contact Guidelines, we wish to provide an effective compliance tool in line with the EU Framework Regulation on Food Contact Materials by ensuring an efficient exchange of information along the supply chain” explained Jori Ringman, Deputy Director General at CEPI and expert in product safety.

Since their launch in 2010, the guidelines have gained much support among users and well proved their value: watch our explanatory video to learn more!

The paper and board industry will continue to focus on ensuring compliance with existing EU provisions and supporting the demand of the market and customers for unquestionable product safety.

FEFCO takes on EPRC chaimanship

The European Paper Recycling Council is pleased to announce the appointment of Angelika Christ as the new chair for a two years period starting as of 4 April 2019, taking over from Lisa Kretschmann (FEPE). Angelika Christ has been the Secretary General of FEFCO since 2007 and the Secretary General of CITPA since 2014.

She has been involved in associations of corrugated board manufacturers for over 20 years, first in Germany and then at the European level. Prior to FEFCO, she was the Managing Director of the German Association of Corrugated Board Industries (VDW) from 1996 until 2007. Her first professional experience was with the German Chemical Industry Association (VCI), where she executed various positions from 1980-1996.

During her two years mandate as chair of the EPRC, Angelika Christ will pursue the following goal:

“The EPRC has been very successful in bringing all parties together, develop recyclability guidelines for printed graphic paper and boosting recycling of all papers. We will continue this work and support the industry efforts to further improve the recyclability of paper packaging on the market.

“The EPRC has been very successful in bringing all parties together, develop recyclability guidelines for printed graphic paper and boosting recycling of all papers. We will continue this work and support the industry efforts to further improve the recyclability of paper packaging on the market.

Paper packaging is a recycling champion.

We need to intensify our communication and increase the public awareness about the great recyclability of paper packaging”.

For further information, please contact Ulrich Leberle, Secretary of the EPRC and CEPI Raw Materials Director at This email address is being protected from spambots. You need JavaScript enabled to view it. or by phone at (+32) 2 627 49 23.

The European Paper Recycling Council (EPRC) was set up as an industry self-initiative in November 2000 to monitor progress towards meeting the paper recycling targets set out in the 2000 European Declaration on Paper Recycling.

Since then the commitments in the Declaration are renewed every five years. In 2017 the EPRC committed to meeting and maintaining both a voluntary recycling rate target of 74% in the EU27 plus Switzerland and Norway by 2020 as well as qualitative targets in areas such as waste prevention, ecodesign and research and development.

In 2018, Members of the EPRC are ACE, CEPI, CITPA, EMFA, ETS, FEPE, INGEDE and INTERGRAF. Supporters are Afera, EuPIA, FINAT, FEICA and RadTECH Europe.

The 2018 recycling rate was 72,3%. The environment (DG Environment) and industry (DG Grow) departments of the European Commission are permanent observers to the EPRC.

Metsä Board’s takeaway packaging achieves success in a Finnish innovation competition

The Helsinki Wholesale Market area launched, in October 2018, an innovation competition aimed at finding new ideas and solutions for the development of services and versatile entrepreneurship. From around 60 entries submitted, the best seven were chosen for a pilot phase. Metsä Board is delighted to announce that one of the selected entries is for its recyclable packaging concept targeted at restaurant takeaway services.

The Metsä Board’s project involves the whole packaging value chain, and these needs formed the basis for the packaging development. In addition, a consumer study was carried out at the beginning of the pilot stage. “The current takeaway packages used by restaurants either have functional challenges or consumers regard them as non-ecological. We also got feedback that current packaging does not fulfil the criteria of premium packaging,” says Leena Yliniemi, Technical Marketing Director from Metsä Board.

Metsä Board cup clamshell pouch

Metsä Board cup clamshell pouch

The piloted packaging concept is manufactured from Metsä Board’s paperboard which is suitable for direct food contact and is recyclable. Furthermore, the packaging can be easily personalised to the restaurant. The packages are designed and manufactured by a Finnish company, Cadpack Oy. Package Testing & Research Oy is responsible for coordinating the pilot as well as for the consumer study. The pilot project will continue until the end of May 2019.

The innovation competition, funded by the City of Helsinki and Business Finland, was organised to find new technological and other innovative solutions specifically for food and food production, and also packaging, circular economy and clean technologies. The competition jury consisted of members representing the City of Helsinki, the University of Helsinki and the business sector.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards including folding boxboards, food service boards and white kraftliners. Our lightweight paperboards are developed to provide better, safer and more sustainable solutions for consumer goods as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants. In 2018, the company’s sales totalled EUR 1.9 billion, and it has approximately 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group is a forerunner in sustainable bioeconomy utilising renewable wood from sustainably managed northern forests. Metsä Group focuses on wood supply and forest services, wood products, pulp, fresh fibre paperboards and tissue and cooking papers.

In 2018, Metsä Group’s sales totalled EUR 5.7 billion, and it employs approximately 9,300 people. Metsäliitto Cooperative is the parent company of Metsä Group and is owned by approximately 103,000 Finnish forest owners.

Michael Berggren leaves Rottneros Group

The Mill Director for Vallvik Mill, Michael Berggren, has decided to take up a position outside Rottneros and will therefore leave his position as Mill Director. Michael has six months' notice and will remain in full capacity during this period.

“Vallvik Mill has, under Michael's management, developed rapidly and major efforts are being made to achieve the decided goals”, says Lennart Eberleh, President and CEO of Rottneros AB. “Vallvik Mill has today a strong and competent organisation and I feel confident that Vallvik Mill will continue to develop on its current path. We begin to see the result of a value-based leadership that in a structured and systematic way works towards improved productivity and higher capacity utilisation. I would like to thank Michael for his efforts for Vallvik Mill and Rottneros and wish him good luck in his continued career. It is rewarding to see Rottneros contribute to the personal development of its staff who are sought after by other companies.”

“Vallvik Mill has, under Michael's management, developed rapidly and major efforts are being made to achieve the decided goals”, says Lennart Eberleh, President and CEO of Rottneros AB. “Vallvik Mill has today a strong and competent organisation and I feel confident that Vallvik Mill will continue to develop on its current path. We begin to see the result of a value-based leadership that in a structured and systematic way works towards improved productivity and higher capacity utilisation. I would like to thank Michael for his efforts for Vallvik Mill and Rottneros and wish him good luck in his continued career. It is rewarding to see Rottneros contribute to the personal development of its staff who are sought after by other companies.”

“It has been very developing and rewarding to have been responsible for the development of Vallvik Mill after major investments have been made”, says Michael Berggren. “It was no easy decision to now accept the assignment to become the mill manager for Aspa Bruk, part of Ahlström-Munksjö, but in the end I made the decision based on personal reasons. I am happy and proud of what we have achieved in Vallvik in the last few years and I will miss all the competent and happy colleagues.”

The recruitment of a new Mill Director for Vallvik Mill will begin immediately.

For further information please contact:

Lennart Eberleh, President and CEO, Rottneros AB, +46 (0)270 622 65, This email address is being protected from spambots. You need JavaScript enabled to view it.

The information was submitted for publication, through the agency of the contact person set out above, at 12:00 CET on 8 April 2019.

Rottneros is an independent producer of market pulp. The Group comprises the parent company Rottneros AB, listed on Nasdaq Stockholm, and its subsidiaries Rottneros Bruk AB and Vallviks Bruk AB with operations involving the production and sale of market pulp. The Group also includes Rottneros Packaging AB, which manufactures fibre trays, and the wood procurement company SIA Rottneros Baltic in Latvia. The Group has about 300 employees and had a turnover of approximately SEK 2.3 billion in the 2018 financial year.

Valmet to deliver fifth tissue production line to Papel San Francisco in Mexico

Valmet will supply an Advantage DCT 100TS tissue production machine to Papel San Francisco in Mexico. The new machine will be installed at the company's mill in Mexicali and the start-up is planned for the third quarter of 2020.

The order is included in Valmet's first quarter 2019 orders received. The value of the order is not disclosed.

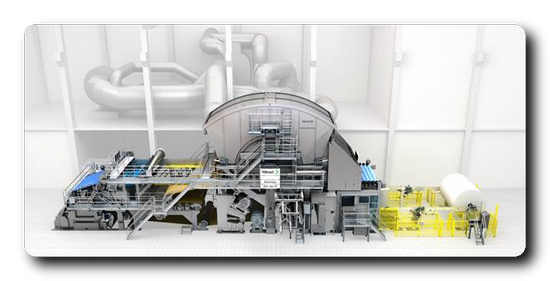

Valmet Advantage DCT 100TS tissue machine

Valmet Advantage DCT 100TS tissue machine

The new tissue line will fulfill Papel San Francisco's need of new capacity for standard tissue products. Valmet has previously delivered four tissue machines to the company. Three Advantage DCT machines started up in 2006, 2009 and 2018. In addition, Papel San Francisco was the first to start up an Advantage NTT line in 2013, which fulfills the company's demand of textured tissue.

"The choice to select the Advantage DCT machine was quite easy. Equipped with the Advantage ViscoNip press, it is the most efficient and best choice for the grades we need to produce. It is also in our philosophy to go for low energy consumption and lowest possible emissions to air and water. With this new tissue line, we expect to achieve the best tissue quality combined with lowest energy consumption," says Dario Palma y Meza Espinoza, Operational Director, Papel San Francisco.

"We are very proud to be the chosen supplier and partner for yet another expansion by Papel San Francisco. After many years of several projects together, we know that Papel San Francisco is a very demanding customer expecting continuous improvements. The company is continuously running their assets at or near world record speed and still achieving very high efficiency numbers. This is yet another opportunity for us to take another step forward in performance in a very strong and trustful relationship," says Jan Larsson, Director of Sales, North America, Tissue Mills Business Unit, Valmet.

From left: Jan Erikson (Valmet), Dario Palma y Meza (PSF), Julio Rodriguez (PSF), Jan Larsson (Valmet), Fernando De La Torre (PSF), Enrique Zarate (PSF), Anders Lorentzon (Valmet) and Jose Luis Emanuel Garcia (PSF).

From left: Jan Erikson (Valmet), Dario Palma y Meza (PSF), Julio Rodriguez (PSF), Jan Larsson (Valmet), Fernando De La Torre (PSF), Enrique Zarate (PSF), Anders Lorentzon (Valmet) and Jose Luis Emanuel Garcia (PSF).

Technical information about the delivery

The new tissue machine will have a width of 2.8 m and a design speed of 2,200 m/min. It will add 30,000 tons tissue paper per year to Papel San Francisco's current production of toilet tissue, kitchen towels and napkins.

Valmet's scope of delivery will comprise an Advantage DCT 100TS tissue machine. The machine will be equipped with OptiFlo headbox and cast alloy Yankee cylinder. The machine will also be featured with the well proven Advantage tissue technology including ViscoNip press, AirCap hood and WetDust dust system. Start-up and commissioning are also included in the delivery.

About the customer Papel San Francisco

Papel San Francisco started up their first tissue machine in 1980. In the past 35 years the company has grown steadily and is today operating six tissue machines with a yearly capacity of 180 000 tons of tissue products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Mondi PERGRAPHICA® premium design papers enter UK market with Fenner Paper

Mondi, the global packaging and paper Group, has announced that Fenner Paper is their distributing partner for Pergraphica in the United Kingdom. This ensures full availability of the product white range in folio formats and optimal customer service nationwide.

Award-winning projects

“We launched Pergraphica only four years ago, and we are already seeing award-winning projects in Germany, Russia, Italy, Poland, Slovakia or the Czech Republic printed on our premium paper. I’m happy that we have now found a great partner in Fenner Paper to continue our creative journey in the UK”, says Johannes Klumpp, Marketing and Sales Director at Mondi Uncoated Fine Paper.

“We launched Pergraphica only four years ago, and we are already seeing award-winning projects in Germany, Russia, Italy, Poland, Slovakia or the Czech Republic printed on our premium paper. I’m happy that we have now found a great partner in Fenner Paper to continue our creative journey in the UK”, says Johannes Klumpp, Marketing and Sales Director at Mondi Uncoated Fine Paper.

Even before the agreement, a prestigious book project was realised on Pergraphica in Great Britain: “AOP50”, celebrating the 50 years anniversary of the Association of Photographers. Further creative projects are showcased on Pergraphica’s Instagram account.

PERGRAPHICA®, paper for perfectionists

Pergraphica is Mondi's exclusive design paper range that fulfils the needs of the creative and professional printing industry in the premium segment. Pergraphica meets the highest requirements for demanding, high-quality print projects and meets the strict criteria of numerous renowned international sustainability standards, such as FSC® or EU Ecolabel.

Its range is characterised by excellent printing properties and is available in two different surfaces (rough and smooth), in five colour variants (High White, Classic, Natural, Ivory and Infinite Black) and in six grammages between 70 and 350 g / m² in Folio and digital formats.

At the beginning of the year 2018, Mondi launched its "Vienna Stories" campaign for Pergraphica. Its centerpiece, the Pergraphica Collection Box with the book "Vienna Stories", won the Special Prize for Paper for the Paperazzo Haptics Award 2018. Several customer projects realised with Pergraphica, such as the special issue of the Hamburger Abendblatt for the opening of the Elbphilharmonie, were awarded creative prizes. In addition, the programme leaflets at the Moscow Bolshoi Theater, the current yearbook of the Creativ Club Austria and the Czech design magazine Barlife are printed on Pergraphica, among others.

The emotional power of paper

“What is special about Pergraphica is that the brand is not only committed to premium print quality, but also to inspiring paper lovers everywhere. It’s all about creatives inspiring other creatives, and that absolutely fits our idea of working with the industry”, says Justin Hobson, Marketing Director at Fenner Paper.

“With the Vienna Stories campaign and a beautiful book on the creative scene in Pergraphica’s home town, Mondi has shown that they are more than just great papermakers. They get the emotional power of paper and print.”

http://pergraphica.mondigroup.com

https://www.instagram.com/pergraphica/

About Mondi

Mondi is a global leader in packaging and paper, delighting its customers and consumers with innovative and sustainable packaging and paper solutions. Mondi is fully integrated across the packaging and paper value chain - from managing forests and producing pulp, paper and plastic films, to developing and manufacturing effective industrial and consumer packaging solutions. Sustainability is embedded in everything Mondi does. In 2018, Mondi had revenues of €7.48 billion and underlying EBITDA of €1.76 billion.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker MND, and a premium listing on the London Stock Exchange for Mondi plc, under the ticker MNDI. Mondi is a FTSE 100 constituent, and has been included in the FTSE4Good Index Series since 2008 and the FTSE/JSE Responsible Investment Index Series since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi Group. In six operating sites in Austria, Slovakia, Russia, and South Africa, Mondi Uncoated Fine Paper produces pulp and environmentally sound office and professional printing papers tailored to the latest professional digital and offset print technologies. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, Pergraphica, NEUJET®, Snegurochka or ROTATRIM are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication. Converters appreciate the excellent printability and smooth handling of Mondi’s professional printing papers.

About Fenner Paper

Fenner Paper has developed over 30 years to become one of the leading independent paper merchants in the UK. With a warehouse in Kent, papers are distributed nationally by contract distribution and through links with other paper merchants. The wide range of speciality products are sourced from some of the most established paper mills in Europe with a collection of papers and board for print, packaging and box covering. The Fenner Paper range is of interest to all printers and designers who need creative and distinctive paper solutions.

ANDRITZ to supply wood processing plant for Ilim Group in Russia

International technology Group ANDRITZ has received an order from the Ilim Group to supply a wood processing plant with two debarking and chipping lines, chip and bark handling equipment, and a SmartWoodyard advanced control system to the Koryazhma mill in the Arkhangelsk region, Russia. Start-up is scheduled for mid-2021.

The new woodyard will replace existing woodroom and chip storage facilities, which have a pneumatic conveying system. The technology supplied by ANDRITZ will substantially contribute towards reducing emissions and operating costs, resulting in environmentally friendly, high-quality chip production and considerable savings in raw material.

HQ-Press bark press increases the energy value of bark. © ANDRITZ

HQ-Press bark press increases the energy value of bark. © ANDRITZ

The ANDRITZ scope of supply includes new debarking and chipping lines with:

- unique de-icing process for logs in the debarking drums

- horizontally fed HHQ-Chipper

- two HQ-Press bark presses

- chip and bark handling equipment, including chip storage

- SmartWoodyard advanced control system, including Decision Support Wall (DSW) and process optimization system with smart sensors like WoodScan, BarkScan, ChipperEKG, CrusherEKG, and ScanChip wood chip analyzer.

Description from the Ilim Group:

The Ilim Group leads the Russian pulp and paper industry in terms of market share, production, and investment, as well as being one of the world’s leading players in this industry. The largest pulp and paper company in the world, International Paper, is a strategic partner of the Ilim Group. Over the past few years, the Ilim Group has invested 3.2 bn US dollars in the development of its own enterprises, which is unprecedented for the Russian pulp and paper market. In the next five years, the company plans to invest another 3.6 bn US dollars in the modernization of facilities and the launch of new capacities. Implementation of the investment program will allow the group to increase the volume of production by one million tons. As a result, the Ilim Group will retain its leadership position and produce 4.4 million tons of final products per year by 2023 (in 2018, the company produced 3.4 million tons).

The Ilim Group’s production facilities are located in the Arkhangelsk, Irkutsk, Leningrad, and Moscow regions. The Ilim Group exports its products to more than 70 countries. The key market is the export market, and the main partners are Asian countries (especially China, with 40% of the exports).

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

Technidyne showcases emtec´s innovations at the PaperCon 2019

The paper and packaging professionals will meet again this year at Tappi´s PaperCon 2019 in Indianapolis, Indiana, USA from May 05th to 08th. At booth no. 707, the company Technidyne will be the contact for all inquiries regarding the innovative testing equipment from the German company emtec Electronic GmbH. The representative from the U.S. will showcase a variety of testing instruments by which the complete production process can be controlled and guided in the right direction. From the wet end to the finished product, the application of the equipment enables an efficient process, to get the best possible quality with the lowest possible costs.

The smallest, lightest and most-modern charge measuring systems for the wet-end in paper and board production are the CAS touch! and the FPA touch! These instruments are used to measure the interaction between particles or fibers with additives and process chemicals in the pulp suspension. The use of both instruments in the production process helps to optimize the utilization of chemicals with the target to stabilize the process, to improve the product quality and to reduce costs.

FPA touch & CAS II touch

FPA touch & CAS II touch

Besides this, the EST12 emtec Surface & Sizing Tester is shown. A useful tool to determine those surface properties of paper and board, that are relevant for the converting process, in particular the surface hydrophobia (sizing) as well as the surface porosity. Both parameters help to predict the converting behavior while printing, coating and gluing. The usage of the device enables the optimal runnability during the finishing or converting processes of paper and board.

Especially for tissue and nonwoven products, the popular TSA Tissue Softness Analyzer gives reliable and objective information about the three basic parameters, which determine the human feeling: the softness, roughness and stiffness. From these three, an overall hand feel value can be calculated. The availability of these values opens a huge amount of chances to optimize the tissue production and converting processes. New for hand sheet measurements: an updated version of the TSA and an improved measuring method for hand sheets (made in the lab) enables a reliable prediction of the final product quality in the lab without expensive trials at the tissue machine.